Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Strong shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

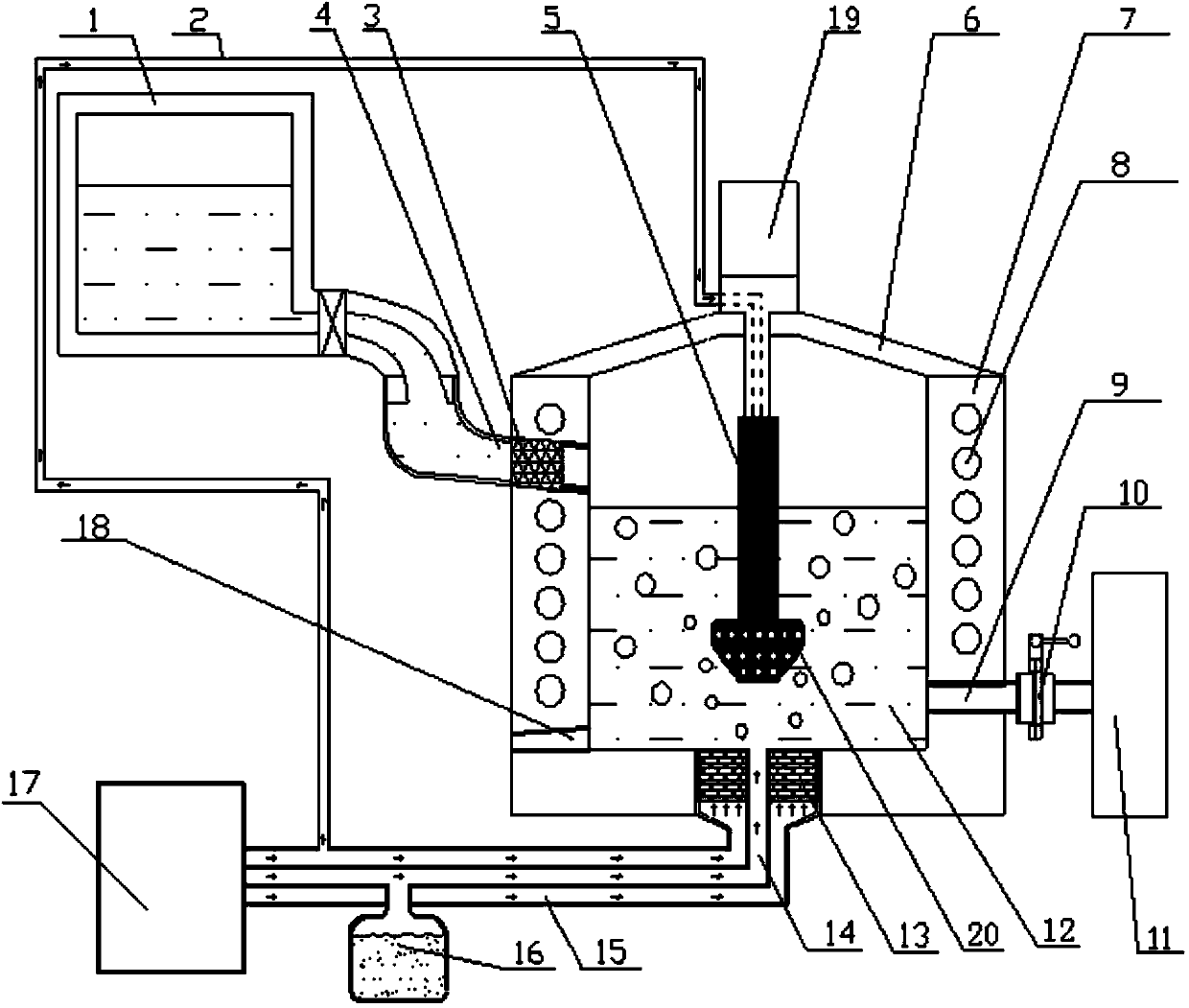

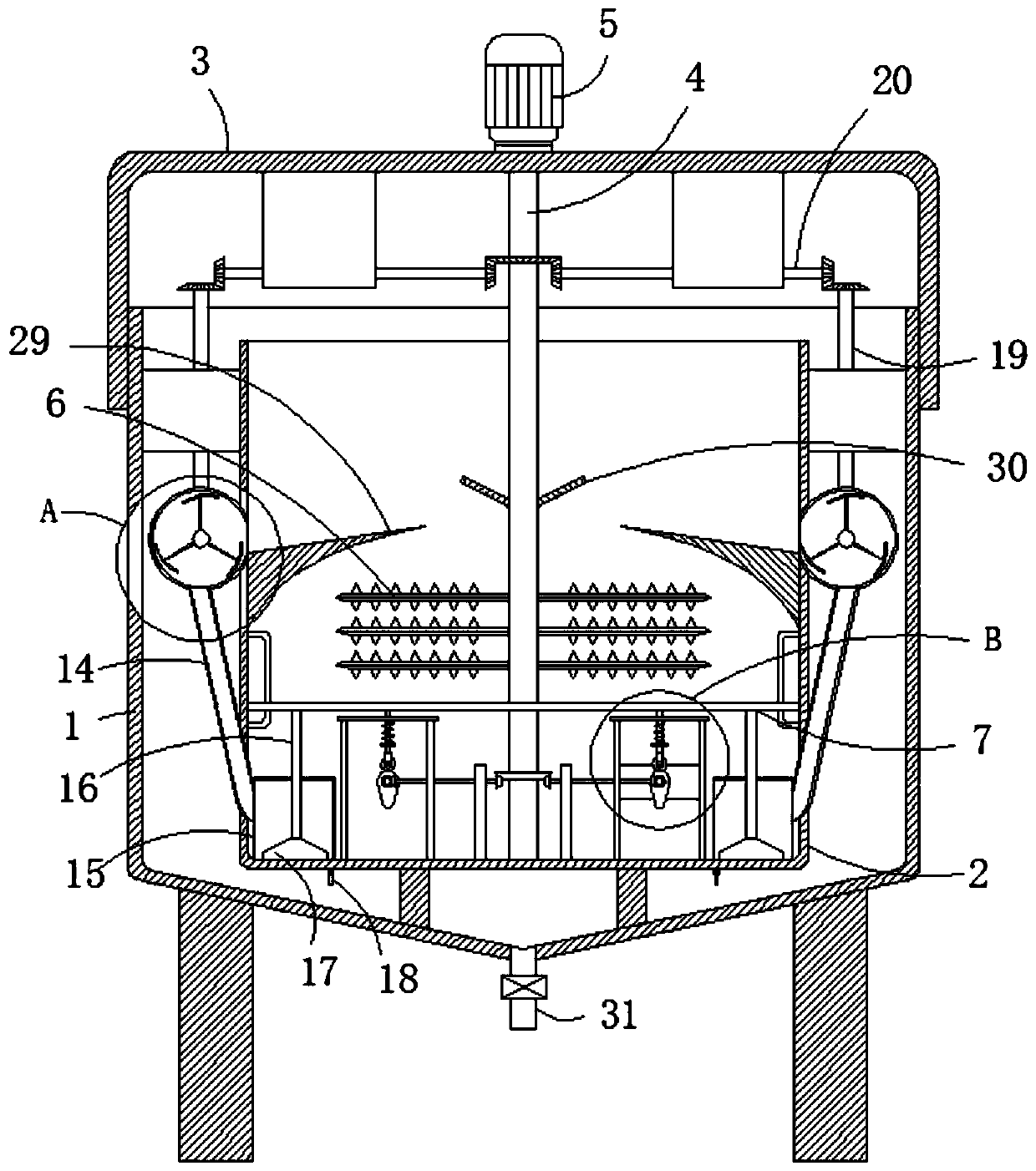

Manufacturing device for light alloy or light metal semi-solid slurry and manufacturing method

The invention discloses a manufacturing device for light alloy or light metal semi-solid slurry and a method for manufacturing the semi-solid slurry through the device. The manufacturing device for the light alloy or light metal semi-solid slurry comprises a smelting furnace, a runner, a mechanical stirring device, an inert gas stirring device, a powder spray device and a heating device. The semi-solid slurry manufacturing device reasonable in structure is designed, continuity for manufacturing the semi-solid slurry is good, and products can be cast industrially and continuously in a large scale by applying a semi-solid pressure casting or squeeze casting forming method. According to the manufacturing method for the semi-solid slurry, efficiency for manufacturing the light alloy or light metal semi-solid slurry is high, energy consumption is less, cost is low, and the manufactured semi-solid slurry cannot generate oxide inclusions, and is even in organization and excellent in quality.

Owner:机械科学研究总院(将乐)半固态技术研究所有限公司

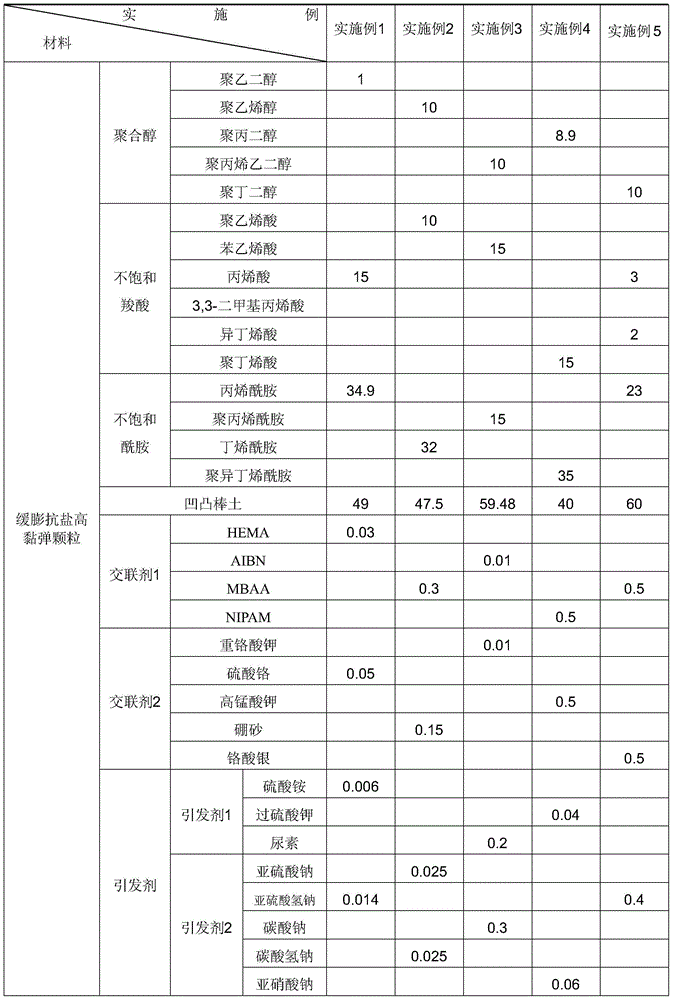

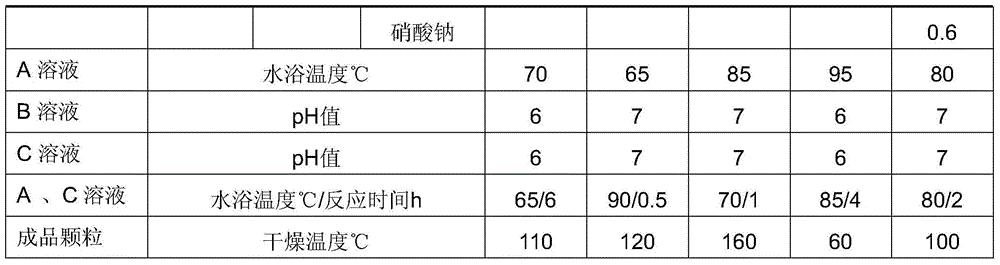

Retarding-swelling salt-tolerant high-viscoelasticity particles with interpenetrating network structure and preparation method thereof

InactiveCN104479653AImprove acid resistanceImprove salt toleranceDrilling compositionAlcoholNetwork structure

The invention discloses retarding-swelling salt-tolerant high-viscoelasticity particles with an interpenetrating network structure and a preparation method thereof. The method comprises the following steps: preparing liquid A: dissolving polymeric alcohol at certain temperature and cooling; preparing liquid B: neutralizing unsaturated carboxylic acid to a certain pH value; preparing liquid C: uniformly mixing a crosslinking agent 1, unsaturated amide, an initiator and attapulgite with the liquid B; uniformly mixing the liquid A with the liquid C, adding a crosslinking agent 2, and preserving heat at certain temperature; and finally, drying and granulating the polymer. The novel retarding-swelling salt-tolerant high-viscoelasticity particles with the interpenetrating network structure, disclosed by the invention, have the advantages of good retarding-swelling property, high water swelling rate, good viscoelasticity and toughness and high strength, and can adapt to deep water injection profile control; and moreover, the cost is low, the preparation is convenient, and the environmental pollution is avoided.

Owner:XI'AN PETROLEUM UNIVERSITY

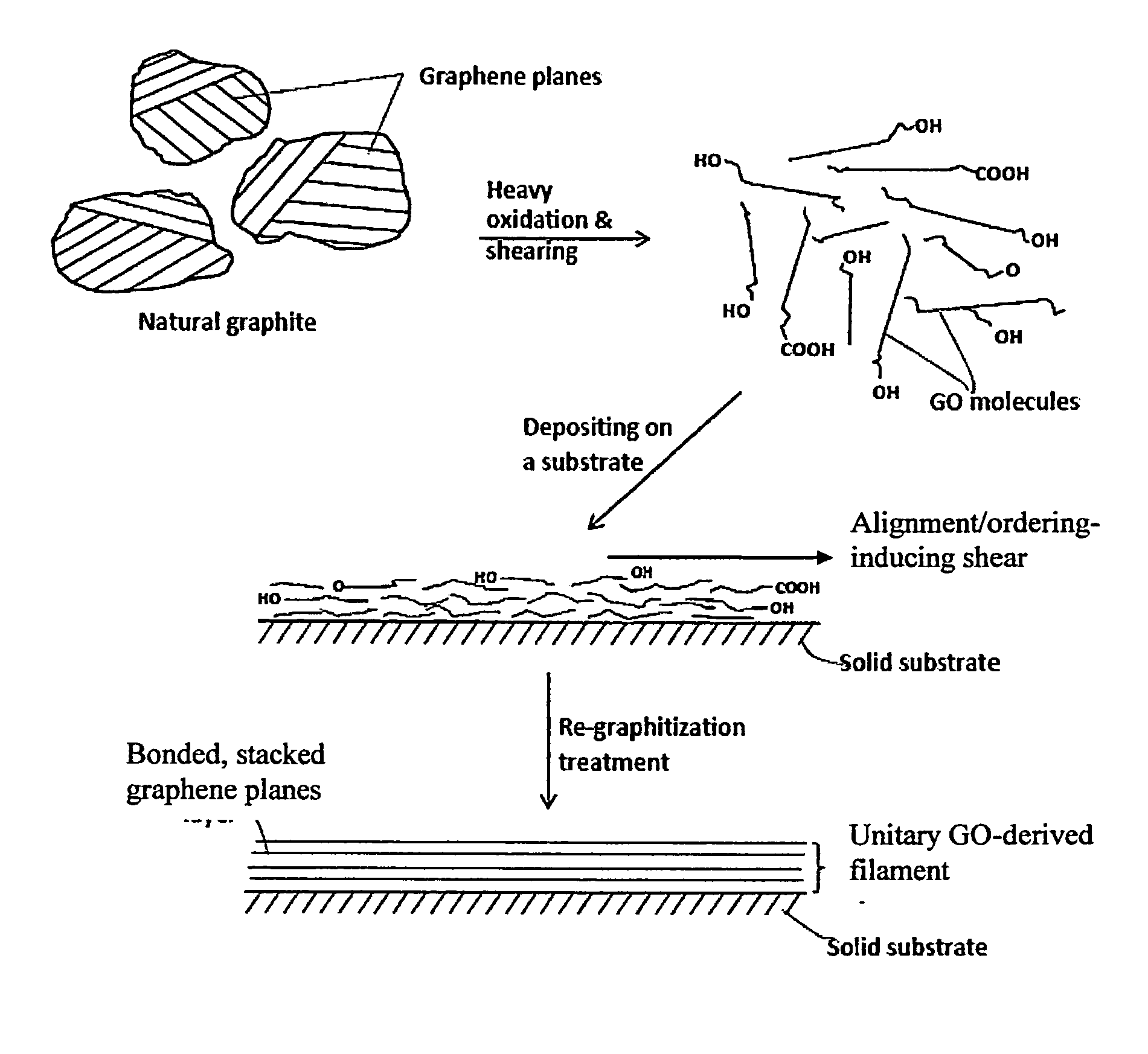

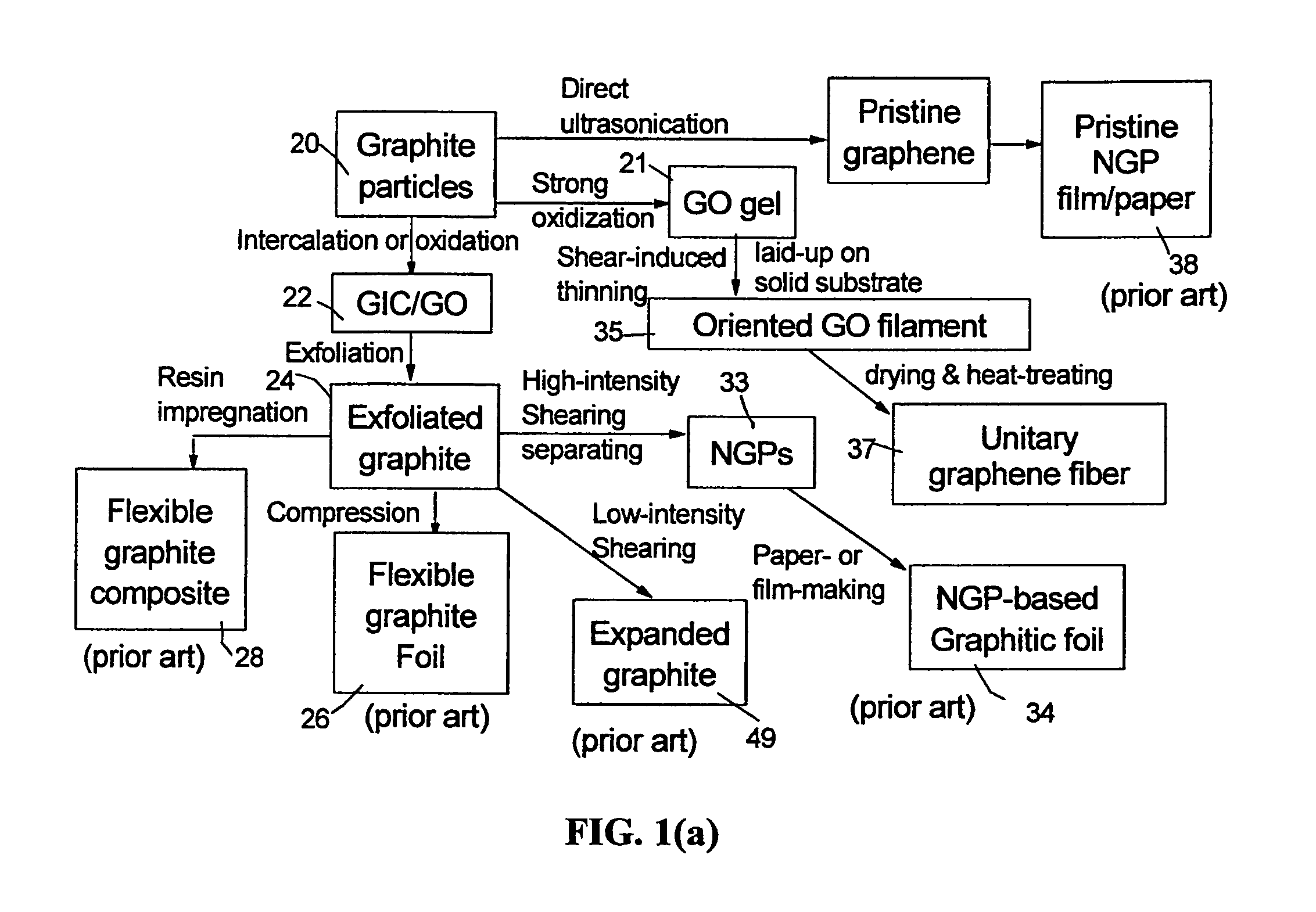

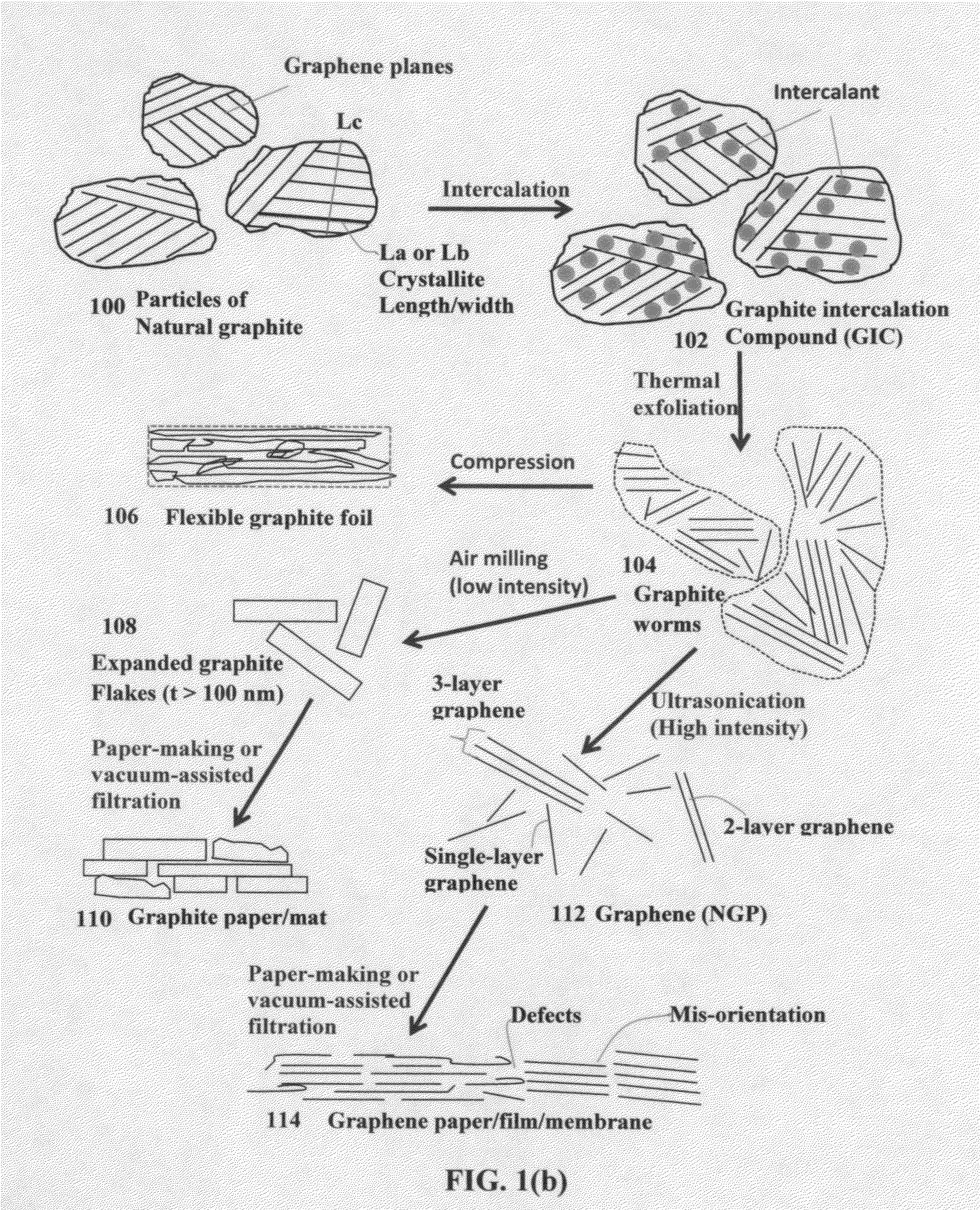

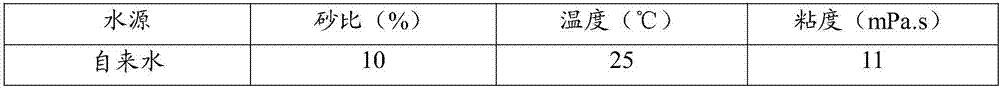

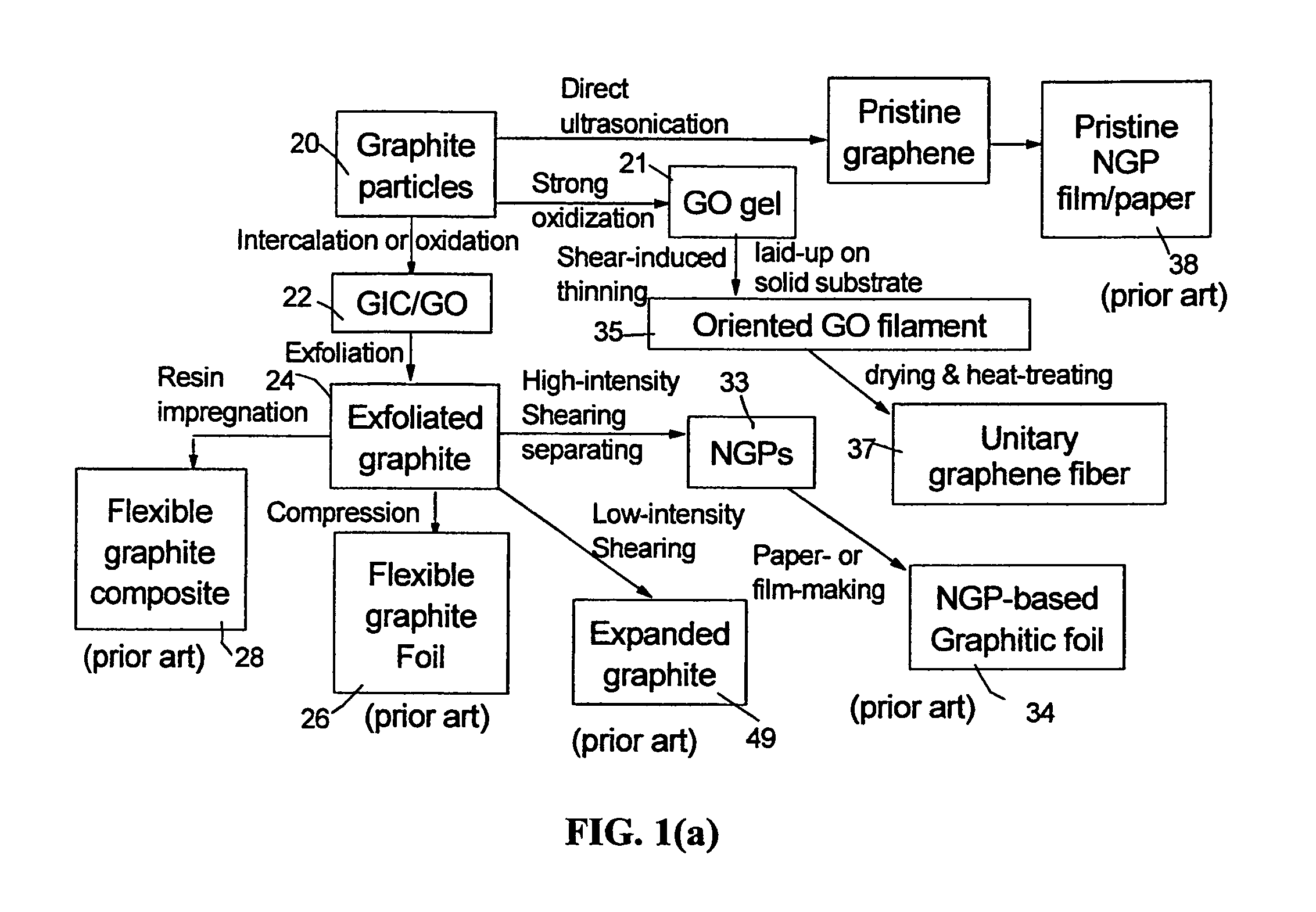

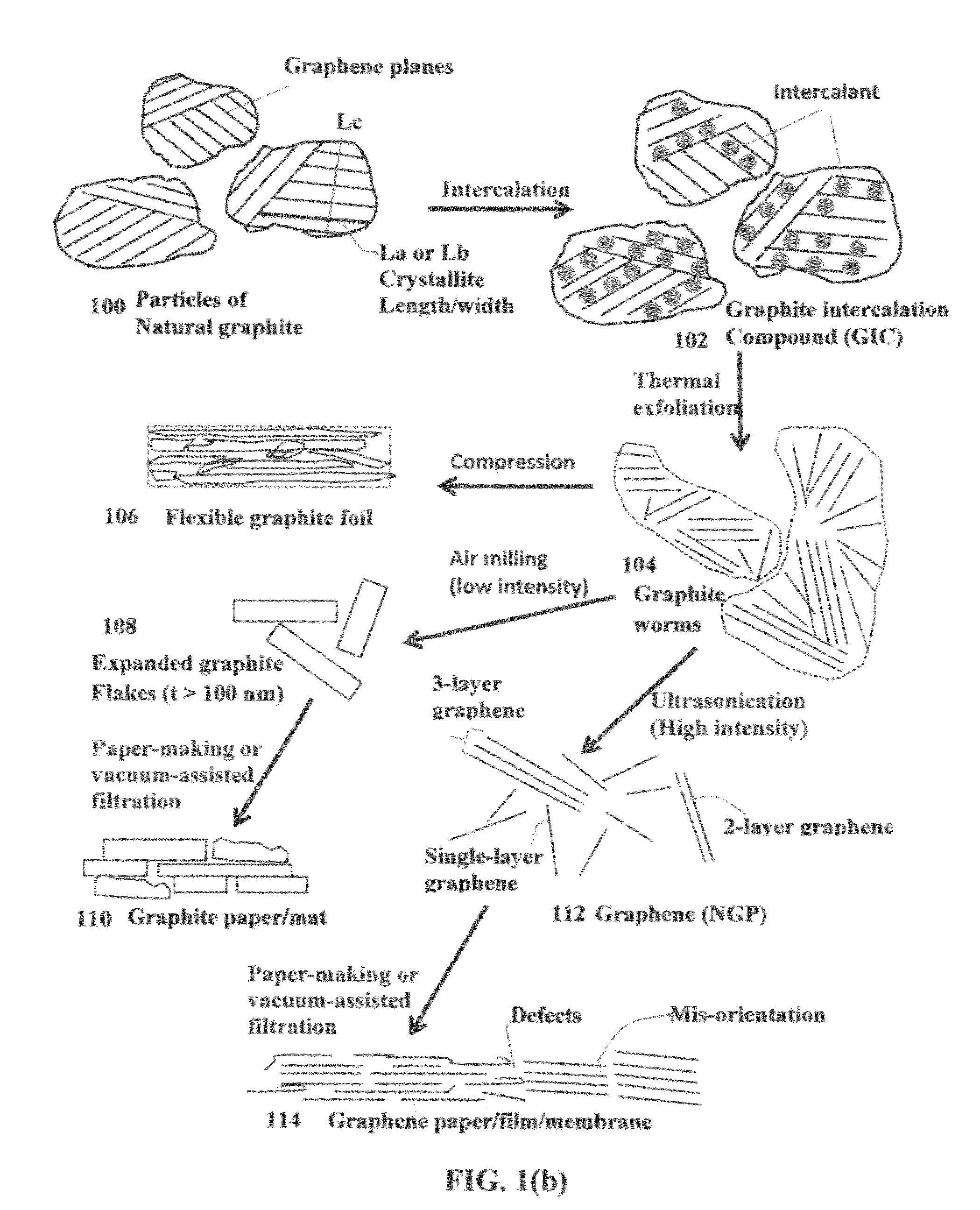

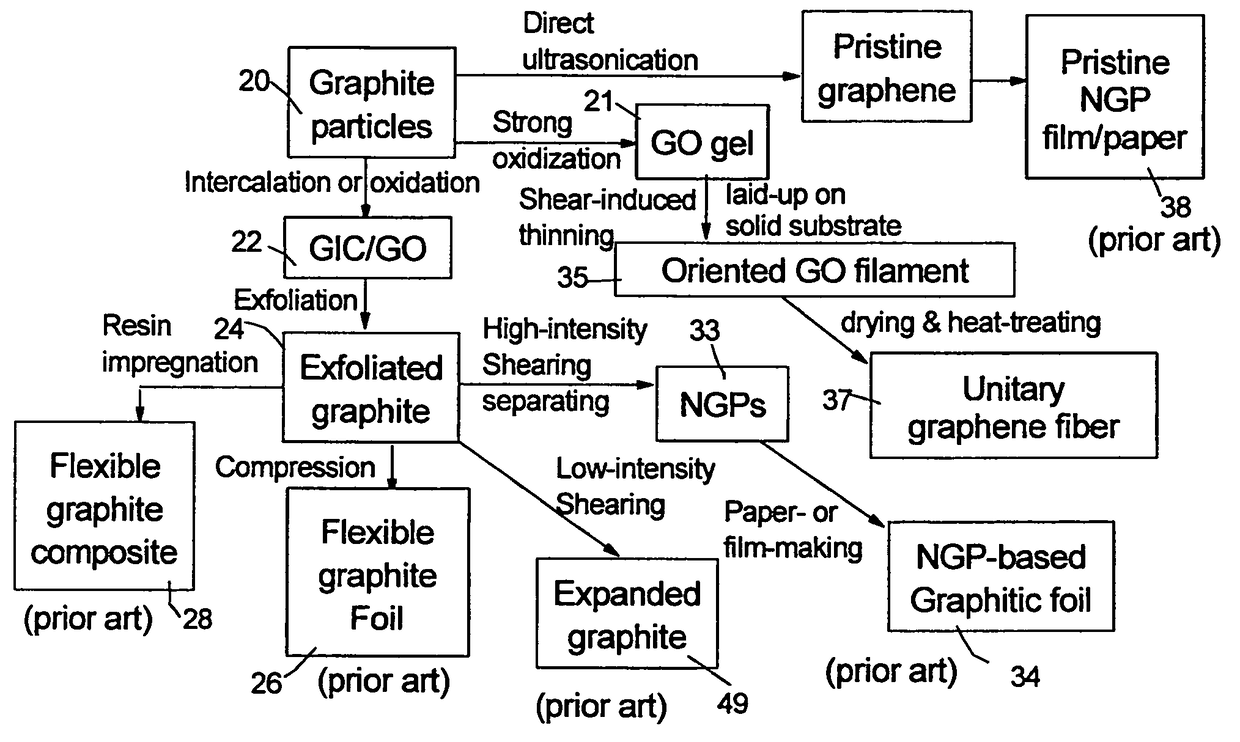

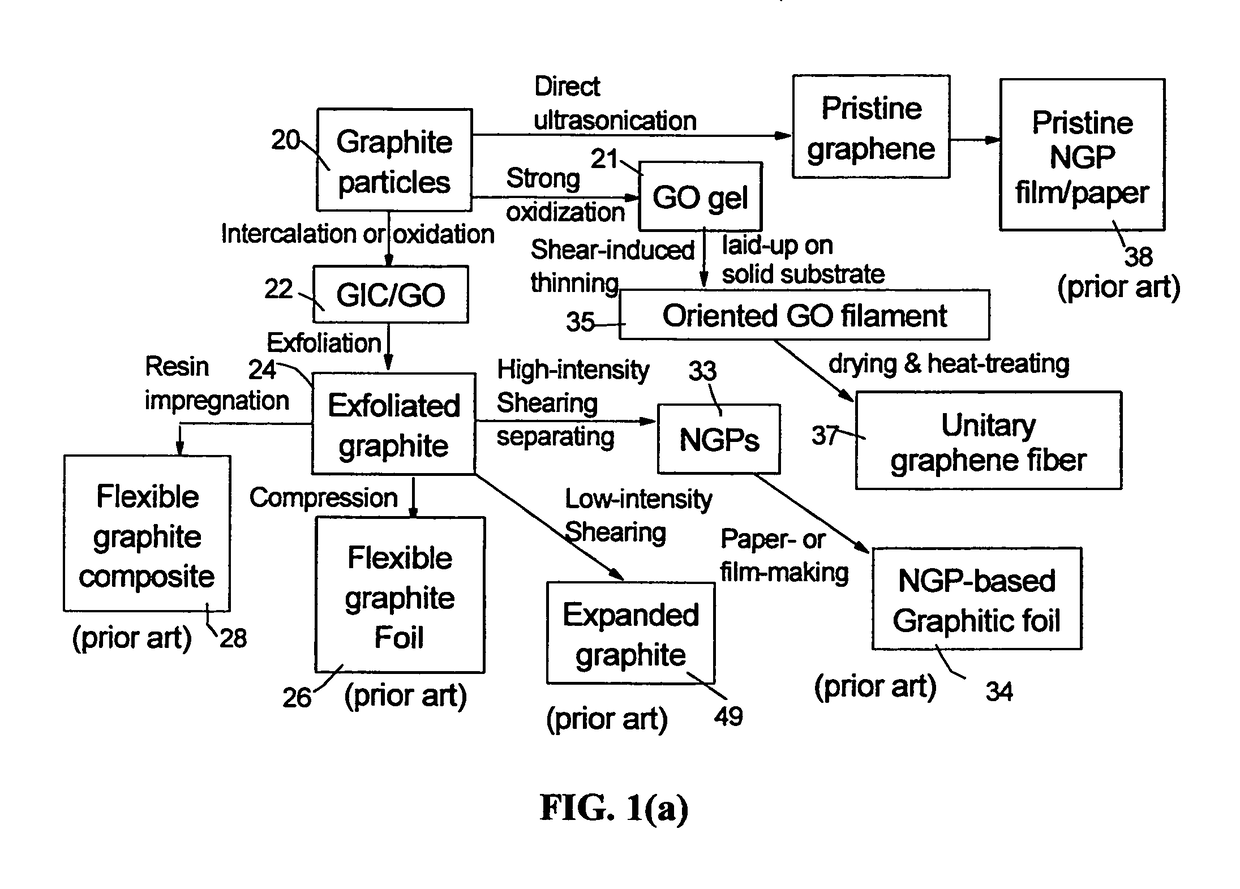

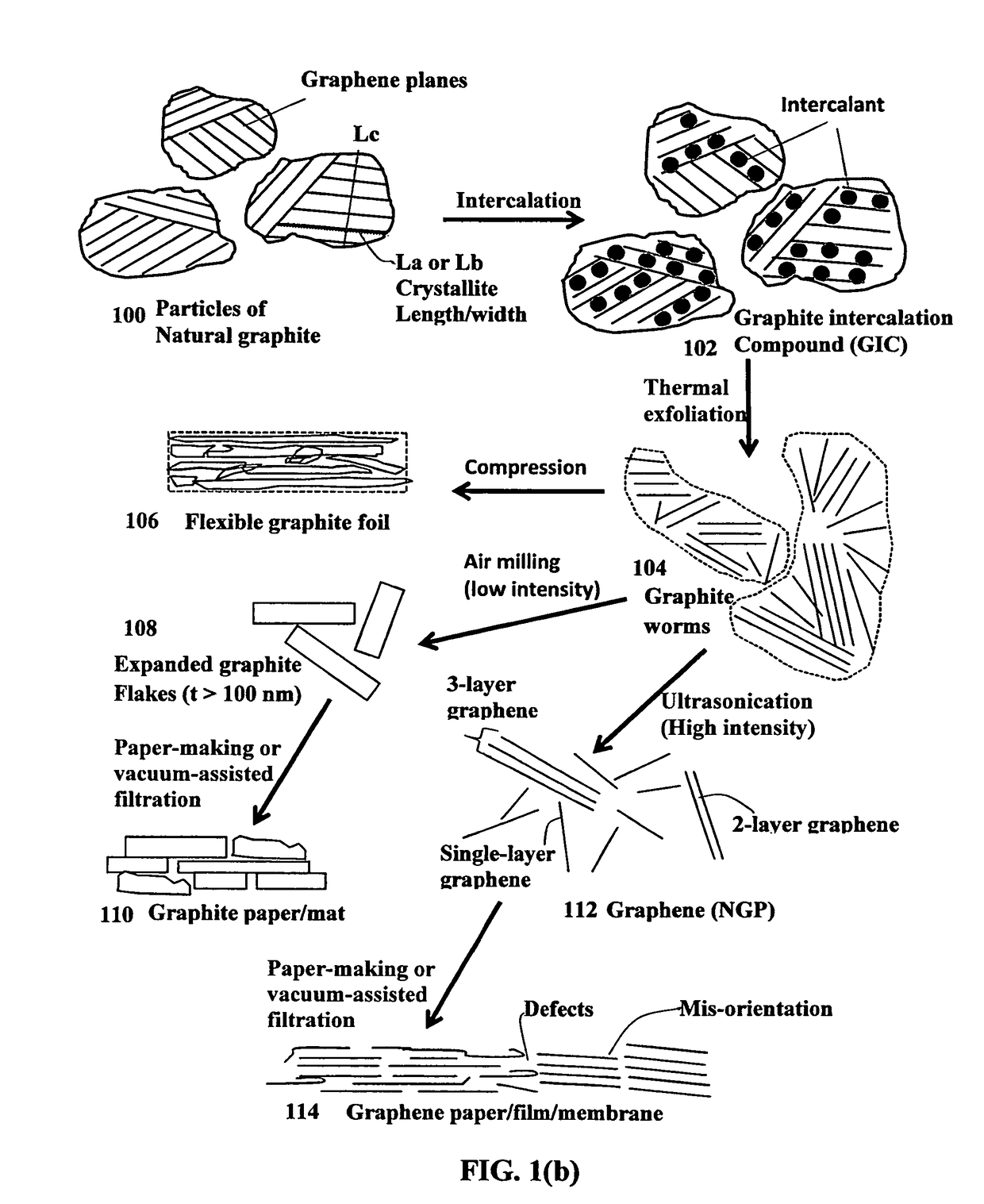

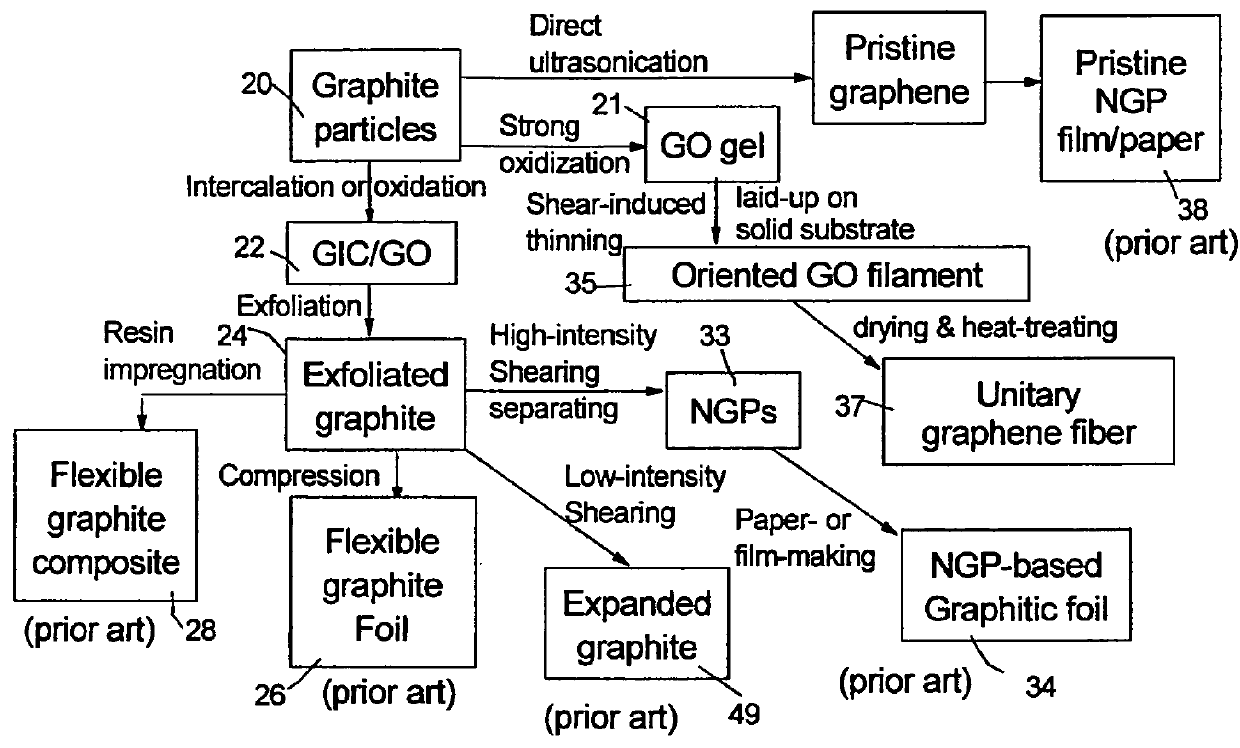

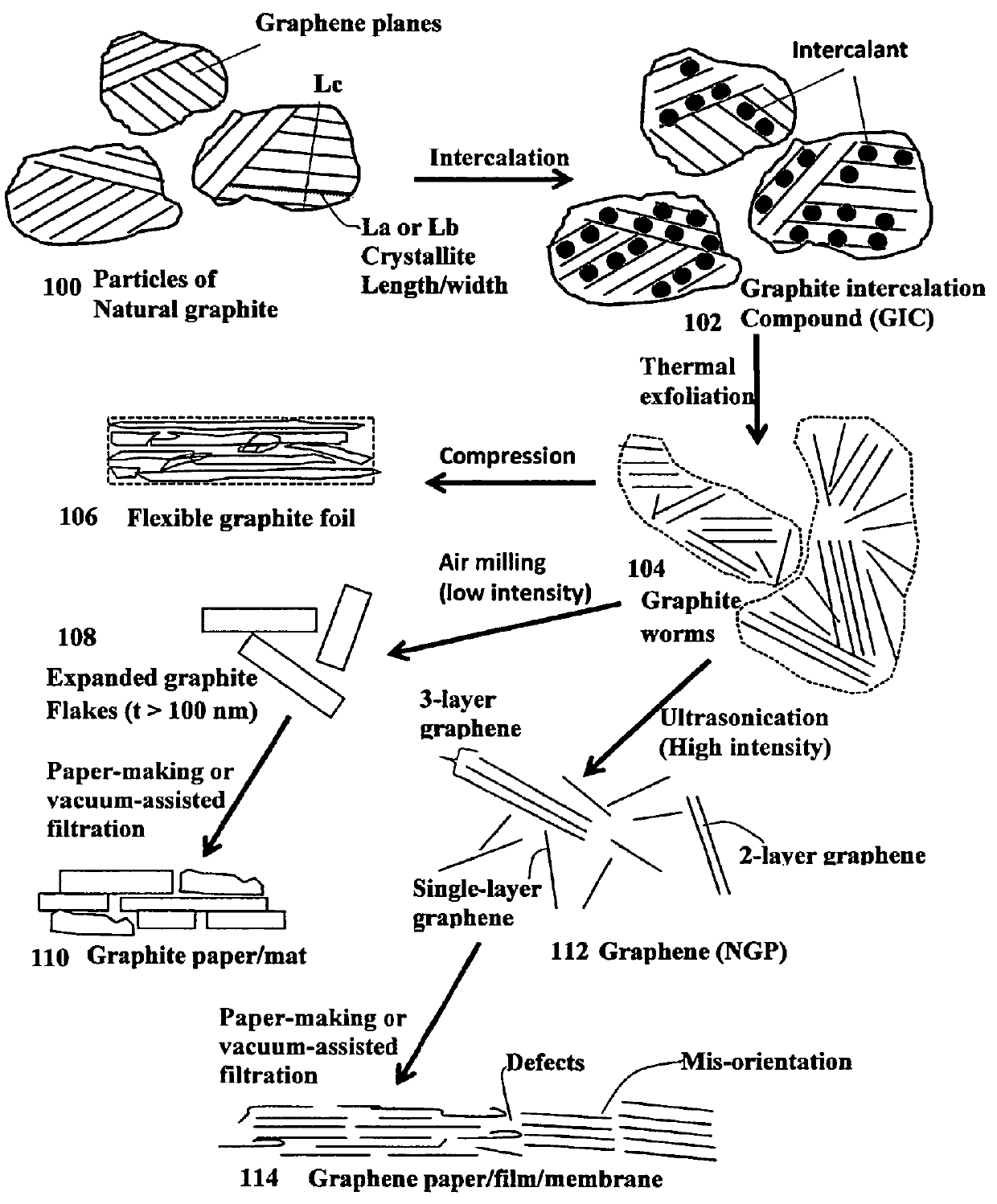

Process for producing continuous graphitic fibers from living graphene molecules

ActiveUS20140308449A1Low viscosityEffective shear stressCarbon compoundsPretreated surfacesStress inducedFiber

A process for producing a continuous graphitic fiber, comprising: (a) preparing a graphene oxide gel having living graphene oxide molecules or functionalized graphene chains dissolved in a fluid medium; (b) depositing at least a continuous filament of graphene oxide gel onto a supporting substrate under a condition of stress-induced molecular alignment of living graphene oxide molecules along a filament axis direction; (c) removing the fluid medium to form a continuous graphene oxide fiber, having an inter-plane spacing d002 of 0.4 nm to 1.2 nm and an oxygen content no less than 5% by weight; and (d) heat treating the continuous graphene oxide fiber to form the continuous graphitic fiber at a temperature higher than 100° C. (preferably >600° C.) to an extent that an inter-plane spacing d002 is decreased to a value of 0.3354-0.4 nm and the oxygen content is decreased to less than 5% by weight.

Owner:GLOBAL GRAPHENE GRP INC

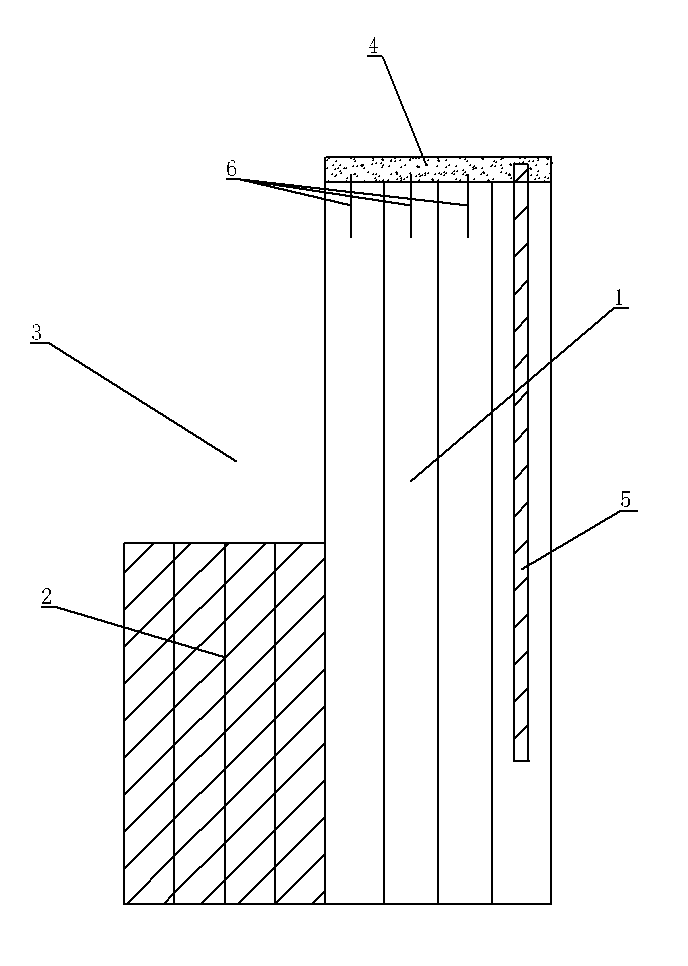

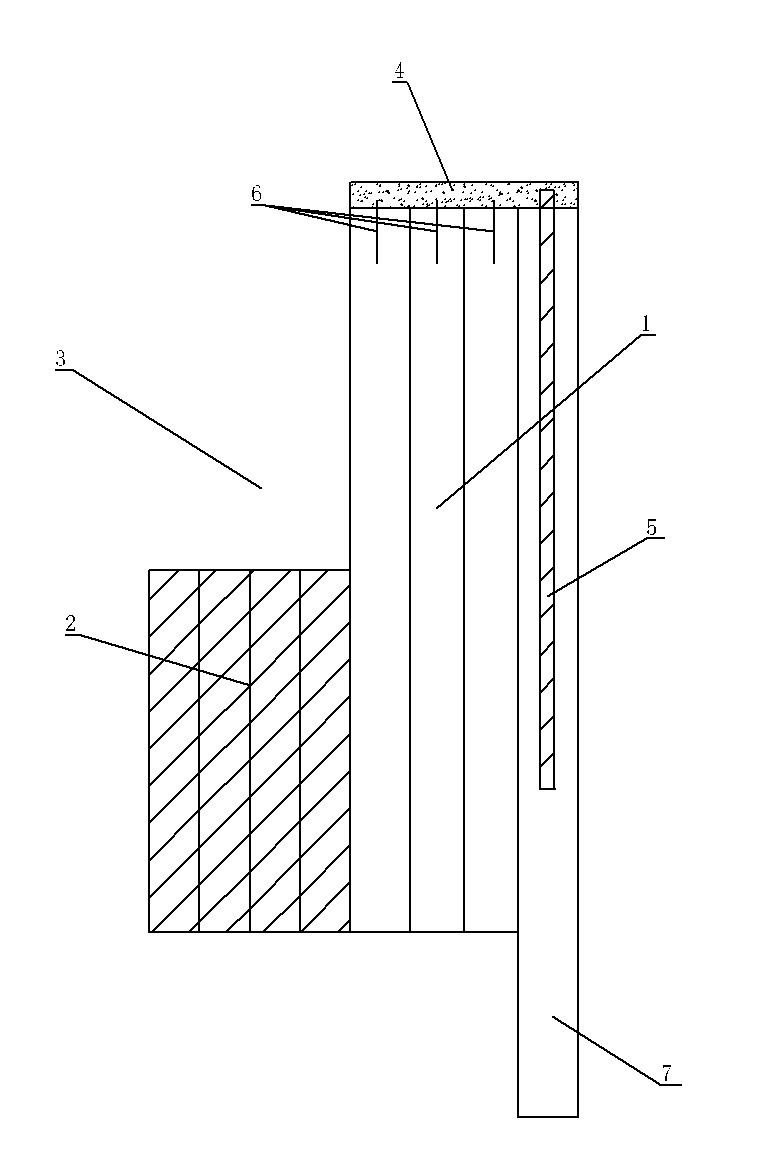

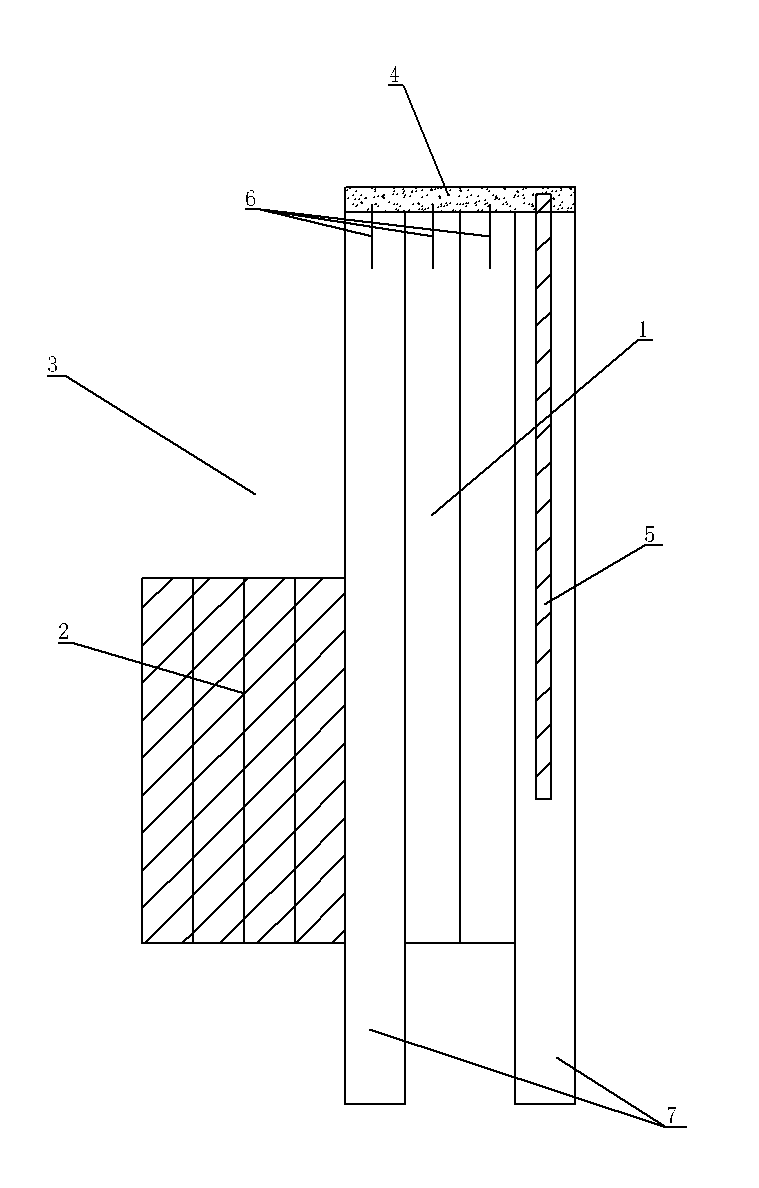

Variable section cement-soil gravity type retaining wall and construction method thereof

ActiveCN102071693ASmall footprintStrong anti-tilt abilityArtificial islandsExcavationsSmall footprintSoil horizon

The invention discloses a variable section cement-soil gravity type retaining wall and a construction method thereof. The retaining wall comprises a main wall body which consists of main cement mixed pile bodies, and an attached wall body which is positioned below the bottom face of a foundation pit and on one side or two sides of the main wall body, is connected with the main wall body and consists of attached cement mixed pile bodies, wherein the main wall body and the attached wall body form the variable section retaining wall. The construction method comprises the following steps of: forming the main wall body by using a cement mixed pile machine, forming the attached wall body, and excavating empty pile parts, so that the variable section cement-soil gravity type retaining wall is formed by the main wall body which consists of the main cement mixed pile bodies and is positioned above the bottom of the foundation pit, and the main wall body consisting of the main cement mixed pile bodies and the attached wall body consisting of the attached cement mixed pile bodies, which are positioned below the bottom of the foundation pit. By using the retaining wall formed by the construction method, when the soil layer at the bottom of the foundation pit is disturbed by cushion cap excavation and substrate structure construction, the foundation pit deforms a little, and the formed gravity type retaining wall has small width and floor area and high inclination resistance, shear resistance and bending resistance.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

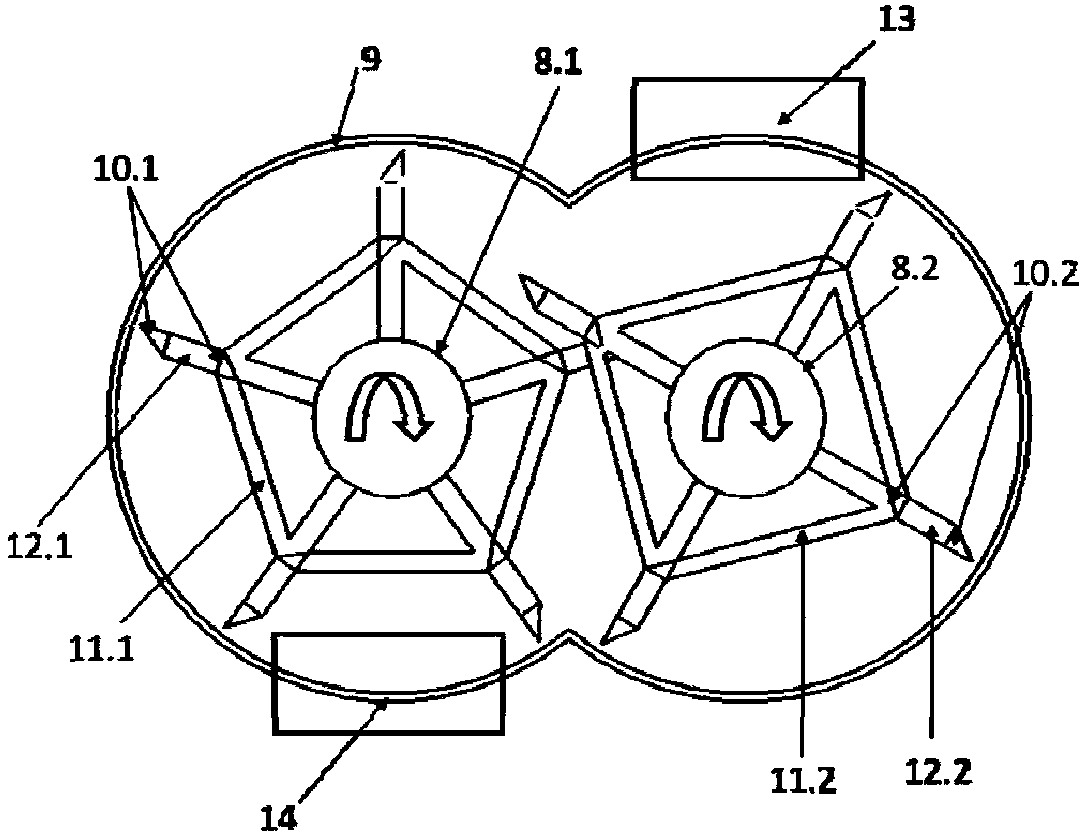

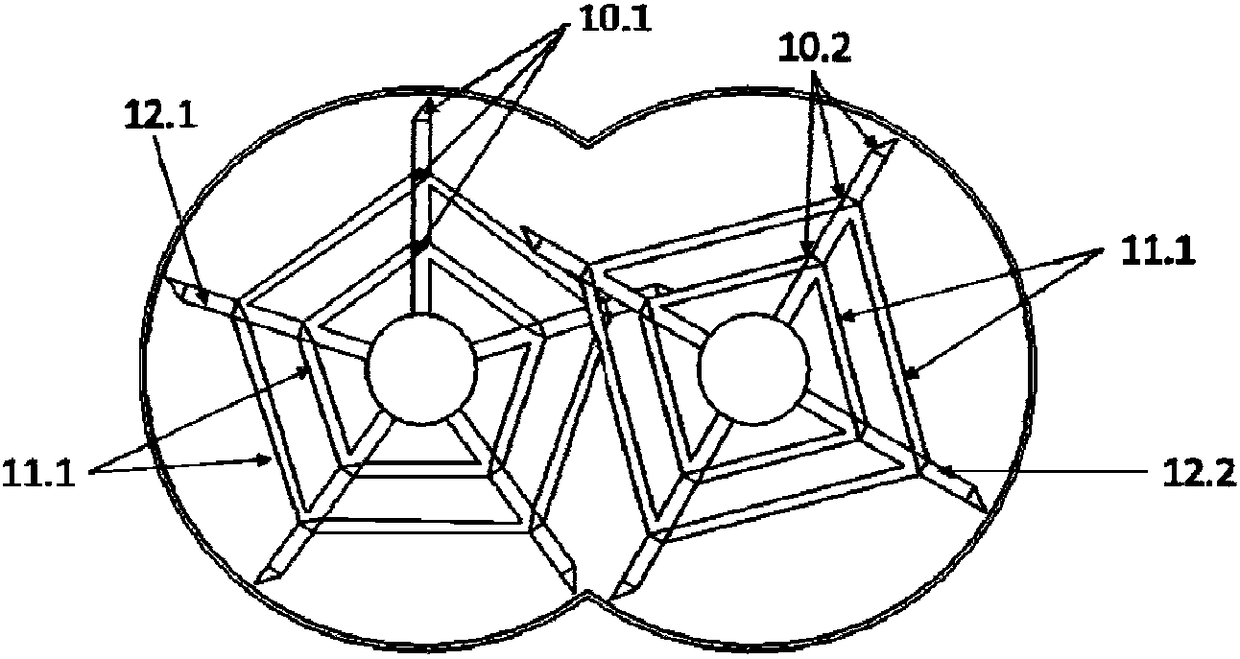

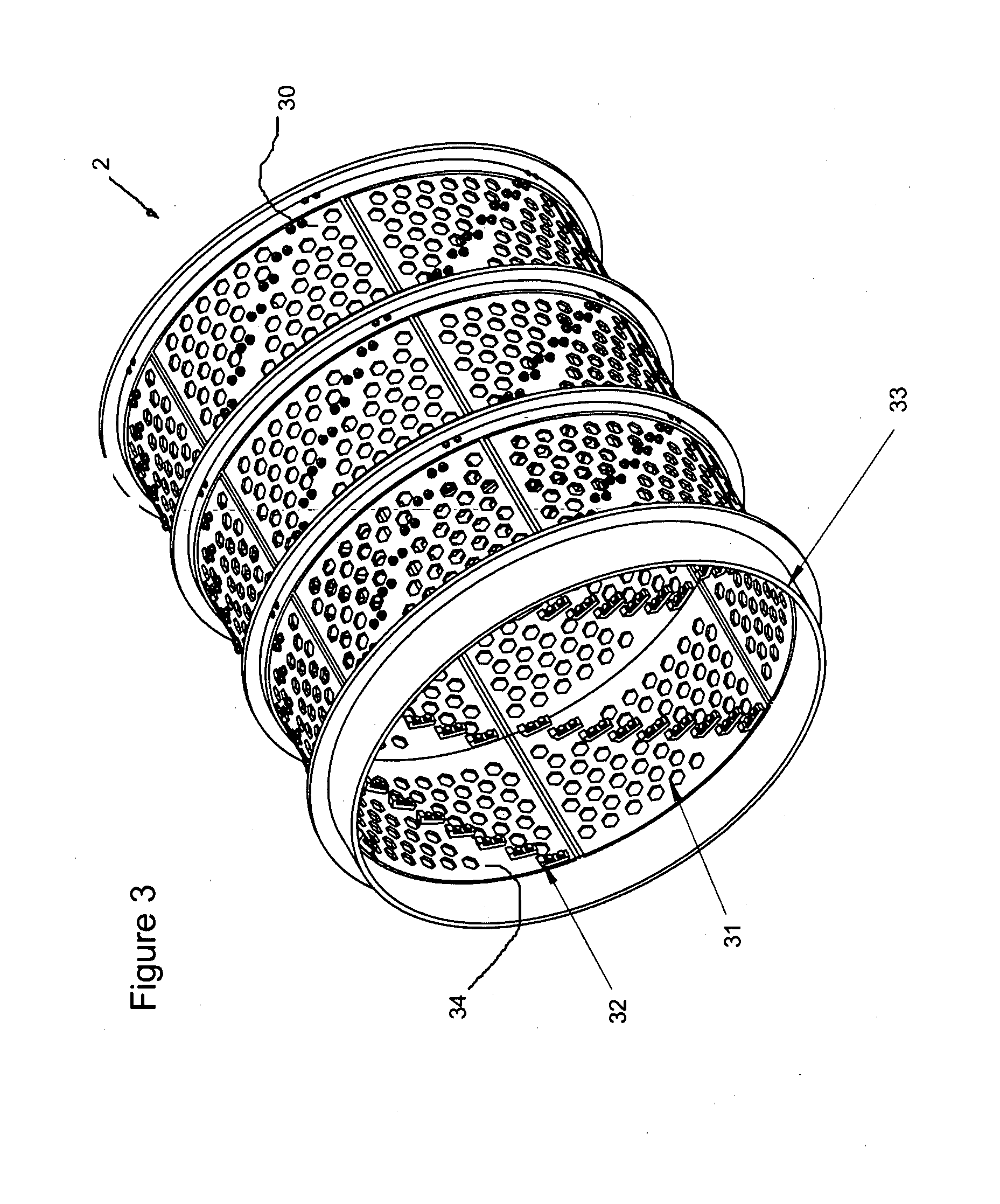

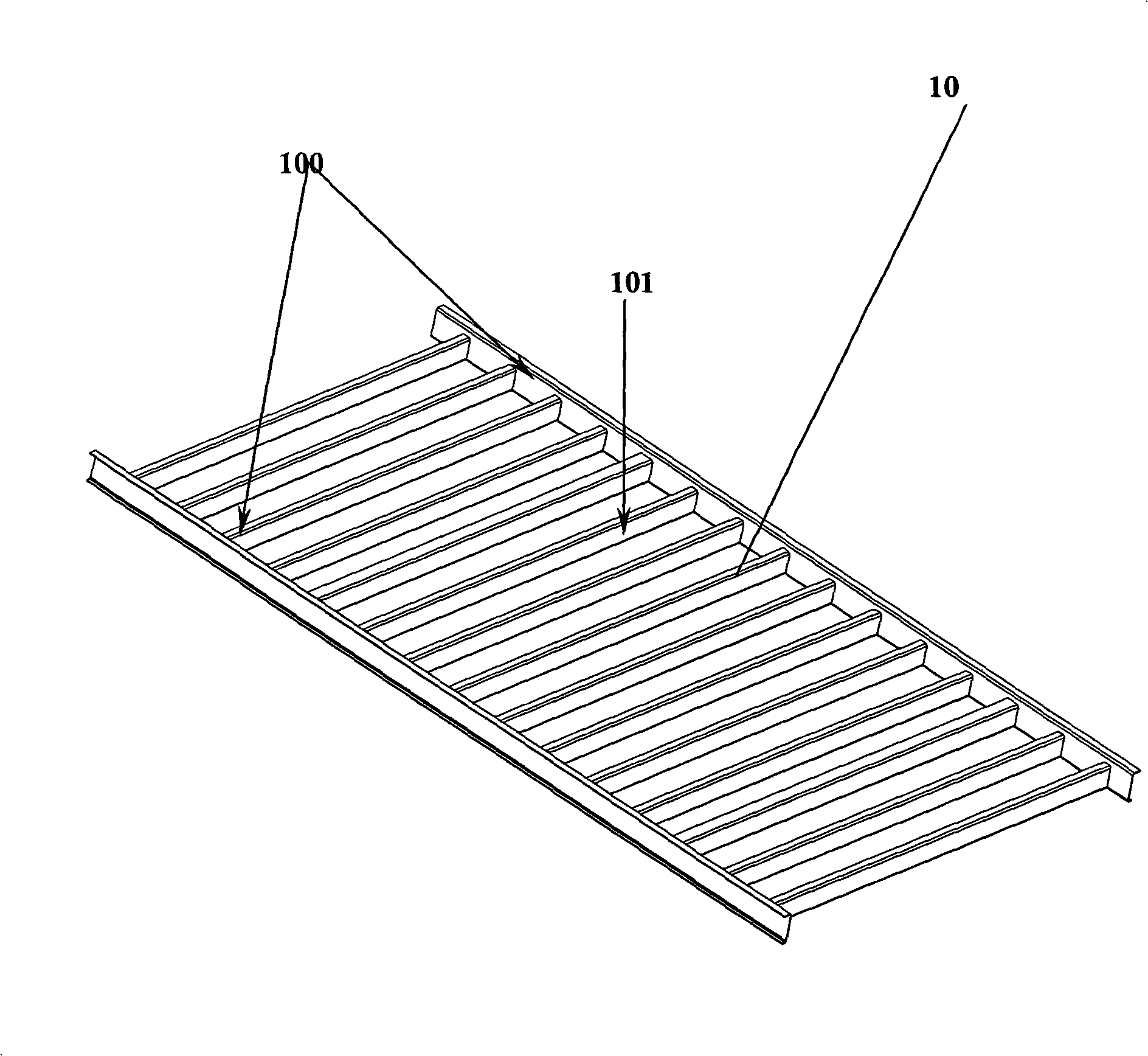

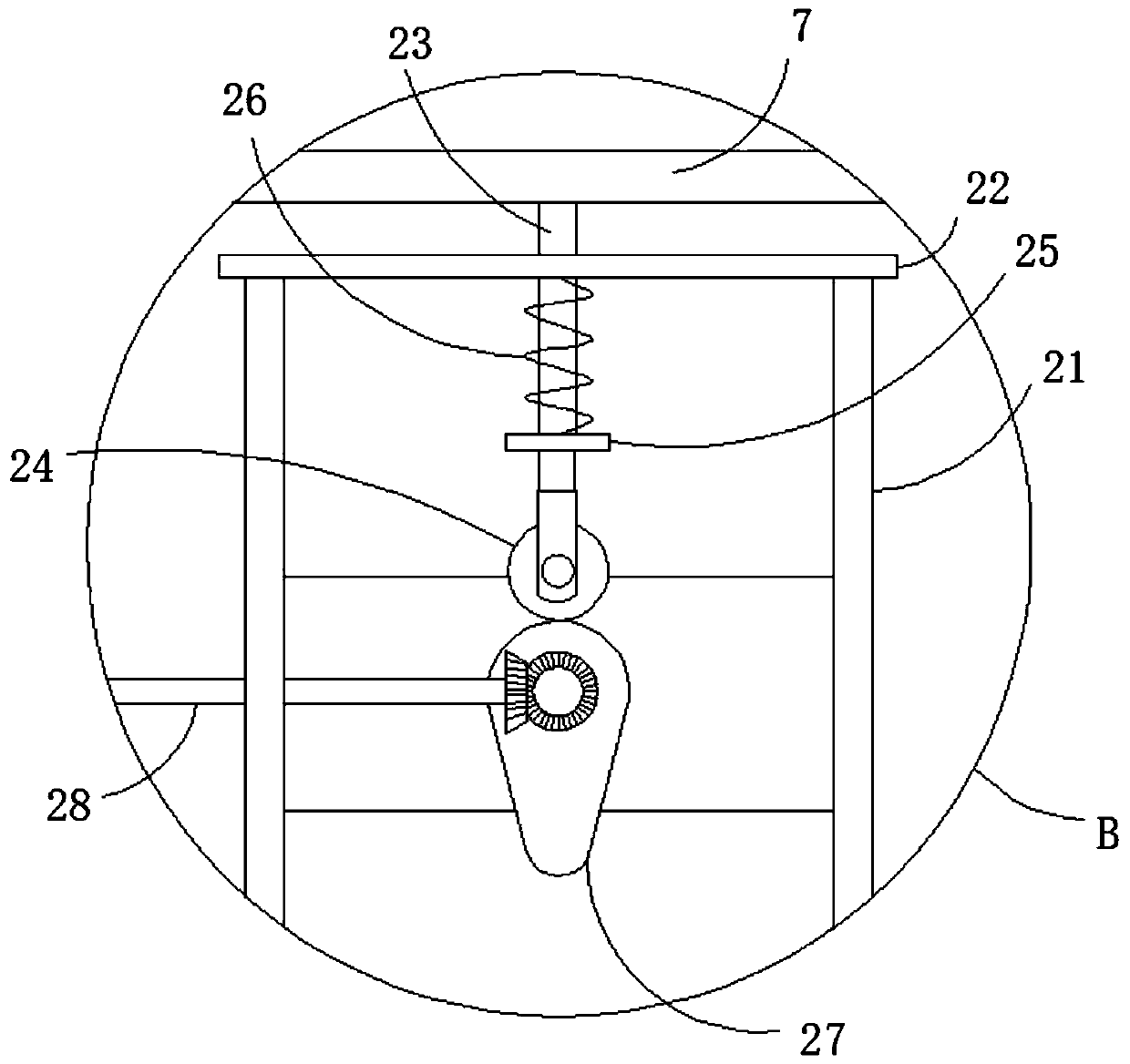

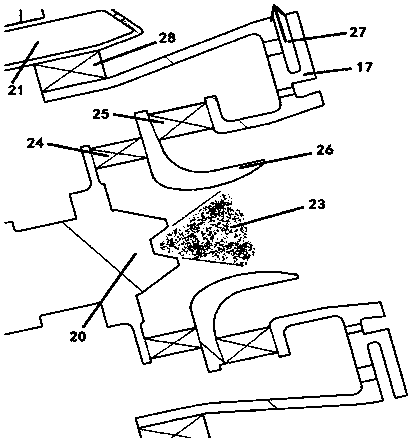

Stirring device and horizontal double-shaft self-cleaning reactor

ActiveCN108236910AImprove clippingStrong shearRotary stirring mixersTransportation and packagingEngineeringViscosity

The invention relates to a stirring device which comprises two rotating shafts, wherein a plurality of same stirring discs are axially fixed to the rotating shaft; each stirring disc is composed of aplurality of same radially arranged stirring rods and a fixed rod connected to two adjacent stirring rods; each stirring rod comprises supporting rods arranged radially and two or more stirring bladesarranged on the supporting rods vertically, wherein one of the stirring blades is located at the tail end of the supporting rod, and the stirring discs on the two rotating shafts are arranged in a staggered manner. The invention also provides a horizontal double-shaft self-cleaning reactor based on the stirring device. Compared with a conventional horizontal double-shaft reactor, the horizontal double-shaft self-cleaning reactor is simple in structure, has a bigger reaction space, materials are sheared and stretched in a kettle body, so that the reactor is suitable for fluids with different viscosities; the standing time is controllable; compared with the conventional horizontal double-shaft reactor, full reaction regions in the kettle body scratch one another, so that the self-cleaning effect is good. The reaction energy consumption is low, and the mixing efficiency is high.

Owner:ZHEJIANG UNIV

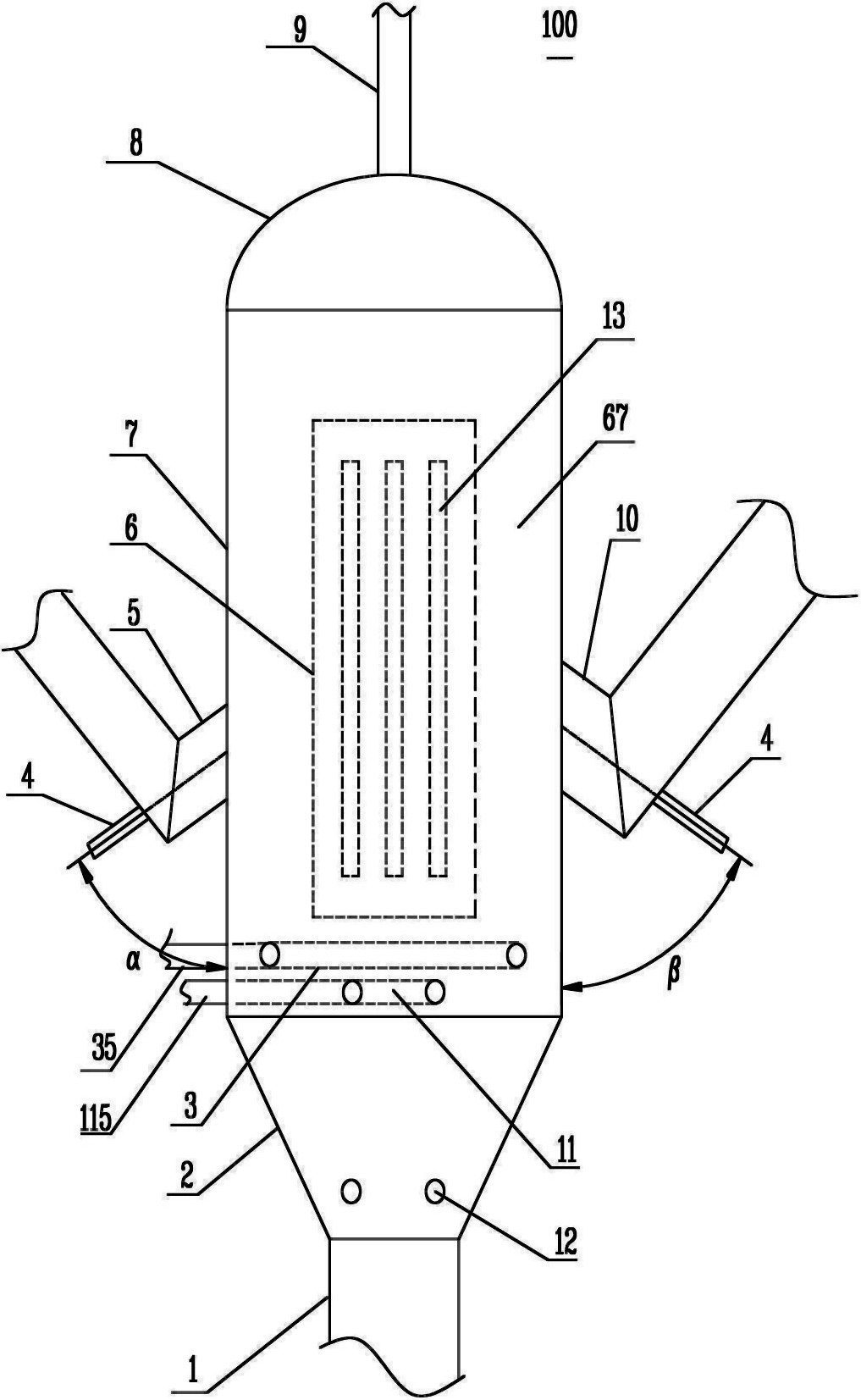

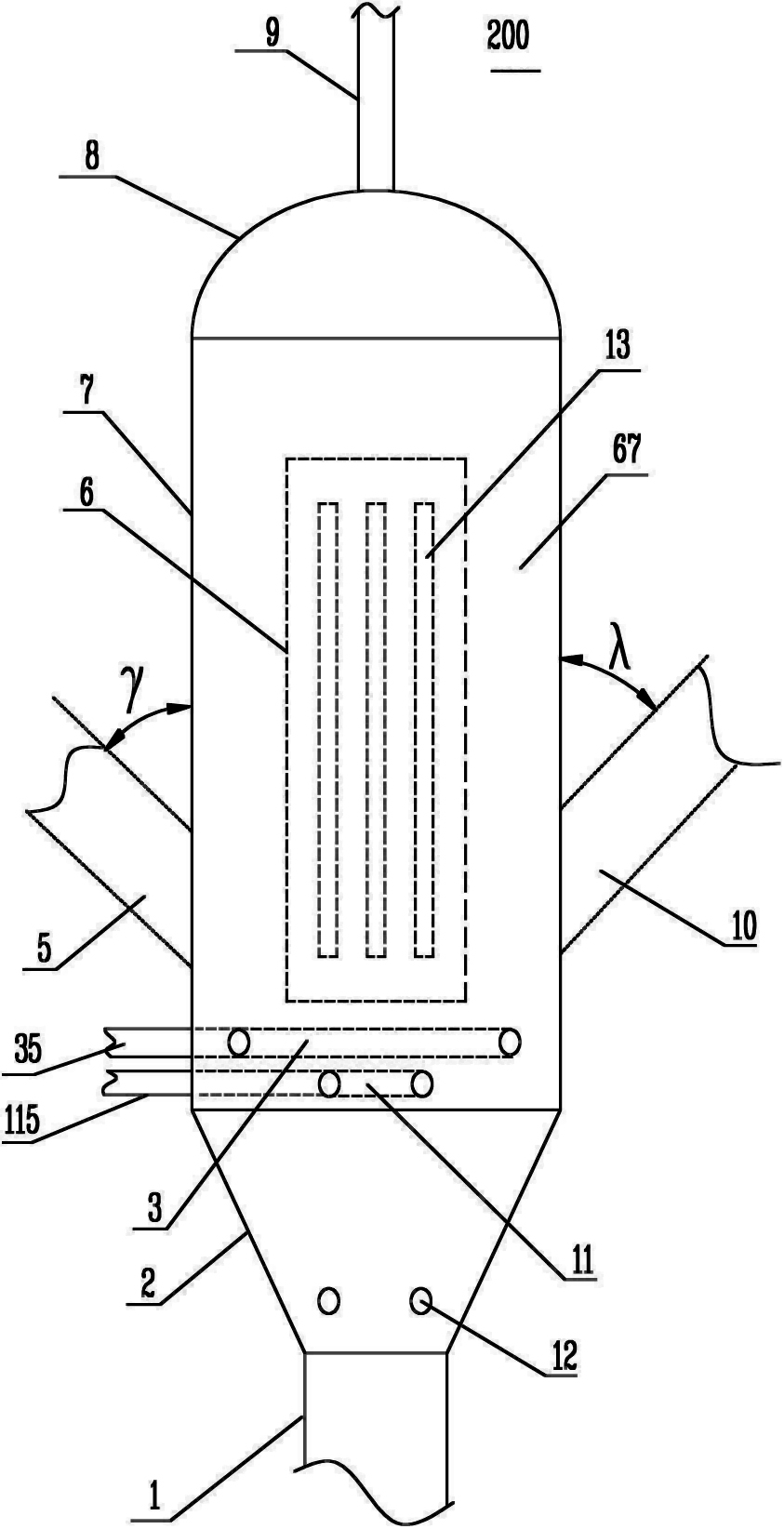

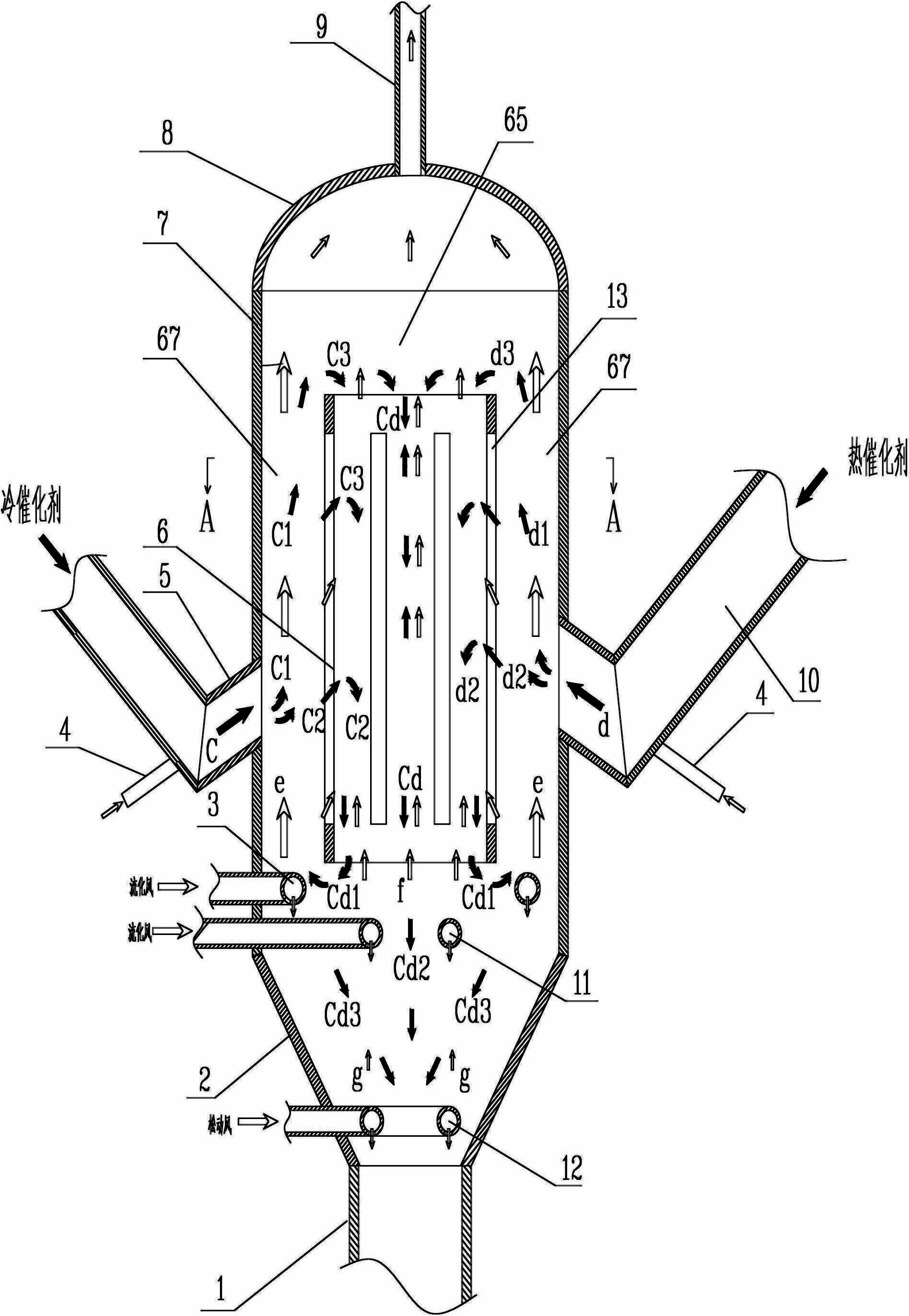

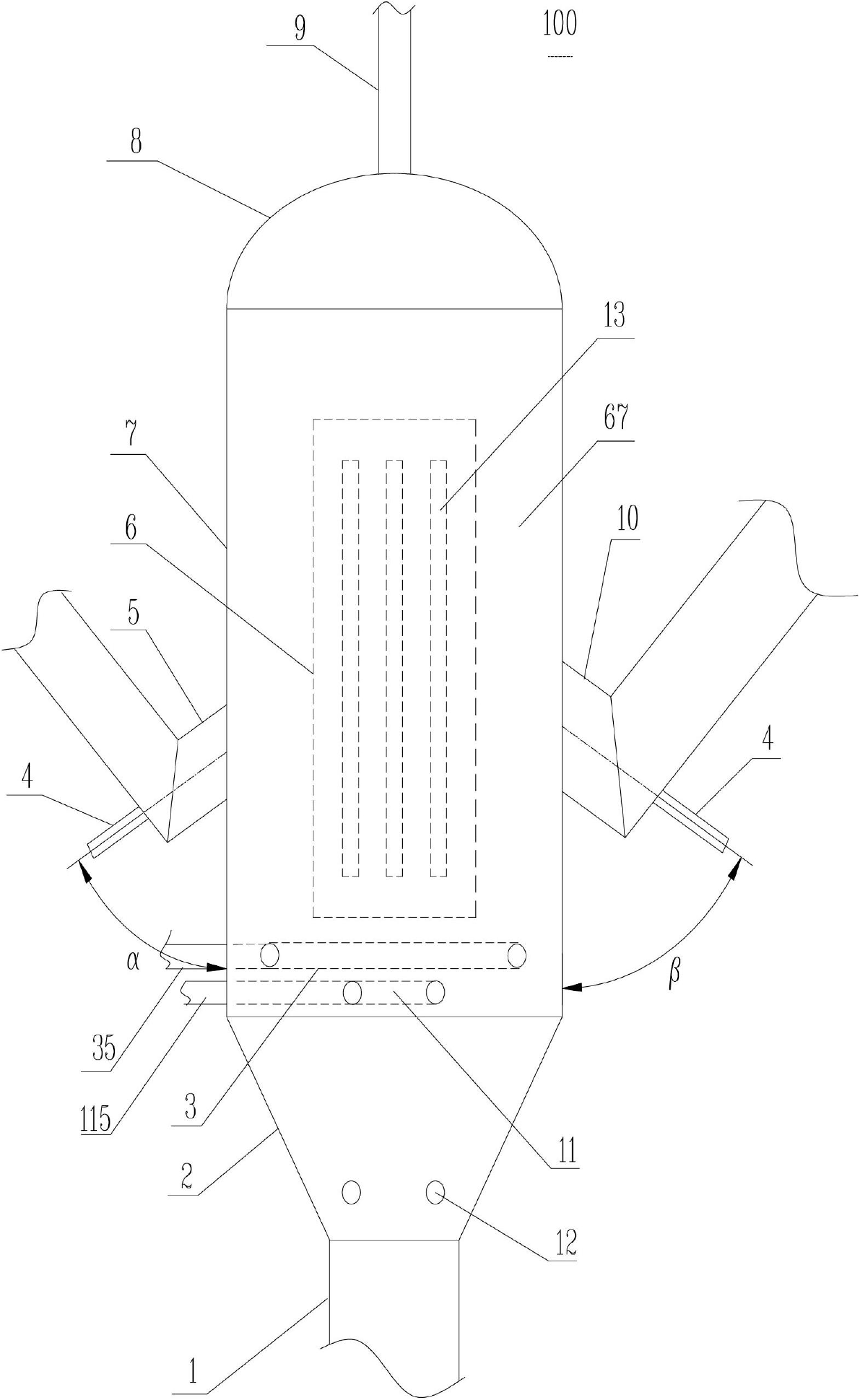

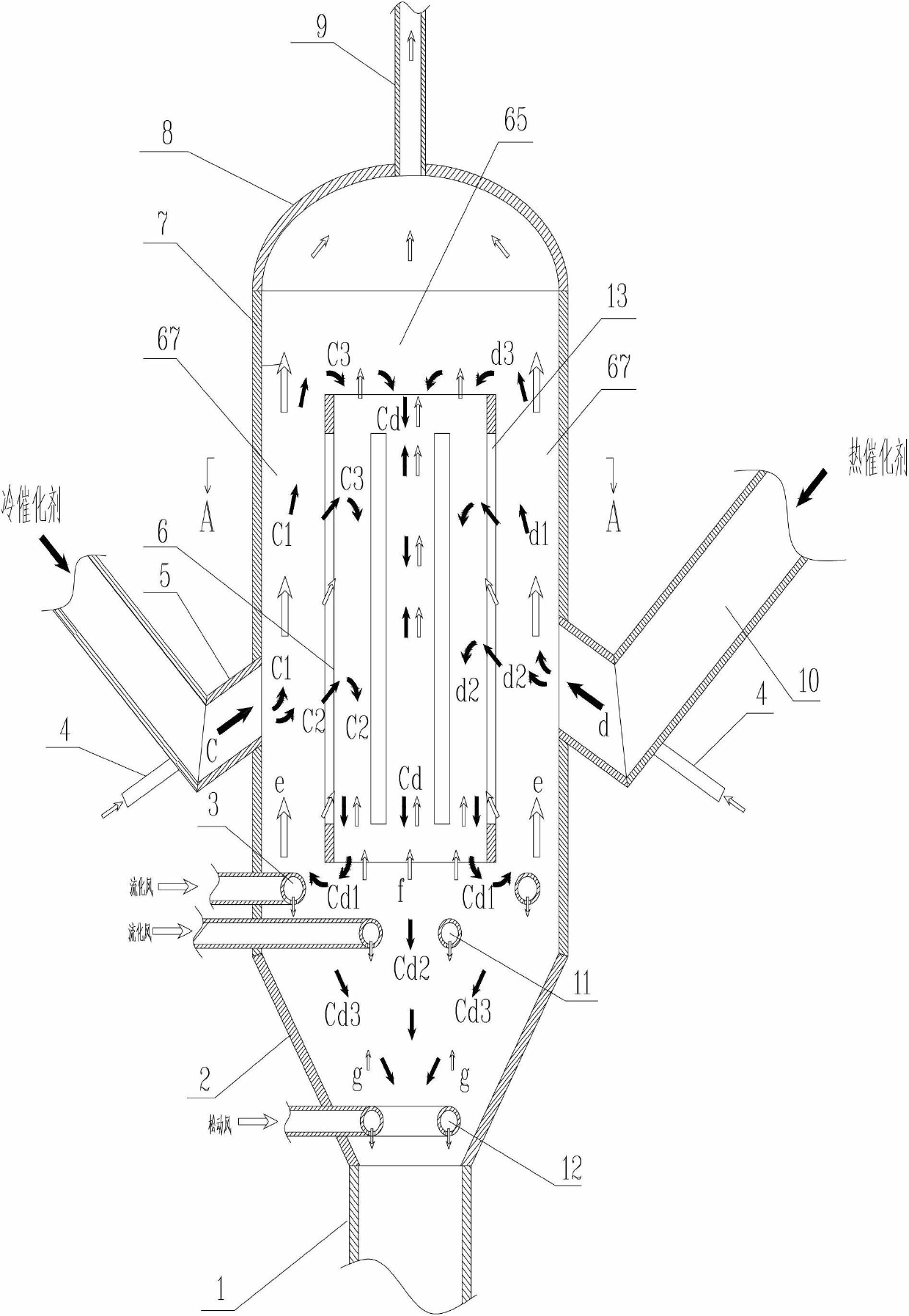

Circulating method for cold regenerated catalyst and catalytic cracking reaction regenerating system

The invention provides a circulating method for a cold regenerated catalyst and a catalytic cracking reaction regenerating system. The catalytic cracking reaction regenerating system comprises a hoisting pipe reactor, a pre-hoisting section, a regenerator, a heater and a gas-solid annular flow mixing stripper, wherein the gas-solid annular flow mixing stripper is used for mixing a first solid grain and a second solid grain at different temperatures during a regenerating form fluid catalytic cracking process and stripping the smoke and air taken by the solid grains after being mixed; the first solid grain is a low-temperature catalyst or low-temperature to-be-generated agent; and the second solid grain is a high-temperature catalyst. The circulating method for the cold regenerated catalyst comprises the following steps of: mixing and exchanging heat of the first solid grain from the heater and the second solid grain from the regenerator in the gas-solid annular flow mixing stripper, and meanwhile, stripping the taken smoke and air, forming the mixed catalyst and then entering into the pre-hoisting section.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of foamed polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

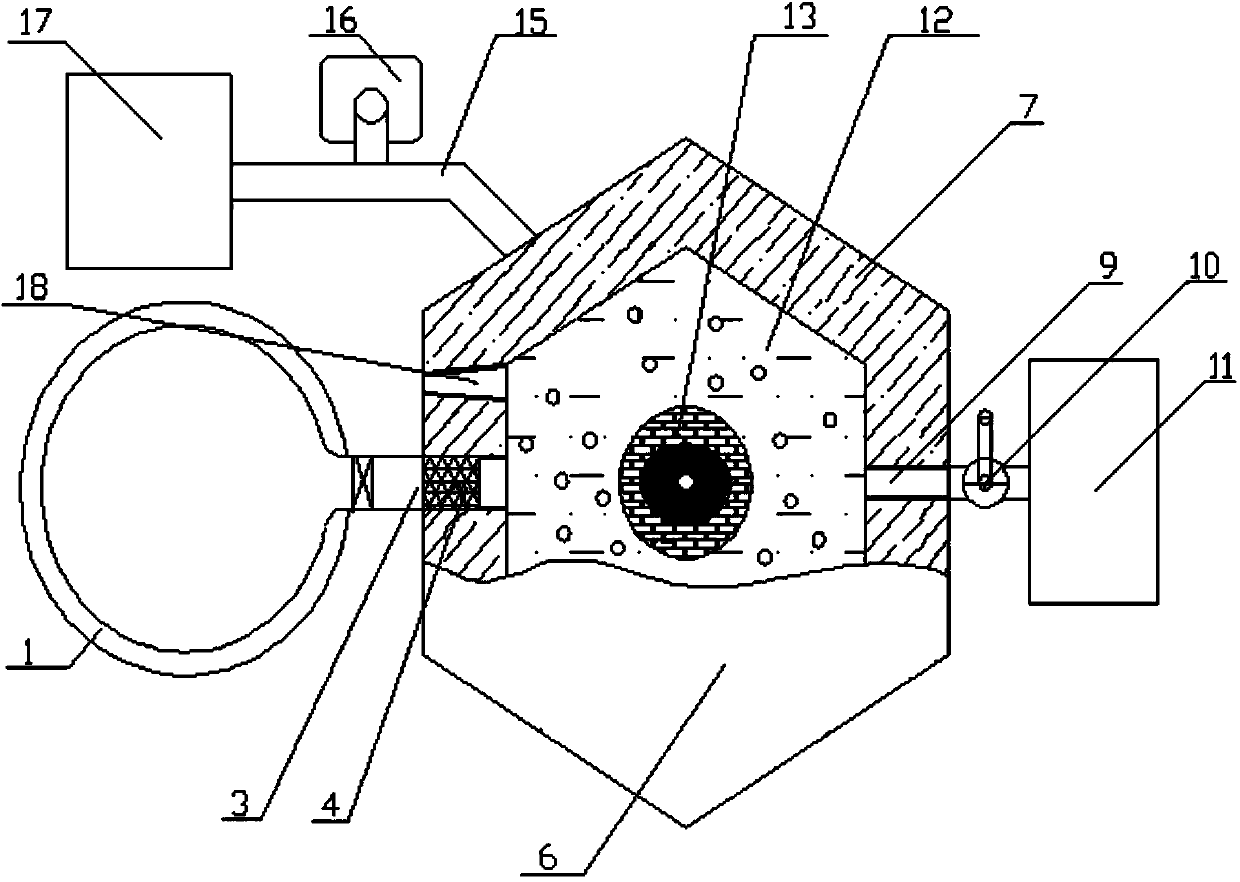

Gas/solid circulation mixing steam stripper and mixing and steam stripping method of solid particles

ActiveCN102676206AStrong shearImprove contact efficiencyCatalytic crackingCatalyst regeneration/reactivationEngineeringProduct gas

The invention provides a gas / solid circulation mixing steam stripper and a mixing and steam stripping method of solid particles. The gas / solid circulation mixing steam stripper comprises a cylinder body (7) with an inner cavity, a flow guide cylinder (6), a ring-gap gas distributor (3), a gas distributor (11) of the flow guide cylinder, a gas outlet extending into the inside of the cylinder body (7), a cone (2) connected with the lower end of the cylinder body (7), a mixed solid particle outlet (1) arranged below the cone (2), a loose steam ring (12) which is positioned at the bottom of the cone (2) and is also positioned above the mixed solid particle outlet (1), a first solid particle inlet passage and a second solid particle inlet passage, wherein the first solid particle inlet passage and the second solid particle inlet passage are respectively connected to the inside of the cylinder body. The gas / solid circulation mixing steam stripper is adopted by the mixing and steam stripping method of the solid particles.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

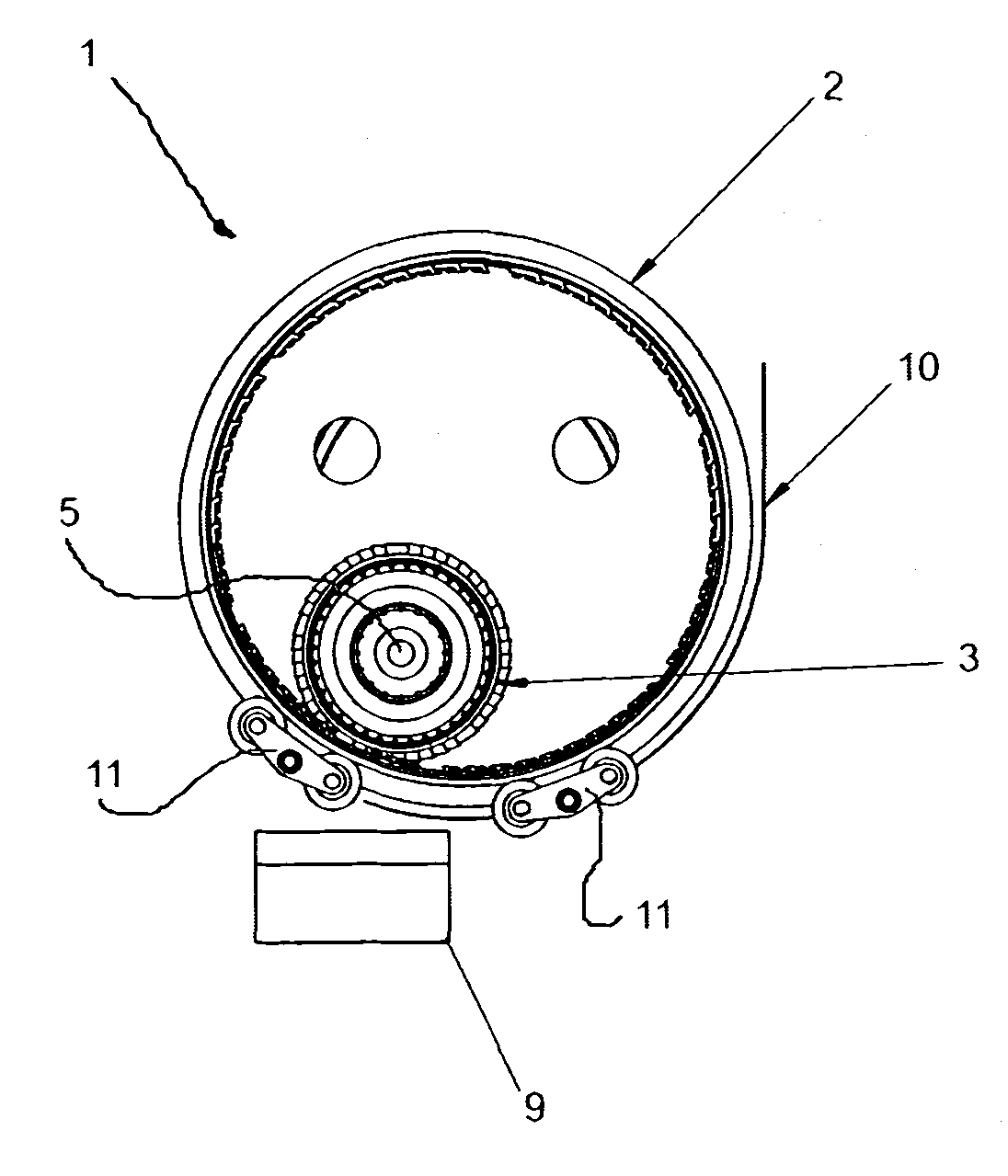

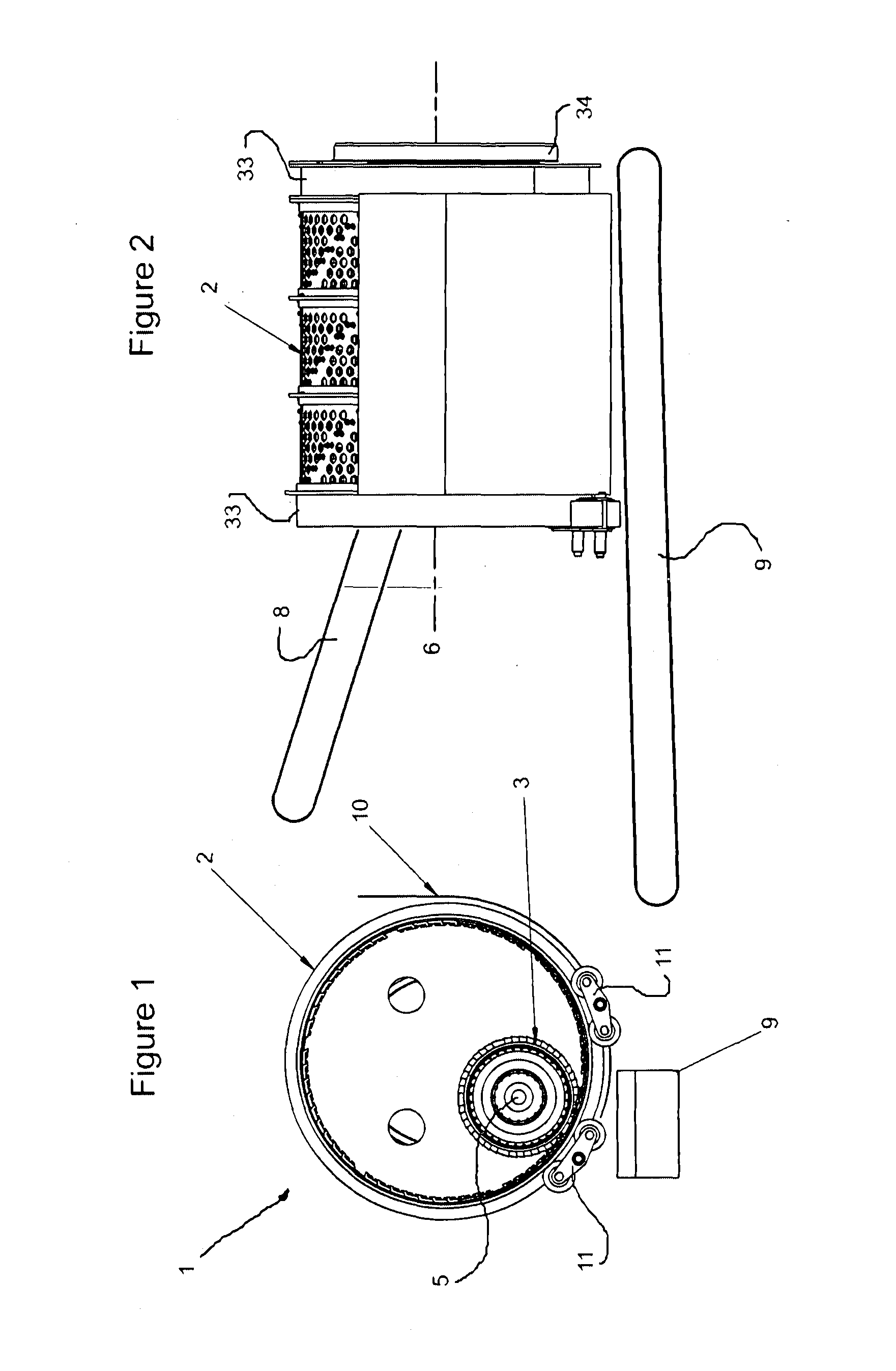

The comminution of waste & other materials

Comminution apparatus is described which is tailored for the processing of green, soft, and fibrous waste. Inner and outer comminution drums bear projecting macerating features which can progressively interact to provide a shearing action on material on waste within the outer comminution drum. Screening apertures on the outer comminution drum allow for the exit of comminuted material.

Owner:PROGRESSIVE IP

Barley powder food and production method thereof

InactiveCN101715923AStrong shearImprove mixing abilityFood preparationAdditive ingredientAqueous solution

The invention discloses barley powder food and a production method thereof. The barley powder food is prepared by the following method: extruding and puffing barley powder with a twin-screw extruder; and obtaining the barley powder food having regular shapes. In the method, only the barley powder is used as a raw material, and the barley powder can be shaped without adding other materials and can be made into a product having various regular shapes as required. The barley product prepared by the method is regular and uniform in shape and has a porous structure; the product is rich in special nutritional and functional health-care components of barley such as protein, VE and beta-glucan; the food has good brittleness in water solution; and the food can be solely eaten, can be added into beverage such as yogurt, milk, coffee and the like, or can be used as cooking raw materials of other food; and the food has storability and is a truly healthy and nutritious barley powder food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

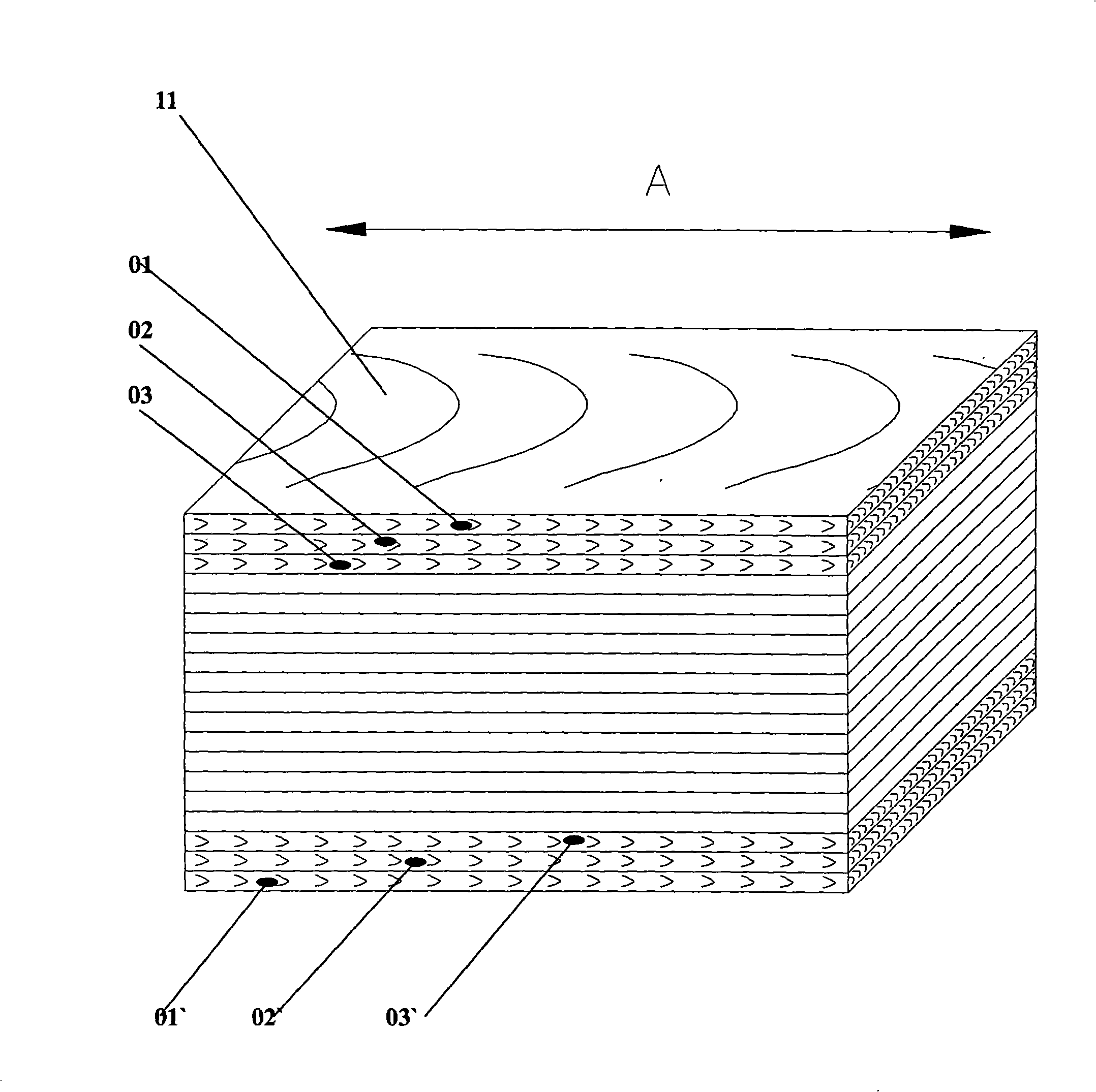

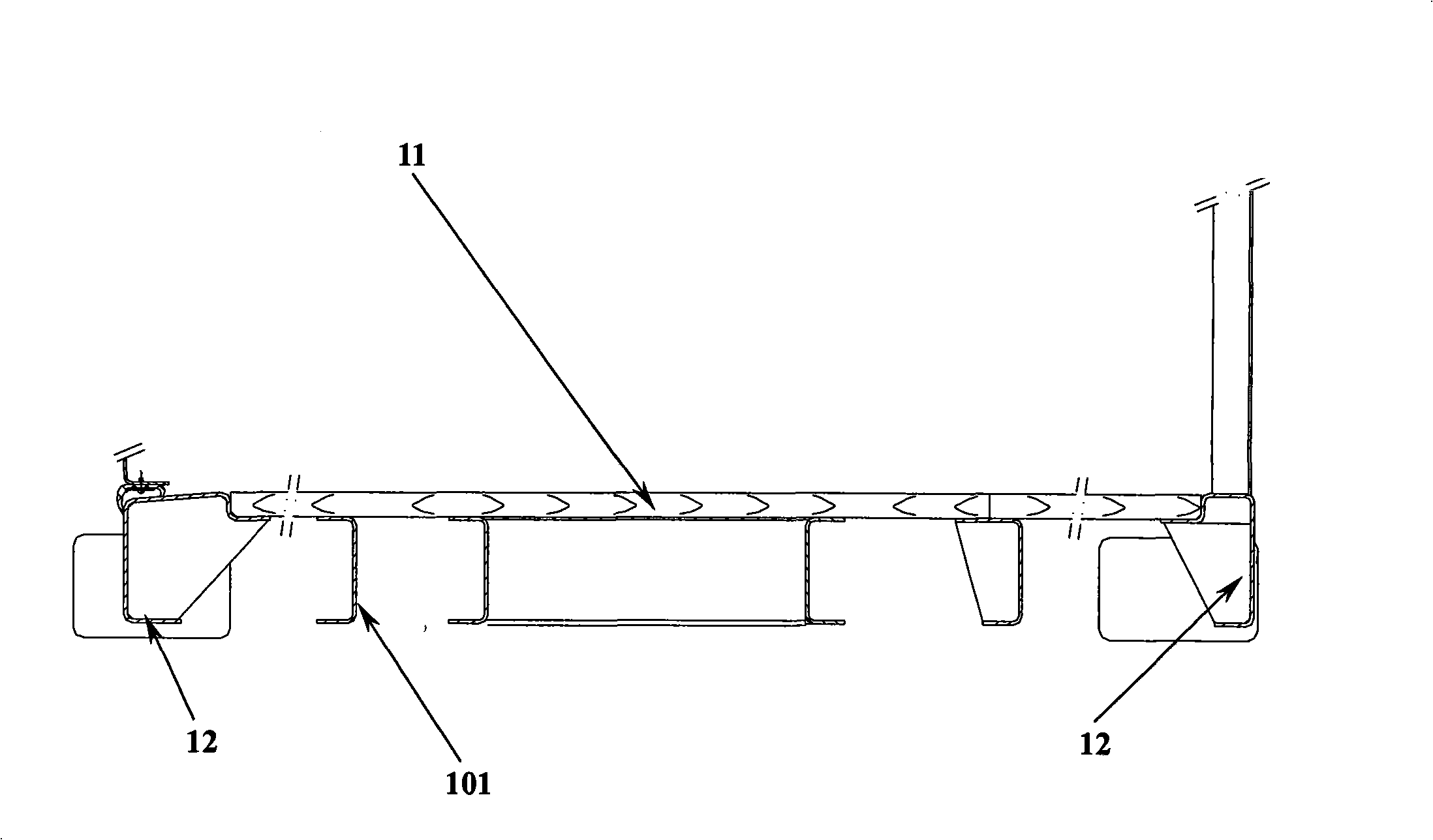

Glued board for container floor

ActiveCN101274438AImprove bearing strengthAvoid shearWood veneer joiningWood layered productsSingle plateEngineering

The invention relates to a plywood used for a bottom board of a container, which comprises a bearing layer positioned on the upper part of the plywood and mainly used for bearing compressive stress and a single-board layer positioned on the lower part of the plywood and mainly used for bearing tensile stress. The bearing layer comprises a flakeboard and / or a fiberboard; the single-board layer comprises a wooden single-board and / or a bamboo single-board; the adjacent boards are connected by pressing and gluing. As the invention adopts anisomerous structure in design of every group of embryonic board for the bottom board of the container, the defect that the flakeboard and the fiberboard are poor in shearing resistance, bending resistance and tensile property is avoided, thus exerting the advantages of shearing resistance, bending resistance and tensile property of the wooden single-board and the bamboo single-board so as to greatly enhance the load bearing strength of the bottom board of the container.

Owner:中集新型环保材料股份有限公司

Oat whole powder foodstuff and method for manufacturing the same

The invention discloses a regular-shaped all powder oat foodstuff and a production method thereof. The method of producing the regular-shaped all powder oat foodstuff provided by the invention is that all powder oat is extruded and swelled by a twin screw extruder, thereby acquiring the regular-shaped all powder oat foodstuff. The method adopts only the oat as raw material, and can be formed without adding any additive, and various regular-shaped foodstuffs can be made according to specific requirements. The oat product acquired by adopting the method has rich nutrient, can be stored for a long time, and is a healthy and nutritious all powder oat foodstuff.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Mixing device integrating screening and crushing

ActiveCN110404640AStrong shearStrong impactRotary stirring mixersTransportation and packagingEngineeringLarge particle

The invention relates to the technical field of architectural coating mixing, and discloses a mixing device integrating screening and crushing. In order to solve the problem that existing stirring andmixing equipment has poor processing quality, the following scheme is proposed, the mixing device comprises an outer cylinder, an inner cylinder is arranged in the outer cylinder, a U-shaped plate arranged in a handstand manner is arranged on the top of the outer cylinder, a rotating shaft is rotatably mounted between the bottom of the U-shaped plate and the bottom inner wall of the inner cylinder, the bottom of the rotating shaft extends into the inner cylinder and is fixedly provided with a stirring rod, a horizontally-arranged vibrating plate is installed in the inner cylinder in a slidingmanner, the vibrating plate is located below the stirring rod, the vibrating plate is slidably connected with the rotating shaft, the inner wall of the inner cylinder is provided with a flow guide plate, and the rotating shaft is fixedly provided with a baffle arranged in an inclined manner. The mixing device can achieve mixing, dissolving, dispersing and refining of coating and has the screeningfunction, larger particles in the coating are screened out to be chiseled and chopped, refinement of the large particles is realized, the quality of the coating is improved, and promotion is easy toachieve.

Owner:阜阳市广联普惠自动化技术有限公司

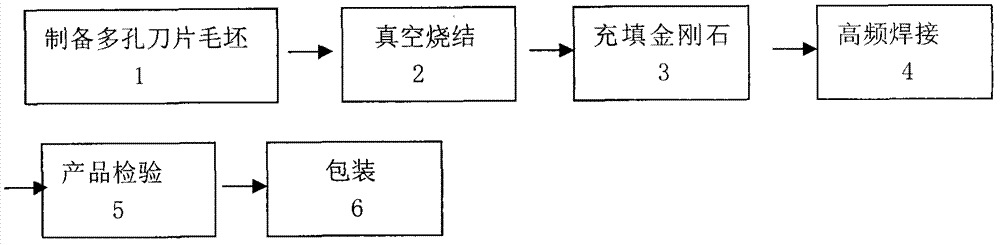

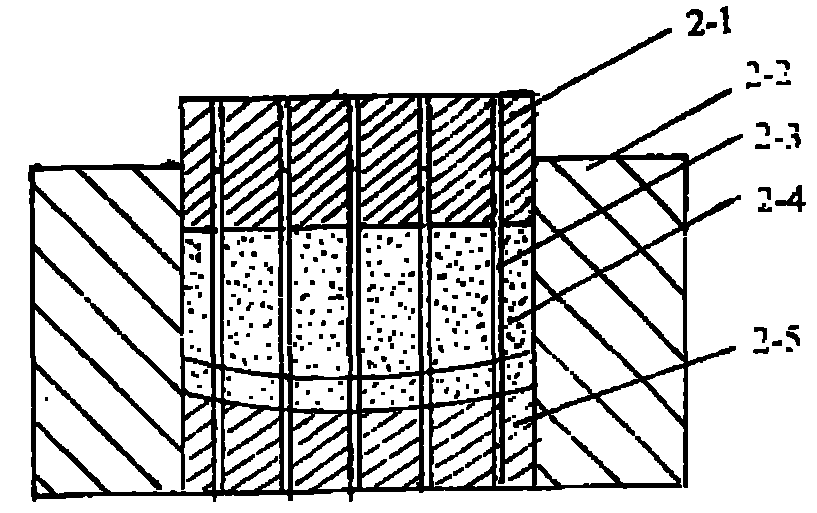

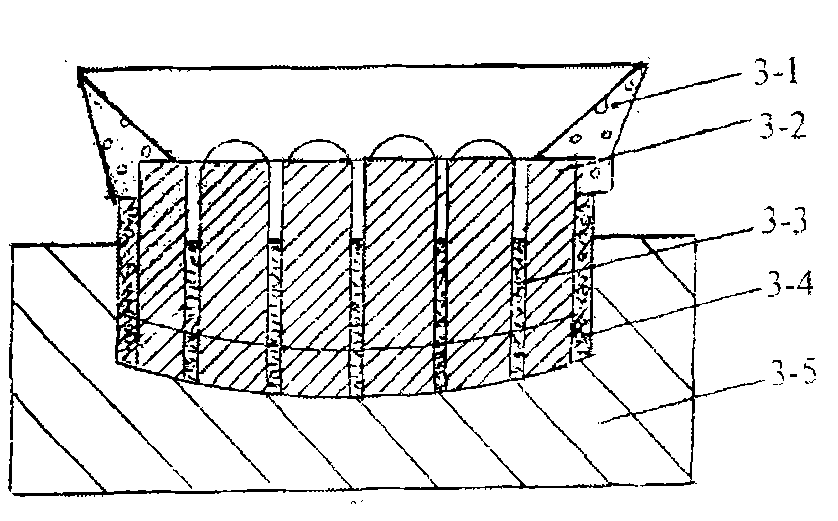

Technology for preparing diamond sandwich type hard alloy mine rock drilling blade

InactiveCN103362445AAddressing adverse effects on performanceStrong shearDrill bitsMedium enterprisesMature technology

With continuous development of national economy, hard alloy mine rock drilling bit blades are used a lot in the industries of railways, highways, mines, coal mines, real estates and the like. Over the sixty years, the drilling rate and anti-abrasion service life of a mine rock drilling bit are always what people expect to improve because the kind of drilling bit blade is usually used in the underground and cave conditions, wherein the underground and the cave conditions are very cold, wet or hot, and ventilation and dust exhausting are very poor. Therefore, obviously, anyone expects that the faster the cutting drilling of the mine rock drilling bit blade is, the better the blade will be, and the longer service life is, the better the blade will be. Unfortunately, over the sixty years, the performance of the drilling bit blade has no big changes. The invention provides a technology for preparing a diamond sandwich type hard alloy mine rock drilling blade. By the adoption of a novel artificial diamond sandwich technology, artificial diamond particles are evenly and deeply embedded into the working section of a common YG11C hard alloy mine blade in a high-pressure and mechanical mode. Moreover, high-temperature brazing is performed for solidifying, and the novel hard alloy mine rock drilling bit blade is prepared and low in cost, very high in drilling rate and very good in anti-abrasion performance. Therefore, working efficiency of the existing mine rock drilling blade is greatly improved. The technology and equipment used for the technology for preparing the diamond sandwich type hard alloy mine rock drilling blade are mature technologies of years. The technology for preparing diamond sandwich type hard alloy mine rock drilling blade is suitable for large-scale production, low in investment, very wide in domestic and foreign markets and suitable for investment and management of small enterprises, medium enterprises and micro enterprises.

Owner:吴庆华 +2

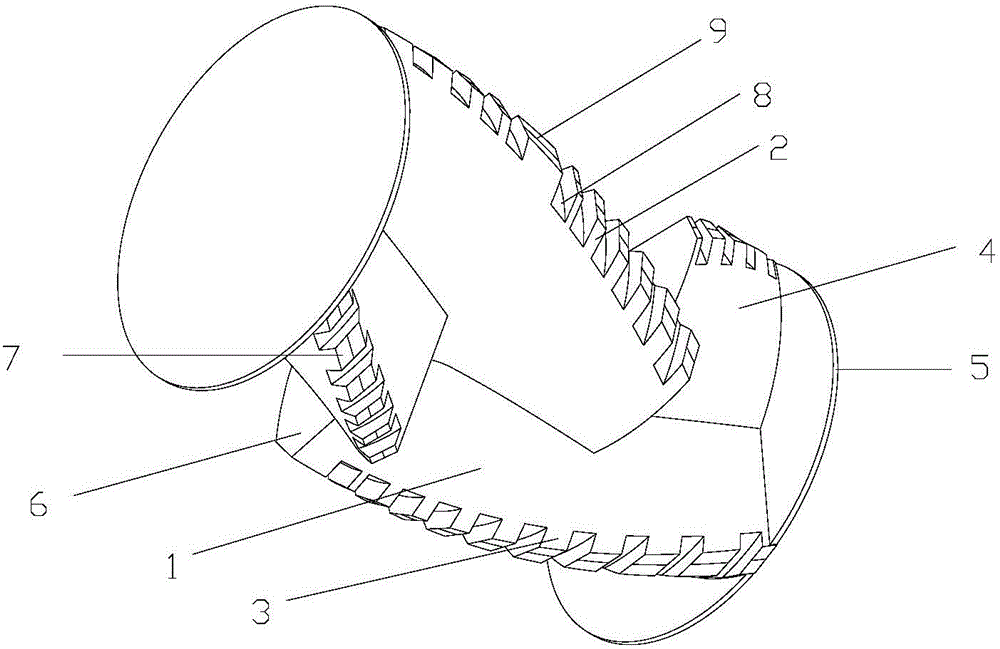

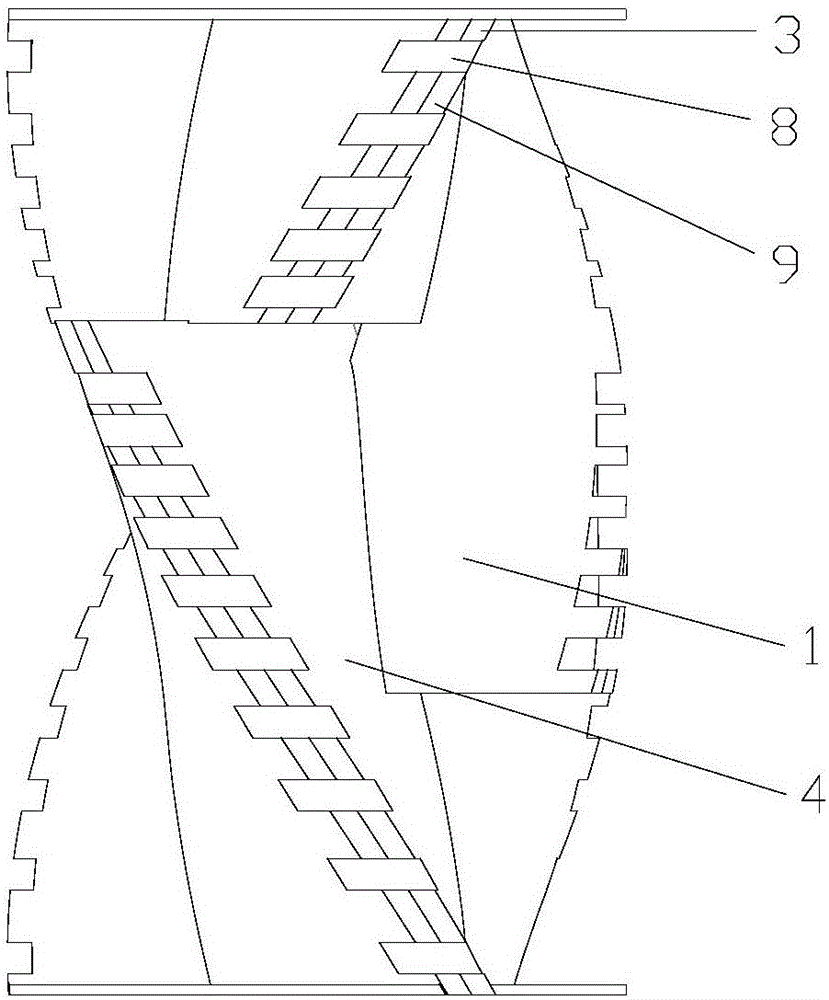

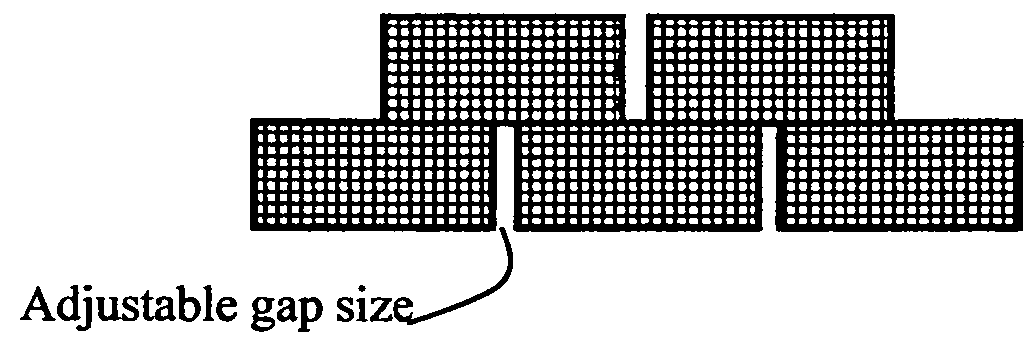

Six-ridge serrated dynamic variable-gap internal mixer rotor

The invention discloses a six-ridge serrated dynamic variable-gap internal mixer rotor which comprises a rotor body. Six protruded ridges are arranged on the rotor body, include three long ridges and three short ridges, spirally extend from two ends of the rotor body to the middle of the rotor body and comprise starting ends and finish ends; a plurality of tooth spaces are respectively arranged on ridge tops of the protruded ridges, the difference of the widths of the tooth spaces on each protruded ridge keeps unchanged in the direction from the starting end to the finish end of the protruded ridge, and the distances among the tooth spaces on each protruded ridge are gradually shortened in the direction from the starting end to the finish end of the protruded ridge. The six-ridge serrated dynamic variable-gap internal mixer rotor has the advantages that the tooth spaces are additionally arranged at the protruded ridges of the six-ridge serrated dynamic variable-gap internal mixer rotor, accordingly, peripheral flowing of rubber materials can be changed, and the six-ridge serrated dynamic variable-gap internal mixer rotor is favorable for distributing and dispersing various fillers and compounding ingredients; the quantities and the distribution density of the tooth spaces are increased along with increase of the peripheral flowing speeds of the rubber materials, accordingly, effects of masticating the lump-shaped rubber materials among the ridges can be enhanced, the rubber materials can flow in internal mixing chambers chaotically, and the rubber mastication quality and the rubber mastication efficiency can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

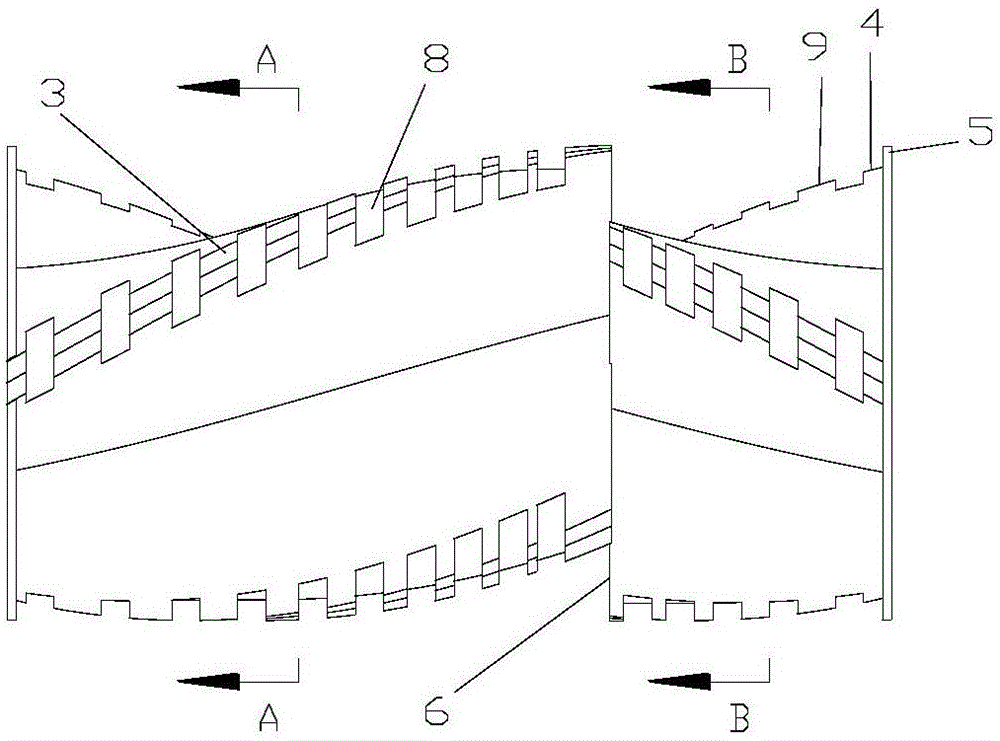

Self-suspension propping agent and preparation method thereof

ActiveCN107033871AStrong shearStrong shear resistanceFluid removalDrilling compositionChemistrySilane coupling

The invention provides a preparation method of a self-suspension propping agent. The preparation method comprises the following steps: mixing a pre-heated propping agent matrix and a polymer capable of being swollen with water; in a stirring process, spraying a silane coupling agent solution into a mixture; and reacting for 3h to 4h at a temperature of 60 DEG C to 80 DEG C to obtain the self-suspension propping agent. According to the preparation method of the self-suspension propping agent, the silane coupling agent and the polymer capable of being swollen with the water are used for coating the propping agent matrix so that a cross-linking agent is realized; the silane coupling agent is connected with the propping agent matrix by adopting a siloxane chemical bond and is also subjected to a chemical reaction with the polymer to form a chemical bond; the self-suspension propping agent provided by the invention has a good anti-shearing capability and a great buoyant force; the self-suspension propping agent has long suspension time in clean water; a toxic organic solvent does not need to be added and a gel breaking performance is good; and gel breaking liquid has a relatively good anti-swelling performance and a strong crack backward flowing capability.

Owner:GUANGHAN HUAXING NEW TECH DEV INST GENERAL PARTNERSHIP +1

Process for producing continuous graphitic fibers from living graphene molecules

ActiveUS8927065B2Low viscosityEffective shear stressCarbon compoundsPretreated surfacesFiberStress induced

A process for producing a continuous graphitic fiber, comprising: (a) preparing a graphene oxide gel having living graphene oxide molecules or functionalized graphene chains dissolved in a fluid medium; (b) depositing at least a continuous filament of graphene oxide gel onto a supporting substrate under a condition of stress-induced molecular alignment of living graphene oxide molecules along a filament axis direction; (c) removing the fluid medium to form a continuous graphene oxide fiber, having an inter-plane spacing d002 of 0.4 nm to 1.2 nm and an oxygen content no less than 5% by weight; and (d) heat treating the continuous graphene oxide fiber to form the continuous graphitic fiber at a temperature higher than 100° C. (preferably >600° C.) to an extent that an inter-plane spacing d002 is decreased to a value of 0.3354-0.4 nm and the oxygen content is decreased to less than 5% by weight.

Owner:GLOBAL GRAPHENE GRP INC

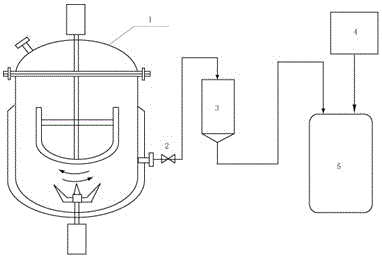

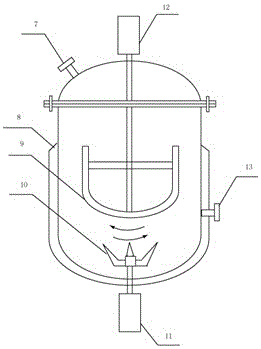

Device and method for peeling graphene slurry by utilizing fluid accelerated stirring

ActiveCN106542526ARealize large-scale continuous productionImprove clippingGrapheneChemical/physical/physico-chemical stationary reactorsLiquid storage tankEngineering

The invention provides a device and a method for peeling graphene slurry by utilizing fluid accelerated stirring. The device comprises a stirring kettle, a slurry filter, a liquid storage tank and a mixing tank which are sequentially connected through pipelines; a turbine is additionally arranged at the bottom of the stirring kettle, and a relatively strong shearing effect is formed to the inner wall along with high-speed rotation of the turbine, so that the moving direction of graphite slurry is nearly parallel to the inner side wall of the stirring kettle; meanwhile, a U-shaped stirring paddle is arranged at the top end of the stirring kettle, and a shearing force is supplied to the graphite slurry by means of rotation of the U-shaped stirring paddle; the rotating direction of the turbine is opposite to that of the U-shaped stirring paddle, so that two intensively relative-moving shearing forces are provided, the graphite powder is repeatedly sheared in a parallel manner, the graphite shearing effect is improved, and the graphene can be peeled with high efficiency, the graphene laminar structure is kept to be complete, and large-scale continuous production of graphene can be realized.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

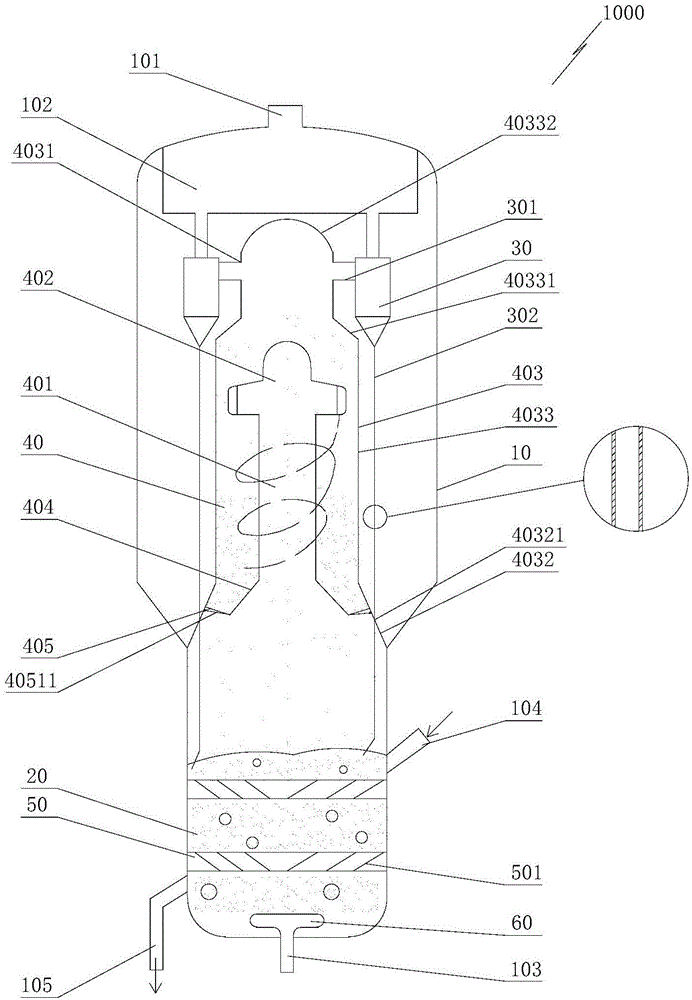

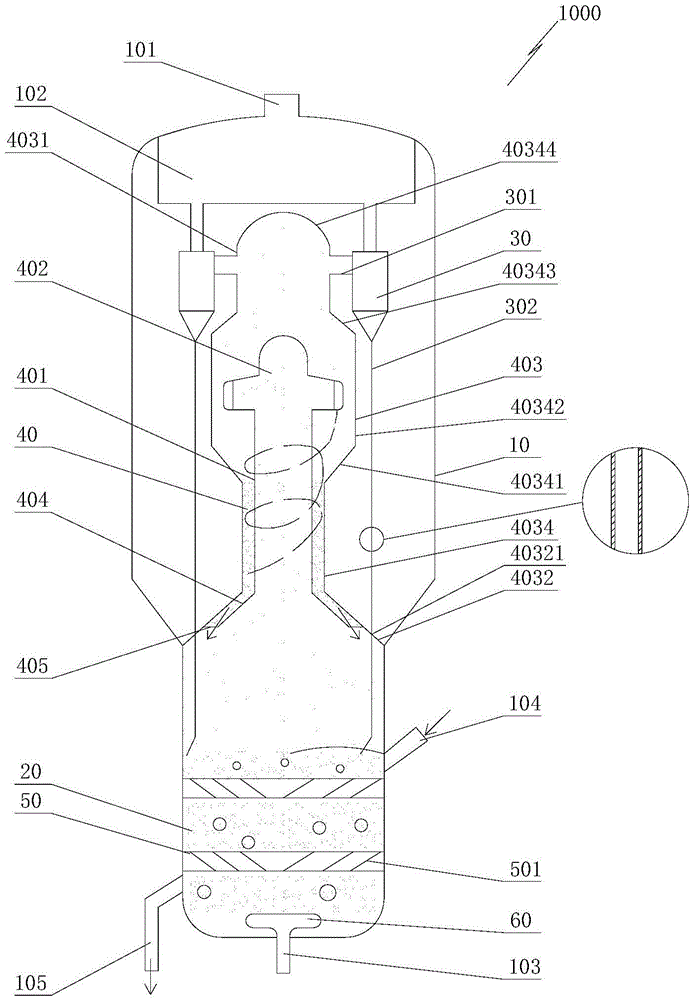

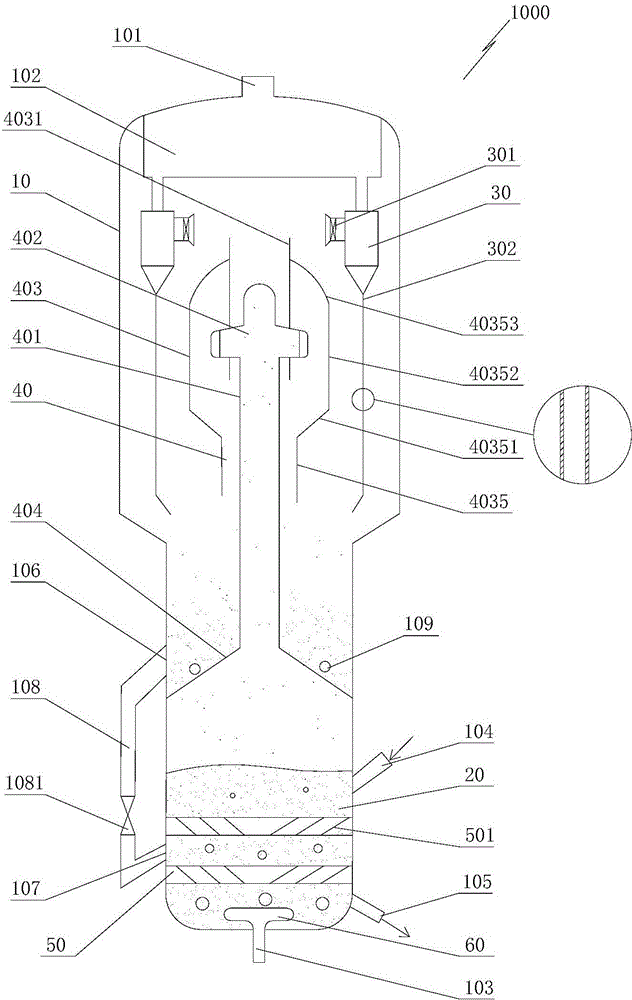

Methanol-to-olefin reaction device

ActiveCN104801243AImprove operational stabilityStrong shearHydrocarbon from oxygen organic compoundsEthylene productionCycloneFluidized bed

The invention relates to a methanol-to-olefin reaction device which comprises a shell; a dense phase fluidized bed is arranged at the lower part of the inner side of the shell, and a produced gas outlet is formed in the top of the shell; an air chamber is arranged under the produced gas outlet; one or more cyclone separator(s) is / are in through connection under the air chamber; the inner side of each cyclone separator is in through connection with a first inlet pipe along the tangential direction; the bottom of each cyclone separator is provided with a granule output pipe communicated with the dense phase fluidized bed; a gas-solid separation device is arranged at the upper part of the inner side of the shell; the gas-solid separation device is communicated with the first inlet pipe(s); grating plates are fixedly arranged in the dense phase fluidized bed along the transverse direction. After the methanol-to-olefin reaction device is used, the free space at the upper part of the reaction device is effectively reduced, the reaction time is shortened, and the operation conditions of the reaction device are closer to the best operation conditions, so that the selectivity of target products (ethylene and propylene) and the yield of olefin are improved, and the economic benefit of the device is improved; furthermore, the fine powder particle concentration in the gas at the inlet(s) of the cyclone separator(s) can be effectively reduced, and the service efficiency of a catalyst is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Rapid detection method of freeze-thaw stability of emulsion used for emulsion paint

ActiveCN103364536AShorten detection timeStrong shearMaterial testing goodsFreeze thawingFlocculation

The invention relates to a rapid detection method of freeze-thaw stability of emulsion used for emulsion paint. The rapid detection method comprises the following steps of: (1) weighing 200 parts of emulsion to be detected and pouring an emulsion into a detection cup; (2) placing a dispersion disk of a dispersion machine at a position 1 / 2-1 / 4 below the liquid level of the emulsion; (3) starting the dispersion machine, and adjusting the rotating speed to be 800-1200 revolutions per minute; (4) weighing 1.4-1.8 parts of hydroxyethyl cellulose and 0.4-0.6 part of organic amine, and adding the hydroxyethyl cellulose and the organic amine into the detection cup successively; (5) when the emulsion viscosity is increased to the appropriate degree, increasing the rotating speed of the dispersion machine to be 1300-1700 revolutions per minute and then timing for 30-35 minutes; (6) adding water into the detection cup under low-speed stirring to decrease the emulsion viscosity to be in an initial state; (7) stirring and observing whether abnormal phenomena such as hard lumps or flocculation exist in an object to be detected or not, if not, the emulsion to be detected is considered to have 'no abnormality', and the freeze-thaw stability of the emulsion to be detected is proven to be good. The rapid detection method can be used for greatly shortening the detection period simultaneously when ensuring the accuracy of detection results.

Owner:SKSHU PAINT

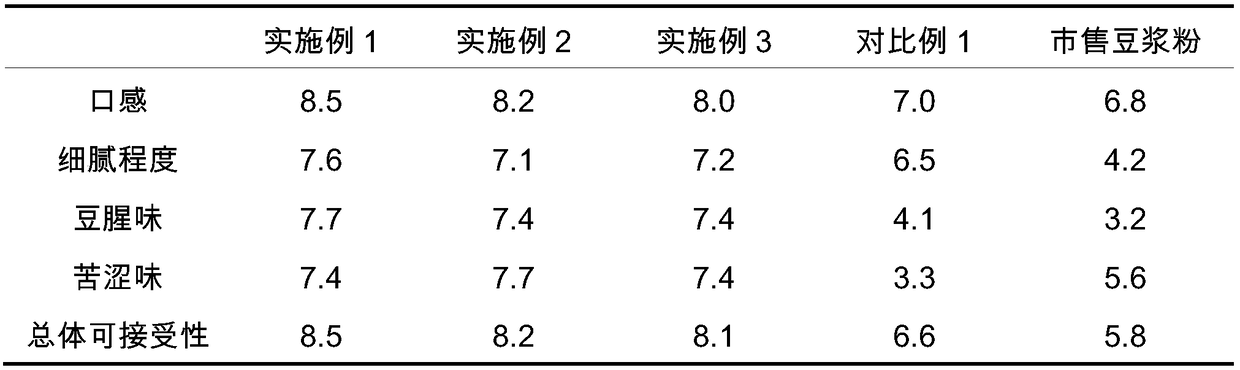

Preparation method of soybean milk powder

InactiveCN109169939AReduce processing stepsHigh dissolution rateMilk substitutesFood scienceEmulsionDietary fiber

The invention relates to a preparation method of soybean milk powder. The preparation method of the soybean milk powder takes whole soybean meal as a raw material, and comprises the following steps: mixing the whole soybean meal with water at ratio of 1 to (3-8), adjusting the pH value to 6.5-7.3, and respectively carrying out first cyclic shear extraction and second cyclic shear extraction so asto obtain a soybean emulsion; and then, performing sterilization on the soybean emulsion, and carrying out flash steaming, concentrating, blending, homogenizing, drying and the like so as to obtain the soybean milk powder. The preparation method of the soybean milk powder disclosed by the invention is improved in production efficiency by changing traditional processes; and the prepared soybean milk powder is relatively high in contents of water-soluble dietary fiber and proteins, and has the function of regulating intestinal flora balance. The soybean milk powder is rich in nutrients. Being brewed, the soybean milk powder produces mellow soybean aroma but light peculiar bean smell.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

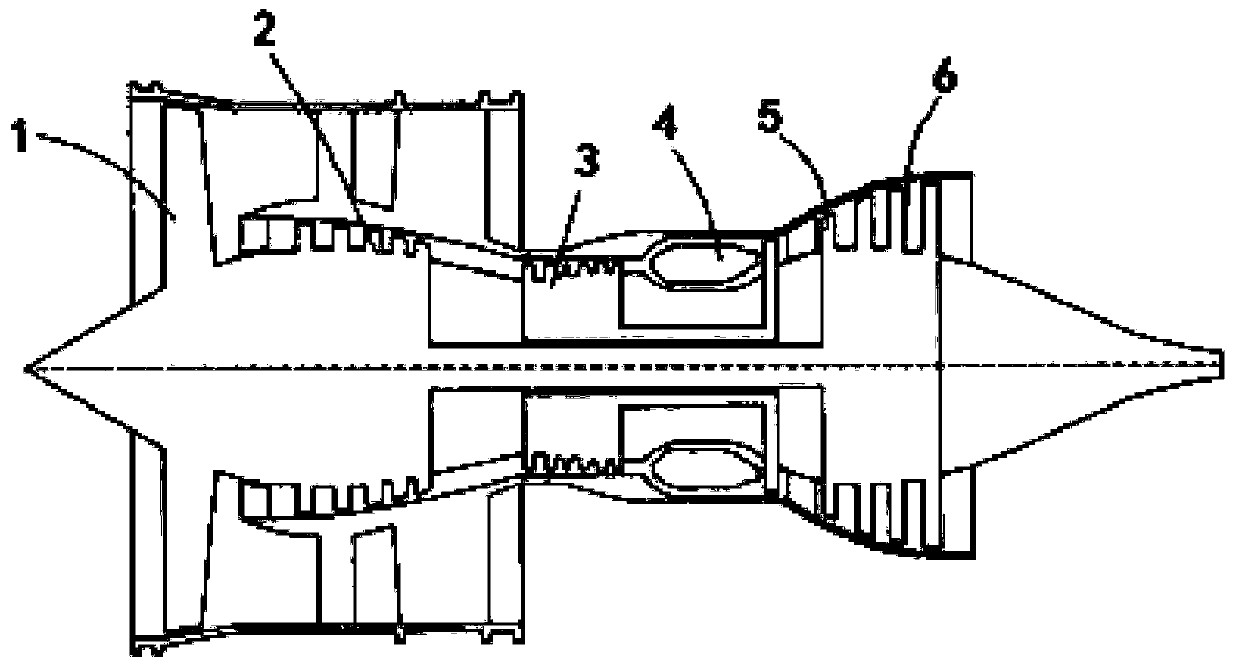

Combustion chamber

ActiveCN110657455AImprove circumferential uniformityImprove the mixing effectContinuous combustion chamberCombustion chamberEngineering

The invention aims to provide a combustion chamber. The combustion chamber adopts a single-ring-cavity flame tube structure, and the pollution emission of a whole LTO cycle of an engine is reduced onthe premise of ensuring the performance of the combustion chamber. In the combustion chamber, the main combustion stage involves an inner swirler, an outer swirler, an oil collecting ring and a premixing pre-evaporation section; the outer swirler adopts a radial swirler, the inner swirler adopts an axial swirler, and the oil collecting ring adopts direct fuel injection holes which are uniformly distributed in the circumferential direction, the fuel oil forms a direct spraying oil mist and forms the main combustion stage pneumatic atomizing oil mist by crushing and atomizing under the shearingaction of an inner swirling flow and an outer swirling flow; and the premixing pre-evaporation section adopts a nozzle structure and has a throat, the direct fuel injection holes are located in the 20%-80% range of the throat height relative to the radial position of the premixing pre-evaporation section of the main combustion stage, and the included angle between the injection direction of the direct fuel injection holes and the axis direction of the main combustion stage is negative 15 degrees to 60 degrees.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

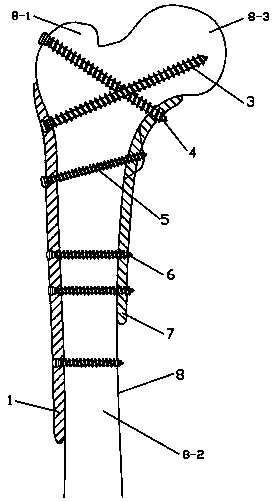

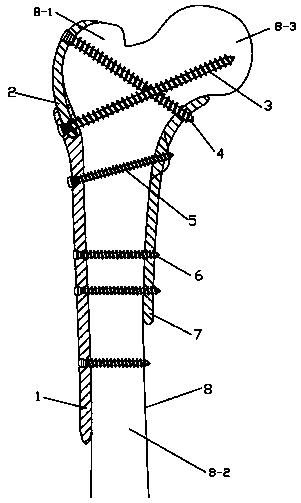

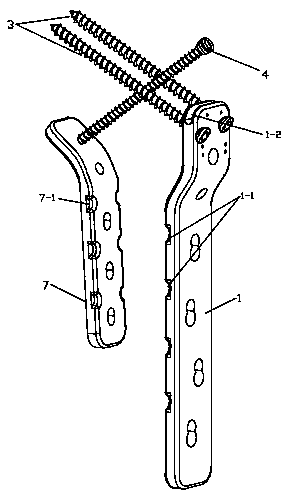

Combined splint internal fixation device for femoral intertrochanteric fracture and auxiliary aiming apparatus

PendingCN108261233AFirm internal fixationStrong shearInternal osteosythesisFastenersIntertrochanteric fractureBiomechanics

The invention relates to a combined splint internal fixation device for a femoral intertrochanteric fracture and solves the problem that an internal fixation device in the prior art cannot provide strong and biomechanical fixation for the proximal end of femurs. The device is mainly characterized in that an inside distance bone plate is added, a clamping structure that the inside distance bone plate and an outside bone plate are respectively arranged on the inner side and outer side of the femur and clamp the proximal end of the femur is adopted, and the inside distance bone plate is fixed after the external distance bone plate is implanted with screws. Correspondingly, the invention also designs auxiliary aiming apparatus for proper matching use. The auxiliary aiming apparatus is providedwith two clamping claws which can be used for fixing and clamping the inside distance bone plate and the outside bone plate respectively, and screw holes of the inside distance bone plate and the outside bone plate are always kept in concentric positions. The device has the beneficial effect that absolutely stable inside fixation of the inner side and the outer side of the proximal end of the femur can be provided simultaneously, and shear resistance and rotation resistance are high. Besides, the device is simple in design structure and has certain universality with some parts of the existinginternal fixation system.

Owner:魏奇峰

Fabric of continuous graphitic fiber yarns from living graphene molecules

ActiveUS9657415B2Low viscosityEffective shear stressArtificial filament washing/dryingArtificial filament heat treatmentPorosityFiber

Multi-functional and high-performing fabric comprising a first layer of yarns woven to form the fabric wherein the yarns comprise at least one unitary graphene-based continuous graphitic fiber comprising at least 90% by weight of graphene planes that are chemically bonded with one another having an inter-planar spacing d002 from 0.3354 nm to 0.4 nm as determined by X-ray diffraction and an oxygen content less than 5% by weight. A majority of the graphene planes in such a continuous graphitic fiber are parallel to one another and parallel to a fiber axis direction. The graphitic fiber contains no core-shell structure, has no helically arranged graphene domains or domain boundaries, and has a porosity level less than 5% by volume, more typically less than 2%, and most typically less than 1% (practically pore-free).

Owner:GLOBAL GRAPHENE GRP INC

Impregnated continuous graphitic fiber tows and composites containing same

ActiveUS9362018B2Low viscosityEffective shear stressLayered productsNon-conductive material with dispersed conductive materialPorosityFiber

An impregnated fiber tow comprising multiple unitary graphene-based continuous graphitic fibers impregnated with a matrix material, wherein at least one of the continuous graphitic fibers comprises at least 90% by weight of graphene planes that are chemically bonded with one another having an inter-planar spacing d002 from 0.3354 nm to 0.4 nm as determined by X-ray diffraction and an oxygen content less than 5% by weight, wherein the graphene planes are parallel to one another and parallel to a fiber axis direction and the graphitic fiber contains no core-shell structure, has no helically arranged graphene domains or domain boundary, and has a porosity level less than 5% by volume.

Owner:GLOBAL GRAPHENE GRP INC

Anti-shearing cigarette mouth glue and preparation method thereof

InactiveCN109251703ASmooth surfaceFine texturePolyureas/polyurethane adhesivesPlastic recyclingEmulsionChemistry

The invention belongs to the technical field of cigarette mouth glue, in particular to cigarette mouth glue with good wet viscosity and shear resistance and a preparation method thereof. The cigarettemouth glue is synthesized by using an ethylene-vinyl acetate copolymer emulsion as the main raw material, polyethylene glycol as a dispersion medium, a polyvinyl alcohol aqueous solution as a colloidprotective agent, and a modified polyurethane thickener, a non-silicone antifoaming agent, a 2,2,4-trimethyl-1,3-pentanediol diisobutyrate plasticizer, a buffer solution and the like as adjuvant materials. The cigarette mouth glue belongs to a water-based adhesive. The invention has the following beneficial effects: the cigarette mouth glue is suitable for tipping of tipping paper on a high-speedcigarette making machine, and suitable for roll coating of the cigarette equipment; clean operation of machines is guaranteed; and the preparation method is beneficial to high shear viscosity.

Owner:CHANGDE FURONG INDAL DEV

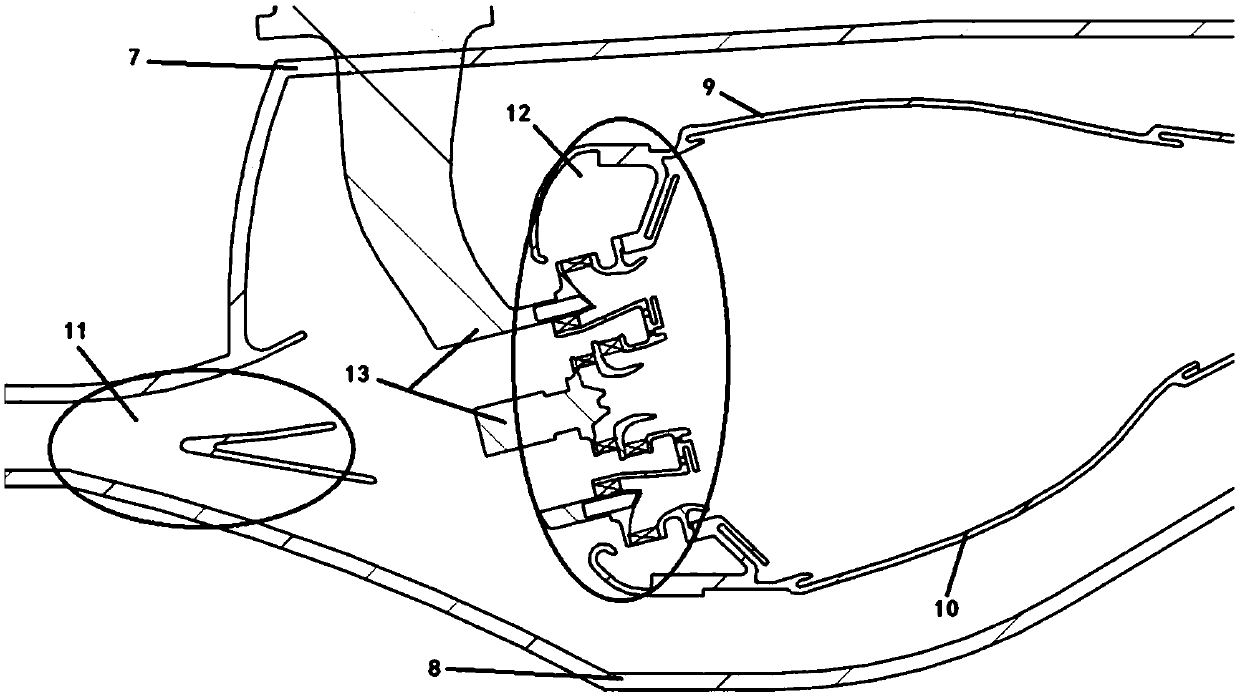

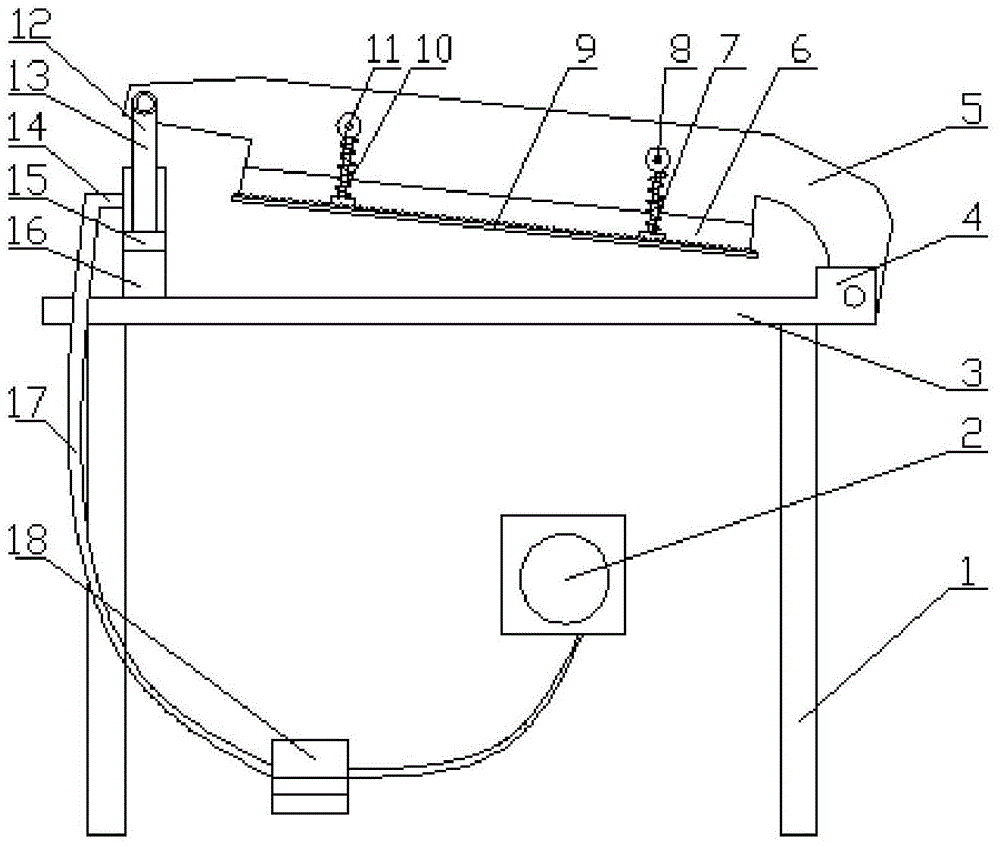

Automatic pneumatic cutting machine

InactiveCN104999492ASimple structureSave spaceSevering textilesMetal working apparatusCutting forceAtmospheric pressure

The invention relates to an automatic pneumatic cutting machine. The automatic pneumatic cutting machine comprises a machine frame, a panel, a cutter rest and a pneumatic device. The panel is installed on the machine frame. The cutter rest is arranged over the panel, one side of the cutter rest is hinged to a supporting piece fixed to the panel, and the other side of the cutter rest is hinged to one end of a pneumatic rod of a pneumatic system. The other end of the pneumatic rod is installed in a pneumatic cylinder. The pneumatic cylinder controls air generated by a pneumatic pump to enter the pneumatic cylinder through a pedal. The pneumatic system is adopted for controlling the cutter rest to move vertically to cut off leather or cloth. The pneumatic system occupies a small space of the cutting machine due to the simple structure and has a better cutting effect due to the large cutting force.

Owner:WUJIANG XINJIN TEXTILE

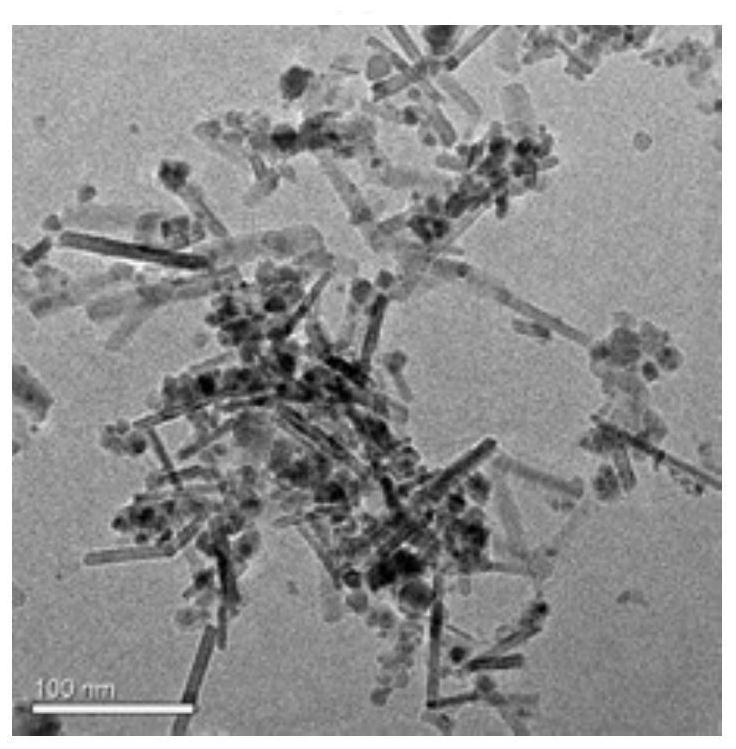

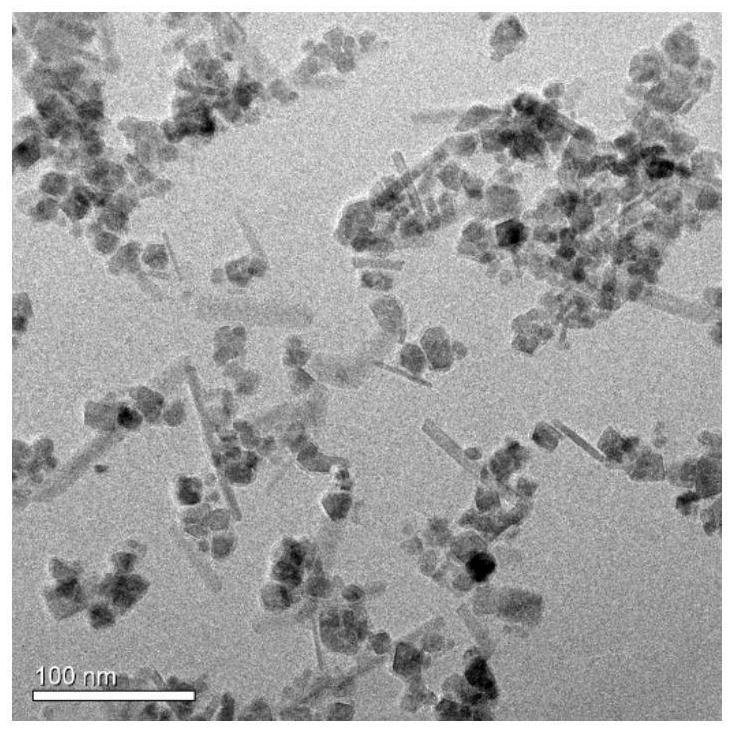

Magnetic nanorod demulsifier, preparation method thereof and method for treating nano-emulsion by using magnetic nanorod demulsifier

ActiveCN112138430AMicrostructural stabilityEfficient demulsification and separationNon-miscible liquid separationActive agentSurface-active agents

The invention discloses a magnetic nanorod demulsifier, a preparation method thereof and a method for treating nano-emulsion by using the magnetic nanorod demulsifier, and belongs to the technical field of demulsifiers. The preparation method of the demulsifier comprises the steps that FeCl3. 6H2O and FeSO4. 7H2O are dissolved in deionized water under the N2 introduction condition to obtain a ferric salt solution, the molar ratio of Fe < 3 + > to Fe < 2 + > is 2.15, polyethyleneimine is taken and dissolved in distilled water to obtain a polyethyleneimine solution, the molecular weight of polyethyleneimine is 10000, and the molar ratio of N to Fe is not lower than 1.47; the polyethyleneimine solution is added into the ferric salt solution dropwise while continuously introducing N2 and stirring, concentrated ammonia water is dropwise added at the water bath temperature of 50-80 DEG C, stirring is carried out to react for 1-4 hours, solid particles in the reaction solution are separated by using a magnet, the solid particles are cleaned with deionized water, re-dispersing the solid particles into the deionized water, a glutaraldehyde solution is added, and stirring, uniformly mixing and magnetic field separation are carried out to obtain the demulsifier. The demulsifier prepared by the preparation method disclosed by the invention can be used for efficiently demulsifying the nano-emulsion of which the mass ratio of the surfactant to the oil is 0-0.909.

Owner:TONGJI UNIV

A kind of preparation method of expanded polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

Video watermark realizing method against geometric attack based on three-dimensional discrete cosine transform (DCT)

InactiveCN102510490AStrong resistance to conventional attacksDoes not affect contentTelevision systemsDigital video signal modificationThird partyFeature vector

The invention relates to a video watermark realizing method against geometric attack based on three-dimensional discrete cosine transform (DCT), which firstly embeds a watermark, and (1) global three-dimensional DCT conversion is carried out to an original video section, and a visual characteristic vector which resists geometric attack is extracted from a conversion efficient; (2) a binary logic sequence is worked out with the visual characteristic vector and the watermark to be embedded through a Hash function, and the binary logic sequence is stored in a third party, and the watermark is extracted; (3) the global three-dimensional DCT conversion is carried out to a tested video, and the characteristic vector of the video which resists geometric attack is extracted; and (4) the watermark is extracted with the characteristics of the Hash function and the binary logic sequence which is stored in the third party. The method,based on a three-dimensional DCT conversion video digital zero-watermark technology realizes the embedment of the watermark without affecting the video image, moreover the method has higher robustness and stronger attack resistant capability, and provides a powerful technical path for protecting the copyright of the video.

Owner:HAINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com