Magnetic nanorod demulsifier, preparation method thereof and method for treating nano-emulsion by using magnetic nanorod demulsifier

A technology of magnetic nanorods and demulsifiers, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of limiting the replacement and application expansion of magnetic nanoparticle demulsifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

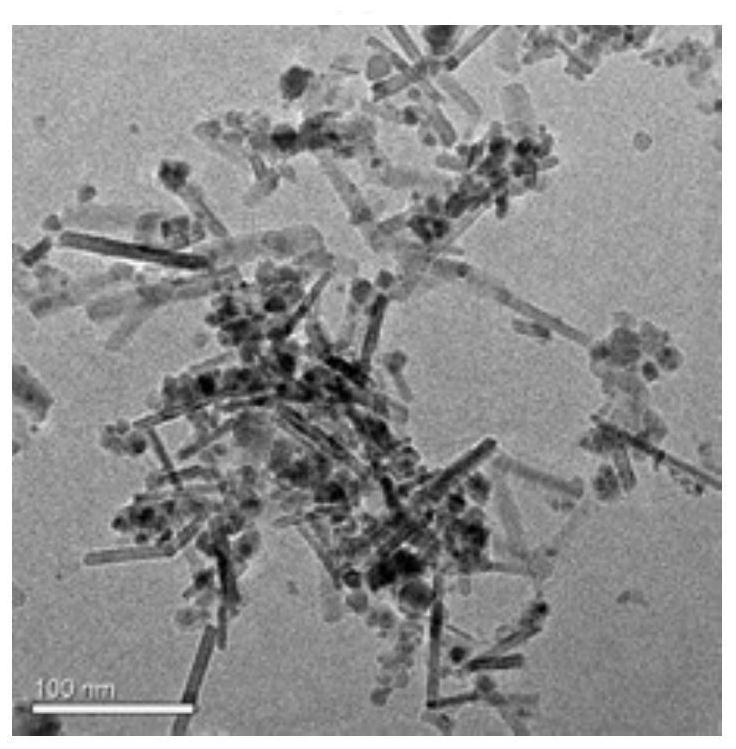

[0028] 11.6g FeCl 3 ·6H 2 O (M=270.3) and 5.56g FeSO 4 ·7H 2 O(M=278) in pass N 2 Dissolve in 250mL deionized water under the conditions to obtain iron salt solution, take 5.0g of polyethyleneimine with a molecular weight of 10000 (monomer M=43.06, n=0.116mol, N / Fe=1.84) and dissolve it in 50mL of distilled water to obtain polyethylene imine solution, in the continuous flow of N 2 Under the condition of stirring at 500rpm, add polyethyleneimine solution dropwise to the iron salt solution, mix well, and at 60°C water bath temperature, add 30mL concentrated ammonia water (25%) dropwise, stir for 2 hours and use a magnet to The solid particles in the reaction solution were separated, and the solid particles were washed with deionized water and redispersed into 50mL of deionized water. Added 250mL of glutaraldehyde solution with a concentration of 0.25%, stirred at 500rpm for 30min, and separated by magnetic field to obtain stable Magnetic nanorod demulsifier M-5, its morphol...

Embodiment 2

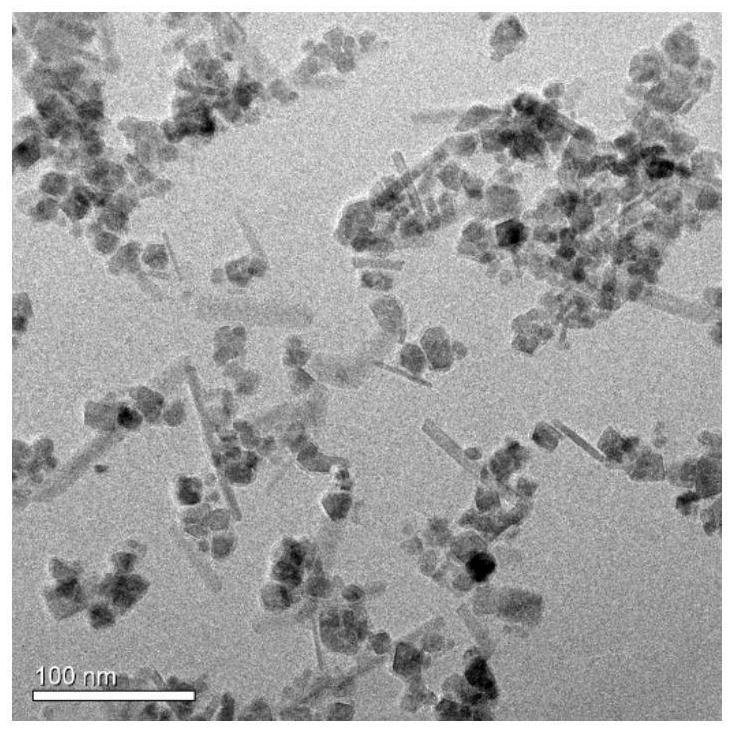

[0030] 11.6g FeCl 3 ·6H 2 O (M=270.3) and 5.56g FeSO 4 ·7H 2 O(M=278) in pass N 2 Dissolve in 250mL deionized water under the conditions to obtain an iron salt solution, take 4.0g of polyethyleneimine with a molecular weight of 10000 (monomer M=43.06, N / Fe=1.47) and dissolve it in 50mL of distilled water to obtain a polyethyleneimine solution. Keep on N 2Under the condition of stirring at 500rpm, add polyethyleneimine solution dropwise to the iron salt solution, mix well, and at 60°C water bath temperature, add 30mL concentrated ammonia water (25%) dropwise, stir for 2 hours and use a magnet to The solid particles in the reaction solution were separated, and the solid particles were washed with deionized water and redispersed into 50mL of deionized water. Added 250mL of glutaraldehyde solution with a concentration of 0.25%, stirred at 500rpm for 30min, and separated by magnetic field to obtain stable Magnetic nanorod demulsifier M-4, its morphology was characterized by TE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com