Method and device for electromagnetically assisted laser printing of NiCrAlY-Al2O3 ceramic

A technology that assists lasers and ceramics. It is applied in the direction of additive manufacturing and additive processing. It can solve the problems of unstable workpiece structure, difficulty in maintaining gradient structure, and deterioration of structural strength of components, so as to overcome the low structural strength and restrain Marangoni. Effect of convection, good structural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

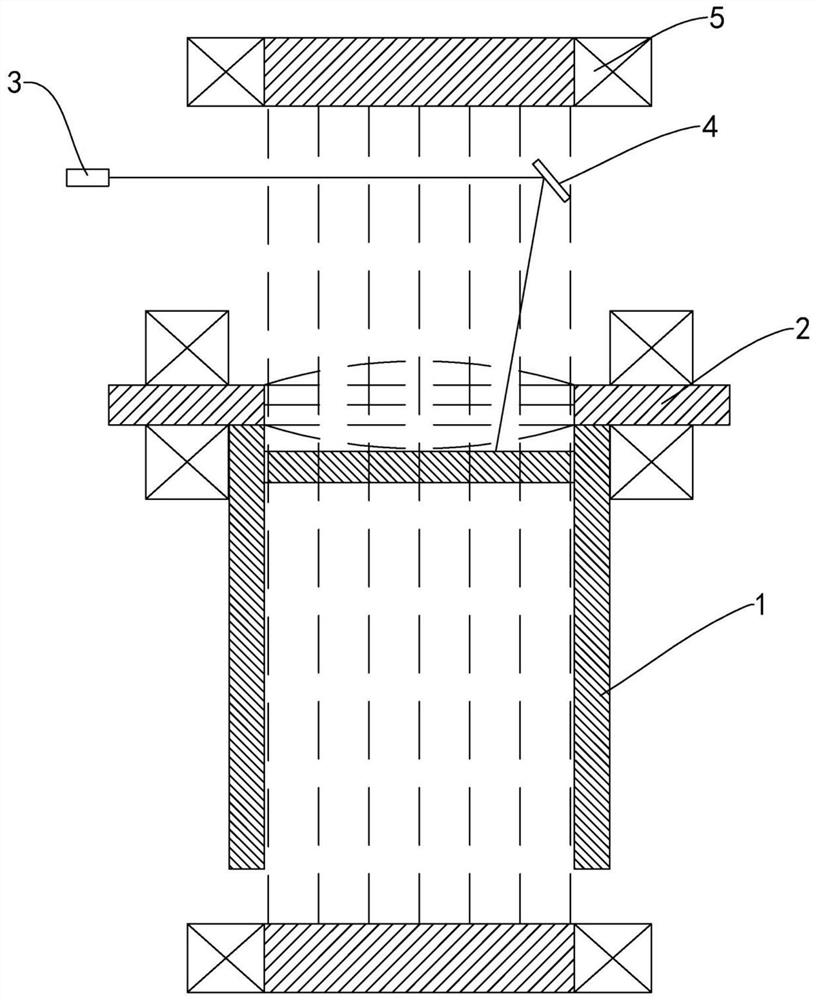

Image

Examples

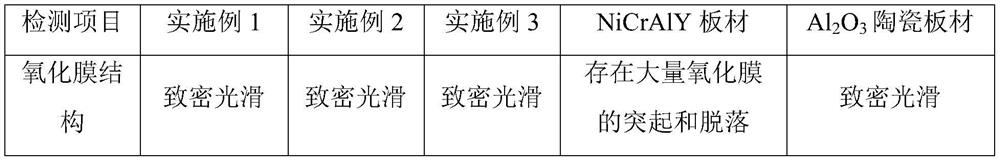

Embodiment 1

[0044] Preparation of a NiCrAlY-Al with a 12-layer structure 2 o 3 The plate of ceramic functionally graded material, the thickness of each layer of powder laying is 0.05mm, wherein the first layer of laying NiCrAlY powder, the second layer of laying contains 90 (wt)% NiCrAlY powder and 10 (wt)% Al 2 o 3 Mixed powder of powder, the third layer laying contains 80(wt)% NiCrAlY powder and 20(wt)% Al 2 o 3 Mixed powder of powder, the third layer laying contains 70(wt)% NiCrAlY powder and 30(wt)% Al 2 o 3 powder mixed powder, and so on, the last layer laying Al 2 o 3 Powder, the speed of laser printing is 0.5m / s, the laser power is 25000mW / cm2, the diameter of the printing laser is 0.1mm, when printing the first layer, the current of the first excitation coil is 6A, and the current of the second excitation coil is 8A , when printing the second layer, the current of the first excitation coil is 5.8A, and the current of the second excitation coil is 7.9A. When printing the thi...

Embodiment 2

[0046] Preparation of a NiCrAlY-Al with a 22-layer structure 2 o 3 The plate of ceramic functionally graded material, the thickness of each layer of powder laying is 0.03mm, wherein the first layer of laying NiCrAlY powder, the second layer of laying contains 95 (wt)% NiCrAlY powder and 5 (wt)% Al 2 o 3 Mixed powder of powder, the third layer laying contains 90(wt)% NiCrAlY powder and 10(wt)% Al 2 o 3 Mixed powder of powder, the third layer laying contains 85(wt)% NiCrAlY powder and 15(wt)% Al 2 o 3 powder mixed powder, and so on, the last layer laying Al 2 o 3 Powder, the speed of laser printing is 1m / s, the laser power is 20000W / cm2, and the diameter of the printing laser is 0.1mm. When printing the first layer, the current of the first excitation coil is 6A, and the current of the second excitation coil is 8A. When printing the second layer, the current of the first excitation coil is 5.9A, and the current of the second excitation coil is 7.95A. When printing the thi...

Embodiment 3

[0048] Preparation of a NiCrAlY-Al with a 42-layer structure 2 o 3For the plate of ceramic functionally graded material, the thickness of each layer of powder laying is 0.02mm, wherein the first layer is laying NiCrAlY powder, and the second layer is laying containing 97.5 (wt)% NiCrAlY powder and 2.5 (wt)% Al 2 o 3 Mixed powder of powder, the third layer laying contains 95(wt)% NiCrAlY powder and 5(wt)% Al 2 o 3 Mixed powder of powder, the third laying layer contains 92.5(wt)% NiCrAlY powder and 7.5(wt)% Al 2 o 3 powder mixed powder, and so on, the last layer laying Al 2 o 3 Powder, the speed of laser printing is 2m / s, the laser power is 10000W / cm2, and the diameter of the printing laser is 0.1mm. When printing the first layer, the current of the first excitation coil is 6A, and the current of the second excitation coil is 8A. When printing the second layer, the current of the first excitation coil is 5.95A, and the current of the second excitation coil is 7.975A. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com