Process for preparing functional film on fused substrate surface

A substrate surface and thin film technology, which is applied in the field of preparation of functional thin films, can solve the problems of undisclosed key parameters and achieve the effects of overcoming microstructure instability, simple preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

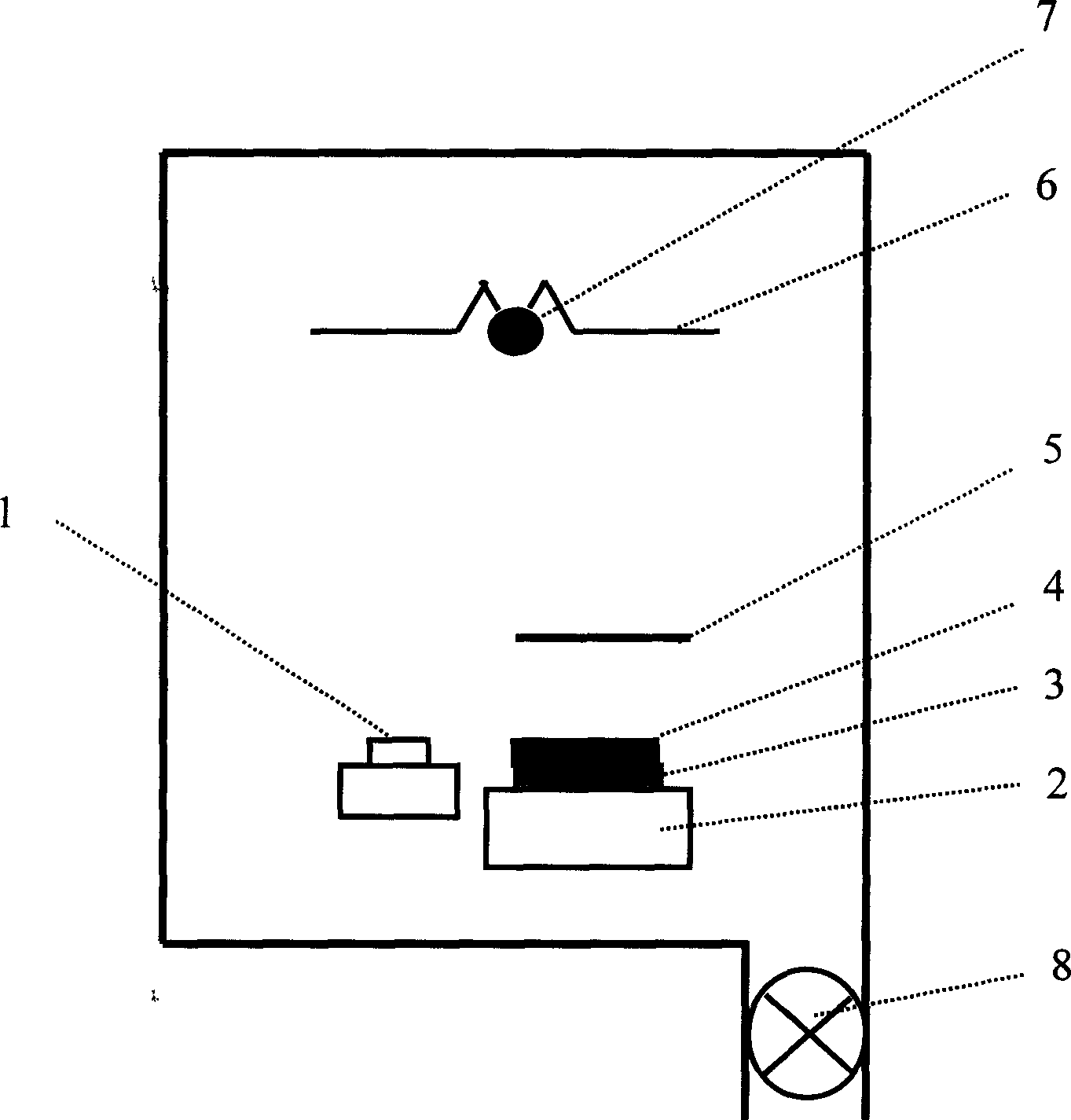

[0034] (a) refer to figure 1 , in the vacuum chamber of the vacuum evaporation device, a small amount of low-melting point and low-melting vapor pressure substrate material 4 is placed on the frosted glass slide 3, and the substrate frame is formed together with the electric furnace 2 for controlling the substrate temperature, and the low-melting point and low-melting The vapor pressure base material can be one of low melting point glass and low melting point polymer material; the evaporation source is composed of the evaporation material 7 and the heating tungsten wire 6, and the material of the evaporation source can be non-magnetic material Au with a purity of 99.9% to 99.99%. , Ag, Al, Cu or one of the magnetic materials Fe, Ni. The base surface of the film on the substrate frame faces the evaporation source, and the distance between the substrate frame and the evaporation source is 8-15 cm, and they are separated by a baffle plate 5 . The crystal oscillator thickness gau...

Embodiment 2

[0041] A gold film is deposited on the surface of an insulating substrate with a low melting point and low melting vapor pressure by radio frequency magnetron sputtering:

[0042] (a) In the vacuum chamber of radio frequency magnetron sputtering, the substrate is made of low melting point and low vapor pressure glass with a melting temperature of 500°C, and the sputtering target material (ie thin film material) has a purity equal to 99.99%, a diameter of 81.5mm, and a thickness of 0.5mm pure gold (Au) sheet material, the distance between the substrate holder and the sputtering target is 8cm, and they are separated by a baffle.

[0043] (b) Evacuate the chamber to 6×10 with mechanical pump and molecular pump -4 Pa vacuum.

[0044] (c) Heating the substrate to 510° C. with an electric furnace to melt the glass substrate into a liquid phase (colloid) substrate whose vapor pressure is lower than that in the vacuum chamber.

[0045] (d) Increase the sputtering power to about 10W,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com