Glued board for container floor

A technology for container floor and plywood, which is applied in the field of plywood, can solve the problems of high density of bamboo, low gluing strength, inability to meet the strength requirements of containers, etc., and achieves the effect of strong tensile capacity and improved bearing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

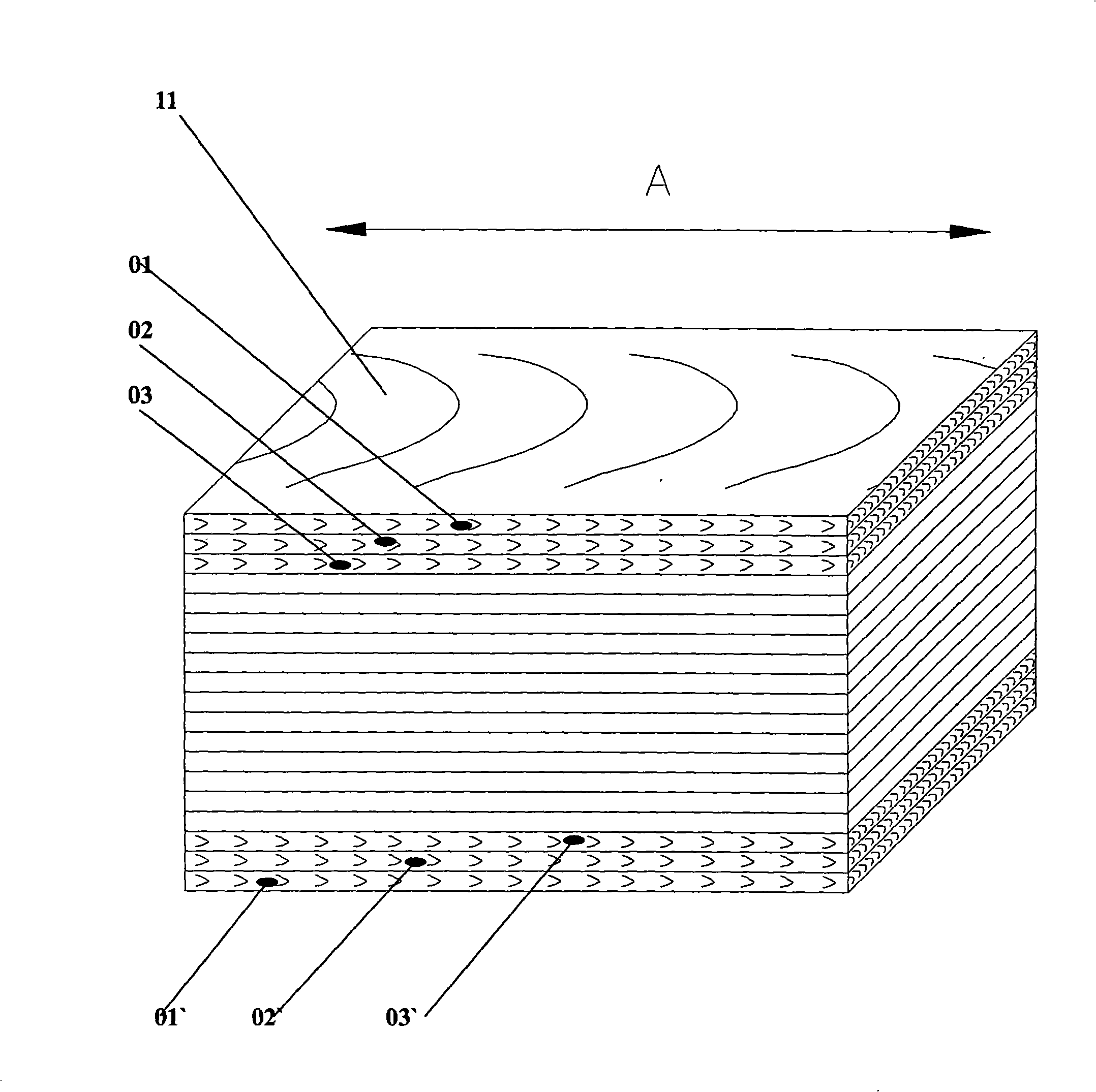

[0046] Such as Figure 5 As shown, a kind of plywood 3 for the bottom plate of a container includes a pressure-bearing layer composed of one layer of particleboard 30, a veneer layer composed of 2 bamboo curtains 31 and 3 wooden veneers 32 arranged alternately, wherein, and Adjacent to the particleboard 30 is a wood veneer 32'. Considering that the requirements for the flexural strength of the bottom plate in the length direction of the container are higher than the requirements for the flexural strength in the width direction of the container, the wooden veneer 32 (32') in this example all adopts Long veneer along the grain.

[0047] The plywood 3 of present embodiment can adopt two kinds of methods when making:

[0048] Method 1: Glue the processed particleboard 30, wood veneer 32 and bamboo curtain 31 and press Figure 5 Embryos with the structure shown in , and then formed by hot pressing;

[0049] Method 2: Glue the wood veneer 32 and bamboo curtain 31 first, then pre...

Embodiment 2

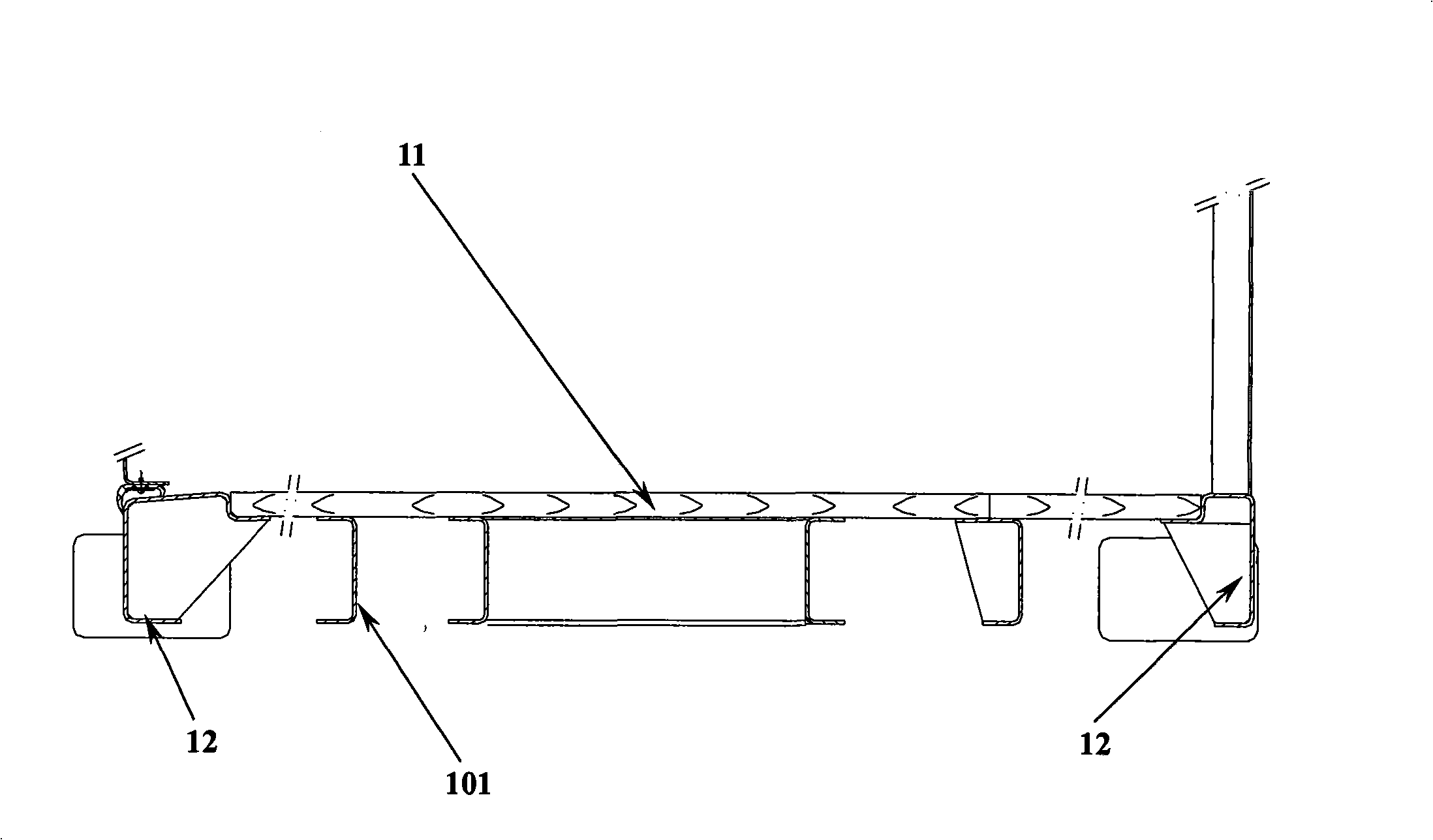

[0057] Such as Figure 11 Shown, a kind of plywood 4 for container floor, this board includes the pressure-bearing layer that is made of two particle boards 40 and the wood veneer 43 that is sandwiched between two particle boards 40 and is made of two wood veneers 42 and two bamboo curtains 41 The veneers arranged alternately are wood veneers, and the veneers adjacent to the pressure-bearing layer are wood veneers 42 . Same as Example 1, considering that the requirements of the container for the flexural strength of the bottom plate in the length direction are higher than the requirements for the flexural strength in the width direction, the wood veneer 42 and wood veneer 43 in this example are all used in the same way as the container box The length direction of the body is consistent with the grain long veneer.

[0058] Such as Figure 12 shown in the Figure 11 Add a layer of bamboo mat 44 on the pressure bearing layer of the shown plywood to further enhance the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com