Small-sized soluble bridge plug

A small size, bridge plug technology, applied in wellbore/well components, earthmoving, sealing/packing, etc., can solve the problems of long setting stroke and insufficient setting capacity, save the use area, and achieve reliable performance. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

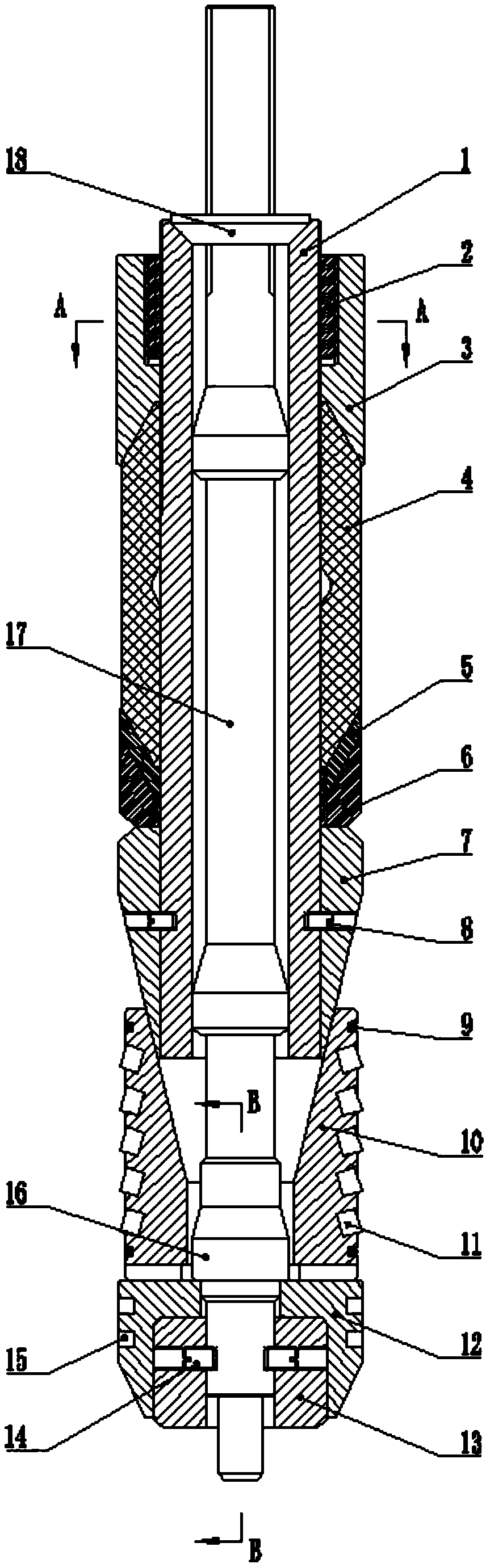

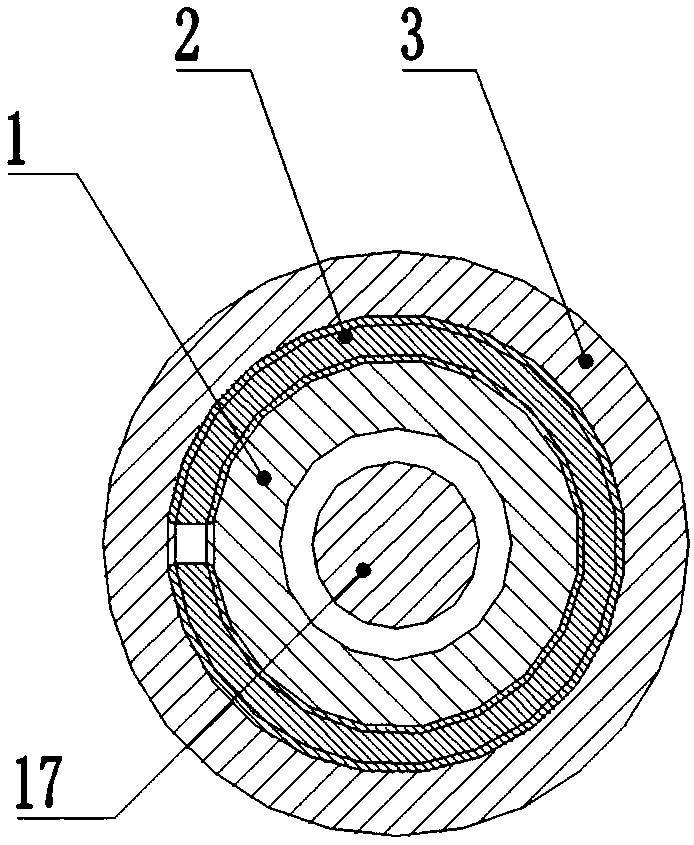

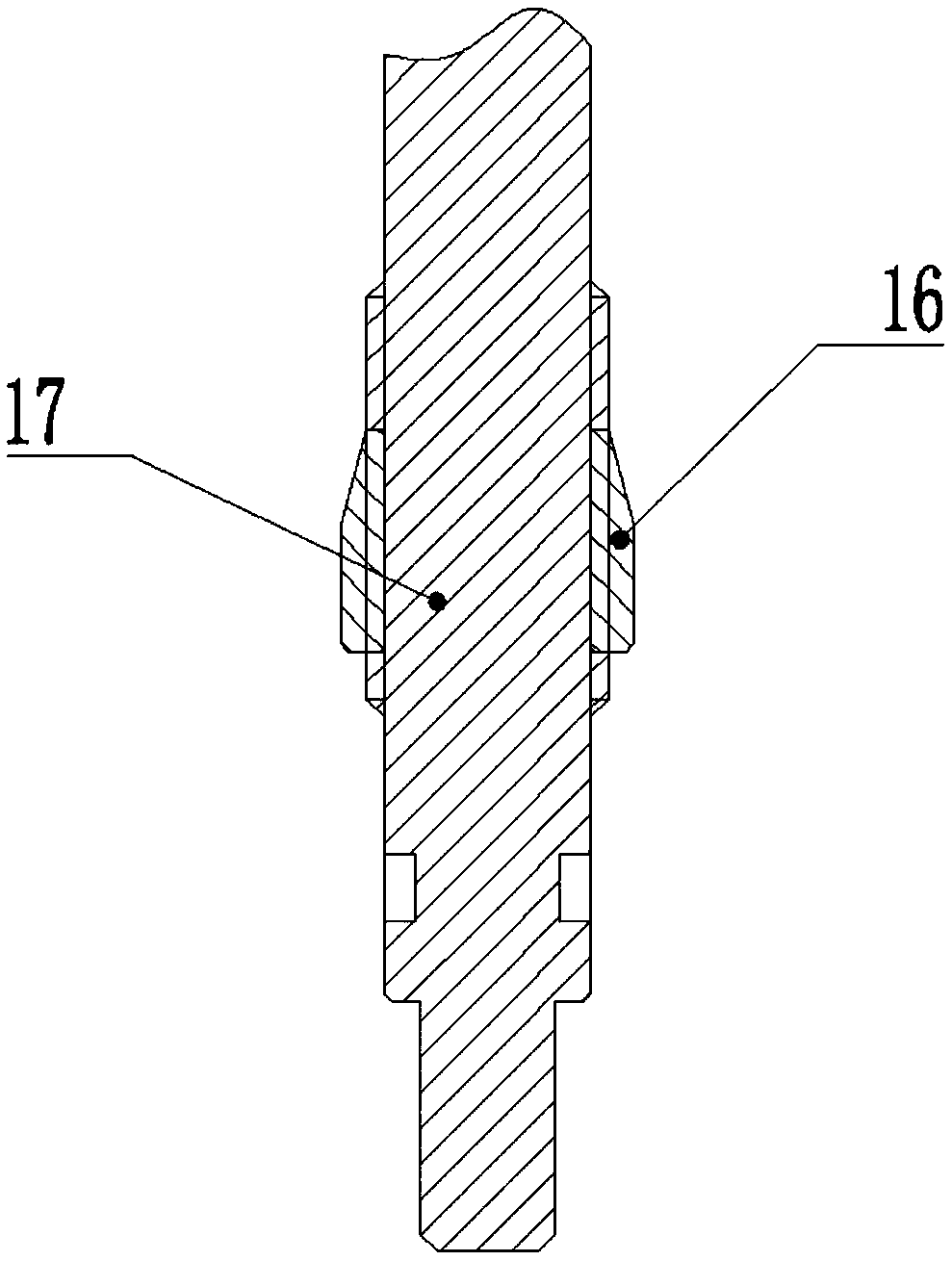

[0048] The small-sized dissolvable bridge plug of present embodiment, its structure is as follows figure 1 As shown, the bridge plug includes a central tube 1, the central tube 1 is in the shape of a hollow tube, one end of the central tube 1 is helically provided with a limiting C-shaped ring 2, the inner and outer sides of the limiting C-shaped ring 2 are threads, and the outer and outer sides of the limiting C-shaped ring 2 are threaded. A compression sleeve 3 is provided on the helical sleeve, and a cone 7 is sleeved on the other end of the central tube 1. The cone 7 and the central tube 1 are locked with a locking nail 8, which is made of copper. Between the compression sleeve 3 and the cone 7, the central tube 1 is sequentially sheathed with a rubber sleeve 4 of soluble composite rubber, a first wrist guard 5 and a second wrist guard 6 . The cone 7 is followed by a slip ring 10 , an anti-collision ring 12 and a shear ring 13 in sequence. The slip ring 10 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com