Technology for preparing diamond sandwich type hard alloy mine rock drilling blade

A cemented carbide and sandwich technology, applied in drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of high impact force and high frequency, achieve high cutting speed, save consumption, and have broad application prospects in the product market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

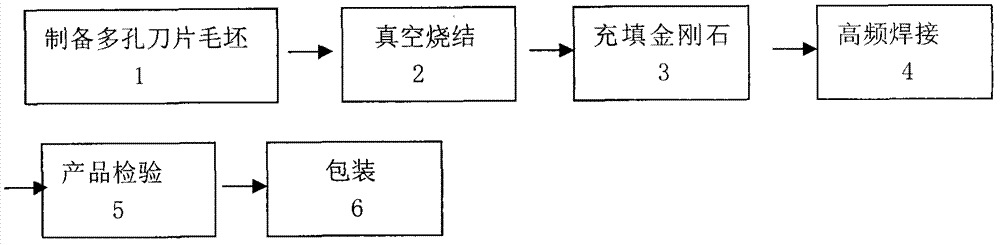

Method used

Image

Examples

Embodiment 1

[0033] Prepare 100 samples of the K42-5 model, 5-hole diamond sandwich type mining rock drilling blade, the alloy grade is Y611C, and no brazing with the steel drill bit is required. It should be done in the following steps.

[0034] 1. Preparation of porous blade blank:

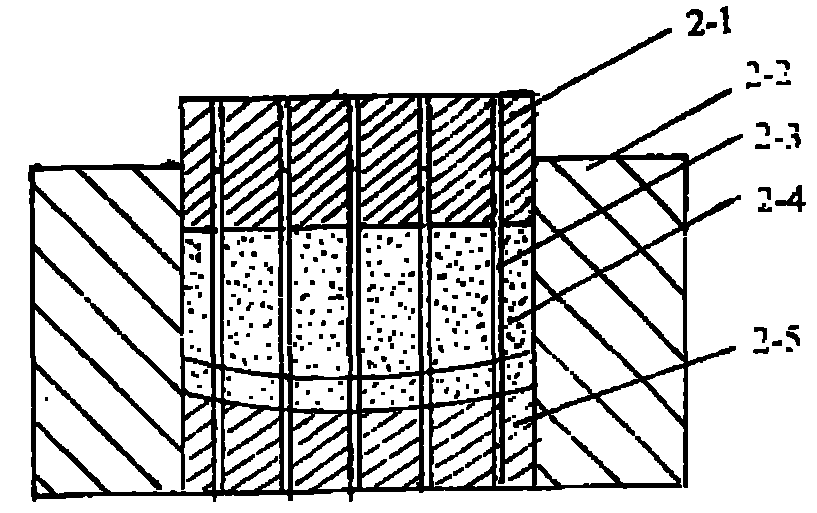

[0035] a. According to the shape and size requirements of the blade actually used, all relevant dimensions are enlarged by 20%, and the molding mold is designed after the enlargement. figure 2 . All dimensions shall be calculated as follows:

[0036] L=1.2×R where: L- mold linear size (including the inner diameter of the small hole);

[0037] R- the actual required size of the blade after sintering;

[0038] 1.2 - Amplification factor.

[0039] Note: The mold design work can be entrusted to professional units.

[0040] b. Mixture preparation:

[0041] Prepare a 15Kg alloy mixture according to the composition requirements of the YG11C alloy grade, first weigh 13.35kg of WC powder with an average parti...

Embodiment 2

[0070] Prepare 100 samples of K42-4 type schematic, 4-hole diamond sandwich type mining rock drilling blade, alloy grade is YG11C, no need to braze with steel drill bit.

[0071] It should be done in the following steps.

[0072] 1. Preparation of porous blade blank:

[0073] The following are basically the same as in Example 1, a; 1, b; 1, c; except that the mixed powder is pressed into four porous blanks with a diameter of Φ2mm and vertically through.

[0074] 2. Vacuum sintering:

[0075] It is basically the same as 2 and 2 in Example 1, except that the inner diameter of the inspection four holes should be (φ1.60~1.66) mm. After passing the test, turn to the filling process.

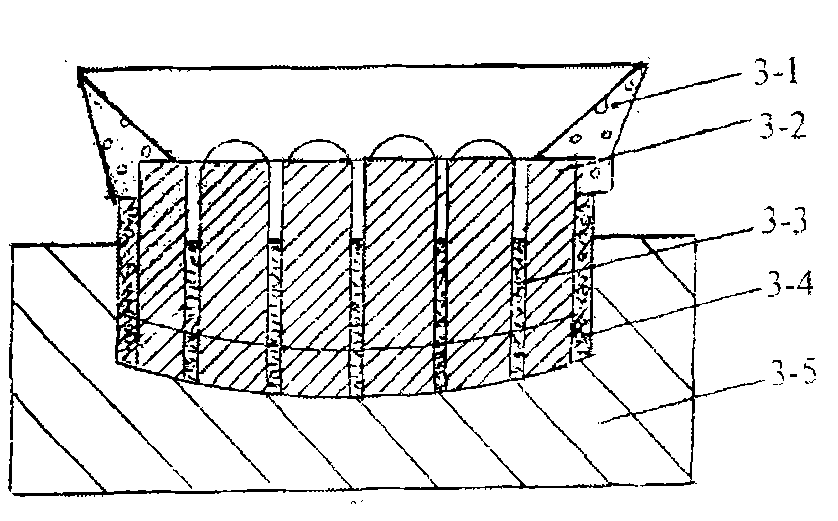

[0076] 3. Filled with diamond:

[0077] It is basically the same as 3 and 3 in Example 1, the difference is that the 4-hole blade is placed in the filling mold, see the attached image 3 Continuously add diamond powder with the help of a funnel, and continuously punch it with a steel needle until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com