Self-suspension propping agent and preparation method thereof

A proppant and self-suspension technology, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve problems such as personnel, environmental hazards, and failure to meet fracturing, and achieve good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method of self-suspending proppant, comprises the following steps:

[0027] (1) mixing the preheated proppant matrix with the water-swellable polymer to obtain a mixture;

[0028] (2) Spray the silane coupling agent solution into the mixture obtained in the step (1) under stirring condition, and react at 60-80° C. for 3-4 hours to obtain the self-suspending proppant.

[0029] The present invention combines a preheated proppant matrix with a water-swellable polymer to produce a mixture. In the present invention, the mass ratio of the proppant matrix to the water-swellable polymer is preferably 1000:5-15, more preferably 1000:8-10.

[0030] In the present invention, the preheating of the support matrix can accelerate the reaction speed of the silane coupling agent on the surface of the proppant; in the present invention, the preheating temperature of the proppant matrix is preferably 60-80°C, more preferably 65-80°C....

Embodiment 1

[0055] 1) Select 16 / 20 mesh (that is, pass through a 16 mesh screen and cannot pass through a 20 mesh screen) ceramic particles as the proppant matrix; select 100 to 200 mesh poly(meth)acrylic acid potassium salt as a water-swellable polymer; Choose silane coupling agent KH550, and configure it as a 10% silane coupling agent solution with distilled water.

[0056] 2) Add 1000g of 16 / 20 mesh ceramic particles into the rotary fluidized bed, heat the ceramic particles to 60°C, add 10g of poly(meth)acrylate potassium salt with a size of 100 mesh into the fluidized bed, stir evenly, and obtain Mixture; 30g mass fraction is that 10% silane coupling agent solution is sprayed in described mixture from the top of fluidized bed, after spraying finishes, ceramic particle, poly(meth)acrylic acid potassium salt and silane coupling agent solution are stirred and mixed After uniformity, the stirring was stopped, and the reaction was carried out at constant temperature for 3 hours under the e...

Embodiment 2

[0074] 1) Select 40 / 70 mesh (that is, pass through the 40 mesh screen and cannot pass through the 70 mesh screen) quartz sand as the proppant matrix; Polymer; choose silane coupling agent KH570, configure 20% silane coupling agent solution with distilled water.

[0075] 2) Add 1000g of 40 / 70 mesh quartz sand to the rotary fluidized bed, heat the quartz sand to 80°C, add 15g of 200 mesh cross-linked carboxymethyl cellulose grafted acrylamide into the fluidized bed, and stir Uniformly, obtain mixture; 50g mass fraction is that the silane coupling agent solution of 5% is sprayed in the described mixture from the top of fluidized bed, after spraying, quartz sand, cross-linked carboxymethyl cellulose graft acrylamide and silane After the coupling agent solution was stirred evenly, the stirring was stopped, and the temperature was maintained at 80° C. for 4 hours. After natural cooling, sieve to obtain.

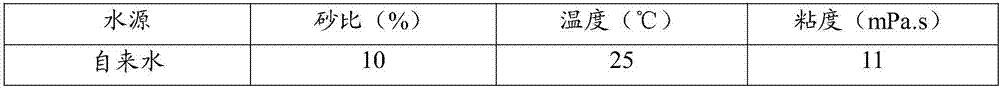

[0076] Taking the self-suspending proppant prepared in Example 1 and Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com