Oat whole powder foodstuff and method for manufacturing the same

A technology of oat whole powder and food, applied in food preparation, food science, application, etc., can solve the problems of difficult molding, reduction, single variety, etc., and achieve good brittleness, high-efficiency biochemical reactor, and regular shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

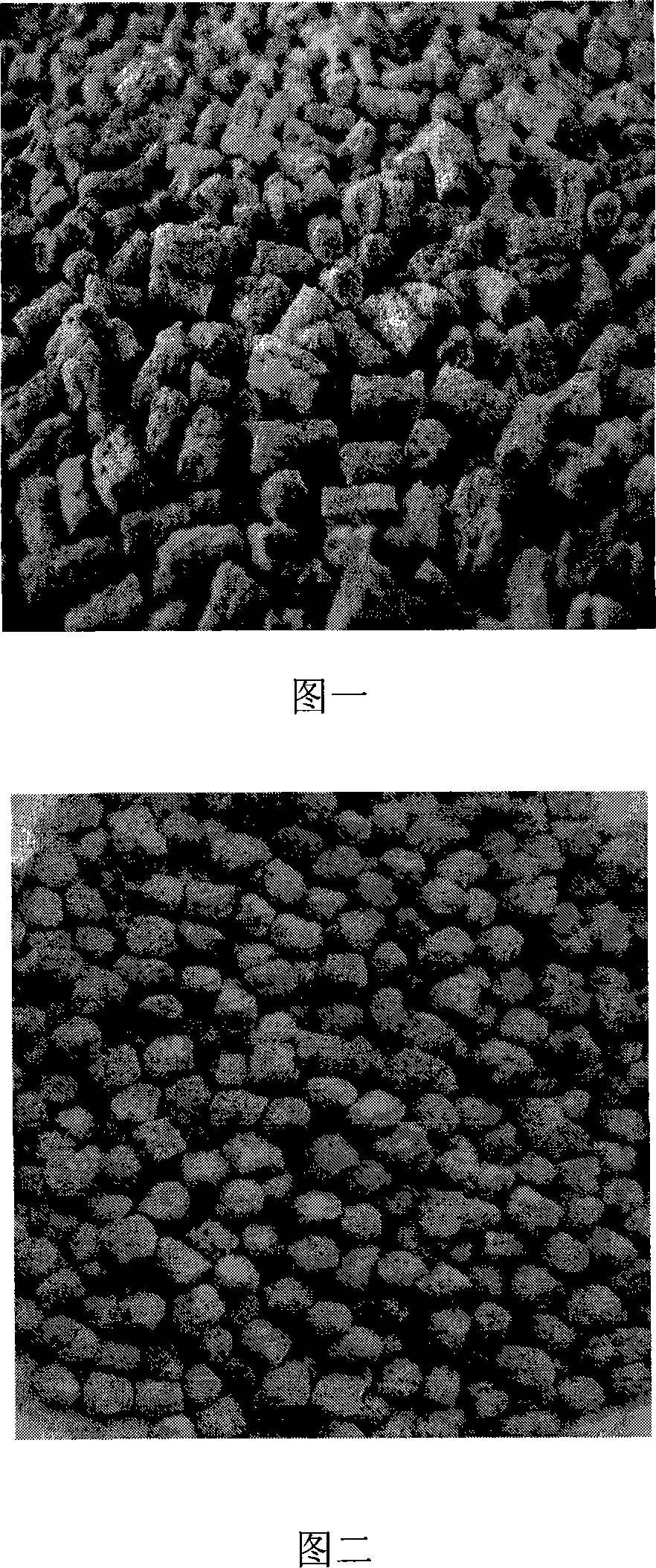

Image

Examples

Embodiment 1

[0027] The first step of milling step mainly includes the following steps:

[0028] 1) Select high-quality naked oat grains, wash and remove impurities;

[0029] 2) Adjust the moisture content of the cleaned oat grains to 20%, and balance the moisture for 12 hours;

[0030] 3) Bake the moistened oat grains in an oven (Shanghai Jinghong, DHG9123A) at about 170°C for 30 minutes;

[0031] 4) Adjust the moisture content of the roasted oat grains to 13%. Use a Chopin mill (French Chopin, CD-2 type) to make flour, and mix powder according to the ratio of 40% skin powder, 25% heart powder, 20% fine bran and 15% wheat bran (weight), to obtain whole oats. pink.

[0032] The nutritional components of the whole oat powder were analyzed, and the contents of the main nutritional components are shown in Table 1.

[0033] Table 1 Nutritional components of whole oatmeal powder

[0034] nutrient content

Content 100g

Moisture / g

crude protein / g

Crude fat / g ...

Embodiment 2

[0041] The first step of milling step mainly includes the following steps:

[0042] 1) Select high-quality naked oat grains, wash and remove impurities;

[0043] 2) Adjust the moisture content of the cleaned oat grains to 20%, and balance the moisture for 12 hours;

[0044] 3) Bake the moistened oat grains in a far-infrared oven (YXD-8B type, Yuehai West Kitchen Equipment Factory) at 200°C for 15 minutes,

[0045]4) Adjust the moisture content of the roasted oat grains to 13%. Use a Chopin mill (French Chopin, CD-2 type) for flour milling, and mix the flour according to the ratio of 30% skin flour, 25% heart flour, 20% fine bran and 25% wheat bran to obtain whole oat flour.

[0046] The second step extrusion puffing step mainly comprises the following steps:

[0047] Set the barrel temperature of the first to fifth zones of the extruder to 70°C-110°C-140°C-165°C-175°C, preheat the extruder until the temperature of the barrel in each zone of the extruder reaches the preset v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com