External-circulation airlift type reactor adopting membrane tube aeration

An air-lift reactor and external circulation technology, which is applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biochemical instruments, etc., can solve the problem of unfavorable aerobic microbial fermentation, volumetric mass transfer coefficient low, limiting bacterial growth, etc., to achieve the effect of convenient disassembly and maintenance, small bubble diameter, and improved mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

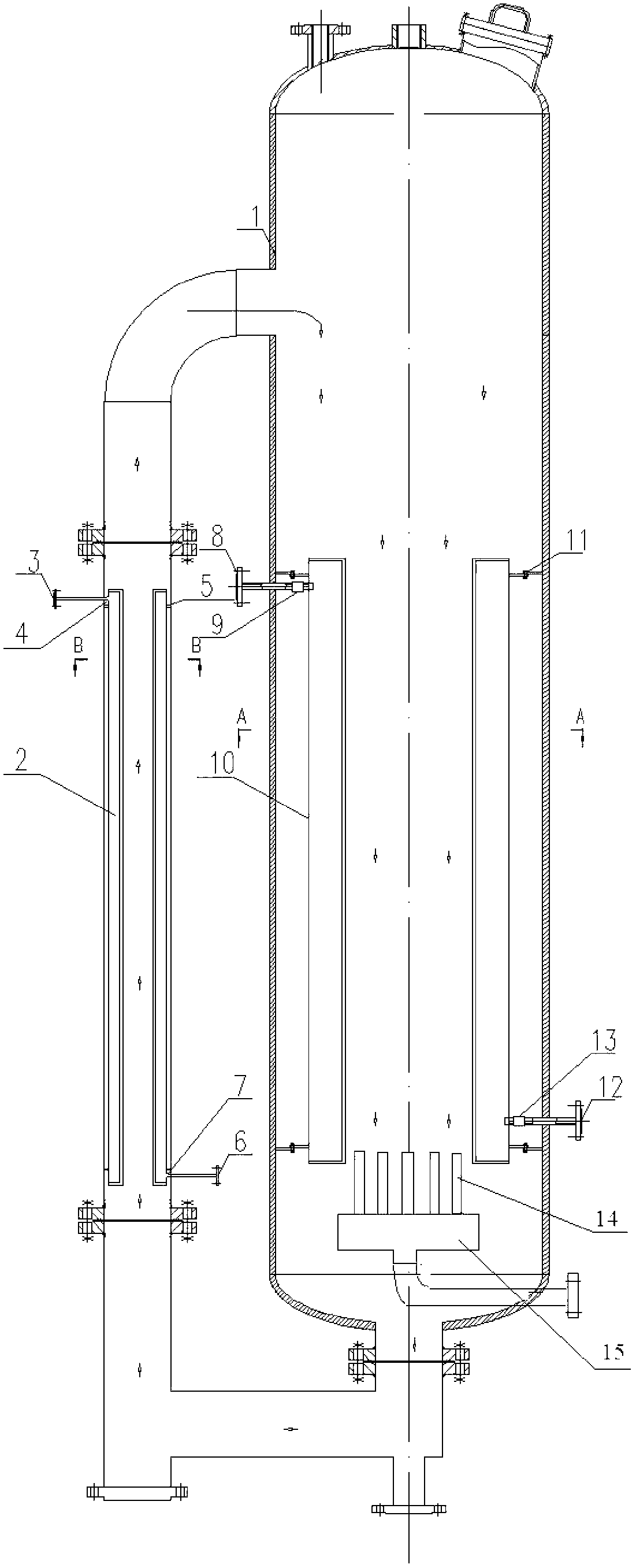

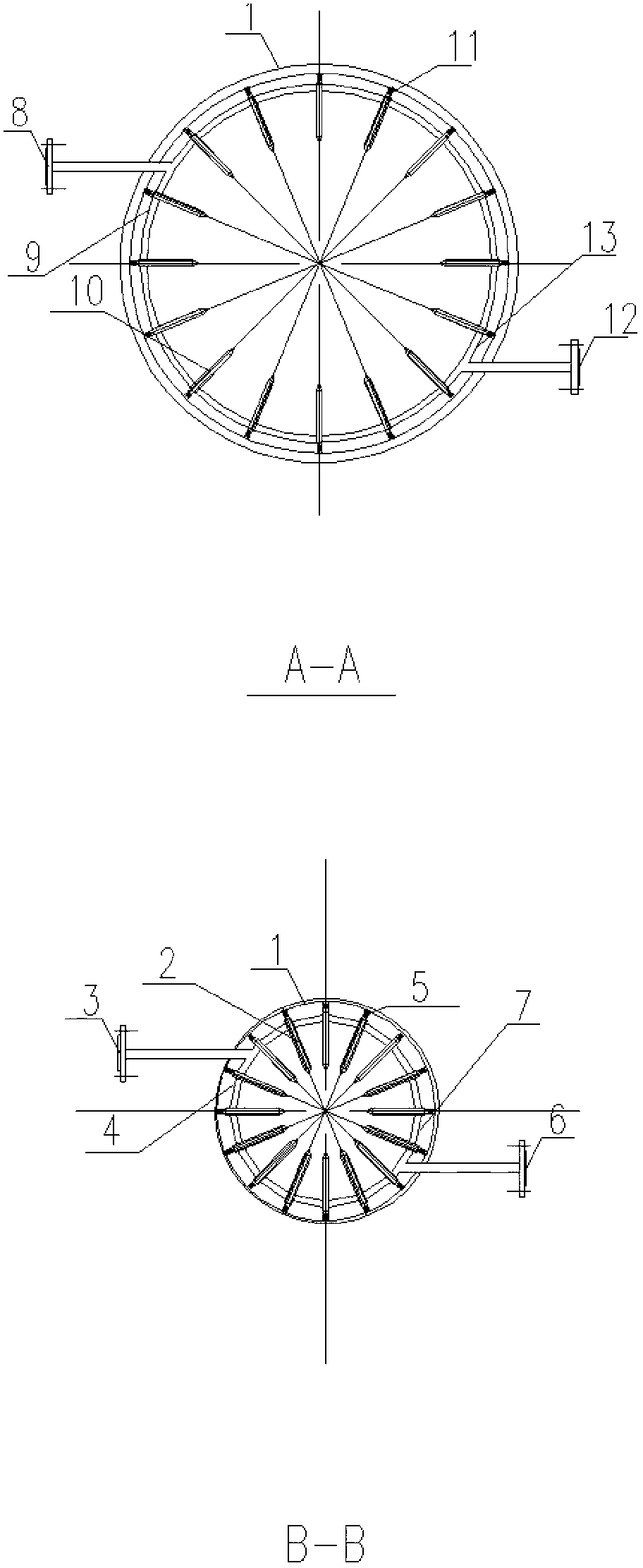

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 yes figure 1 The top view of A-A direction and B-B direction in the center, combined with figure 1 , figure 2 As shown, the external circulation airlift reactor using membrane tube aeration includes the external circulation airlift reactor 1, and the ascending zone and descending zone of the external circulating airlift reactor 1 are respectively provided with a plurality of fan-shaped plate fins Plate-fin heat exchanger 1 2 and plate-fin heat exchanger 2 10 of heat exchanger fins, fan-shaped plate-fin heat exchangers are used to exchange heat, figure 1 Shown is an external circulation airlift reactor with two rising zones. The upper end of the plate-fin heat exchanger-2 has steam inlet and cooling water outlet flange-3, and the lower end has steam condensate outlet and cooling water inlet flange-6. Among them, the steam inlet and cooling water outlet flange-3 pass through the ring T...

Embodiment 2

[0024] This example is used to illustrate the use of 10 m 3 The method for fermenting and producing L-lysine in a reactor using a membrane tube aeration method.

[0025] First, the culture medium is sterilized, and the stirring motor is turned on at a speed of 100 r / min, so that the fermentation broth is evenly heated. When the temperature rises above 95 degrees, the stirring can be stopped. Carry out the sterilization of the air filter and the air pipeline again, and slightly open the filter and the drain valve to ensure the sterilization of the air pipeline. Finally, the outlet, sampling valve, steam valve and outlet valve are slightly opened to ensure that the pipeline is sterilized.

[0026] Fermentation culture and results: Escherichia coli producing L-lysine (purchased from CGMCC, strain preservation number CGMCC1.0281) was inserted into a 5 m 3 10 m of fermentation medium 3 In a stirred reactor with membrane tube aeration (1L fermentation medium contains: glucos...

Embodiment 3

[0029] This example is used to illustrate the use of 50 m 3 The reactor adopts the method for fermenting and producing citric acid in a membrane tube aeration mode.

[0030] First, the culture medium is sterilized, and the stirring motor is turned on at a speed of 100 r / min, so that the fermentation broth is evenly heated. When the temperature rises above 95 degrees, the stirring can be stopped. Carry out the sterilization of the air filter and the air pipeline again, and slightly open the filter and the drain valve to ensure the sterilization of the air pipeline. Finally, the outlet, sampling valve, steam valve and outlet valve are slightly opened to ensure that the pipeline is sterilized.

[0031] Fermentation culture and results: According to the inoculation amount of 10%, citrate-producing Aspergillus niger (purchased from CGMCC, the preservation number of Aspergillus niger is CGMCC5343) was inserted into a 35m 3 50m of fermentation medium 3 In an aerated reactor using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com