Compound type concrete foaming agent, preparation method and application thereof

A technology for concrete and foaming agent, applied in the field of building materials, can solve the problems of decreased flexural strength, failure to meet engineering requirements, delayed setting, etc., and achieve the effects of increasing the amount of foaming, low price, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples. It should be understood that these examples are only for the purpose of illustration, and in no way limit the protection scope of the present invention.

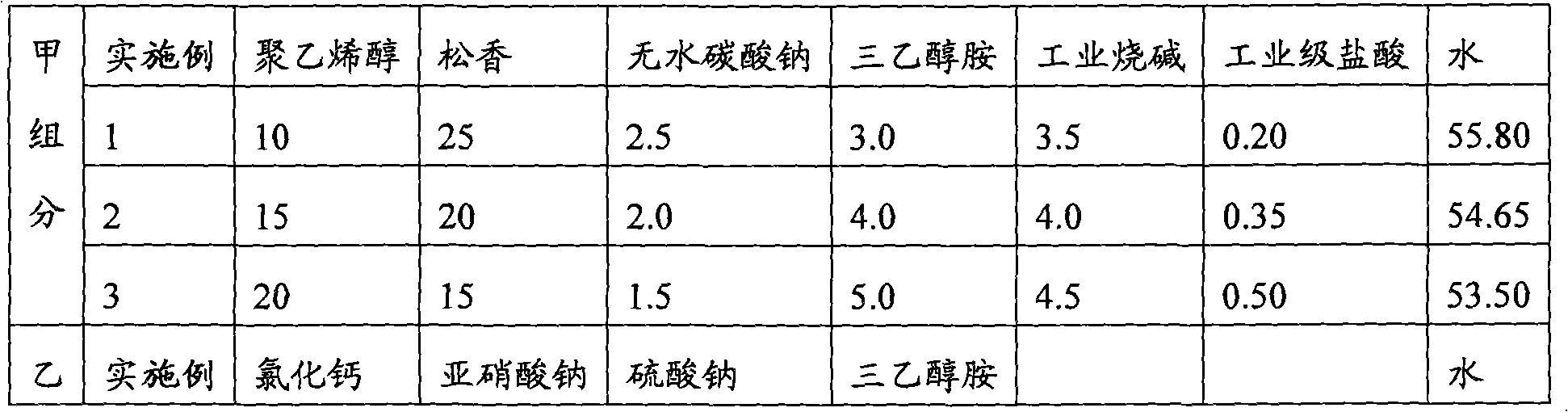

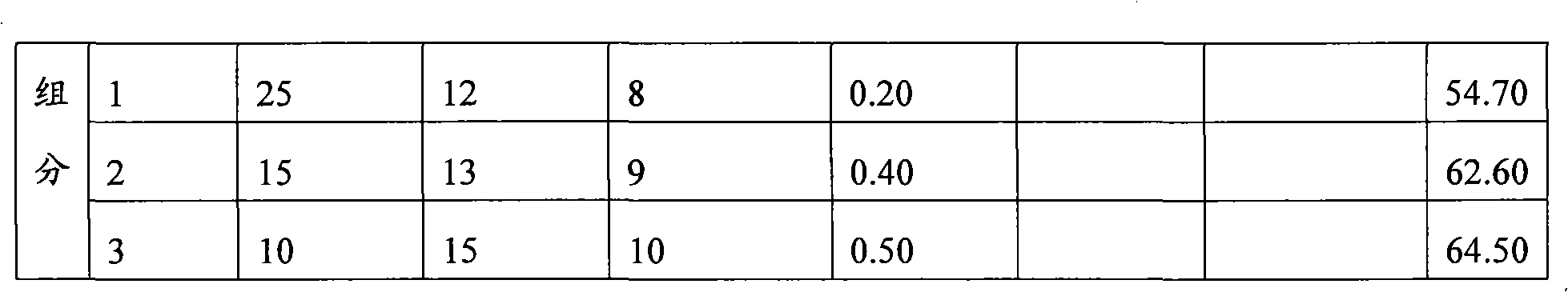

[0019] Composite blowing agent implementation mode is expressed by the ratio of each raw material and text in Table 1, and its weight unit is calculated by heart:

[0020] Table 1

[0021]

[0022]

[0023] Take embodiment 2 as example to illustrate that the preparation method of composite concrete foaming agent of the present invention is as follows:

[0024] Take each raw material by weighing in table 1, get water 54.65kg, with wherein 30% water is heated to 70-80 ℃ after polyvinyl alcohol is diluted stand-by; Remaining water is put into heat container, processing industry caustic soda 4kg; Add 20kg of rosin, stir and pyrolyze at a temperature of 70-80°C, wait for about 100 minutes for the raw materials to fully dissolve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com