A foamed cement insulation material

A technology of thermal insulation materials and foamed cement, which is applied in the field of foamed cement thermal insulation materials, can solve the problems of high water absorption rate of foamed cement, and achieve the effects of improving compressive strength and anti-seepage performance, improving anti-seepage performance, and making the strength not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

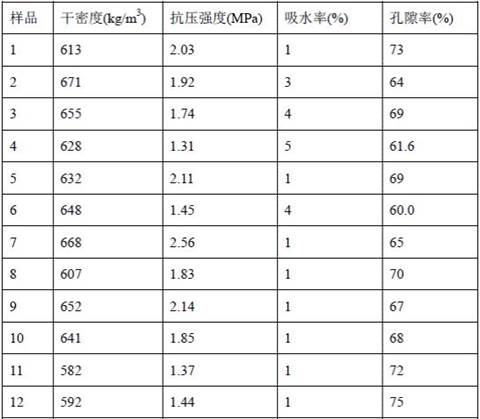

Examples

Embodiment 1

[0023] Example 1 Preparation of foamed cement insulation material

[0024] Hydrogen peroxide, fatty alcohol polyoxyethylene ether, sodium dodecyl benzene sulfonate and tapioca starch are prepared into a composite foaming agent according to a mass ratio of 10:1:0.5:2;

[0025] SILRES Powder D silane water repellent and aluminum potassium sulfate dodecahydrate are formulated into a water repellent in a mass ratio of 0.2:1;

[0026] Weigh the raw materials according to the following parts by weight to prepare foamed cement insulation materials: 35 parts of 42.5-strength ordinary Portland cement, 5 parts of aluminate cement, 0.1 part of PCA-I polycarboxylate superplasticizer (Subote), compound 5 parts of foaming agent, 0.5 part of waterproofing agent, and the water-to-binder ratio is 0.60;

[0027] Prepare foamed cement insulation material according to the following preparation method:

[0028] (1) Add some water to the cement and mix well, then add admixtures and mix well;

[...

Embodiment 2

[0033] Example 2 Preparation of foamed cement insulation material

[0034] Hydrogen peroxide, fatty alcohol polyoxyethylene ether, sodium dodecyl benzene sulfonate and tapioca starch are prepared into a composite foaming agent according to a mass ratio of 10:1:0.5:2;

[0035] SILRES Powder D silane water repellent and aluminum potassium sulfate dodecahydrate are formulated into a water repellent in a mass ratio of 0.2:1;

[0036] Weigh the following raw materials by weight to prepare foamed cement insulation materials: 30 parts of 42.5-strength ordinary Portland cement, 5 parts of aluminate cement, 5 parts of fly ash (average loss on ignition 3.18%), 5 parts of PCA-I polymer 0.2 part of carboxylate water reducing agent (Subote), 5 parts of composite foaming agent, 0.5 part of waterproofing agent, and the water-to-binder ratio is 0.60;

[0037] Prepare foamed cement insulation material according to the following preparation method:

[0038] (1) Add some water to cement and fl...

Embodiment 3

[0042] Example 3 Preparation of foamed cement insulation material

[0043] Hydrogen peroxide, fatty alcohol polyoxyethylene ether, sodium dodecyl benzene sulfonate and tapioca starch are prepared into a composite foaming agent according to the mass ratio of 10:1:1:2;

[0044] SILRES Powder D silane water repellent and aluminum potassium sulfate dodecahydrate are formulated into a water repellent in a mass ratio of 0.4:1;

[0045] Weigh the raw materials according to the following parts by weight to prepare foamed cement insulation materials: 35 parts of 42.5-strength ordinary Portland cement, 5 parts of aluminate cement, 10 parts of fly ash (average loss on ignition 4.03%), FDN-I naphthalene System-fatty acid composite water reducing agent 0.4 parts, composite foaming agent 5 parts, waterproofing agent 2 parts, water-to-binder ratio 0.65;

[0046] Prepare foamed cement insulation material according to the following preparation method:

[0047] (1) Add some water to cement an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com