Slurry for hydrogen oxidation catalyst coating and preparation method of slurry

An oxidation catalyst and coating technology, applied in the field of slurry for hydrogen oxidation catalyst coating and its preparation, can solve the problems of poor catalyst performance and stability, long catalyst production cycle, high coating wear rate, etc., and achieve slurry The effects of stable distribution, shortened slurry preparation time, and uniform foam size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 300 grams of water, 1200 grams of 10% aluminum sol, 800 grams of γ-alumina powder, and 8 grams of calcium silicate into the circulating colloid mill for grinding for 90 minutes, and add 20 grams of 20% aluminum chloride solution to adjust the flow of the slurry At the same time, take 10 grams of HPC, 5 grams of Span, add 300 grams of water and place them in a foaming machine to foam, add them to the above-mentioned circulating slurry, continue to add 20% aluminum chloride to adjust the pH value to ≈4.70, and continue to circulate and grind After 25 minutes, the required slurry A was obtained.

Embodiment 2

[0024] Add 500 grams of water, 1000 grams of 20% aluminum sol, 1200 grams of δ-alumina powder, 50 grams of calcium oxide, and 60 grams of magnesium aluminate into the circulating colloid mill to grind 100 grams, add 60 grams of 50% tin chloride solution to adjust Slurry fluidity, take 50 grams of PVA, 10 grams of Tween and 600 grams of water and place it in a foaming machine to foam to make a foam, add it to the above-mentioned circulating slurry, continue to add 50% tin chloride to adjust the pH value to ≈4.50, Continue to circulate and grind for 20 minutes to obtain the required slurry B.

Embodiment 3

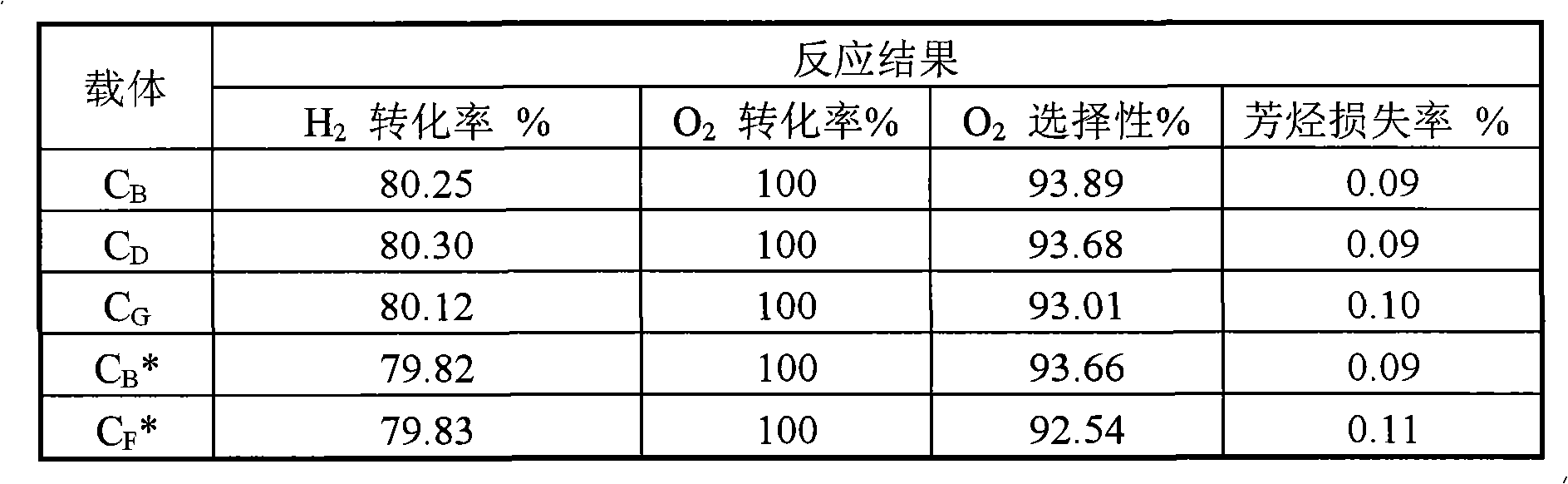

[0026] 300 grams of water, 2000 grams of 40% aluminum sol, 300 grams of θ-alumina powder, and 30 grams of spodumene are added to the circulating colloid mill and ground for 80 degrees. Adding 40 grams of magnesium chloride solution with a concentration of 10%, the concentration of 30 grams is 20% stannous chloride solution, adjust fluidity, take 50 grams of EMC, 10 grams of polyethylene glycol and add 500 grams of water and place it in a foaming machine to foam to make foam, add it to the above-mentioned circulating slurry, and continue to increase the concentration Adjust the pH value to ≈4.3 for the 20% stannous chloride solution, and continue to circulate and grind for 30 minutes to obtain the required slurry C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com