Continuous production method and device for preparing propionic acid through air oxidation of propionaldehyde

An air oxidation and production method technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of large external circulation, increase the complexity of the process, unsafe, etc., and achieve the intrinsic safety of the process High performance, high reaction conversion rate and product selectivity, and low environmental pollution

Inactive Publication Date: 2016-01-20

TIANJIN UNIV

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method uses external circulation heat exchange to remove the heat of reaction, which increases the complexity of the process. Due to the large amount of external circulation (generally more than 20 times the amount of feed), the increased energy consumption is also considerable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0050]

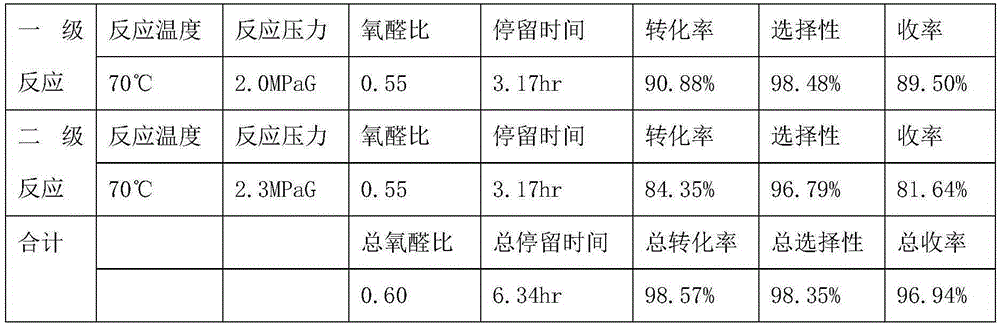

Embodiment 2

[0052]

Embodiment 3

[0055] temperature reflex reaction pressure Oxygen aldehyde ratio dwell time Conversion rates selectivity yield 70℃ 1.0MPaG 0.58 3.17hr 92.26% 94.87% 87.52% 80℃ 1.0MPaG 0.57 3.17hr 92.06% 93.63% 86.20% 90℃ 1.0MPaG 0.52 3.17hr 88.70% 93.40% 82.84%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

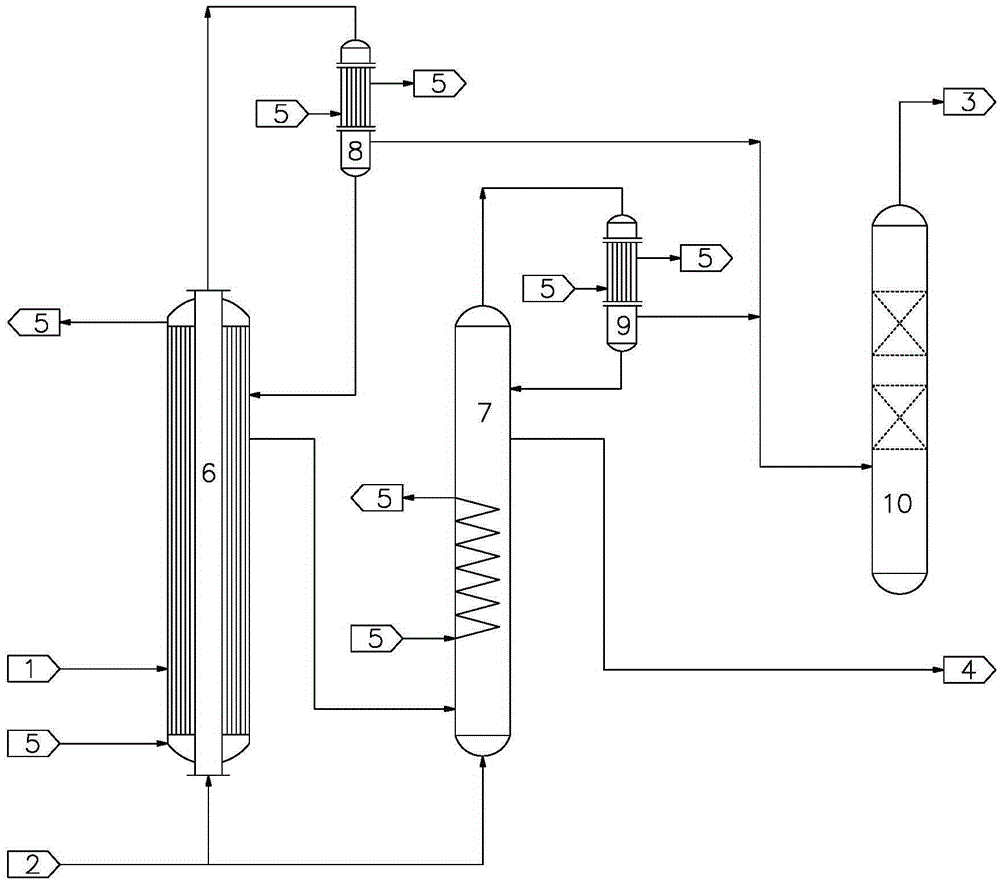

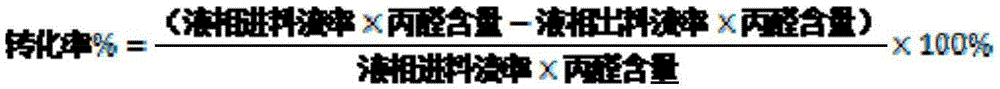

The invention relates to a continuous production method and device for preparing propionic acid through air oxidation of propionaldehyde. The method comprises the steps that propionaldehyde enters a reactor through a liquid phase inlet in the bottom of a first-order oxidation reactor and makes contact with and is mixed with some compressed air, a majority of propionaldehyde in the raw material is converted into propionic acid through an oxidation reactor, a first-order oxidation product containing a small amount of propionaldehyde continuously enters a second-order or multi-order oxidation reactor and is continuously subjected to the oxidation reaction with the compressed air, and finally the propionic acid with the high-purity is generated. The device comprises two or more oxidation reactors connected in series, a condenser is arranged on the top of each oxidation reactor, and gas phase pipelines and backflow pipelines are arranged between the oxidation reactors for connection. A tail gas processing device is arranged behind each oxidation reactor. A gas phase pipeline is arranged between each condenser and the corresponding tail gas processing device for connection. The reaction conditions are mild, the product yield is high, the product quality is good, the propionaldehyde conversion rate is larger than 98.5%, the selectivity of the propionic acid is larger than 97.5%, and the product purity is larger than 99.5%.

Description

technical field [0001] The invention is a production process for preparing propionic acid through continuous oxidation reaction using propionaldehyde and air as raw materials; in particular, it relates to a continuous production method and device for preparing propionic acid by air oxidation of propionaldehyde. Background technique [0002] Propionic acid is a colorless and transparent liquid with a strong pungent odor, which is miscible with water, ethanol, ether, chloroform and other organic acids, and can be used to prepare propionate, ester, acid chloride, amide and acid anhydride. Propionic acid esters are important solvents and spices, and propionyl chloride and propionic anhydride are important pesticide and pharmaceutical intermediates. Propionic acid and its derivatives have been widely used in agriculture, textile, food, medicine and other industries, and its use is expanding, and its consumption is increasing year by year. [0003] At present, there are three kin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C51/235C07C53/122

CPCC07C51/235C07C53/122

Inventor 张绍军马海洪石建明陶然陈勇强

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com