Fluidized bed reactor used for light olefin cracking and Methanol To Olefin (MTO)

A fluidized bed reactor, methanol-to-olefin technology, applied in hydrocarbon cracking to hydrocarbon production, chemical instruments and methods, organic chemistry, etc., can solve the problem of back-mixing of catalyst and oil and gas, reducing gas-solid contact efficiency, low single-pass conversion rate, etc. It can reduce the back-mixing of gas, improve the contact reaction efficiency, and improve the gas-solid contact efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

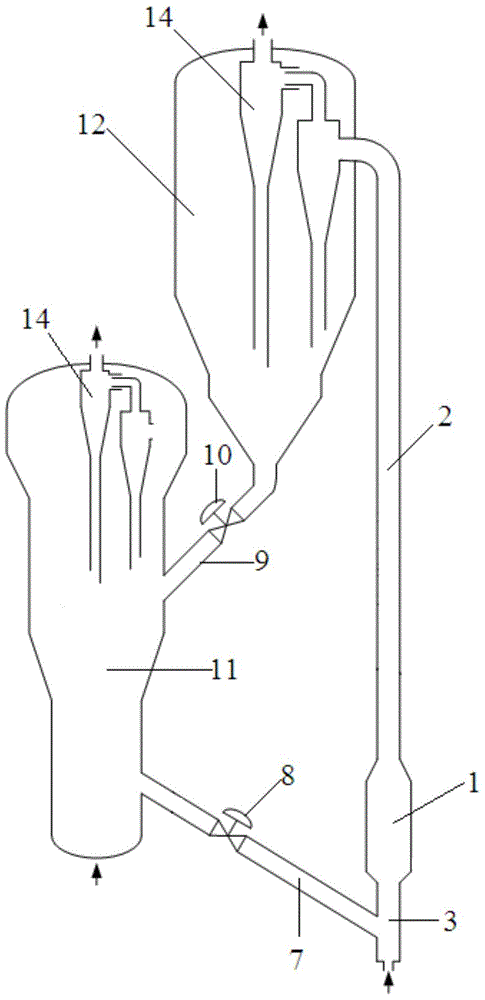

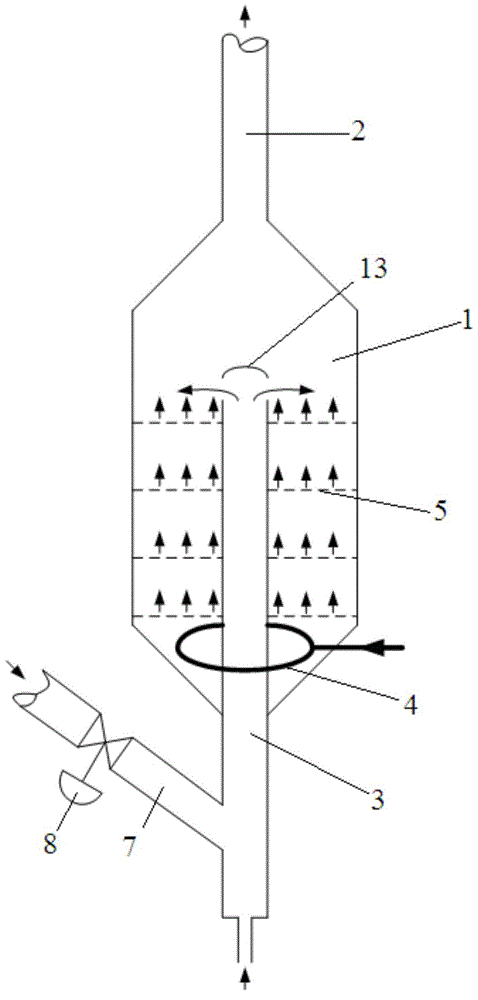

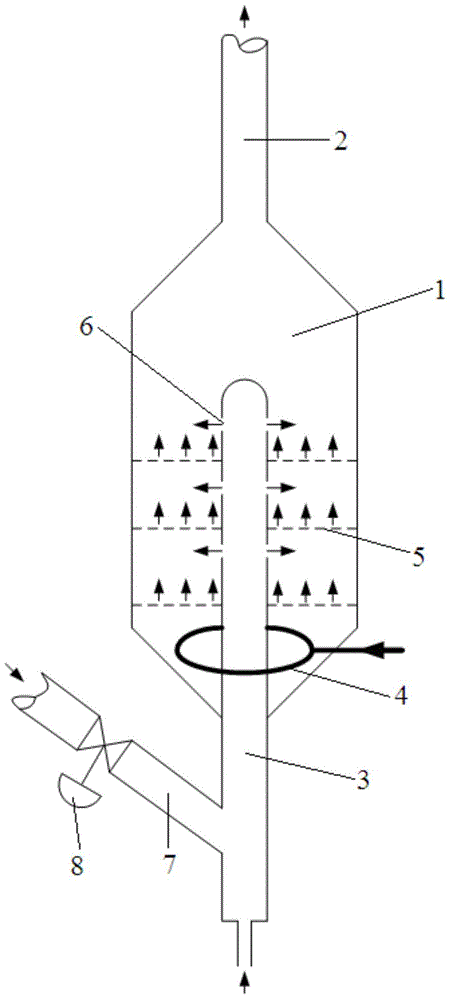

[0047] like Figure 1-3 As shown, a high gas-solid contact efficiency dense-phase fluidized bed reactor for light olefin cracking and methanol to olefin of the present invention includes a reactor, a settler 12, a catalyst standby inclined tube 9, and a catalyst regenerator 11 , a pre-riser 3 and a catalyst regeneration inclined pipe 7; the reactor includes a dense-phase fluidized bed reactor 1 and a dilute-phase conveying reactor 2, and the dense-phase fluidized-bed reactor 1 and the dilute-phase conveying reactor 2 are in On the same axis, the pre-lift pipe 3 and the dilute-phase transport reactor 2 are respectively located at the upper and lower parts of the dense-phase fluidized-bed reactor 1; the diameter of the pre-lift pipe 3 is smaller than the diameter of the dense-phase fluidized-bed reactor 1, and the pre-lift The upper part of the pipe 3 extends into the dense phase fluidized bed reactor 1 . From the upper port of the pre-riser 3 to the bottom of the dense-phase f...

Embodiment 2

[0055] The catalysts used in the reaction example of methanol to olefins are industrial LTB-8 catalysts, and the active component is hierarchically porous HZSM-11 molecular sieve (ZL201210003750.5). After aging for 4 hours under steam conditions, it is ready for use.

[0056] The dense-phase fluidized bed reactor shown in appendix 2 is installed in such as appendix figure 1 In the circulating fluidized bed reaction regeneration device shown, the LTB-8 catalyst of 20kg aging is loaded into as attached figure 1 The circulating fluidized bed reaction regeneration device shown. A 3-layer grid is installed between the feed distributor and the outlet of the pre-lift pipe, and the distance between the grids is 0.4m. The feed rate of pure methanol is 4kg / h, preheated to 200°C, and enters the dense-phase fluidized bed reactor through the feed distributor, and the reaction temperature is controlled at 500°C; the average line of the gas in the dense-phase fluidized bed reactor The vel...

Embodiment 3

[0059] Other conditions are identical with embodiment 2, and the pure methanol feed rate is reduced to 1.5kg / h, and the gas average linear velocity in the dense phase fluidized bed reactor is 0.3m / s, and the average residence time is about 2.0s; The average linear velocity in the dilute phase region is 3.0m / s, and the average residence time is about 1.8s. The reaction results are shown in attached table 1, the conversion rate is similar to that of Example 1, but due to the long residence time of oil and gas in the reactor, the content of ethylene and propylene in dry gas and liquefied gas has decreased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com