Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

531 results about "Aluminum alkyl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrially, simple aluminium alkyls of the type Al2R6 (R = Me, Et) are prepared in a two-step process beginning with the alkylation of aluminium powder: The reaction resembles the synthesis Grignard reagents. The product, (CH3CH2)3Al2Cl3, is called ethylaluminium sesquichloride.

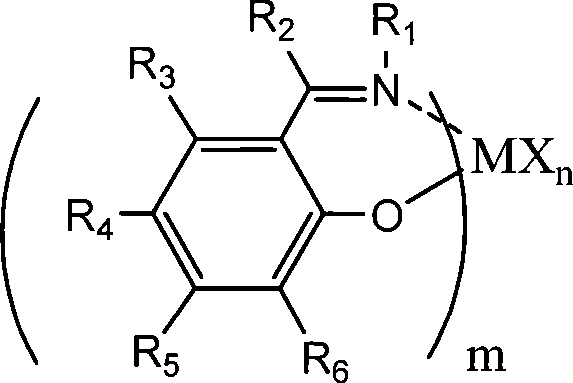

Mono-active center Ziegler-Natta catalyst for olefinic polymerization

The invention relates to a new catalyst for single active central Ziegler-Natta alkene polymerization. Said catalyst takes salicylal containing dentate or substituted salicylal derivatives as electrons, and is prepared by adding pretreated carrier, metallic compound and electrons into magnesium compound / tetrahydrofuran solution. The catalyst can produce ethane homopolymer and copolymer with narrow molecular weight distribution (1.6-3.8) and even comonomer distribution, with high activity and under action of adjuvant catalyst of alkyl aluminium and alkyl aluminoxanes. The ethane polymerization, homopolymerization or combined polymerization of ethane and 1- olefin, ring olefin and polar monomer through slurry method or gas phase method by using said catalyst can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Supported non-metallocene single site catalyst component and preparation method thereof and use

The invention discloses a loading non-metallocene single active central catalyst composition which is obtained through adopting an alkyl aluminoxane / magnesium chloride / silica gel carrier as a carrier and loading a non-metallocene single active central transition metal composition and a preparation method thereof. The catalyst system consisting of the catalyst composition catalyzes ethylene to polymerize or copolymerize and has high polymerization activity. The carrier is simple to prepare; the prepared loading catalyst granule has good shape and adjustable size; and the obtained polythene powdery material has high stacking density.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of broad molecular weight polyethylene

ActiveUS20050272886A1Easy to controlIncrease productivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationProduction rateAluminum alkyl

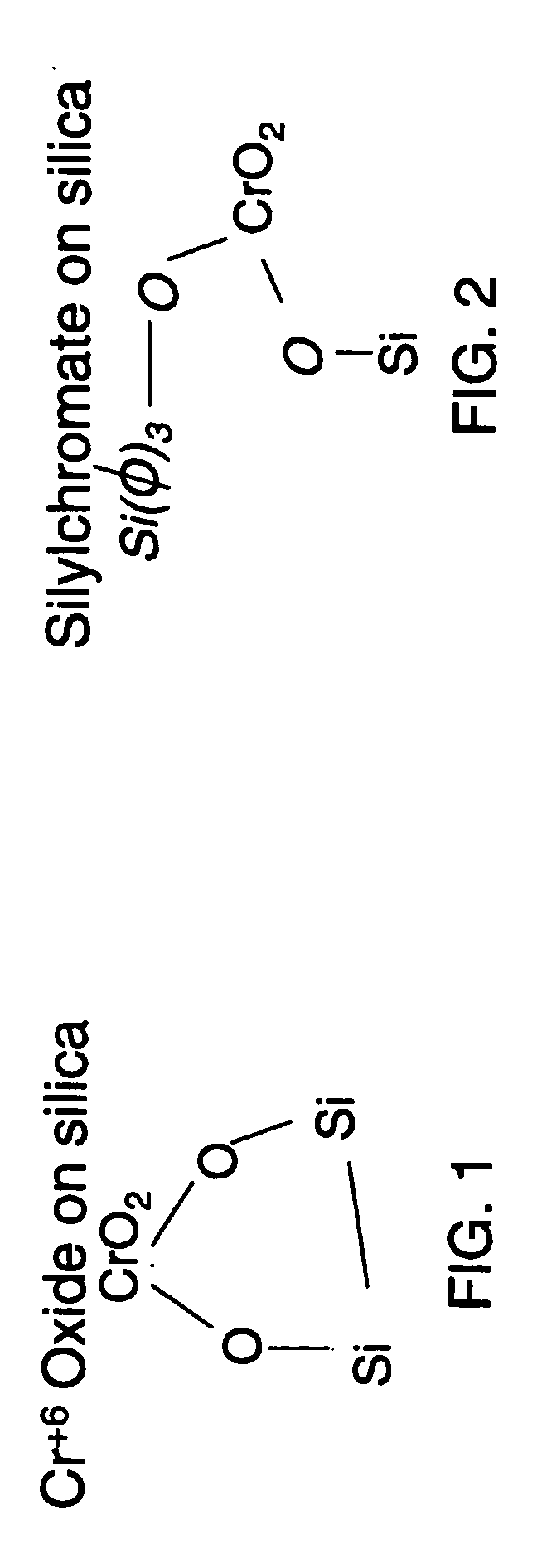

The present invention is directed to the use of aluminum alkyl activators and co-catalysts to improve the performance of chromium-based catalysts. The aluminum alkyls allow for the variable control of polymer molecular weight, control of side branching while possessing desirable productivities, and may be applied to the catalyst directly or separately to the reactor. Adding the alkyl aluminum compound directly to the reactor (in-situ) eliminates induction times.

Owner:UNIVATION TECH LLC

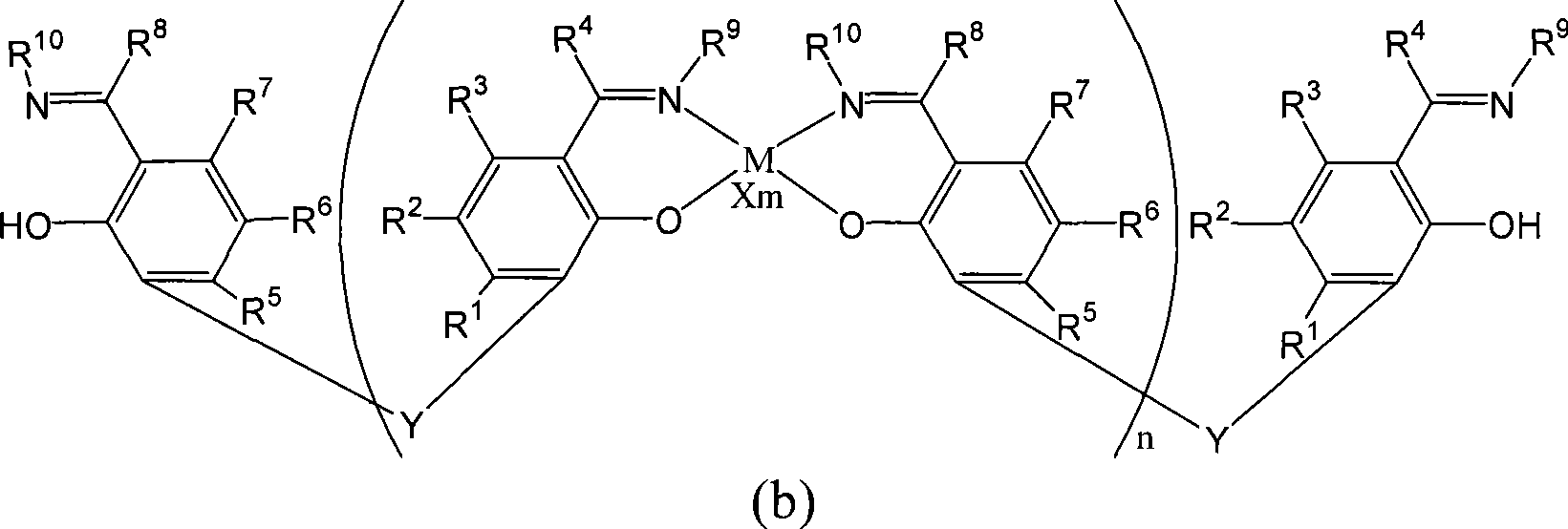

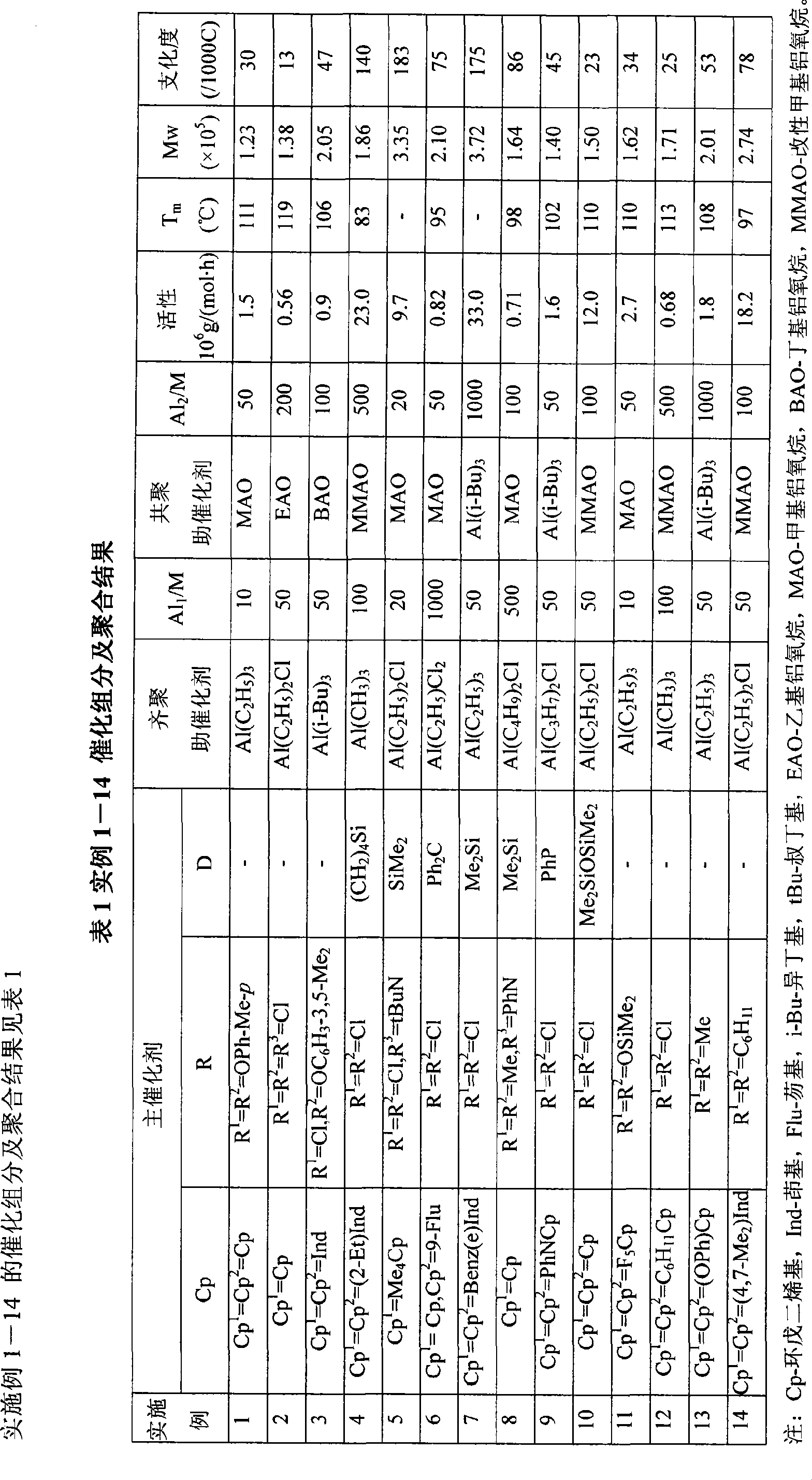

Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

InactiveCN101392036ALower synthesis costAchieve the effect of molecular tailoringTriisobutylaluminiumStructural formula

The invention discloses a domino catalyzing system of a primary metallocene catalyst, which takes ethane as a sole monomer to prepare branched polyethylene, and the application thereof, which relates to vinyl copolymer. the catalyzing system is a compound catalyzing system consisting of the single primary metallocene catalyst and two different catalyst promoters, wherein, the primary catalyst is a metallocene catalyst with a structural formula of Cp<1>MR<1>R<2>R<3>, Cp<1>Cp<2>MR<1>R<2> or Cp<1>-D-Cp<2>MR<1>R<2>; alkyl aluminium acts as an oligomerization catalyst promoter; methylaluminoxane or triisobutyl aluminium or triethyl aluminum that is not used together with the oligomerization catalyst promoter acts as a copolymerization catalyst promoter; the mole ratio between the oligomerization catalyst promoter and the primary catalyst is 10-1000 to 1, and the mole ratio between the copolymerization catalyst promoter and the primary catalyst is 20-1000 to 1. The catalytic activity of the metallocene domino catalyzing system for preparing the branched polyethylene is 5 multiplied by 10<5> to 5 multiplied by 10<7>gPE / (molM per hour), the degree of branching is 10-200 / 1000C, the molecular weight of the branched polyethylene prepared under the effect of the catalyzing system ranges from 1 multiplied by 10<5> to 4 multiplied by 10<5> and the melting point is below 120 DEG C or even no melting point exists.

Owner:HEBEI UNIV OF TECH

Catalyst for olefin polymerization or copolymerization at high temperature

The catalyst for olefin polymerization or copolymerization at high temperature consists of three components, including component A, component B and component C. The component A is solid prepared through dissolving magnesium chloride in organic epoxy compound or organic phosphorus compound to form solution, mixing the solution with titanium tetrahalide and separating assistant to separate soli, and treating with electron donor and titanium tetrahalide. The component B is mixture of aluminoxane and alkyl aluminum compound. The component C is organic silane. At polymerization temperature higher than 90 deg.c, the catalyst has high stereo selectivity and high activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic system for the preparation of polybutadienes and preparation process

InactiveUS7056998B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationRare earthPhosphoric acid

The present invention relates to a catalytic system usable for the preparation of polybutadienes by polymerisation, to a process for the preparation of said catalytic system and to a process for the preparation of polybutadienes by means of this catalytic system.A catalytic system according to the invention is based on at least:a conjugated diene monomer,an organic phosphoric acid salt of one or more rare earth metals, said salt being in suspension in at least one inert, saturated and aliphatic or alicyclic hydrocarbon solvent,an alkylating agent consisting of an alkylaluminium of formula AlR3 or HAlR2, the “alkylating agent:rare earth salt” molar ratio being greater than 5, anda halogen donor which belongs to the family of alkylaluminium halides with the exception of alkylaluminium sesquihalides,and, according to the invention, said catalytic system comprises said rare earth metal(s) in a concentration equal to or greater than 0.005 mol / l.

Owner:MICHELIN RECH & TECH SA

Cocatalyst composition and application thereof

The present invention relates to a cocatalyst composition and application thereof, in particular to a cocatalyst composition. The cocatalyst is characterized by comprising a reaction product of alkylaluminium and water, and alkyl aluminum, wherein based on A1, the molar ratio of the reaction product of the alkylaluminium and the water to the alkyl aluminum is 0.5: 1 to smaller than 4: 1. The present invention further relates to a catalyst system containing the cocatalyst composition, and application of the cocatalyst composition in non-metallocene complexe catalyzed chain alkene-cycloalkene copolymerization. Compared with the alkyl aluminum, the cost of the cocatalyst composition disclosed by the present invention is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

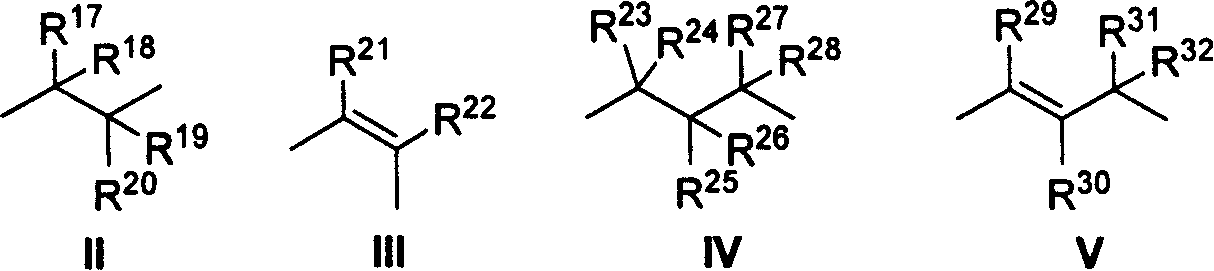

Catalyst composition having improved comonomer reactivity

A process for producing an olefin polymer, which comprises contacting at least two olefin monomers under polymerization conditions with a catalyst composition comprising A) an aluminoxane-impregnated support prepared by contacting an aluminoxane with an inert carrier material and heating to a temperature of at least about 80 DEG C.; B) a metallocene of the formula: (L)y(L')MY(x-y-1) wherein M is a metal from groups IIIB to VIII of the Periodic Table; each L and L' is independently a cycloalkadienyl group bonded to M; each Y is independently hydrogen, an aryl, alkyl, alkenyl, alkylaryl, or arylalkyl radical having 1-20 carbon atoms, a hydrocarboxy radical having from 1-20 carbon atoms, a halogen, RCO2-, or R2N-, wherein R is a hydrocarbyl group containing 1 to about 20 carbon atoms; y is 0, 1, or 2; x is 1, 2, 3, or 4; and x-y> / =1; C) a bulky aluminum alkyl of the formula: AlR1xR2(3-x) wherein R1 is a hydrocarbyl group having 1 to 12 carbon atoms; x is an integer from 0 to 2; R2 is a hydrocarbyl group of the formula -(CH2)y- R3, wherein y is an integer from 1 to 8; and R3 is a saturated or unsaturated hydrocarbyl group having 3 to 12 carbon atoms containing at least one ring, and D) methylaluminoxane is provided. The catalyst composition may be used to prepare olefin polymers having increased short chain branching frequency.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Catalyst for olefin high-temperature polymerization and preparation and use thereof

The present invention discloses catalyst for high temperature olefin polymerization and its preparation process and use. The catalyst includes: supported Ziegler-Natta catalyst of titanium halide compound and organic electron donor compound supported with MgCl2 alcoholate carrier; aluminoxane prepared with trialkyl aluminum and water; and one kind of organic electron donor, such as organosilicon compound R2Si(OCH3)2, where R is phenyl, isopropyl, isobutyl or cyclopentyl. The said catalyst can catalyze propylene polymerizing reaction at 50-120 deg.c in excellent catalytic activity, and the prepared polymer has isotactivity index of 85-99 %, number average molecular weight of 43000-104000 g / mol, molecular weight distribution index of 4.5-10.6.

Owner:ZHEJIANG UNIV

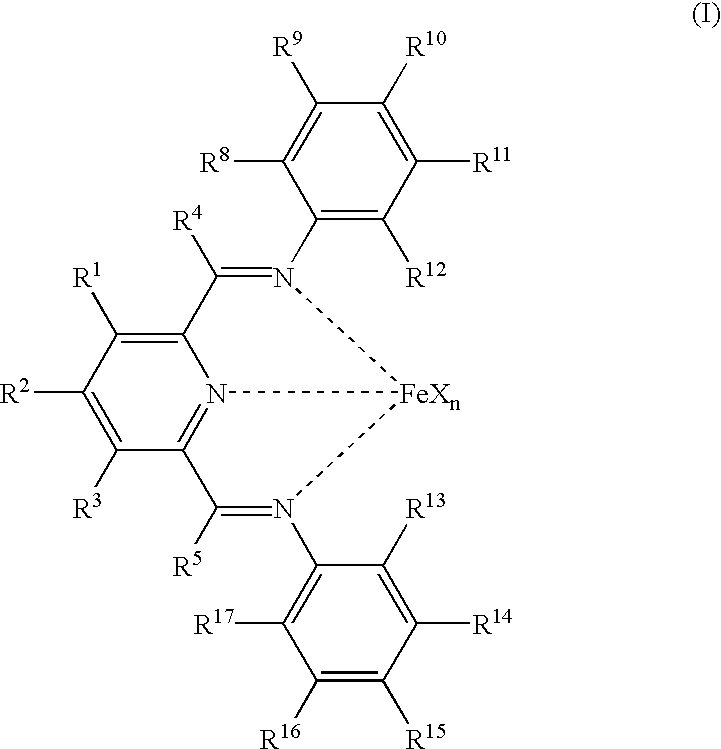

Manufacture of alpha-olefins

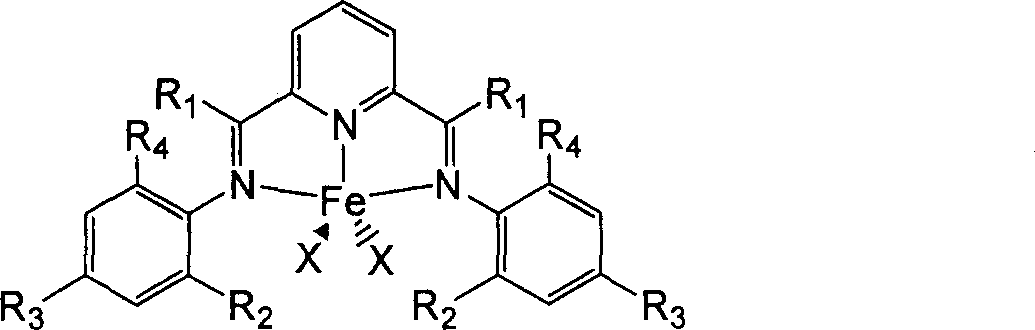

InactiveUS20030036615A1Organic-compounds/hydrides/coordination-complexes catalystsIron group organic compounds without C-metal linkagesPolymer scienceAcyl group

Alpha-olefins are manufactured in high yield and with very high selectivity by contacting ethylene with an iron complex of a selected 2,6-pyridinedicarboxaldehyde bisimine or a selected 2,6-diacylpyridine bisimine, and in some cases a selected activator compound such as an alkyl aluminum compound. Novel bisimines and their iron complexes are also disclosed. The alpha-olefins are useful as monomers and chemical intermediates.

Owner:EI DU PONT DE NEMOURS & CO +1

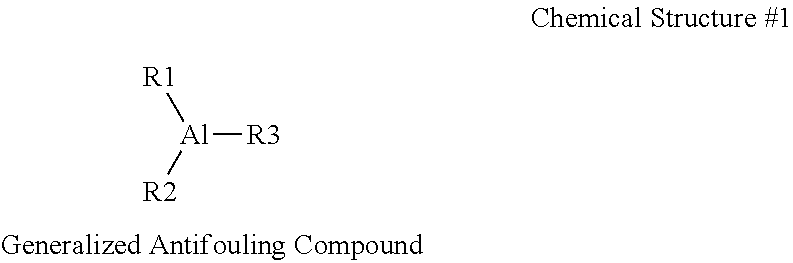

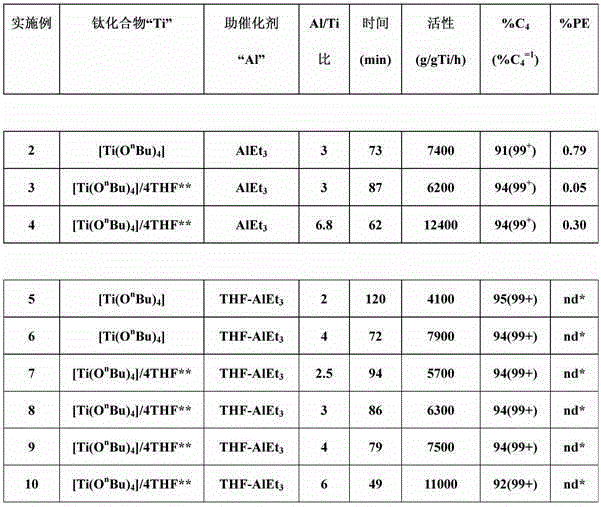

Process for selective ethylene oligomerization with antifouling components

ActiveUS10280125B2Organic-compounds/hydrides/coordination-complexes catalystsCatalystsAluminum alkylEthylene

A process for selectively producing 1-butene comprises contacting at least one antifouling agent with at least one aluminum alkyl compound to form at least one antifouling compound in a first step. The antifouling compound may comprise a structure comprising a central aluminum molecule bound to an R1 group, bound to an R2 group, and bound to an R3 group. The process further comprises feeding the antifouling compound, an additional amount of the aluminum alkyl compound, at least one titanate compound, and ethylene into a reactor to dimerize ethylene in a second step. The titanate compound is fed as a stream separated from the streams of the antifouling compound and the additional amount of the aluminum alkyl compound. The molar ratio of the sum of the aluminum alkyl compound to the titanate compound is equal to or higher than 1.5 and equal to or lower than 3.0.

Owner:SAUDI ARABIAN OIL CO +1

Broad Molecular Weight Polyethylene Having Improved Properties

InactiveUS20100291334A1Easy to controlIncrease productivityOrganic-compounds/hydrides/coordination-complexes catalystsLayered productsPolymer sciencePolyolefin

Disclosed herein is a polyolefin polymer having improved properties wherein the polymer is produced using a chromium based catalyst in combination with aluminum alkyl activators and co-catalysts. Also disclosed is a pipe comprising the inventive polymer and a film comprising the inventive polymer, each having improved properties over those known in the art.

Owner:UNIVATION TECH LLC

Catalyst for preparing ultra-high molecular weight polyethylene

The invention relates to a catalyst system of ultra-high molecular weight polyethylene, which comprises a magnesium compound carrier-supported titanium catalyst solid main component and an aluminum alkyl compound catalyst promoter component. The catalyst system of ultra-high molecular weight polyethylene is characterized in that carbon dioxide, alcohol and silicon compound are added to process the magnesium compound carrier in the preparation process of the catalyst solid main component, and the titanium content and the ester content in the catalyst system are adjusted by adjusting the addition of titanate in the processing of supporting titanium to change the growing ability of polymer on the catalyst active site, adjust the initial activity of the catalyst and improve the performance of the polymer. The catalyst has the advantage of simple preparation method, and is beneficial to industrial production. The particle diameter of ultra-high molecular weight polyethylene prepared by the catalyst is limited in a certain range, the generation of fine powder and coarse particles is reduced, and the stacking density is increased.

Owner:PETROCHINA CO LTD

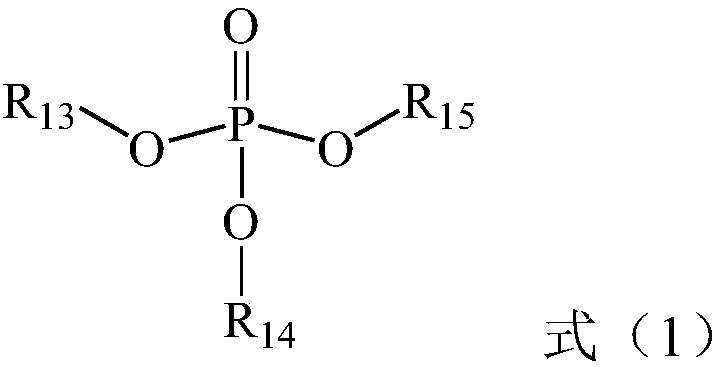

Polypropylene, preparation method and applications thereof

ActiveCN107629155AHigh isotactic indexHigh melt flow indexMonocomponent polypropylene artificial filamentNon-woven fabricsPolymer scienceElectron donor

The invention relates to the field of olefin polymerization, and particularly provides polypropylene, a preparation method and applications thereof, wherein the polypropylene has a melt flow index MFRof more than 30 g / 10 min, has an isotactic index of 96-99.5 wt%, and has a molecular weight distribution index MW / Mn of 3-5.5. The preparation method comprises: polymerizing propylene in the presenceof a catalyst under an olefin polymerization condition to obtain a polypropylene product, wherein the catalyst contains a catalyst component, an alkyl aluminum compound, and optionally an external electron donor, the catalyst component contains the product obtained by carrying out a reaction on a magnesium source, a titanium source and an internal electron donor, the internal electron donor contains a phosphate compound and a diether compound, and the phosphorus content (calculated as the phosphorus element) in the catalyst component is not more than 0.06 wt%. According to the present invention, the polypropylene integrates characteristics of high isotactic index, high melt flow index and narrow molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

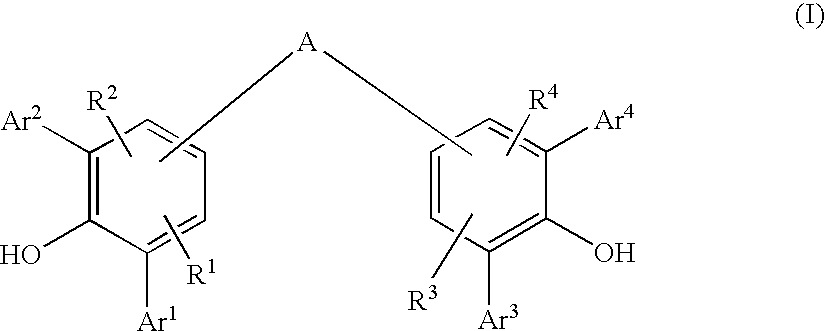

Preparation method of propylene polymer

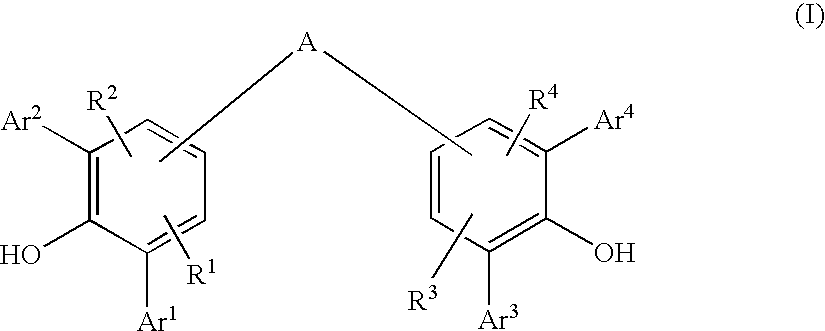

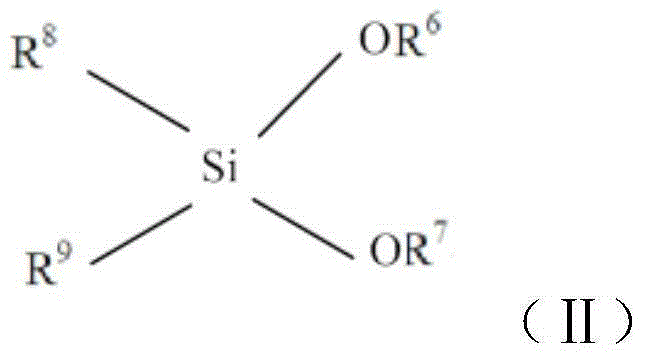

The invention relates to a preparation method of propylene polymer. The method comprises preparing the propylene polymer in the presence of a catalyst under a temperature of 80 to 150 DEG C, wherein the catalyst comprises a catalyst component, an aluminum alkyl compound and an external electron donor compound. The catalyst component is prepared by the following steps: (1) preparing an homogeneous solution; (2) contacting the solution obtained in the step (1) with a titanium compound and reacting in the presence of a precipitation aid agent to obtain a mixture; and (3) contacting the mixture in the step (2) with an internal electron donor, wherein the precipitation aid agent comprises a precipitation aid agent a which is a diol ester compound as shown in a formula (I), a precipitation aid agent b which is alkyl ester of aliphatic or aromatic carboxylic acid, a precipitation aid agent c which is a titanate compound, and a precipitation aid agent c which is 1,3-diether compound as shown in a formula (II), and a is different from b. The propylene polymer prepared by the invention has both high melt index and isotactic index.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic composition and process for the dimerisation of ethylene to 1-butene

ActiveCN105233868AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsButenePolymer science

The invention describes a catalytic composition obtained by interaction of an alkyl titanate on the one hand with a preformed mixture of an alkylaluminium and a Lewis base on the other hand. The invention also describes the use of said composition in a process for the selective dimerization of ethylene to 1-butene.

Owner:INST FR DU PETROLE

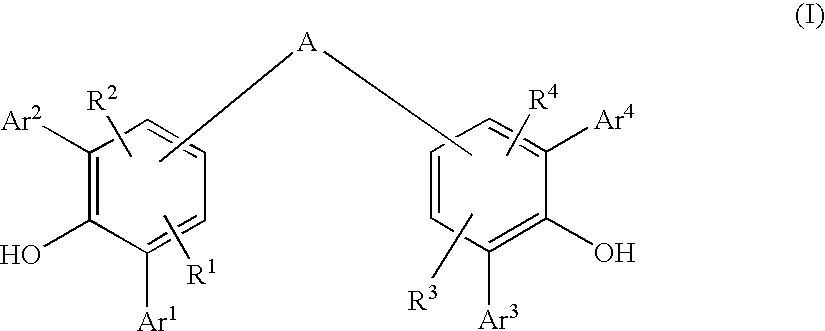

Catalyst solid component for olefin polymerization and preparation method thereof

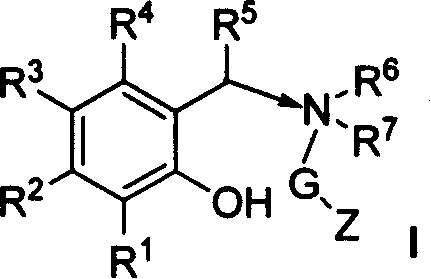

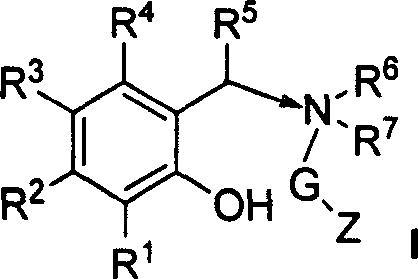

The invention discloses a catalyst solid component for olefin polymerization. A preparation method of the catalyst solid component comprises the following steps of: fully reacting anhydrous magnesium halide, an alcohol compound, titanate and a lipid compound (an internal electron donor) which is shown as picture 1 in an alkane solvent to obtain stable and uniform alcohol compound solution; contacting and reacting the prepared alcohol compound solution and titanium halide; further adding the lipid compound shown as picture 1; and after filtering and washing, obtaining the catalyst solid component. The catalyst solid component is combined with aluminum alkyl and a silane compound to form a catalyst, which can be applied to olefin polymerization.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Synthetic polyisoprenes and a process for their preparation

The present invention provides synthetic polyisoprenes having a high cis-1,4 linkage content and a process for their preparation. The synthetic polyisoprenes according to the invention have a cis-1,4 linkage content, measured by carbon-13 nuclear magnetic resonance and / or medium-wave infrared radiation analysis, of greater than 99.0%. The process for the preparation of these synthetic polyisoprenes involve polymerizing, at a temperature of 0° C. or lower, isoprene in the presence of a catalytic system based on: a) a conjugated diene monomer, b) an organic phosphoric acid salt of one or more rare earth, c) an alkylaluminium alkylating agent of the formula AlR3 or HAlR2, and d) a halogen donor consisting of an alkylaluminium halide, wherein the salt is suspended in at least one inert, saturated aliphatic or alicyclic hydrocarbon solvent and the alkylating agent:rare earth salt molar ratio ranges from 1 to 5.

Owner:MICHELIN RECH & TECH SA

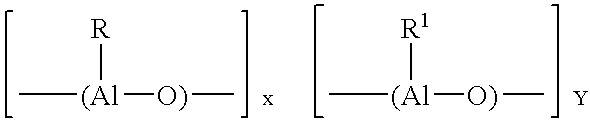

Modified (MAO + aluminum alkyl) activator

A cocatalyst system for olefin polymerization comprises an aluminoxane (especially methylaluminoxane, or “MAO”), an aluminum alkyl and a halogenated phenol. The preferred halogenated phenol is pentafluorophenol. The use of pentafluorophenol permits the substitution of a portion of the MAO cocatalyst (which is expensive) with inexpensive aluminum alkyl. The cocatalyst is most preferably employed in combination with an organometallic catalyst having at lease one pi ligand.

Owner:NOVA CHEM (INT) SA

Method for preparing butadiene/isoprene copolymers and resulting copolymers

The present invention relates to a process for the preparation random copolymers of butadiene and isoprene, essentially consisting of reacting a catalytic system in the presence of butadiene and isoprene and using, as catalytic system, a system based on at least:—a conjugated diene monomer,—an organic phosphoric acid salt of one or more rare earth metals,—an alkylating agent consisting of an alkylaluminium of the formula AlR3 or HAlR2, and—a halogen donor consisting of an alkylaluminium halide, said salt being in suspension in at least one inert, saturated and aliphatic or alicyclic hydrocarbon solvent, which is included in said catalytic system, and the “alkylating agent:rare earth salt” molar ratio falls within a range of from 1 to 8, and performing the copolymerisation reaction in an inert hydrocarbon polymerisation solvent or without solvent. These copolymers are in particular such that the butadiene and isoprene units which they comprise each have an elevated content of cis-1,4 linkages.

Owner:MICHELIN RECH & TECH SA

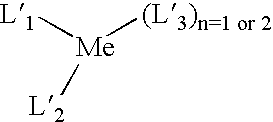

Novel Aluminum Alkyl With C5 Cyclic and Pendent Olefin Polymerization Catalyst

ActiveUS20150119540A1Low costReduced stabilityGroup 3/13 element organic compoundsAluminum alkylIon exchange

This invention relates to organoaluminum compounds, to organoaluminum activator systems, preferably supported, to polymerization catalyst systems containing these activator systems and to polymerization processes utilizing the same. In particular, this invention relates to catalyst systems comprising an ion-exchange layered silicate, an organoaluminum compound, and a metallocene.

Owner:EXXONMOBIL CHEM PAT INC

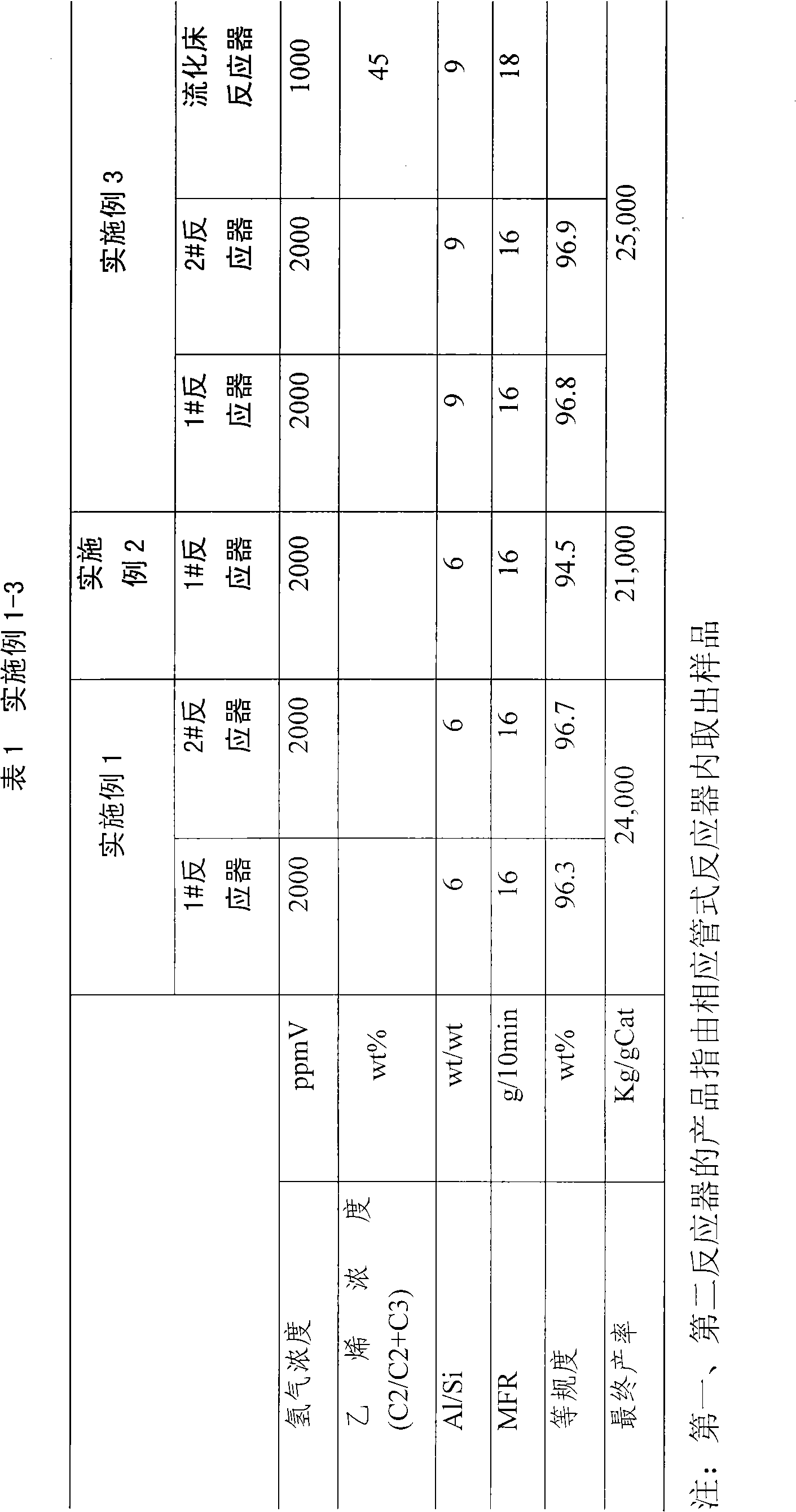

Continuous polymerization process for liquid-phase propylene bulk polymerization

The invention relates to a method used for olefin polymerization by using a plurality of serial polymerization reactors, which is characterized by comprising the following steps of: in the presence of catalysts, adding propylene into the reactors, and discharging generated polymers from outlets of the reactors. In the method, the generated polymer particles pass through reaction regions in a flow mode of piston flow; and at the outlets of the reactors, the generated polymers are all discharged, and back mixing in any mode cannot be generated. The used reactors are vertically arranged pipe reactors, and the flow mode of the fluid in the reactors is laminar flow. In one or more serially operated polymerization reactors, the first reactor is a prepolymerization reactor, the catalysts, aluminum alkyl, external electron donors and a small amount of hydrogen are added into the first prepolymerization reactor, the obtained prepolymer is added into a second reactor, and the generated polymer slurry is discharged from the outlets of the reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diarylphenoxy Aluminum Compounds

ActiveUS20080167504A1Simple wayHigh purityGroup 3/13 element organic compoundsMentholALUMINUM HYDRIDE

The present invention relates to diarylphenoxyaluminum compounds which are obtainable by reacting a bis(diarylphenol) ligand of the formula (I)with an alkylaluminum compound and / or a complex aluminum hydride.The invention moreover relates to the use of such diarylphenoxyaluminum compounds as catalysts.Moreover, the invention relates to a method of producing isopulegol by cyclization of citronellal in the presence of diarylphenoxyaluminum compounds as catalysts.The invention also relates to a method of producing menthol by cyclization of citronellal in the presence of diarylphenoxyaluminum compounds as catalysts and subsequent hydrogenation.

Owner:BASF AG

Olefin polymerization catalyst system and application thereof

The invention relates to the field of olefin polymerization, and discloses a catalyst system. The catalyst system comprises a titaniferous solid catalyst component, an aluminum alkyl compound and an external electron donor compound, wherein the titaniferous solid catalyst component contains at least two internal electron donor compounds of a polytrimethylene terephthalate type compound and a diether type compound, and the external electron donor compound is an ether base ester compound or a combination of the ether base ester compound and hydroxyl silane dialkyl oxygen radicals. The invention further provides application of the catalyst in olefin polymerization reaction. According to the catalyst system and the application of the catalyst in the olefin polymerization reaction, by adding the ether base ester compound or the combination of the ether base ester compound and the hydroxyl silane dialkyl oxygen radicals as the external electron donors to be used in the olefin polymerization reaction when the solid catalyst component with the polytrimethylene terephthalate type compound and the diether type compound being the internal electron donors is subjected to the olefin polymerization reaction, not only can the catalyst maintain high activity, but also sensibility of hydrogen regulation of the catalyst can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aza cyclic carbine rear earth catalyst for crystallinity 3,4-polyisoprene

ActiveCN101157737AHigh molecular weightNarrow molecular weight distributionChlorobenzeneReaction temperature

The present invention relates to a nitrogen heterocyclic carbene rare earth complex, a catalyst system which consists of the present invention, aluminum alkyl and an organoboron salt can catalyse the isoprene to carry out the solution polymerization, so as to prepare the polyisoprene with the crystallization property, high 3, 4-structure and high glass transition temperature (Tg). The molar ratio of aluminum alkyl and the rare earth complex is within the scope of 1 to 100, the molar ratio of the organoboron salt and the rare earth complex is within the scope of 0.5 to 2.0; the solvent which is used for polymerization can be toluene, bromobenzene, n-hexane, dichloromethane or chlorobenzene; the polymerization temperature range is -20 DEG C to 80 DEG C, the reaction time of polymerization at minus 20 DEG C is 36 hours, the reaction time of polymerization at 80 DEG C is 1 hour, and the monomer conversion rate can be up to 100 percent. The reaction is characterized by active polymerization, the molecular weight of the product can be controlled by the molar ratio of the monomer and the catalyst, the molecular weight of the polyisoprene can achieve 360,000 at most, and the glass transition temperature Tg is equal to 5 DEG C to 50 DEG C. The content of the 3, 4 structure of the polyisoprene is affected by the spatial effect and the electronic effect of the rare earth complex, the solvent type for polymerization reaction and the polymerization reaction temperature and so on, which is changed between 76 percent and 99 percent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

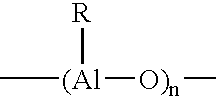

Polymethylaluminoxane preparation, method of producing the same, polymerization catalyst, and polymerization method of olefins

InactiveUS7910764B2Good storage stabilityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCarboxylic acidOxygen

A polymethylaluminoxane preparation exhibiting excellent storage stability with a high yield is provided. A polymethylaluminoxane preparation is formed by thermal decomposition of an alkylaluminum compound having an aluminum-oxygen-carbon bond, the alkylaluminum compound being formed by a reaction between trimethylaluminum and an oxygen-containing organic compound. In this preparation,(i) the oxygen-containing organic compound reacting with trimethylaluminum is an aliphatic or aromatic carboxylic acid represented by the general formula (I),R1—(COOH)n (I),wherein R1 represents a hydrocarbon group of C1-C20 straight or branched alkyl groups, alkenyl groups or aryl groups, and n represents an integer of 1 to 5;(ii) a mole fraction of methyl groups originating from trimethylaluminum, relative to the total moles of methyl groups existing in the generated polymethylaluminoxane preparation is not more than 26 mol %; and(iii) the generated polymethylaluminoxane preparation has a viscosity of not more than 2.1×10−3 Pa·sec at 40° C.

Owner:TOSOH FINECHEM CORP

Gas-phase propylene polymerization process using staged addition of aluminum alkyl

An olefin polymerization process comprises gas-phase polymerization of at least one olefin monomer in more than one polymerization zones using a high activity Ziegler-Natta catalyst system comprising a solid, magnesium-supported, titanium-containing component and an aluminum alkyl component comprising introducing the titanium-containing component and an aluminum alkyl component into the first polymerization zone and then introducing additional aluminum alkyl component into a subsequent polymerization zone without added titanium-containing component.

Owner:INEOS TECH USA

Catalyst system for in-situ copolymerizing linear low-density polyethylene

InactiveCN1935859AImprove ethylene polymerization activityLow melting pointLow-density polyethyleneLinear low-density polyethylene

The invention relates to a catalyst system used to prepare linear low density polyethylene by in situ copolymerization. The catalyst system is made up of oligomerization catalyst formed by homogeneous phase or loading type alpha-bi-imine pyridine iron series catalyst and aluminum alkyl-aluminoxane promoter, and copolymerization catalyst formed by titanium serious catalyst and alkyl aluminum or alkyl-aluminoxane promoter. The invention uses ethylene as the only monomer, makes it oligomerize to generate alpha-olefin, and process in situ copolymerization at the same time to prepare linear low density polyethylene in the same reactor which has the features of low melt pointing, low density, high mutual monomer inserting ratio, different length for side chain. And this method can simplify production technology, greatly reduce production cost.

Owner:INST OF CHEM CHINESE ACAD OF SCI

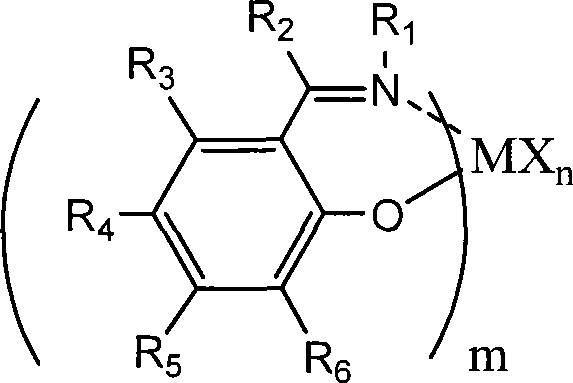

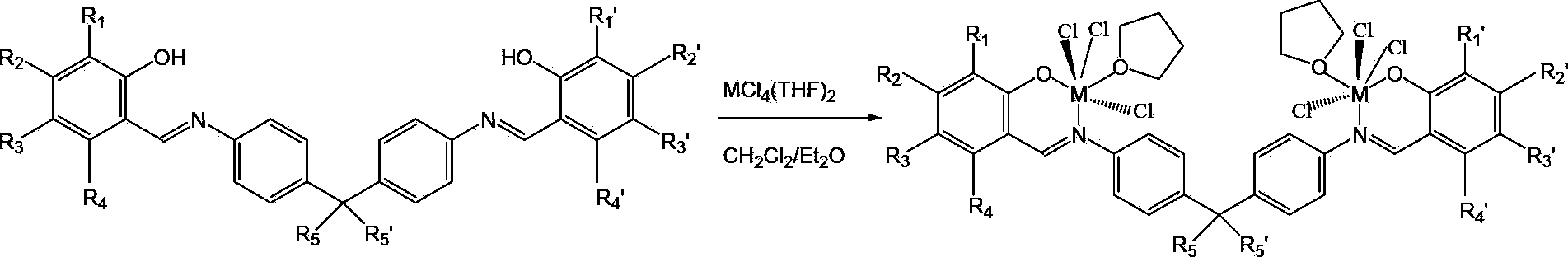

Catalyst precursor and its preparation method, catalyst and its application, and ethylene polymerization method

ActiveCN103804550AHigh polymerization activitySimple structureTitanium organic compoundsAluminoxaneOrganic solvent

The invention discloses a catalyst precursor and its preparation method, a catalyst and its application, and an ethylene polymerization method. The catalyst precursor is a bimetallic catalyst precursor which has an open structure shown as a formula I and is based on a salicylaldehyde imine ligand, the preparation method of the catalyst precursor is as follows: under complexation reaction conditions, contacting a compound having a structure shown as a formula IV with a compound with a molecular structure general formula of MCl4 (THF) 2 in an organic solvent; the catalyst provided by the invention comprises the catalyst precursor and alkyl aluminoxane; the invention also provides the application of the catalyst in olefin polymerization, the invention also provides the ethylene polymerization method which is as follows: under olefin polymerization conditions, in the presence of an organic solvent, contacting ethylene with the catalyst precursor and the alkyl aluminoxane for polymerization. The preparation method of the catalyst precursor is simple, and the catalyst is high in catalytic efficiency. The formula I and the formula IV are shown in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin polymerization catalyst system and applications thereof

ActiveCN106543313AHigh polymerization activityGood hydrogen sensitivityElectron donorMelt flow index

The present invention relates to the field of olefin polymerization, and discloses a catalyst system, which comprises a titanium-containing solid catalyst component, an alkyl aluminum compound and an external electron donor compound, wherein the titanium-containing solid catalyst component comprises at least two internal electron donor compounds such as a diol ester compound and a carboxylic acid ester, and the external electron donor compound is the combination of an ether ester compound and alkyl dialkoxysilane. The present invention further provides applications of the catalyst in olefin polymerization reactions. According to the present invention, when the solid catalyst component using the diol ester compound and the carboxylic acid ester as the internal electron donors is subjected to the olefin polymerization reaction, the compounding of the ether ester compound and the alkyl dialkoxysilane is added and used as the external electron donor used in the olefin polymerization reaction, such that the catalyst can maintain the high activity, and the melt index of the obtained polymer can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com