Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

A technology of branched polyethylene and catalytic system, which is applied in the field of domino catalytic system, can solve the problems of high production cost of branched polyethylene and high synthesis cost of oligomerization catalyst, and achieve the effect of reducing synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

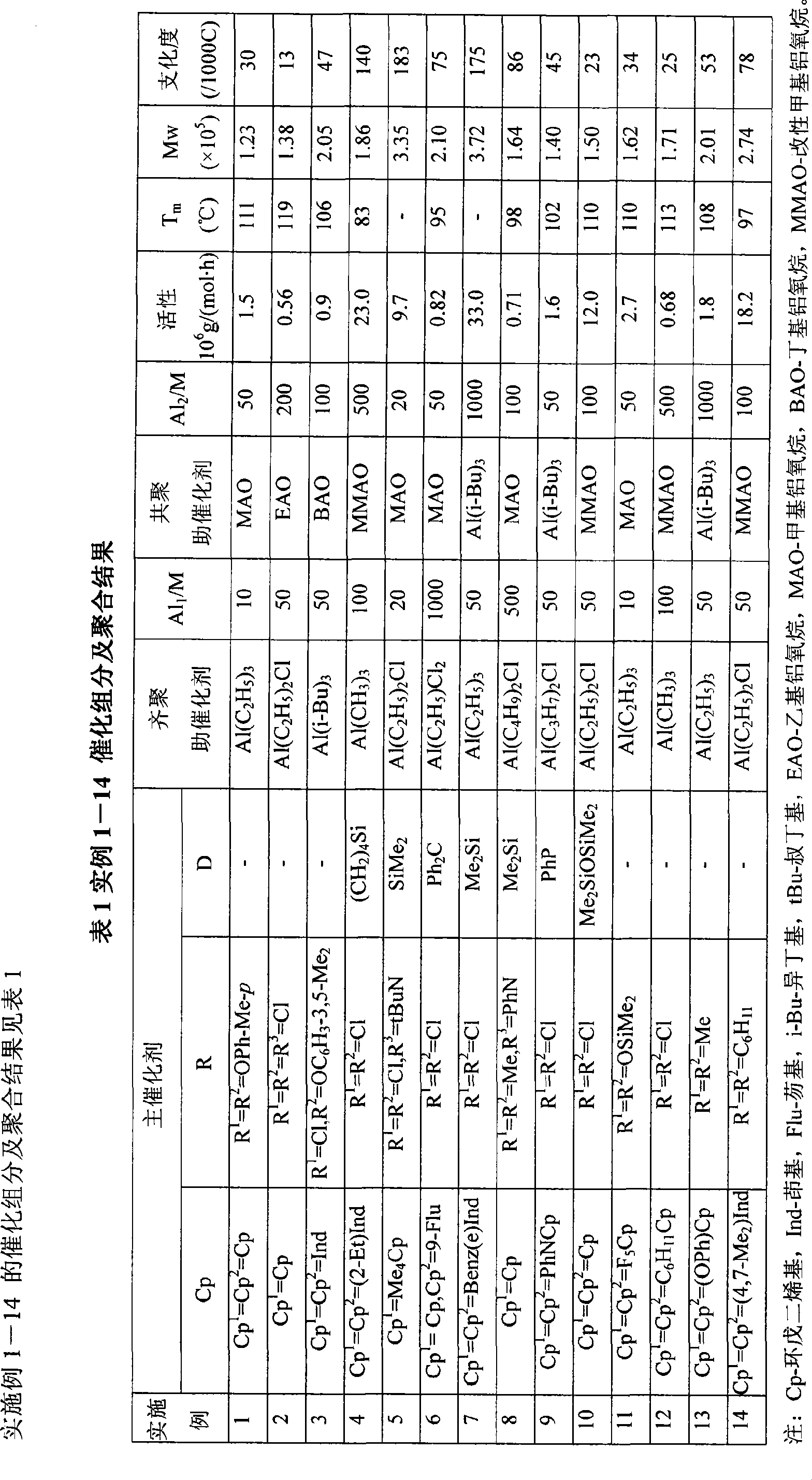

Examples

Embodiment 1

[0029] Add 50ml of xylene distilled by reflux of metal sodium to a 250ml reactor that has been replaced three times with nitrogen and twice with ethylene, stir and raise the temperature to 60°C, and feed ethylene to keep the pressure in the reactor at 3.0MPa. Solvent xylene 6×10 -6 The proportion of mol main catalyst is added to the main catalyst Cp 2 Zr(O-Ph-Me-p) 2 , and the molar ratio of Al to the main catalyst 1 : M=10 oligomerization cocatalyst Al(C 2 h 5 ) 3 , after prepolymerization for 0.5h, keep the reactor at 0.6MPa, temperature 0℃, add the molar ratio of Al to the main catalyst, that is, Al 2 : the co-catalyst MAO of M=50, polyreaction 0.5 hour, finally add 10ml volume percent concentration and be 10% acidified ethanol (that is 37% concentrated hydrochloric acid by volume ratio: dehydrated alcohol=1:9, known in the art) To the termination of the reaction, wash the generated polymer with water and industrial ethanol, filter the polymer, and then dry it in a va...

Embodiment 2

[0031] Add 50ml of xylene distilled by reflux of metal sodium to a 250ml reactor that has been replaced three times with nitrogen and twice with ethylene, stir and heat up to 80°C, feed ethylene to keep the pressure in the reactor at 3.5MPa, Solvent xylene 3×10 -5 The proportion of mol main catalyst is added to the main catalyst CpZrCl 3 , and the molar ratio of Al to the main catalyst 1 : the oligomerization promoter Al(C of M=50 2 h 5 ) 2 Cl, after prepolymerization for 1 hour, keep the reactor at 0.1MPa, temperature 60°C, add the molar ratio of Al to the main catalyst, that is, Al 2 : M=200 co-catalyst co-catalyst EAO, polymerization reaction 1 hour, finally add 10ml10% acidified ethanol to terminate, water, industrial ethanol wash the polymer that generates, filter polymer, then dry 6 hours in 70 ℃ of vacuum ovens, The polymer branched polyethylene was obtained with an activity of 5.6×10 5 g / (molM·h), the degree of branching is 13 / 1000C, the melting point of the poly...

Embodiment 3

[0033] Add 50ml of xylene distilled by reflux of metal sodium into a 250ml reactor that has been replaced three times with nitrogen and twice with ethylene, stir and raise the temperature to 120°C, and feed ethylene to keep the pressure in the reactor at 1.4MPa. Solvent Xylene 5×10 -3 The proportion of mol main catalyst is added to Ind 2 ZrCl(OC 6 h 3 -3,5-Me 2 ), and the molar ratio of Al to the main catalyst 1 : M=50 oligomerization promoter Al(i-Bu) 3 , after pre-polymerization for 0.5h, keep the reactor at 0.4MPa, temperature 20℃, add Al 2 : M=100 co-catalyst BAO, polymerization reaction 0.5 hour, finally add 10ml10% acidified ethanol to terminate, water, industrial ethanol wash the polymer that generates, filter polymer, then dry 6 hours in 70 ℃ of vacuum ovens, The polymer branched polyethylene was obtained with an activity of 9×10 5 g / (molM·h), the degree of branching is 47 / 1000C, the melting point of the polymer branched polyethylene is 106°C, Mw=205000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com