Preparation method of nano layered ZSM (Zeolite Molecular Sieve)-5 zeolite molecular sieve

A ZSM-5, nano-layered technology is applied in the field of preparation of nano-layered ZSM-5 zeolite, which can solve the problems of high cost and complicated process, and achieves reduced pollution, high product purity and crystallinity, and reduced synthesis cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

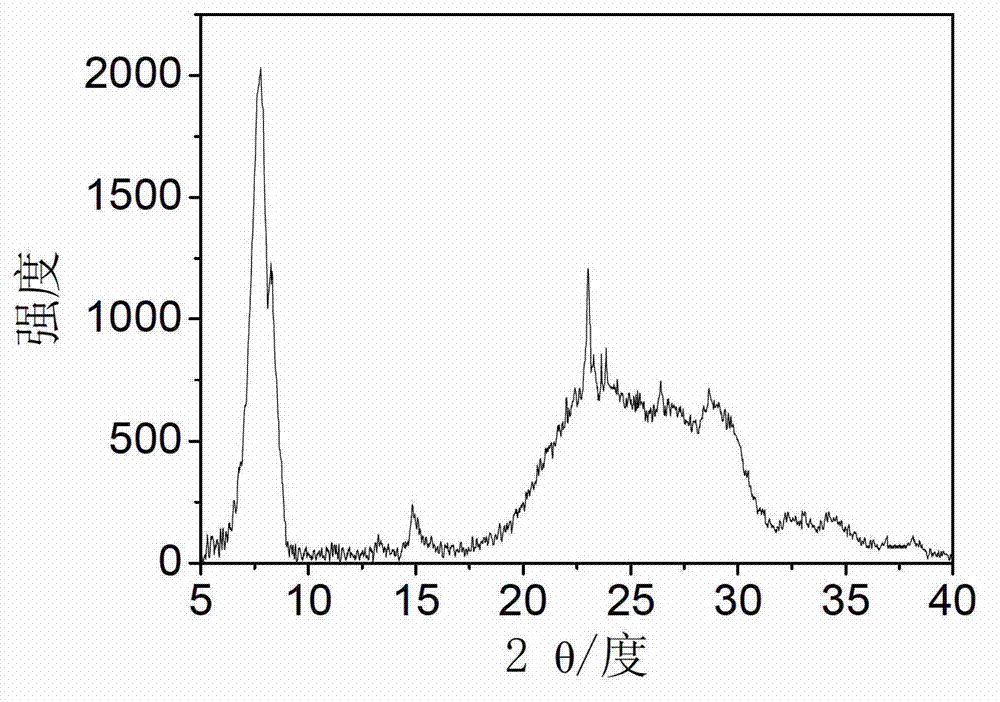

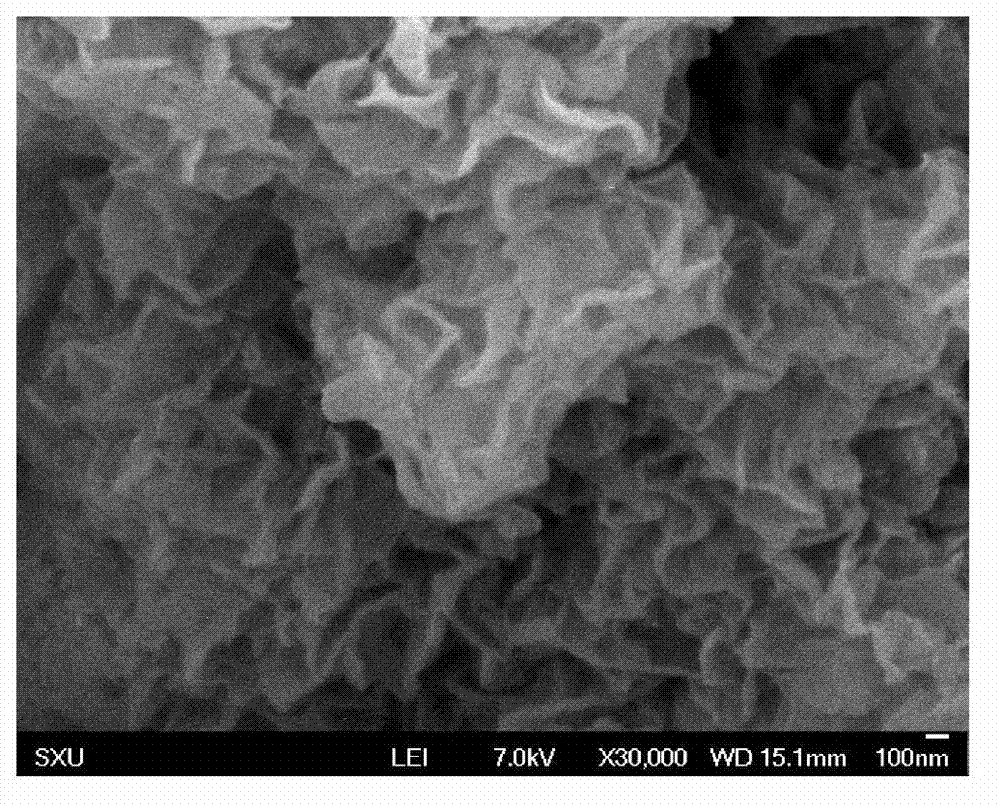

Embodiment 1

[0012] Embodiment 1: According to 1Al 2 o 3 :100SiO2 2 :1Na 2 O:10TPA 2 O:1000H 2 The molar ratio of O, 0.35g sodium aluminate, 30g tetraethyl orthosilicate, 23g tetrapropyl ammonium hydroxide (25wt%), 0.01g sodium hydroxide and 3.0g deionized water were stirred evenly at room temperature to obtain Transparent zeolite precursor solution. Take 2g of the prepared zeolite precursor solution (the rest of the zeolite precursor solution is used as a conventional hydrothermal synthesis system, which is directly crystallized, compared with the method in the present invention), and slowly added to 10g of n-heptane, 5g of hexadecyl In a solution composed of trimethylammonium bromide and 3g n-butanol, stir at 60°C to obtain a microemulsion system, and the final mass ratio is zeolite precursor solution: oil phase: surfactant: co-surfactant = 1:5 :2.5:1.5. The prepared solution was transferred into a crystallization kettle, sealed and crystallized at 120°C for 48h. After the crysta...

Embodiment 2

[0013] Example 2: The zeolite precursor solution was prepared as in Example 1. Mix 4.8g of zeolite precursor solution, 4.8g of n-heptane, 6g of cetyltrimethylammonium bromide and 2.4g of n-butanol at 60°C, and stir until the system is uniform. The prepared solution was transferred into a crystallization kettle, sealed and crystallized at 120°C for 48h. The crystallization kettle was taken out, cooled rapidly, and the product was separated by centrifugation, washed to neutrality, dried at 110°C, and characterized by XRD and SEM techniques. The results showed that the product was ZSM-5 zeolite molecular sieve. SEM results show that the sample is nano-layered, and the thickness of the thin layer is 32nm. Nitrogen adsorption results show that its specific surface area is 558m 2 / g, the pore volume is 0.20cm 3 / g.

Embodiment 3

[0014] Example 3: The zeolite precursor solution was prepared as in Example 1. Mix 4.8g of zeolite precursor solution, 4.8g of n-heptane, 6g of cetyltrimethylammonium bromide and 2.4g of n-butanol at room temperature, and stir until the system is uniform. The prepared solution was transferred into a crystallization kettle, sealed and crystallized at 90°C for 72h. The crystallization kettle was taken out, cooled rapidly, and the product was separated by centrifugation, washed to neutrality, dried at 110°C, and characterized by XRD and SEM techniques. The results showed that the product was ZSM-5 zeolite molecular sieve. SEM results show that the sample is nano-layered, and the thickness of the thin layer is 28nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com