Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122 results about "Triisobutylaluminium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triisobutylaluminium (TiBA) is an organoaluminium compound with the formula Al(CH₂CH(CH₃)₂)₃. This colorless pyrophoric liquid is mainly used to make linear primary alcohols and α-olefins.

Application of supported non-metallocene catalyst in ethene polymerization process by slurry method

The invention discloses an application of load non- metallocene catalyst in the slurry process for vinyl polymerying, the load non- metallocene catalyst and catalyst promoter forming the catalytic system, the alkene polymerization comprising: vinyl homopolymerization, combined polymerization of vinyl with propylene, butylenes, hexane, octane or norbornene; the catalyst carrier being chosen from: inorganic oxide of metallic oxide from IIA, IIIA, IVA, and IVB groups, or oxided mixture and mixing oxide; the catalyst promoter being chosen from: methylaluoxane, ethylaluoxane, isobutylaluoxane, trimethylaluminum,triethylaluminum,triisobutylaluminum,methylaluoxane-trimethylaluminum or methylaluoxane-triethylaluminum; the mole proportion between the catalyst promoter and catalyst being Al / Ti= 1:1-500. The inventioin is characterized by the less methylaluoxane consumption, stable reaction, easy-to-control polymerization temperature and non still-sticking phenomenon. The produced polyolefine possesses perfect granual shape, and the maximum polymer clamp density can reach 0.385 g / ml.

Owner:SINOPEC YANGZI PETROCHEM

Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

InactiveCN101392036ALower synthesis costAchieve the effect of molecular tailoringTriisobutylaluminiumStructural formula

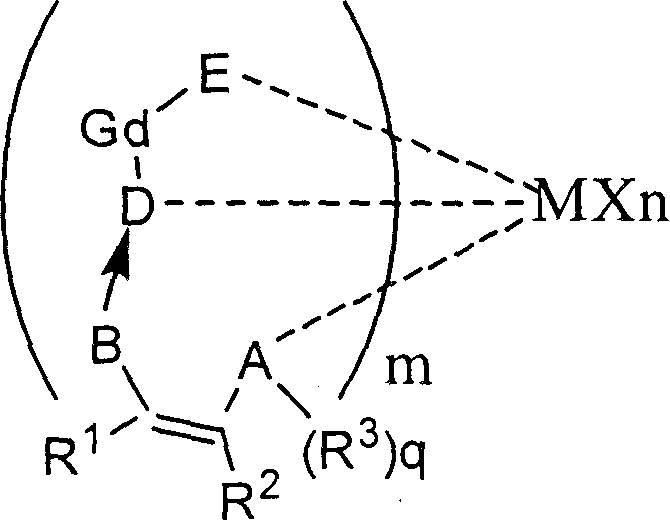

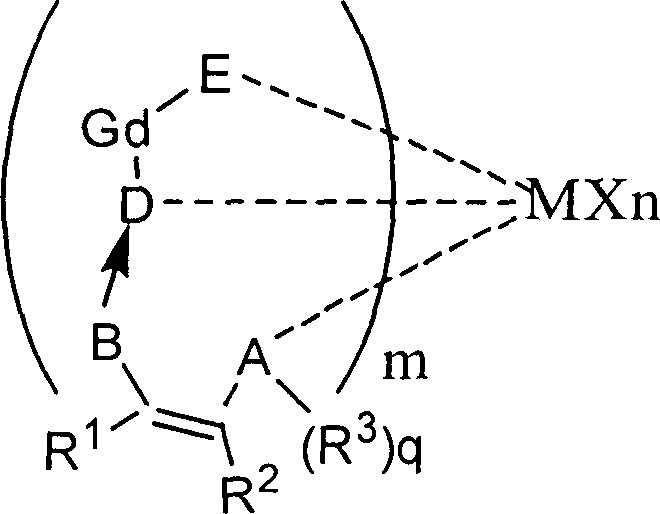

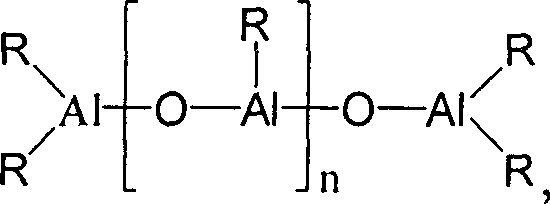

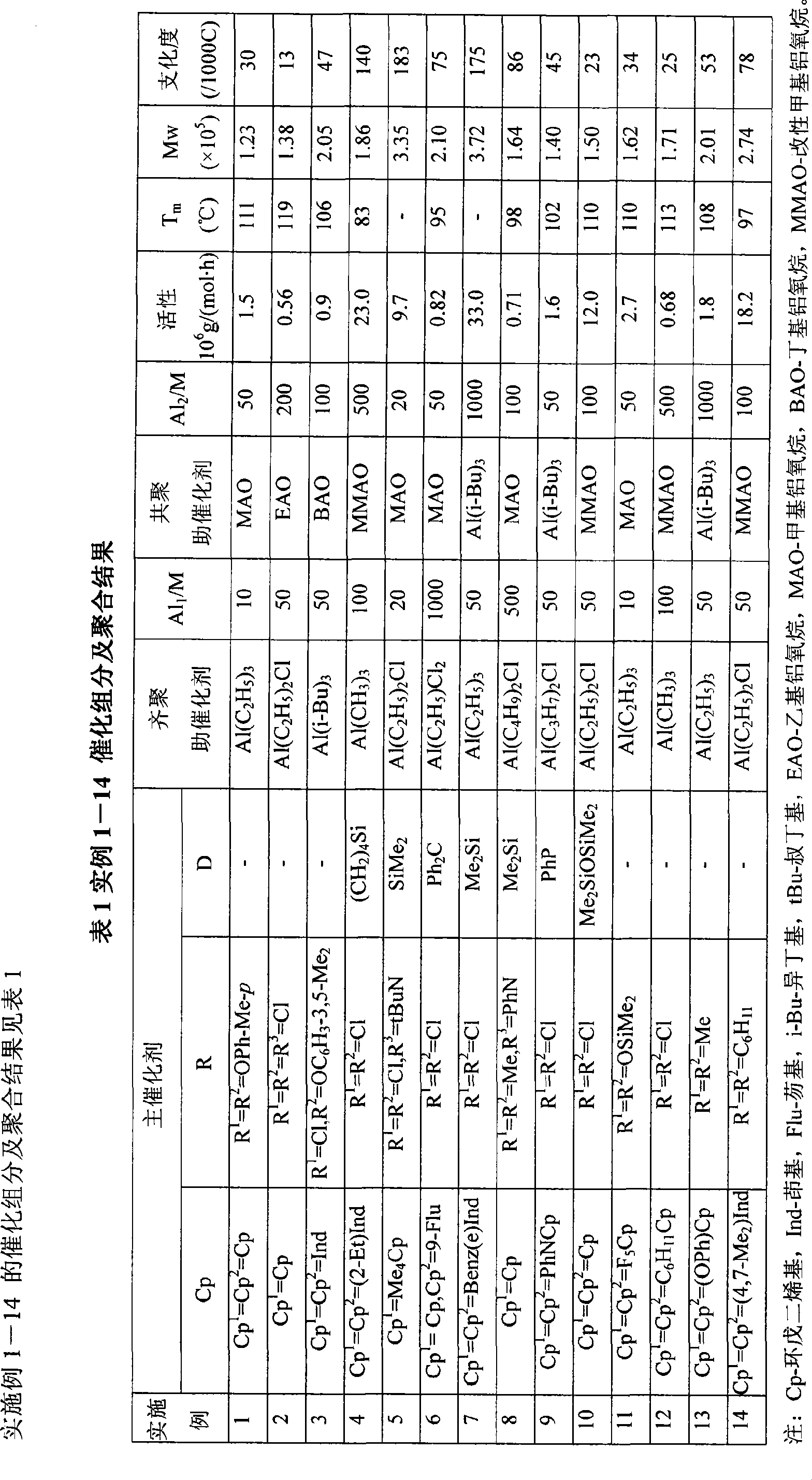

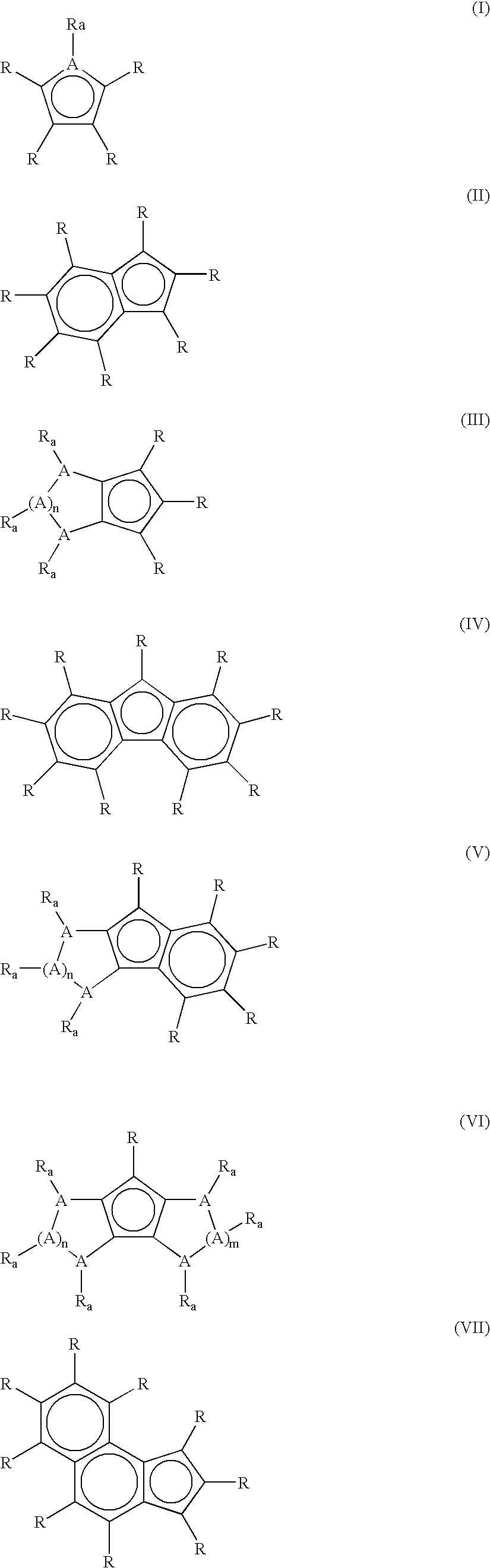

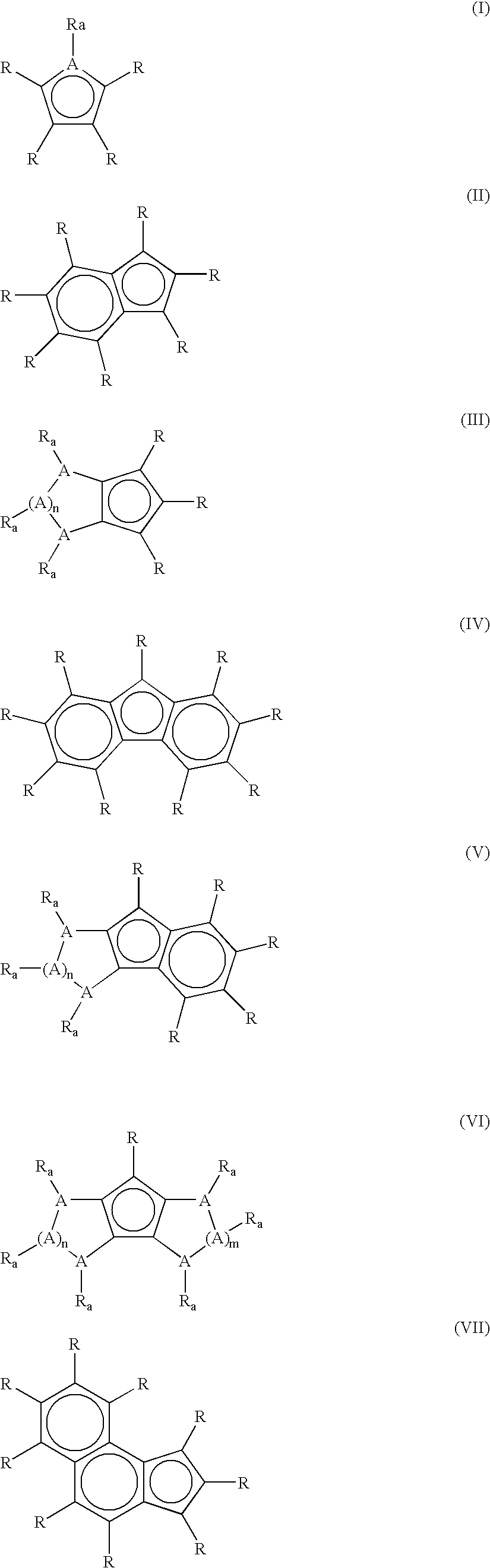

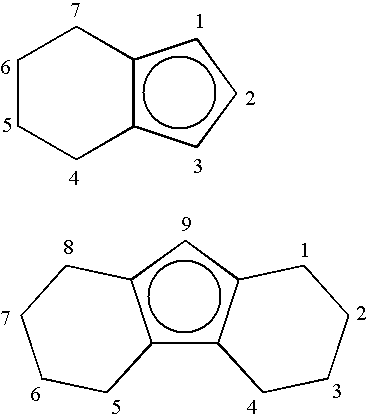

The invention discloses a domino catalyzing system of a primary metallocene catalyst, which takes ethane as a sole monomer to prepare branched polyethylene, and the application thereof, which relates to vinyl copolymer. the catalyzing system is a compound catalyzing system consisting of the single primary metallocene catalyst and two different catalyst promoters, wherein, the primary catalyst is a metallocene catalyst with a structural formula of Cp<1>MR<1>R<2>R<3>, Cp<1>Cp<2>MR<1>R<2> or Cp<1>-D-Cp<2>MR<1>R<2>; alkyl aluminium acts as an oligomerization catalyst promoter; methylaluminoxane or triisobutyl aluminium or triethyl aluminum that is not used together with the oligomerization catalyst promoter acts as a copolymerization catalyst promoter; the mole ratio between the oligomerization catalyst promoter and the primary catalyst is 10-1000 to 1, and the mole ratio between the copolymerization catalyst promoter and the primary catalyst is 20-1000 to 1. The catalytic activity of the metallocene domino catalyzing system for preparing the branched polyethylene is 5 multiplied by 10<5> to 5 multiplied by 10<7>gPE / (molM per hour), the degree of branching is 10-200 / 1000C, the molecular weight of the branched polyethylene prepared under the effect of the catalyzing system ranges from 1 multiplied by 10<5> to 4 multiplied by 10<5> and the melting point is below 120 DEG C or even no melting point exists.

Owner:HEBEI UNIV OF TECH

Catalyst of ethylene trimerization, and application

ActiveCN1872416AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChromium(III) acetylacetonateTriisobutylaluminium

A catalyst for the self-polymerization of the ethene with three molecule to selectively generate 1-hexene is prepared from the Cr compound, the ligand containing P and / or N, aluminum alkylide, and promoter in the mole ratio of 1: (0.5-100): (50-5000): (0.5-100).

Owner:PETROCHINA CO LTD +1

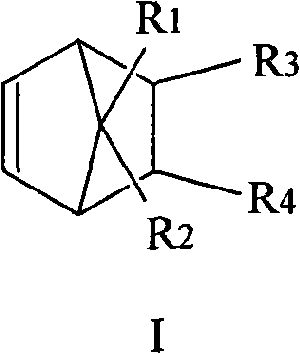

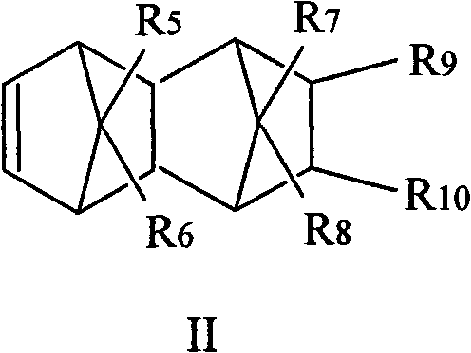

Cyclic olefin copolymer with polar group and preparation method thereof

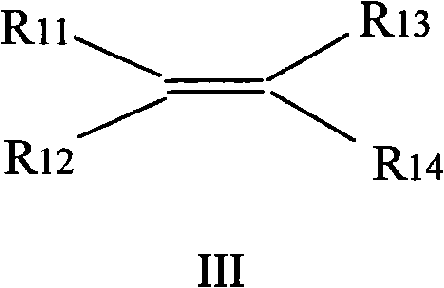

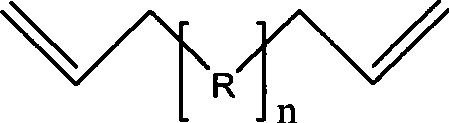

The invention relates to a cyclic olefin copolymer with polar group and a preparation method thereof. The cyclic olefin copolymer comprises the components by molar percent: 20-79.5% of cyclic olefin monomer with general formula I and / or general formula II, 20-79.5% of non-cyclic-olefin monomer with general formula III, and 0.5-20% of polar non-cyclic-olefin monomer with general formula IV. The preparation method of the cyclic olefin copolymer adopts a solution polymerization method; the cyclic olefin monomer, the non-cyclic-olefin monomer and the polar non-cyclic-olefin monomer protected by triisobutyl aluminium are added into a reaction kettle under the condition that metallocene main catalyst and alkyl aluminium catalyst accelerator exist, and then are stirred for polymerization reaction at the temperature of 30-100 DEG C under the atmospheric pressure of 1-100. The prepared cyclic olefin copolymer which has high content of cyclic olefin and the polar group has high heat resistance and cohesive property as well as good compatibility of organic matters.

Owner:ZHEJIANG UNIV

Process for producing high cis-polybutadiene rubber

A production process of cis-rich polybutadiene is to polymerize 1,3-butadiene under the temperature of 40~120íµ in hydrogenated gasoline. The process is characterized in that the initiation system is composed of nickel naphthenate, triisobutylaluminum, boron trifluoride D complex, wherein, D is a C6~C18 alcohol, an ester composed of C2~C4 alkyl acid and C4~C6 alkyl alcohol, or a R3N tertiary amine substance wherein the R is a C4~C8 alkyl. By regulating the content of boron trifluoride D complex, a cis-rich polybutadiene with 25~100 Mooney viscosity, less than 0.05% gel can be synthesized. The cis-rich polybutadiene has improved processing properties and stress at definite elongation, lower Mooney viscosity by 10 Mooney unit than that of general cis-1,4-polybutadiene rubber BR900 with the same molecular weight. The invention has advantages of low energy consumption, simple operation, steady production, long running period, and high conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP

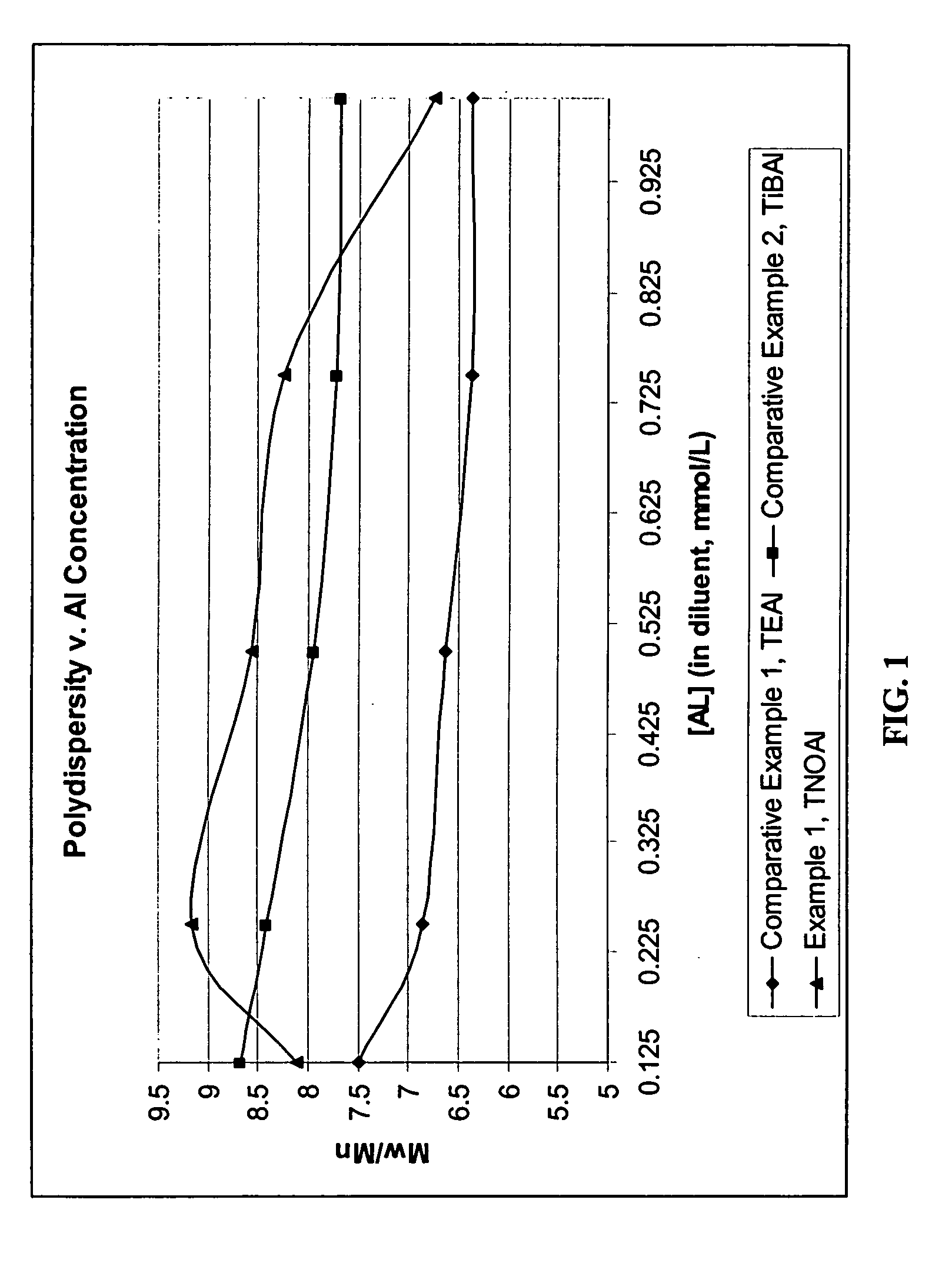

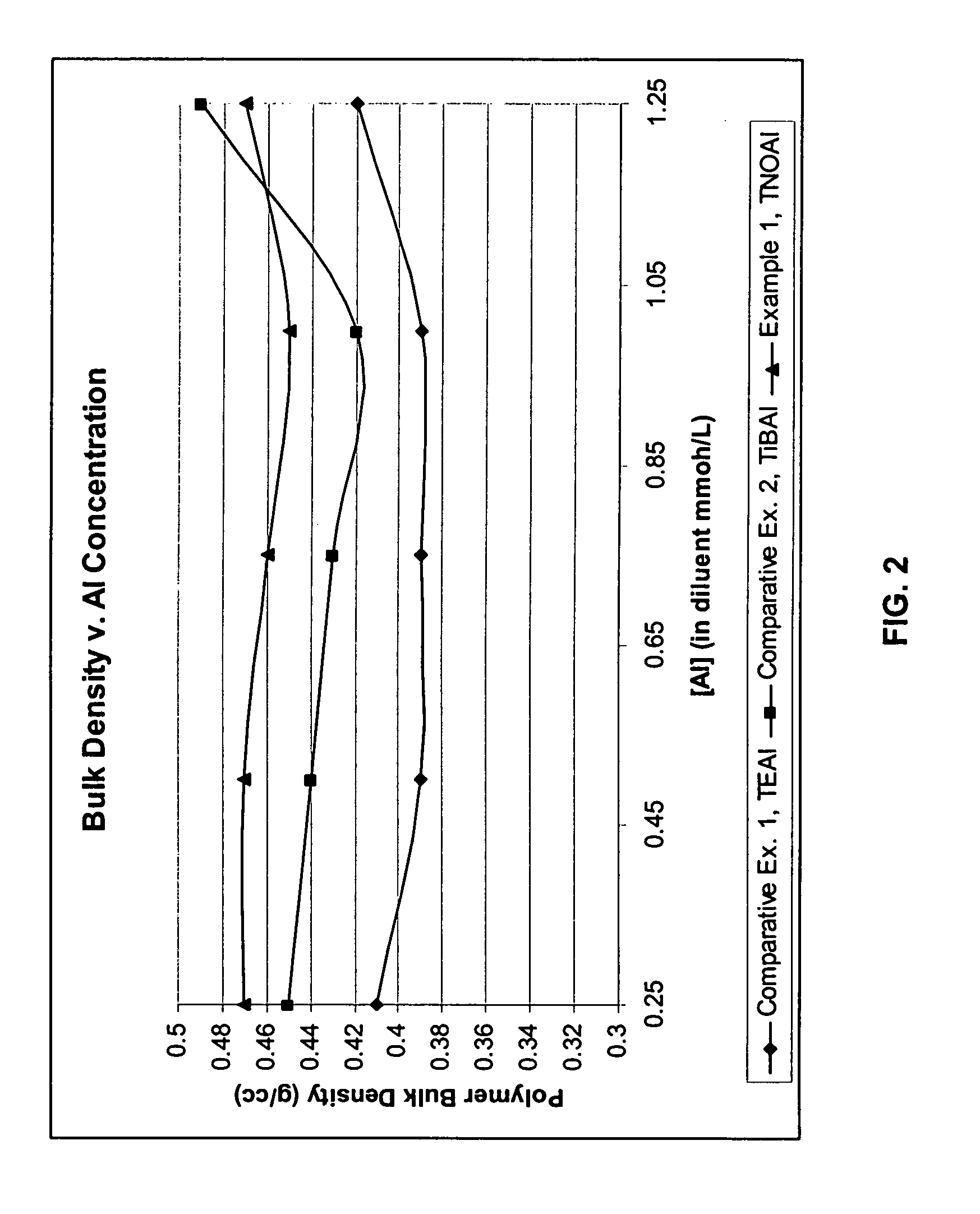

Olefin polymerization process using triisobutylaluminum as a scavenger

Ethylene and optional comonomers are polymerized using a supported metallocene catalyst, an alumoxane activator, and triisobutylaluminum (TIBAL). A silica support is first pretreated with a silane compound and then with an organoboron compound. The treated silica is then combined with a Group 4 metallocene complex and an alumoxane to generate a supported, activated catalyst. While it was previously thought that the particular support treatment technique used herein provided benefits only for polymerizations catalyzed by non-metallocene single-site complexes, it has now been found that similar benefits can be realized even with conventional metallocenes if TIBAL is selected as the scavenger.

Owner:EQUSR CHEM LP

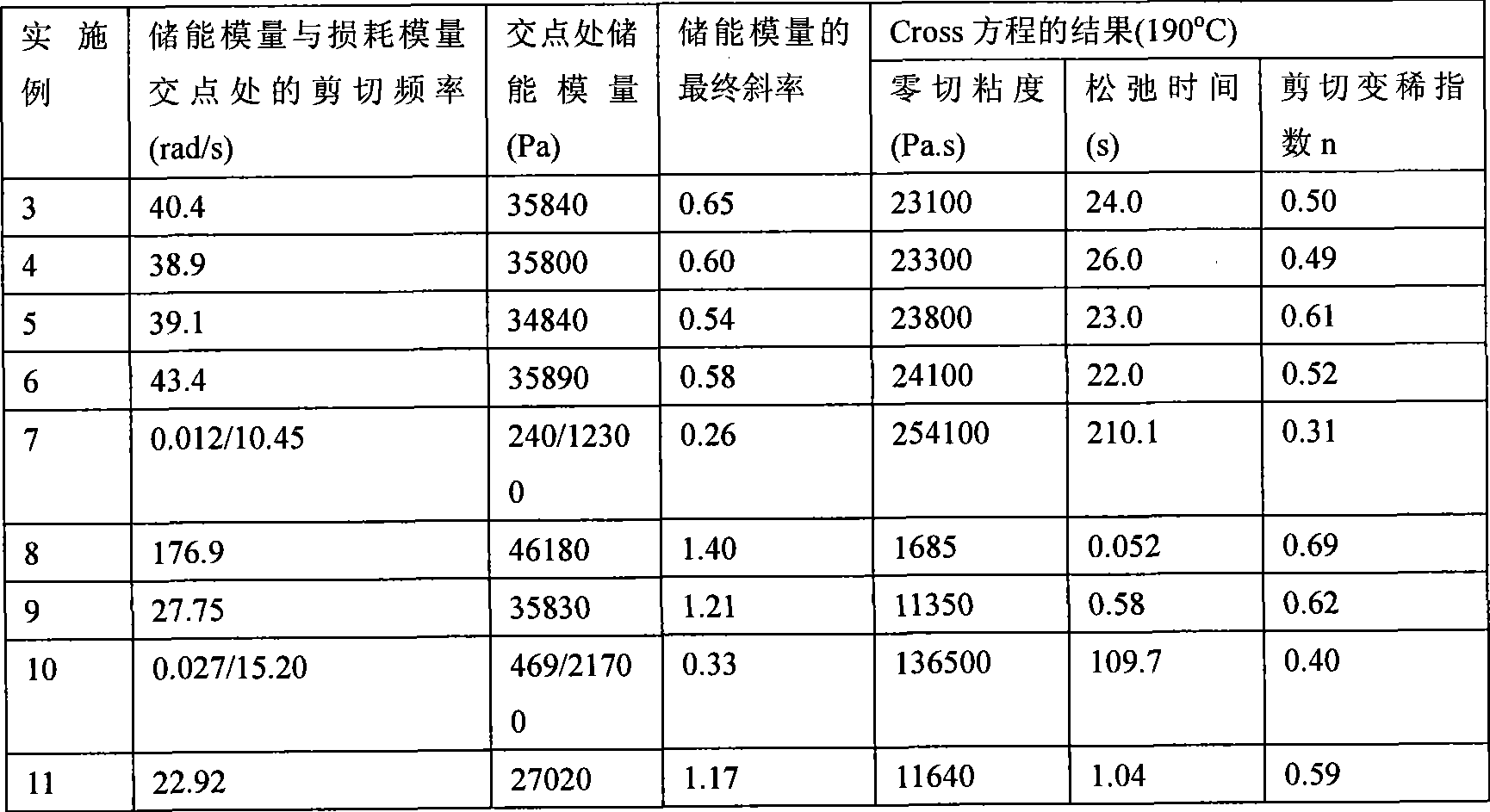

Preparation of high melt strength polypropylene

The invention relates to a preparation method for high bath strength polypropylene with long chain branching. The preparation method comprises the following steps: in a vacuum status, charging a propylene monomer into a reaction kettle, adding 10 to 100mL of solvent, 1 to 1,000mmol non-conjugation Alpha, Omega-diolefin monomer, an external electron donor, a promoter and a main catalyst; setting the mol ratio of the promoter to the main catalyst to 10 to 5,000, setting the mol ratio of the main catalyst to the external electron donor to 1 to 100, setting the reaction temperature between 0 and 100 DEG C, setting the reaction pressure between 0.1 and 10MPa, setting the reaction time between 0.1 and 100 hours, adding acidified alcohol to terminate the polyreaction, and obtaining the high bath strength polypropylene after washing and vacuum drying. The main catalyst is a Ziegler-Natta catalyst; and the promoter can be aluminum triethyl, trimethylaluminum or triisobutyl aluminum. The process is simple and has good processing performance. The high bath strength polypropylene with different performance can be prepared through adjusting the dosage of Alpha, Omega-diolefin.

Owner:PETROCHINA CO LTD

Polypropylene alloy and preparation method thereof

The present invention relates to one kind of polypropylene alloy and its preparation process. The polypropylene alloy is prepared with propylene monomer, Ti, Cl, Mg, diester or diether in certain weight proportion, and through bulk polymerization after adding supported spherical catalyst and composite co-catalyst at 40-80 deg.c and 1.0-4.0 MPa for 1-2hr; and further polymerization after adding monocyclopentadiene Ti or Zr homogeneous catalyst and composite co-catalyst for other 1-3 hr to obtain spherical granular product. The polypropylene alloy has high bending modulus and high impact strength.

Owner:PETROCHINA CO LTD

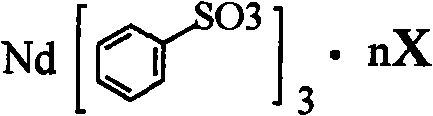

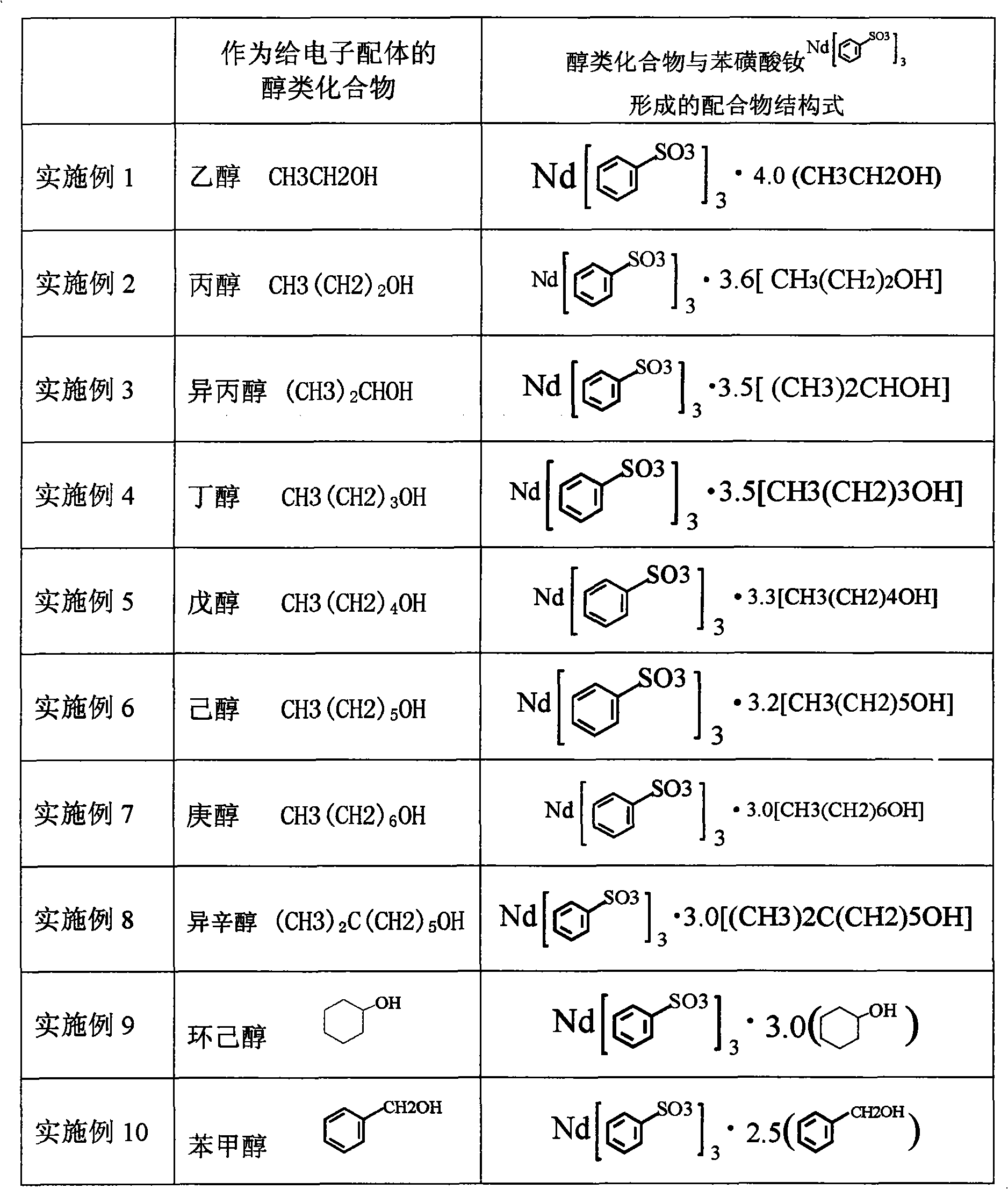

Sulfoacid rare earth catalyst for polymerizing high-cis-isoprene rubber and preparation method thereof

The invention relates to a sulfoacid rare earth catalyst for polymerizing high-cis-isoprene rubber and a preparation method thereof. The catalyst comprises benzenesulfonic acid neodymium rare earth complex and alkyl aluminum; the molar ratio of the alkyl aluminum to the rare earth neodymium in the benzenesulfonic acid neodymium rare earth complex is 15 to 40:1, wherein the benzenesulfonic acid neodymium rare earth complex comprises benzenesulfonic acid neodymium alcohol complex, benzenesulfonic acid neodymium sulphoxide complex, benzenesulfonic acid neodymium furan complex, benzenesulfonic acid neodymium amine complex, benzenesulfonic acid neodymium ether complex and benzenesulfonic acid neodymium ester complex; ligand comprises: alcohol compound, sulfoxide compound, furan compound, amine compound, ether compound and ester compound; and the alkyl aluminum comprises: 3-isobutyl aluminum, triethyl aluminum, diisobutyl aluminum hydride, or diethyl aluminum hydride. The sulfoacid rare earth complex catalyst is used for polymerizing isoprene, and can obtain the high-cis rare earth polyisoprene rubber with the cis 1,4 structure content more than 96.0 percent and the weight-average molecular weight more than 2.2 million.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Carried catalyzer for olefinic polymerization and preparation method

A carried metallocene catalyst or post-transition metal catalyst for the catalytic polymerization of ethylene and propylene contains Zr or Fe (0.05-1.00 wt. portions), aluminium alkylide chosen from trimethyl aluminium, triethyl aluminum and triisobutyl aluminum (1-50) and molecular sieve-like calcium silicon compound (100). Its preparing process is also disclosed. Its advantages are high catalytic activity and no adhesion to reactor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

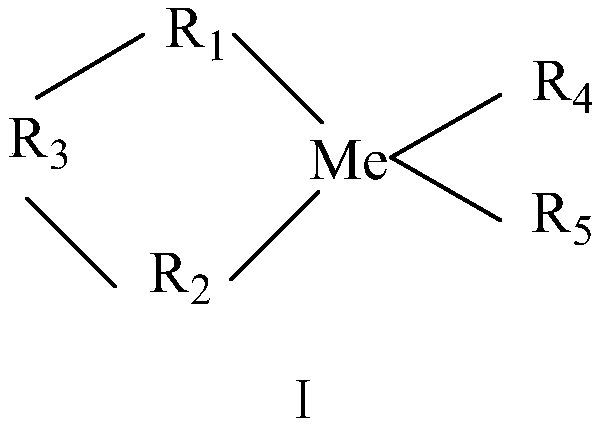

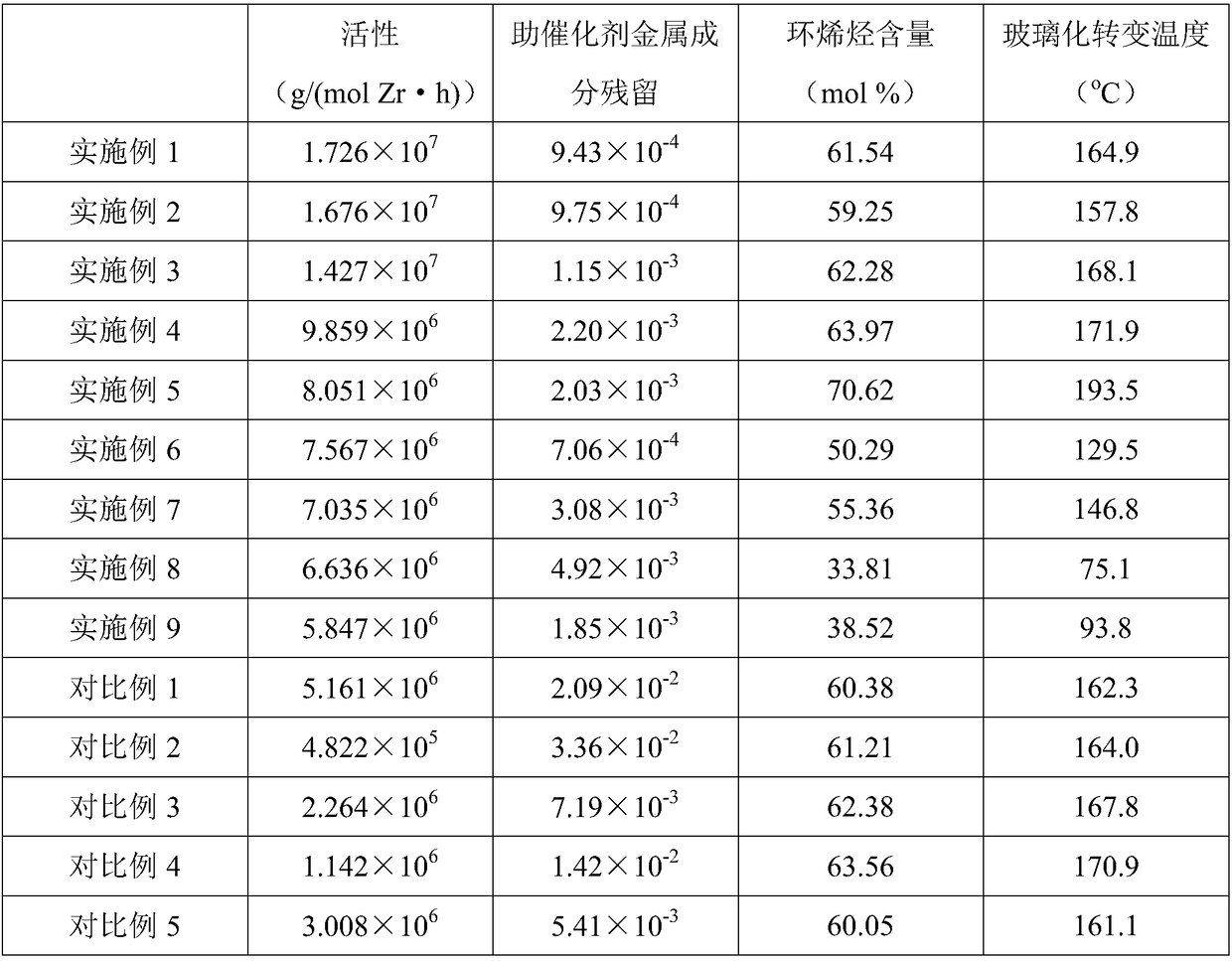

Method for preparing copolymer of ethylene and/or alpha-olefin and cycloolefin and catalysis system thereof

The invention discloses a catalysis system for preparing a copolymer of ethylene and / or alpha-olefin and cycloolefin. The catalysis system comprises a main catalyst and cocatalysts. The main catalystis a metallocene compound. The cocatalysts comprise an organoboron compound and alkyl aluminum. The invention also discloses a method for preparing the copolymer of ethylene and / or alpha-olefin and cycloolefin through the catalysis system. The method comprises that an inert organic solvent, ethylene and / or alpha-olefin and cycloolefin are sequentially added in a reactor at a temperature of 40 to 100 DEG C under pressure of 1 to 30 bar, after the ethylene and / or alpha-olefin is dissolved in the inert organic solvent until saturation, a triisobutyl aluminum solution, a metallocene catalyst solution and an organoboron compound solution are orderly added into the solution and the mixed solution undergoes a reaction. Compared with MAO, MMAO, and dMAO, the cocatalysts can efficiently polymerizethe cycloolefin copolymer, the metal content of the polymerization product is reduced and the post-treatment cost is greatly reduced.

Owner:ZHEJIANG UNIV

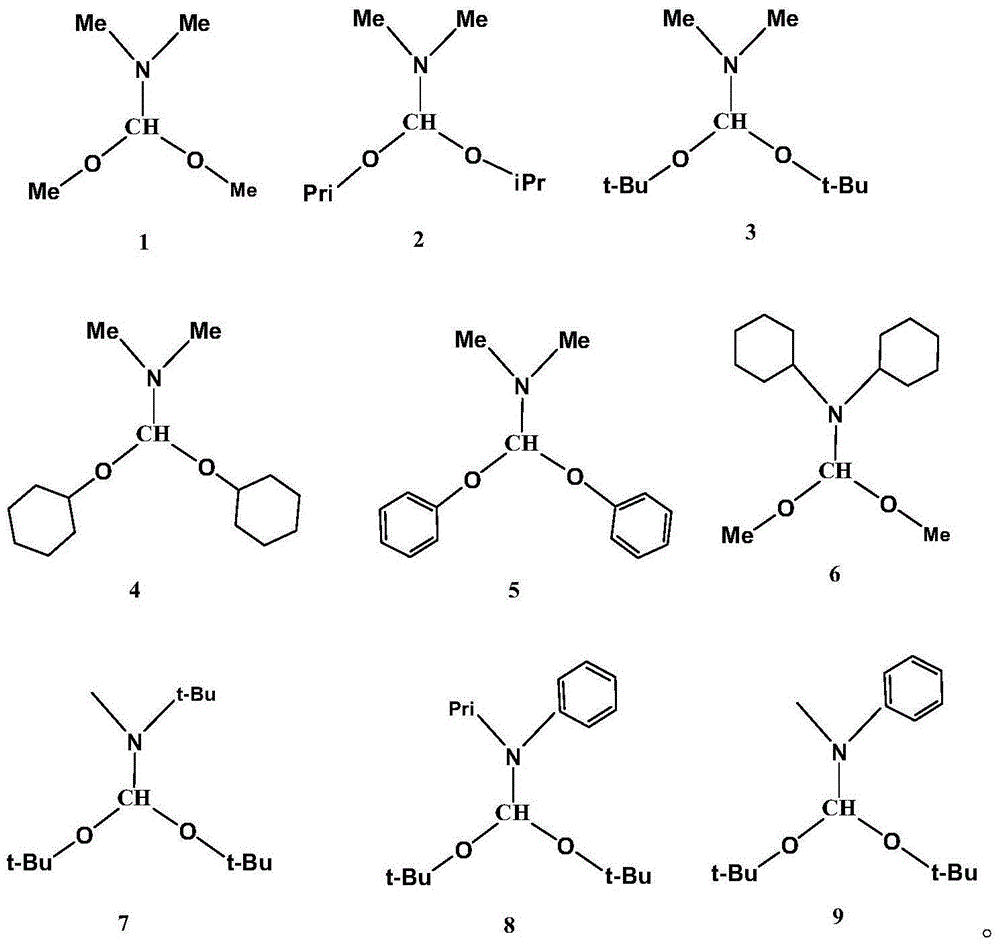

Main catalyst of olefin polymerization catalyst, preparation method thereof, and olefin polymerization catalyst

A main catalyst of an olefin polymerization catalyst comprises the following components: a magnesium compound carrier, transition metal halides, C2-C15 alcohols, and asteroid organic aza-ether compounds. The preparation method of the main catalyst comprises the following steps: (1) dispersing a magnesium compound carrier into an inert organic solvent, adding C2-C15 alcohols into the solvent, and stirring to dissolve the alcohols; (2) cooling the solution obtained in the step (1), and adding asteroid organic aza-ether compounds to carry out reactions; and (3) contacting the system obtained in the step (2) with transition metal halides at a temperature of -25 to 30 DEG C, after reactions, washing the reaction products by toluene or n-hexane, filtering to remove unreacted substances, and carrying out vacuum drying to obtain the main catalyst. An olefin polymerization catalyst comprises the abovementioned main catalyst and an auxiliary catalyst, which is one of trimethyl aluminum, triisobutyl aluminum, tri-n-hexyl aluminum, aluminum diethyl mono-chloride, and methyl aluminoxane (MAO).

Owner:PETROCHINA CO LTD

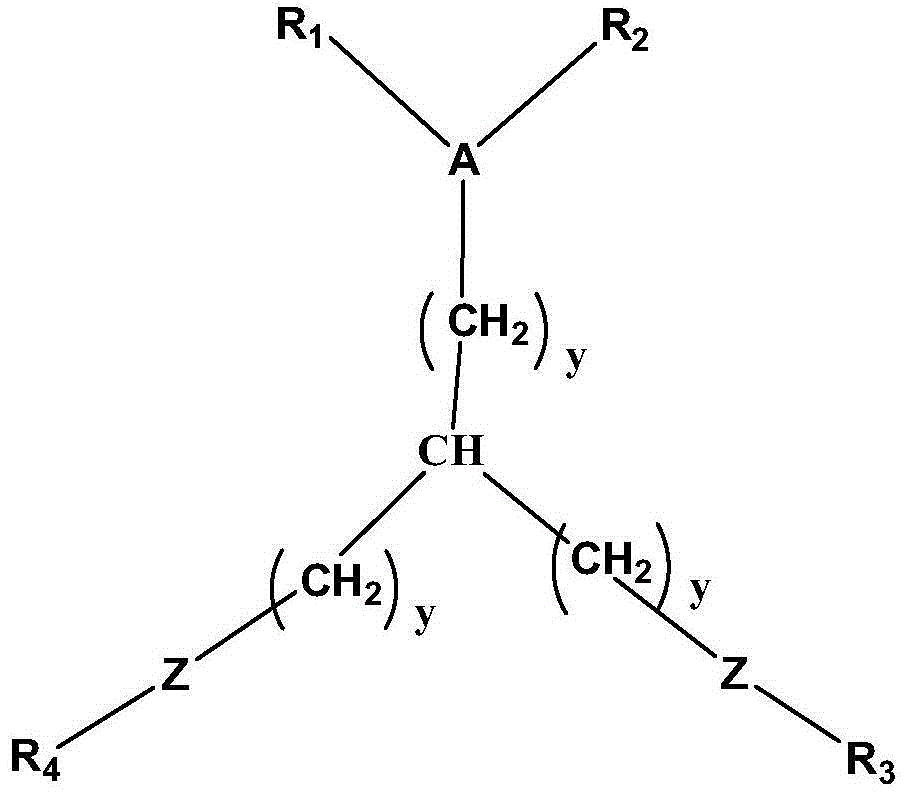

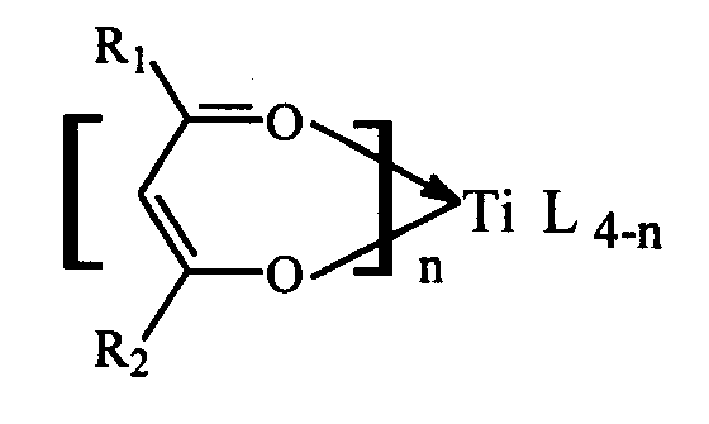

Technical method of preparing polynorbornene using beta diketone titanium non cyclopentadienyl catalyst

A process for preparing polynorbornene with non-cyclopentadiene beta-diketone titanium catalyst includes, adding beta-diketone titanium as primary catalyst, then adding norbornene monomer solution, further adding toluene or o-dichlorobenzene as solvent for dissolving the catalyst, then further adding methyl aloxyane, triethyl aluminium, or triisobutyl aluminium as secondary catalyst, and reaction at 0-90 deg.C. Its product has high-temp. resistance (more than 400 deg.C) and high-vitrification temp. (300-400 deg.C).

Owner:INST OF CHEM CHINESE ACAD OF SCI

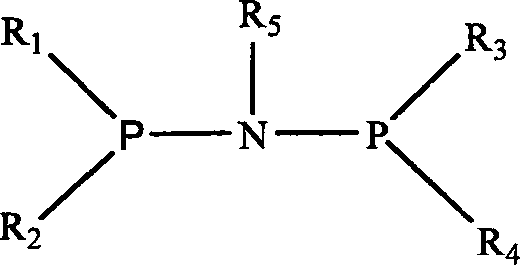

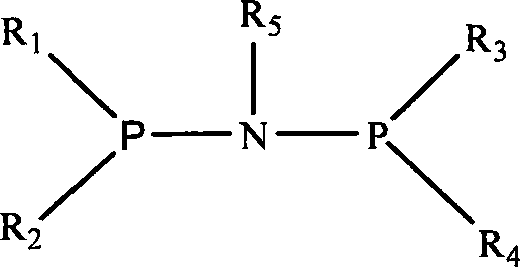

Cocatalysts for olefin polymerizations

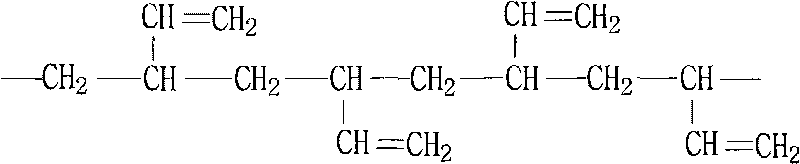

Commonly used triethyl aluminum and tri-isobutyl aluminum cocatalysts may be replaced in olefin polymerizations with a cocatalyst conforming to the formula AlRz(Xz)nLzm wherein Rz may be a linear or branched organic moiety having at least 5 carbons and Xz may be a linear or branched organic moiety having at least 5 carbons or heteroatom substituted organic moiety or a heterocyclic moiety having at least 4 atoms and may be anionic (n=2) or dianionic (n=1). One Xz may also be hydrogen. The aluminum complex may also be in the form of an adduct complex where Lz may be a Lewis base and m=1−3. In the absence of a Lewis base, m=0.

Owner:FINA TECH

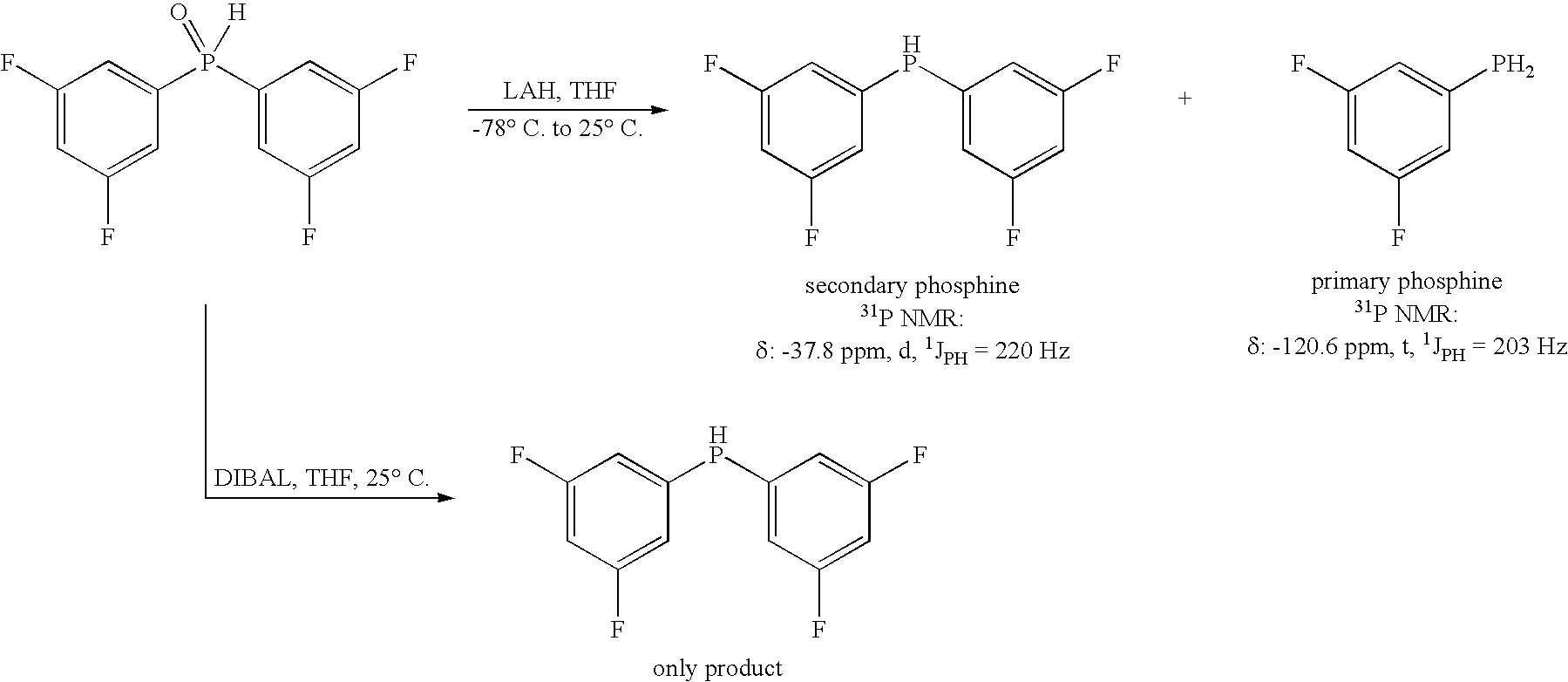

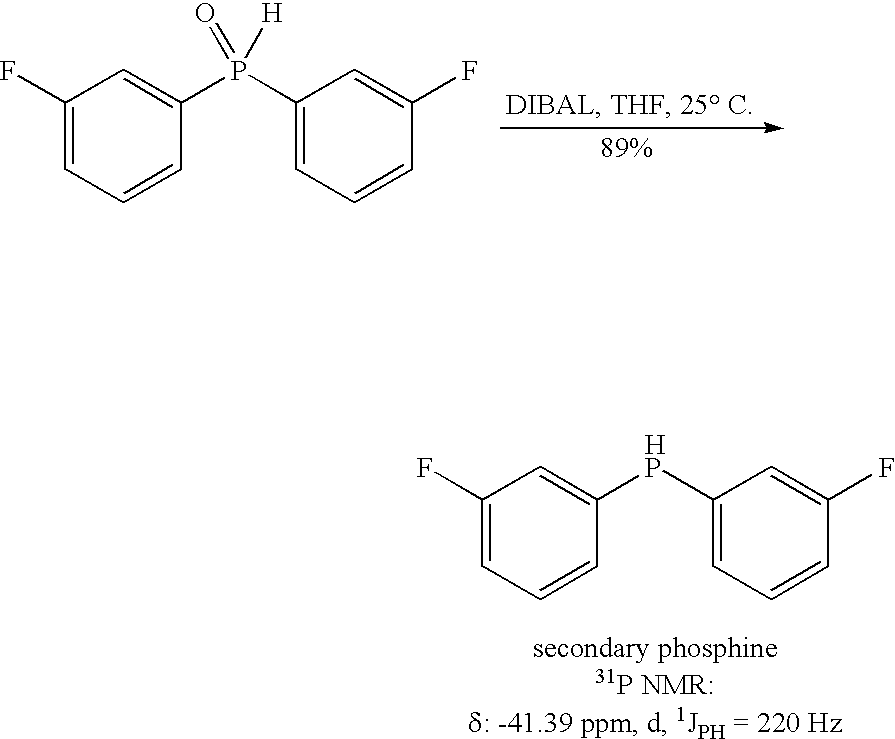

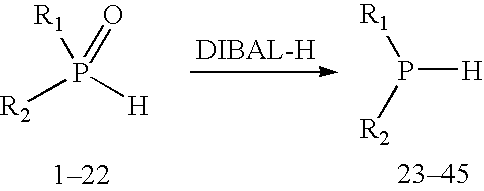

Method for generating secondary phosphines

ActiveUS20050203314A1Rapid responseReduced responsePhosphorus organic compoundsHydrogenTriisobutylaluminium

This invention provides a method for generating secondary phosphines from secondary phosphine oxides in the presence of a reducing agent, such as diisobutylaluminum hydride (DIBAL-H), triisobutyldialuminoxane, triisobutylaluminum, tetraisobutyldialuminoxane, or another reducing agent comprising: (i) an R1R2AlH moiety, wherein R1 and R2 are each an alkyl species or oxygen, and wherein at least one of R1 or R2 comprises at least 2 carbon atoms, or (ii) an R1R2R3Al moiety, wherein R1, R2, and R3 are not hydrogen, and wherein at least one of R1, R2, and R3 is an alkyl species comprising a β-hydrogen, not including triethylaluminum. Preferred reducing agents for the present invention include: diisobutylaluminum hydride, triisobutyldialiuminoxane, triisobutylaluminum, tetraisobutyldialuminoxane, and combinations thereof.

Owner:BOEHRINGER INGELHEIM PHARMA INC

Method for preparing rare earth catalyst applied to isoprene rubber production

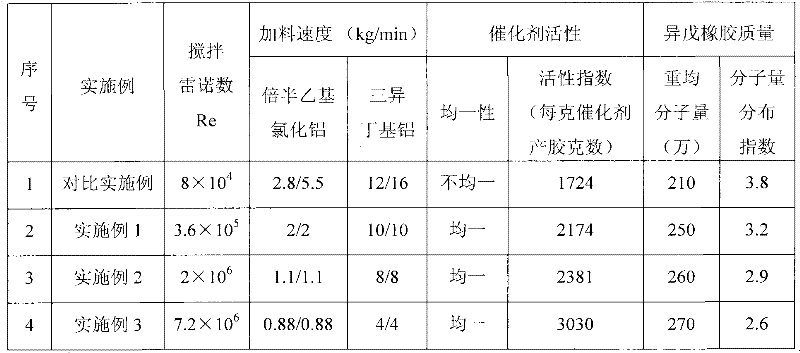

The invention discloses a method for preparing a rare earth catalyst applied to isoprene rubber production, and provides a technology for preparing a catalyst required by industrial and continuous polymerization production, and a high-activity high-uniformity catalytic system required by industrial production of isoprene rubber. By controlling the feeding speed of each component of the catalyst and fully mixing components of the catalyst, the coordination reaction is controlled, so that the preparation efficiency and performance indexes of the rare earth catalyst are improved. In the process of preparing the rare earth catalyst, at least two preparation devices for fully mixing materials are used to alternately perform preparation and standing ageing of the catalyst. The materials for preparing the catalyst comprise a hexane solvent, and neodymium naphthenate, sesquiethyl aluminum chloride and triisobutyl aluminum which are mixed in sequence, and the molar ratio of Nd to Cl to Al is 1:(2-4):(10-20); the preparation and ageing temperatures are controlled to be between 0 and 40DEG C; and the ageing concentration (based on Nd) is 0.01 to 0.05mol / L, and the ageing time is controlled to be 1-24 hours.

Owner:FUSHUN YIKESI NEW MATERIAL

Preparation method of doublet or wide molecular weight distribution polyvinyl

The invention relates to a preparation method of doublet or wide molecular weight distribution polyvinyl. In polymerization, ethylene is used as monomer, butene-1 or hexene-1 as comonomer and hydrogen as molecular weight modifier. Polymerization temperature is 70 DEG C to 110 DEG C, pressure is 0.7 MPa to 2.5 MPa, reaction time is 2 h to 4 h, and catalyst is vanadium catalyst with the structural formula of VMg.nAl, wherein the range of n is 0.1 to 10. Promoter is the mixture of one or two of triisobutyl aluminium and aluminium ethyl, and the molar ratio of aluminum of the promoter and vanadium of the main catalyst is 10 to 10000: 1. The molecular weight and the molecular weight distribution wide of polyethylene products are adjusted through the adjustment of the types and the dosage of the promoter. Polymerized products have the characteristics of high molecular weight and wide molecular weight distribution, and the morphology of the polymerized products is regular spheroidal particles, and has no fine powder and no oligomer. The production of high value-added doublet or wide molecular weight distribution polyvinyl products can be achieved in a single reactor of a slurry process and a gas phase method technology.

Owner:PETROCHINA CO LTD

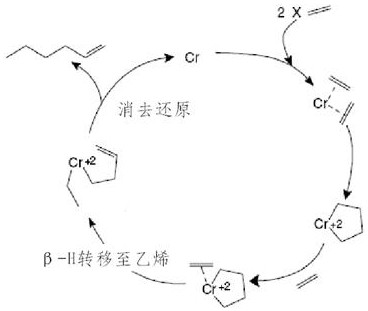

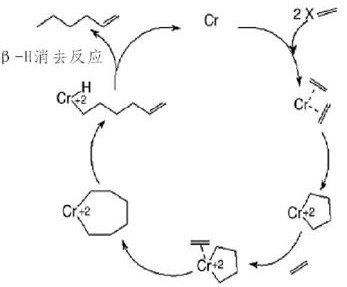

Chromite catalyst for trimerization of ethylene into 1-hexene and preparation and application thereof

InactiveCN113083373ALow running costLow selectivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsAluminoxanePtru catalyst

The invention provides a chromite catalyst for trimerization of ethylene into 1-hexene and preparation and application thereof, raw materials for preparing the chromite catalyst comprise chromite organic acid salt, an electron donor, 2, 5-dimethyl pyrrole and a polydentate PNP compound, and at least one of trimethyl aluminum, triethyl aluminum, triisobutyl aluminum, trioctyl aluminum, diethyl aluminum monochloride, ethyl aluminum dichloride, ethyl aluminum sesquichloride, methylaluminoxane, modified methylaluminoxane and ethyl aluminoxane. According to the chromite catalyst, a chromite source is adopted to synthesize a chromite organic metal compound, and the step of reducing trivalent chromium into chromite by aluminum alkyl is reduced by the generated catalyst, so that the active center is ensured to be + 2 valence, the loss of the catalyst is avoided, and meanwhile, the situation that the reaction selectivity is reduced and the product yield is influenced by excessive aluminum alkyl is avoided. Therefore, 1-hexene with high activity and good selectivity is developed, and the operation cost of the 1-hexene device is greatly reduced.

Owner:BEIJING CORETEAM ENG & TECH

Method for preparing polyepichlorohydrin by catalyzing epichlorohydrin polymerization by using three-element iron catalyst

The invention discloses a method for preparing polyepichlorohydrin by catalyzing epichlorohydrin polymerization by using a three-element iron catalyst, belonging to the field of polymer preparation and solving the problem of low activity of the catalyst for synthesizing polyepichlorohydrin from polymerization, and small molecular weight and wide PDI distribution of the obtained product in the prior art. The three-element iron catalyst (iron compound, alkyl aluminum compound or electron donor) is adopted to catalyze epichlorohydrin homopolymerization to obtain the polyepichlorohydrin, of which the molecular weight is 10000 above, the polymer color is light and the PDI distribution is 1.2 or so; and the reaction is easy to control. The catalyst is easy to prepare and has the advantage of high polymer yield. The iron compound is iron naphthenate, iron neodecanoate, iron isooctoate or the like; the organic aluminum compound is triisobutylaluminum, triethyl aluminum, sesquialuminum or the like; and the electron donor is tri-ortho-methylphenyl phosphite, diethyl phosphite, tributyl phosphate or the like.

Owner:山东菏泽玉皇化工有限公司

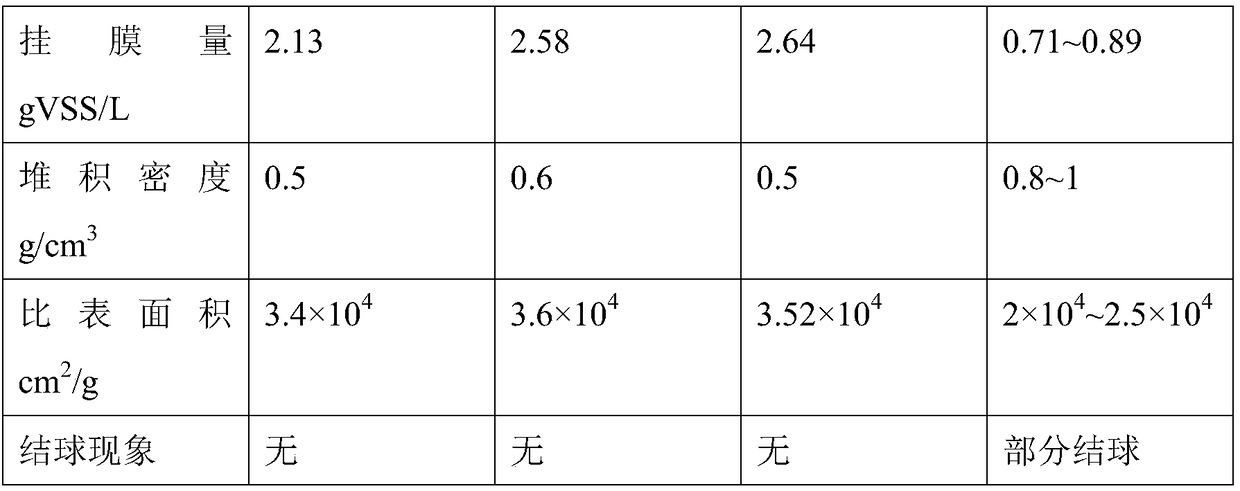

Preparation method of biological packing for wastewater treatment

InactiveCN108821426AAvoid poisoningImprove processing efficiencySustainable biological treatmentBiological water/sewage treatmentBound propertyTherapeutic effect

The invention discloses a preparation method of biological packing for wastewater treatment and belongs to the field of water treatment. According to the preparation method, 10-undecen-1-ol and propylene are taken as raw materials, polar monomers trimethylaluminium and triisobutyl aluminium, methylaluminoxane and 2,6-di-tert-butyl-4-methylphenol are added and taken as promoters, ferrocene is takenas a main catalyst, a polymerization reaction is performed, oxygen atoms in enol are shielded by larger substituent groups on alkyl aluminium, catalyst poisoning caused by the fact that lone pair electrons on the oxygen atoms coordinate with an active center is prevented, protected undecylenyl alcohol monomers are copolymerized with propylene to obtain a polymer, hydroxyl is introduced into the polymer, the polymer has better hydrophilic performance and better binding property with wastewater in wastewater treatment, and water treatment efficiency is improved. The problem that the treatment effect is affected due to the fact that current packing is poor in affinity when bound with microorganisms and is prone to balling is solved.

Owner:CHANGZHOU UNIV

Cocatalyst for use in synthesis of drag reducer

ActiveCN101735365AImprove delivery capacityImprove securityPipeline systemsChemical industryTransportation capacity

The invention relates to polymer synthesis technology, in particular to a cocatalyst for use in the synthesis of a drag reducer, which is mainly used for drag reduction in long-distance pipeline transportation and belongs to the technical field of chemical industry. In the invention, an alpha-olefin is synthesized by coordination anionic polymerization, triisobutyl aluminum is used as a cocatalyst, the triisobutyl aluminum is diluted by a refined solvent till a safe concentration is obtained, and the safety is improved effectively as the cocatalyst gives off smoke upon contact with water and oxygen at the safe concentration. The synthesized reducer for oil product transported in HG pipeline is used in long-distance oil transportation pipelines and can improve the transportation capacity of the pipelines.

Owner:CHINA PETROLEUM & CHEM CORP +1

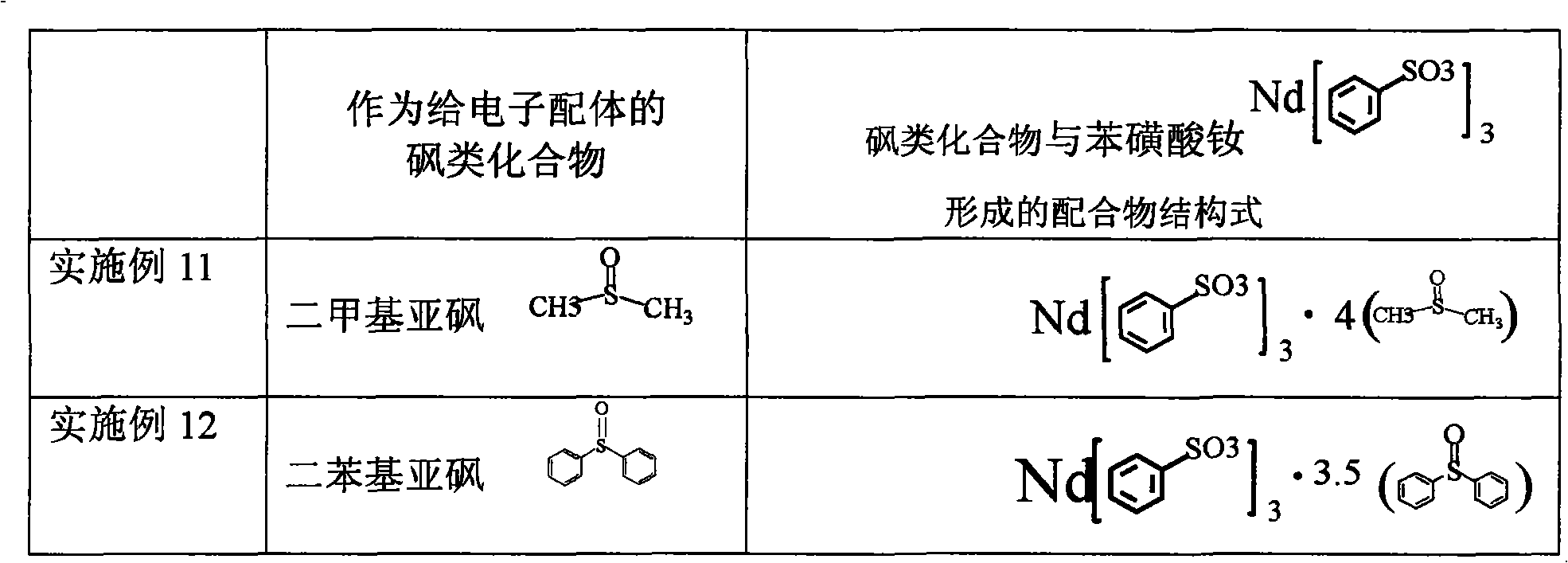

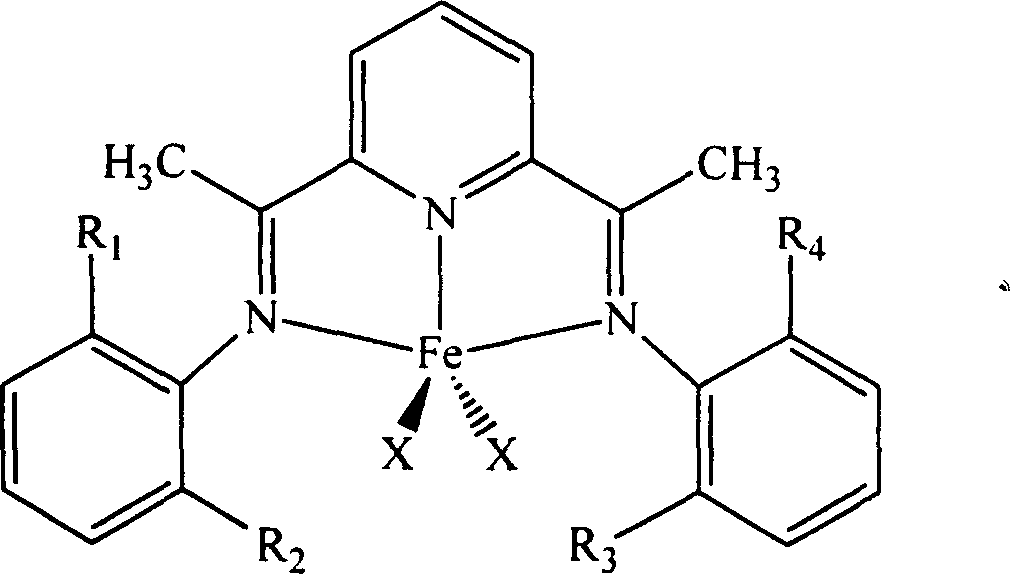

Iron complex on basis of flexible frameworks, method for preparing iron complex and application of iron complex to isoprene polymerization

The invention discloses an iron complex on the basis of flexible frameworks, a method for preparing the iron complex and application of the iron complex to isoprene polymerization. The iron complex onthe basis of the flexible frameworks is used as a primary catalyst. Co-catalysts include trimethylaluminium, triethylaluminum, triisobutylaluminum, methylaluminoxane or modified methylaluminoxane. The application includes steps of adding the primary catalyst, solvents and the co-catalysts; adding isoprene monomers and carrying out polymerization reaction to obtain polyisoprene. The ranges of theproportions of cis-1, 4 structures in obtained isoprene rubber are 29-48%, and the ranges of the proportions of 3, 4 structures are 52-71%. The iron complex, the method and the application have the advantages that polymers are high in molecular weight and narrow in molecular weight distribution; the use efficiency of iron-based catalysts can be effectively improved by the aid of a method for preparing the isoprene rubber, and the industrial application values of the iron-based catalysts can be effectively increased by the aid of the method for preparing the isoprene rubber.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Catalyst for olefin/styrene copolymerization, and process for producing olefin/styrene copolymer

InactiveUS6838409B1High copolymerization activityAmountOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlcoholTriisobutylaluminium

Catalysts for copolymerization of olefins and styrenes, comprising (A) a transition metal compound, (B) an oxygen-containing compound and / or a compound capable of reacting with a transition metal compound to form an ionic complex, (C) a specific compound such as a reaction product of triphenylmethyl alcohol and triisobutylaluminium, and optionally (D) an alkylating agent, and methods for producing olefin-styrene copolymers in the presence of such catalysts, which catalysts have the advantages of enhancing the copolymerization activity and reducing the amount of the promoter such as oxygen-containing compounds, etc, and using them, olefin-styrene copolymers can be produced efficiently and inexpensively.

Owner:IDEMITSU KOSAN CO LTD

Method for preparing syndiotactic poly1,2-butadiene thermoplastic elastomer

The invention relates to a method for preparing a syndiotactic poly1,2-butadiene thermoplastic elastomer, which comprises the following steps: initiating the polymerization of 1,3-butadiene monomer in hexane solution of a synthetic rubber through the addition of 1,2-configurational units by using iron catalysts to form a uniform blend of 1,2-butadiene and synthetic rubber, wherein the catalysts comprise iron isooctanoate or iron naphthenate, diethyl phosphate, triisobutyl aluminium and aluminium triethyl; the adding sequence of the catalysts is that any components are combined or two aluminum alkyls are mixed first and then combined with the other two components optionally; in a polymerization system, every 1,000 millilitres of hexane solution contains 90 to 140 grams of 1,3-butadiene monomer, and the adding amount of the rubber is 0.1 to 25 grams; and the polymerization initiating temperature is 60 to 90 DEG C. The blend has the properties of the typical thermoplastic elastomers and can be used for modifying thin films, shoe soles, tubular materials, rubbers and plastics.

Owner:PETROCHINA CO LTD

Process for preparing additively structured polynorbornene

The method for preparing polynorbornene by using novel bridged diimine nickel and palladium catalyst includes the following steps: firstly, adding main catalyst, then adding norbornene monomer solution, then adding solvent, finally adding catalyst promoter, the described main catalyst is the bridged diimine nickel and palladium compounding material, its concentration is 1X10 to the minus sixth-1X10 to the minus third mal / L, the described catalyst promoter is methyl aluminium-oxane, triethyl aluminium o r triisobutylaluminium, the mole ratio of the catalyst promotor and main catalyst is 1-10000, the solvent of the described norbornene monomer solution is methylbenzene, and the concentration of monomer in reaction system is 0.01-6.0 mol / L, the solvent of the described system i s methylbenzene, and its reaction temp. is 0 deg.C-90 deg.C.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polymerization of vinylic monomers containing a heteroatom

A process for the anionic polymerization of monomers, by the step of polymerizing the monomers in the presence of an initiator composition comprising a metal hydride such as sodium hydride and an organyl metal compound such as triisobutylaluminum, the monomers comprising one or more vinylic monomers comprising one or more elements different from carbon and hydrogen.

Owner:STYRON

Sulfonated long chain alpha-olefin copolymer and its prepn and use

The present invention discloses one kind of sulfonated long chain alpha-olefin copolymer and its preparation process and use. The preparation process includes the following steps: 1. adding triisobutyl aluminum, diphenyl dimethoxy silane, spherical polypropylene catalyst, long chain alpha-olefin and styrene into n-heptane solvent to polymerize styrene-long chain alpha-olefin copolymer; and 2. dissolving the styrene-long chain alpha-olefin copolymer in o-dichlorobenzene through heating and stirring, and dropping concentrated sulfuric acid slowly to sulfonate and obtain sulfonated long chain alpha-olefin copolymer. The preparation process is simple and low in production cost, and the sulfonated long chain alpha-olefin copolymer may be used in preparing agricultural film with excellent surface hydrophilicity, long service life and other advantages.

Owner:ZHEJIANG UNIV

Hydrophilic long-chain alpha-olefin branched copolymer and preparation method and usage thereof

The invention discloses a hydrophilicity long chain alpha-olefin graft copolymer and preparing method and use thereof. The preparing method includes steps: 1) adding water-free and oxygen-free long chain alpha-olefin, triisobutyl aluminum, diphenyl dimethoxyl silicon and spheric polypropylene catalyst in turn to plastic test tube with magnetic force stirring device under inertia gas protection; after polymerizing, transferring the mixture to refrigerator and obtaining poly(long chain alpha-olefin); 2) adding the poly(long chain alpha-olefin) to three-mouth flask with magnetic force stirring device and nitrogen inlet, adding toluene as solvent, heating and stirring to sufficient dissolve, ventilating nitrogen, adding maleic anhydride and organic peroxide initiator, reacting and obtaining hydrophilicity long chain alpha-olefin graft copolymer. Advantages of the invention are: technique is simple, operation is convenient, polyethylene film basal body is not influenced, processing method id simple, cost is low, hydrophilicity of film surface is good and life of fogdrop resistant is long.

Owner:ZHEJIANG UNIV

Process for semicontinuous preparation of syndiotactic polystyrene particles

The invention discloses a process for semicontinuous preparation of syndiotactic polystyrene particles by using styrene as monomer, metallocene titanium compound as main catalyst, aluminium alkyl and triisobutyl aluminium as auxiliary catalyst, carrying out seed semi-continuous polymerization in composite inert medium under normal pressure at 50-80 deg. C, the seeds are polystyrene particles with good granule shape. The invention can realize high styrene conversion rate.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com