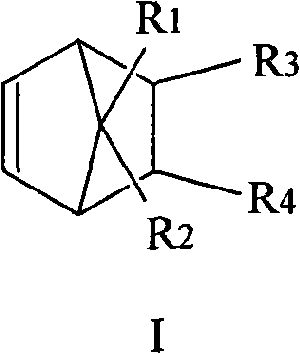

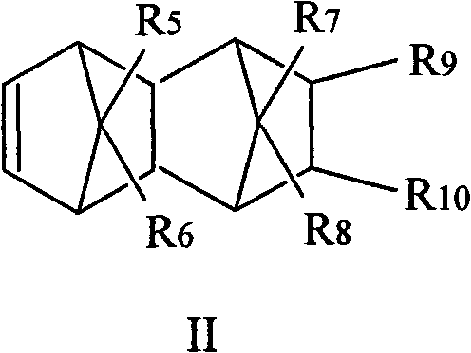

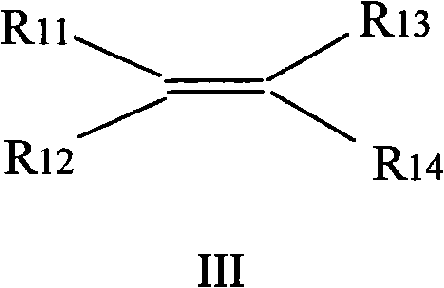

Cyclic olefin copolymer with polar group and preparation method thereof

A technology of cyclic olefin copolymer and polar group, which is applied in the field of cyclic olefin copolymer and its preparation, and achieves the effect of high heat resistance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Protection of polar comonomer 3-buten-1-ol monomer

[0042] First cool 50ml of TIBA in a mixed solution of dry ice and acetone for half an hour, then dilute 17ml of 3-buten-1-ol with 30ml of hexane, slowly pour it into TIBA, and react at -78°C for 1 hour. It was then stirred at room temperature for 3 hours, and finally the hexane was removed in vacuo to obtain TIBA-protected 3-buten-1-ol comonomer in the form of oil, named as B.

Embodiment 2

[0043] Example 2: Protection of Polar Comonomer 10-Undecen-1-ol Monomer

[0044] First cool 50ml TIBA in a mixed solution of dry ice and acetone for half an hour, then dilute 39.5ml 10-undecen-1-ol and 30ml hexane, and slowly pour it into TIBA, and react at -78°C for 1 hour, It was then stirred at room temperature for 3 hours, and finally the hexane was removed in vacuo to obtain an oily TIBA-protected 10-undecen-1-ol comonomer, named U.

Embodiment 3

[0046] Dissolve 1.7ml of refined norbornene in 50ml of refined toluene to form a solution. This solution was added to a 100 ml tank reactor previously flushed with nitrogen, and the solution was saturated with ethylene by punctured with ethylene (1 atm) several times. Then, 2 ml of the monomer B prepared in Example 1, 1.8 ml of toluene solution with a concentration of 1.72 mol / liter of methylalumoxane, and 0.8 mg of rac-vinyl-(diindenyl)-zirconium dichloride were added successively. Polymerize at 70°C for 30 minutes under stirring conditions; during the polymerization process, ethylene is supplemented and metered, and the pressure is controlled at 1 atmosphere. After the reaction was over, the reaction solution was poured into ethanol for precipitation and then filtered. After the filter cake was washed with ethanol, it was dried to obtain 1.9 grams of polymer with a catalyst activity of 1.9×10 6 g / (mole zirconium·hour). The physical properties of the polymers are listed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com