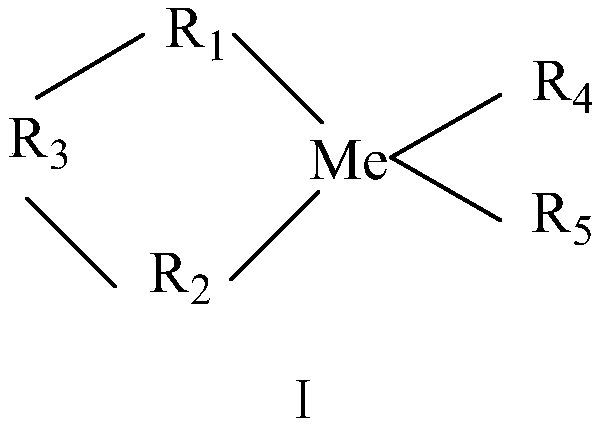

Method for preparing copolymer of ethylene and/or alpha-olefin and cycloolefin and catalysis system thereof

A technology of cycloolefin copolymer and catalytic system, which is applied in the field of preparing ethylene and/or α-olefin and cycloolefin copolymer, can solve the problems of increasing the cost of the post-processing process, unfavorable industrialization development, increasing the content of metals, etc., to achieve Reduce catalyst and co-catalyst residues, facilitate subsequent treatment, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

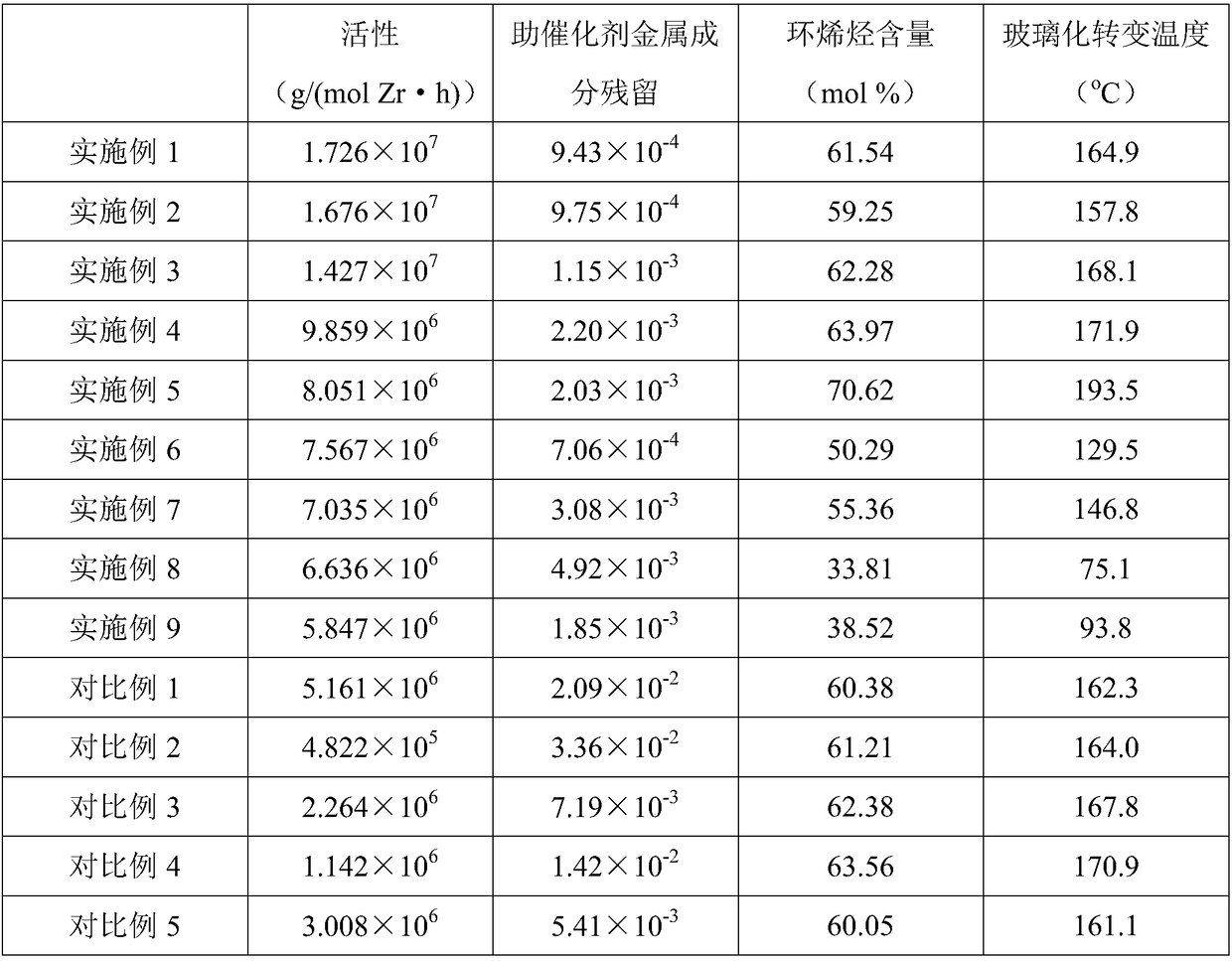

Examples

Embodiment 1

[0037] What used in this embodiment is a 1L tank reactor. First 36.880mg (4 × 10 -5 mol) Ph 3 CB(C 6 f 5 ) 4 Dissolve in 10mL toluene to make a concentration of 4×10 -3 mol / L solution, stand-by; 8.37mg rac-[Et(Ind) 2 ]ZrCl 2 (2×10 - 5mol) was dissolved in 8.37mL of toluene to form a solution for use. Dissolve 265.770g (2.827mol) norbornene in a certain amount of toluene to prepare 476.16mL norbornene toluene solution. The solution was added to the reactor previously flushed with nitrogen, and the ethylene (5bar) was punched several times to make the solution saturated with ethylene. The initial molar ratio of ethylene is 14.0), followed by adding 5.48mL triisobutylaluminum toluene solution with a concentration of 1.1mol / L, 10mL Ph 3 CB(C 6 f 5 ) 4 Toluene solution, 8.37mL catalyst solution, start polymerization; during the polymerization process, the pressure is controlled at 5 bar by supplementing ethylene.

[0038] After 30 minutes of reaction, the reaction so...

Embodiment 2

[0040] What used in this embodiment is a 100mL tank reactor. First mix 30mL toluene and 30mL cyclohexane to make a mixed solvent for use; 3.688mg (4×10 -6 mol) Ph 3 CB(C 6 f 5 ) 4 Dissolve in 1mL of mixed solvent of toluene and cyclohexane to make a concentration of 4×10 -3 mol / L solution, ready for use; 0.84mg rac-[Et(Ind) 2 ]ZrCl 2 (2×10 -6 mol) was dissolved in 0.84mL mixed solvent to form a solution, ready for use. Dissolve 26.577g (0.282mol) norbornene in a certain amount of mixed solvent to prepare 47.61mL norbornene solution. This solution is added in the reactor that has flushed with nitrogen in advance, punches ethylene (5bar) repeatedly, makes solution be saturated by ethylene, under the condition of 50 ℃ of temperature, 5bar and stirring (600r / min) (norbornene and The initial molar ratio of ethylene is 12.4), followed by adding 0.55 mL of triisobutylaluminum cyclohexane solution with a concentration of 1.1 mol / L, 1 mL Ph 3 CB(C 6 f 5 ) 4 Solution, 0.84m...

Embodiment 3

[0043] What used in this embodiment is a 100mL tank reactor. First 3.690mg (4 × 10 -6 mol) Ph 3 CB(C 6 f 5 ) 4 Dissolve in 1mL toluene to make a concentration of 4×10 -3 mol / L solution, ready for use; 0.84mg rac-[Et(Ind) 2 ]ZrCl 2 (2×10 - 6 mol) was dissolved in 0.84mL toluene to form a solution, ready for use. Dissolve 13.289g (0.141mol) of norbornene and 16.920g (0.141mol) of ethylidene norbornene in a certain amount of toluene to prepare 47.61mL of norbornene toluene solution. This solution is added in the reactor that has flushed with nitrogen in advance, punches ethylene (5bar) several times, makes solution saturated by ethylene, under the condition of 60 ℃ of temperature, 5bar and stirring (600r / min) (norbornene, The initial molar ratio of ethylidene norbornene to ethylene is 7.0:7.0:1), followed by adding 0.55mL triisobutylaluminum toluene solution with a concentration of 1.1mol / L, 1mL Ph 3 CB(C 6 f 5 ) 4 Toluene solution and 0.84mL catalyst solution were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com