Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189 results about "Trimethylaluminium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

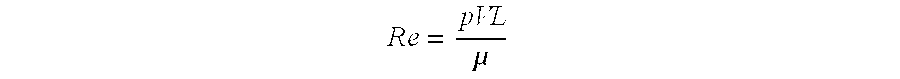

Trimethylaluminium is one of the simplest examples of an organoaluminium compound. Despite its name it has the formula Al₂(CH₃)₆ (abbreviated as Al₂Me₆ or TMA), as it exists as a dimer. This colorless liquid is an industrially important compound but must be handled with care due to its pyrophoricity; it evolves white smoke (aluminium oxides) when the vapor is released into the air.

Solid polymethylaluminoxane composition and method for manufacturing same

ActiveUS20110282017A1High yieldReduce solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationMethyl group

Disclosed are: a solid polymethylaluminoxane composition which does not utilize silica or the like, has the form of relatively fine particles, has more uniform particle sizes, and exhibits a high polymerization activity when used in the preparation of an olefin polymer; a process for producing the solid polymethylaluminoxane composition; a polymerization catalyst; and a process for producing an olefin polymer. Specifically disclosed are: a solid polymethylaluminoxane composition which has an aluminum content of 36 to 41 mass % and contains a methyl group derived from a trimethylaluminum moiety at a molar fraction of 12 mol % or less; a process for producing the solid polymethylaluminoxane composition, which comprises the step of heating an aromatic hydrocarbon solution containing polymethylaluminoxane and trimethylaluminum to cause the precipitation of the solid polymethylaluminoxane composition; a polymerization catalyst for an olefin, which comprises the solid polymethylaluminoxane composition and a transition metal compound as catalyst components; and a process for producing an olefin polymer by using the polymerization catalyst.

Owner:TOSOH FINECHEM CORP

Nucleation of Aluminum Nitride on a Silicon Substrate Using an Ammonia Preflow

InactiveUS20130026480A1Polycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenNucleation

A silicon wafer used in manufacturing crystalline GaN for light emitting diodes (LEDs) includes a silicon substrate, a buffer layer of aluminum nitride (AlN) and an upper layer of GaN. The silicon wafer has a diameter of at least 200 millimeters and an Si(111)1×1 surface. The AlN buffer layer overlies the Si(111) surface. The GaN upper layer is disposed above the buffer layer. Across the entire wafer substantially no aluminum atoms of the AlN are present in a bottom most plane of atoms of the AlN, and across the entire wafer substantially only nitrogen atoms of the AlN are present in the bottom most plane of atoms of the AlN. A method of making the AlN buffer layer includes preflowing a first amount of ammonia equaling less than 0.01% by volume of hydrogen flowing through a chamber before flowing trimethylaluminum and then a subsequent amount of ammonia through the chamber.

Owner:KK TOSHIBA

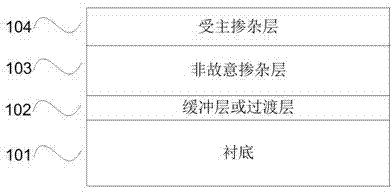

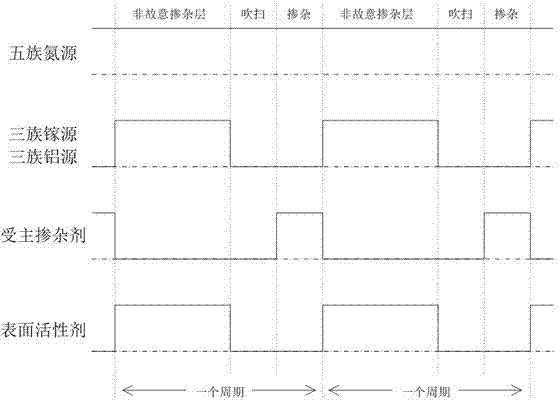

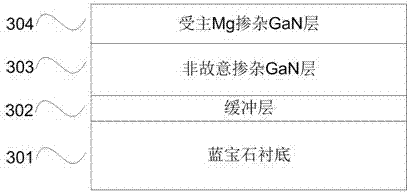

Preparation method of p type GaN and AlGaN semiconductor material

ActiveCN102903615AEasy to desorbImprove bindingSemiconductor/solid-state device manufacturingDimethylhydrazineSemiconductor materials

The invention discloses a preparation method of a p type GaN and AlGaN semiconductor material. A substrate, and a buffer layer or a transition layer, an unintended doped layer and an acceptor doped layer grown on the substrate from bottom to top are contained; in a growth process of the structure, ammonia or nitrogen dimethylhydrazine is used as a five-group nitrogen source; trimethyl gallium or TEGa used as a three-group gallium source, trimethylaluminium or triethyl aluminum used as a three-group aluminium source, and trimethylindium or TEIn used as a three-group indium source are collectively called three-group metal sources; and the trimethylindium or the TEIn is also used as a surface active agent and used in the acceptor doped layer. According to the method, the trimethylindium or the TEIn is used as the surface active agent to assist growth, and simultaneously, the acceptor doped layer is prepared by adopting a delta doping method. According to the method, the doping efficiency of acceptor doped magnesium atoms is increased, and simultaneously, the self-compensation effect is suppressed, so that the p type GaN and AlGaN semiconductor material with favorable crystalline quality and high hole concentration is obtained.

Owner:SUN YAT SEN UNIV

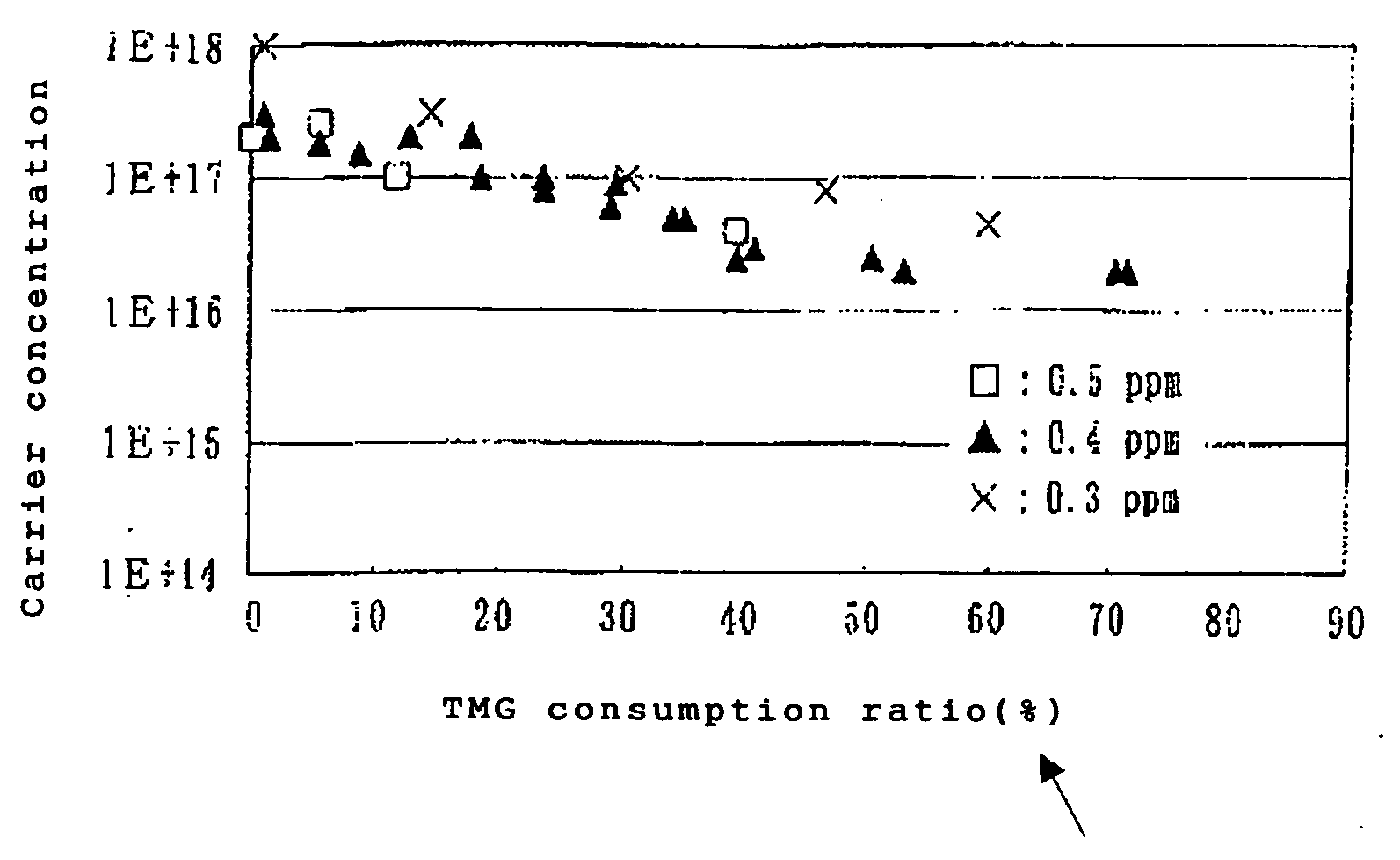

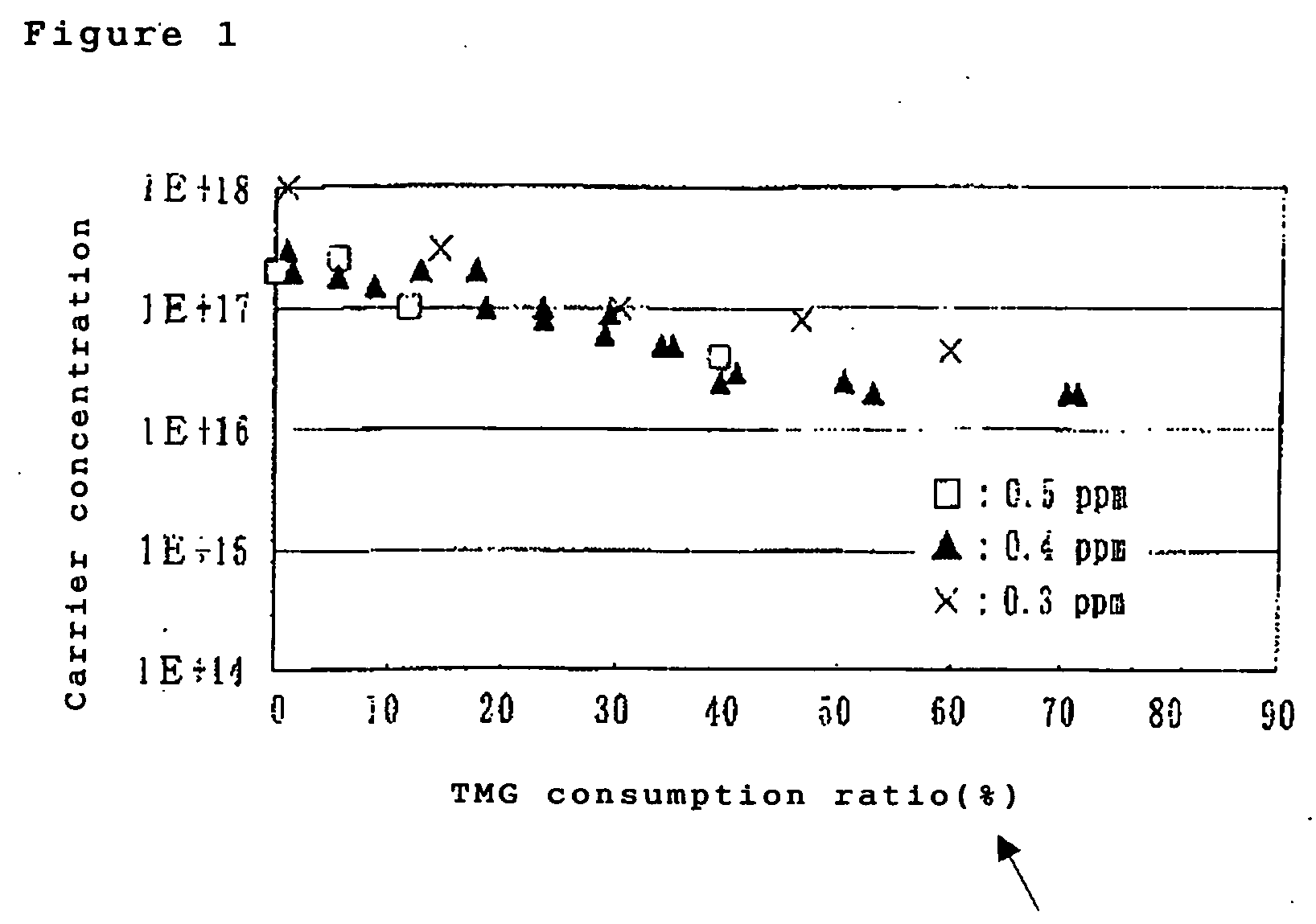

Trimethylgallium, a method for producing the same and a gallium nitride thin film grown from the trimethylgallium

InactiveUS20060075959A1Polycrystalline material growthGallium/indium/thallium compoundsSolventOrganosilicon

The present invention provides a trimethylgallium which has less than 0.1 ppm of a total organic silicon compound content; and a method for producing the trimethylgallium comprises hydrolyzing trimethylaluminum as a raw material, extracting organic silicon compound contained with a solvent, quantifying methyltriethylsilane by a Gas Chromatography-Mass Spectrometry, selecting a trimethylaluminum having less than 0.5 ppm of methyltriethylsilane content for the raw material, purifying by distillation, followed by reaction with gallium chloride and then distilling the reactant solution to obtain the trimethylgallium.

Owner:SUMITOMO CHEM CO LTD

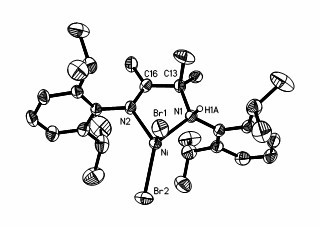

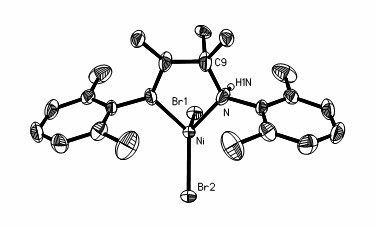

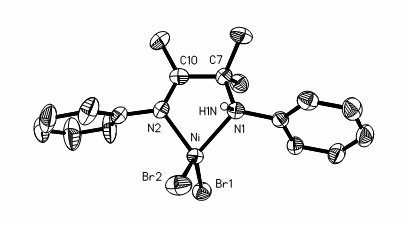

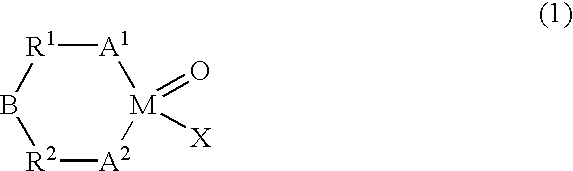

Preparation method and application of amido-imine nickel vinyl polymerization catalyst

ActiveCN102250152AThe synthesis method is simpleRaw materials are cheap and easy to getNickel organic compoundsAnilineBiological activation

The invention discloses a preparation method of an amido-imine nickel catalyst and application of the amido-imine nickel catalyst to catalyzing vinyl polymerization. The complex has the structures of a formula (I) and a formula (II) shown in the specification, wherein R1 is hydrogen or alkyl, R2 is hydrogen or alkyl, R3 is hydrogen or alkyl, R4 is hydrogen or alkyl, and X is halogen. The preparation method of the complex comprises the following steps of: carrying out condensation reaction on a diketone compound and phenylamine through ketoamine to obtain an diimine compound; then reacting with trimethyl aluminum, and hydrolyzing to obtain an amido-imine ligand; finally carrying out coordination reaction on the amido-imine ligand and (DME)NiX2 under the condition without water and oxygen to obtain a nickel complex. The complex disclosed by the invention has a specific ligand replacement structure and can be used for catalyzing the vinyl polymerization under the activation of modified methyl aluminium oxane or alkyl aluminum, showing the characteristics of living polymerization under specific conditions and obtaining the high-molecular-weight narrowly-distributed branched polyethylene.

Owner:SUN YAT SEN UNIV

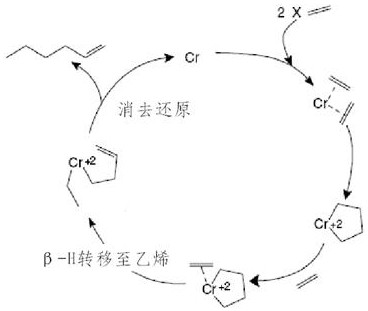

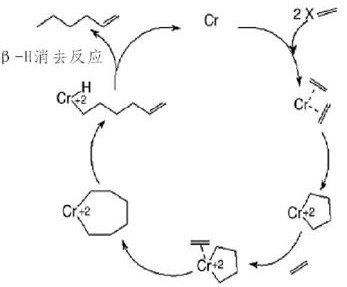

Bulk ethylene oligomerization using a low concentration of chromium catalyst and three-part activator

InactiveUS20140142360A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsOligomerAluminoxane

This invention enables the “bulk” oligomerization of ethylene (i.e. the oligomerization of ethylene in the presence of the oligomer product) using a catalyst system comprising 1) a very low concentration of a chromium catalyst and 2) a three part activator. The chromium catalyst contains a diphosphine ligand, preferably a so called P—N—P ligand. The activator includes an aluminoxane, trimethyl aluminum, and triethyl aluminum.

Owner:NOVA CHEM (INT) SA

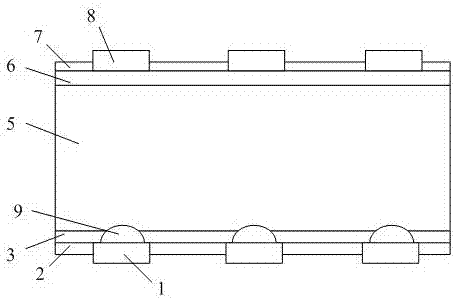

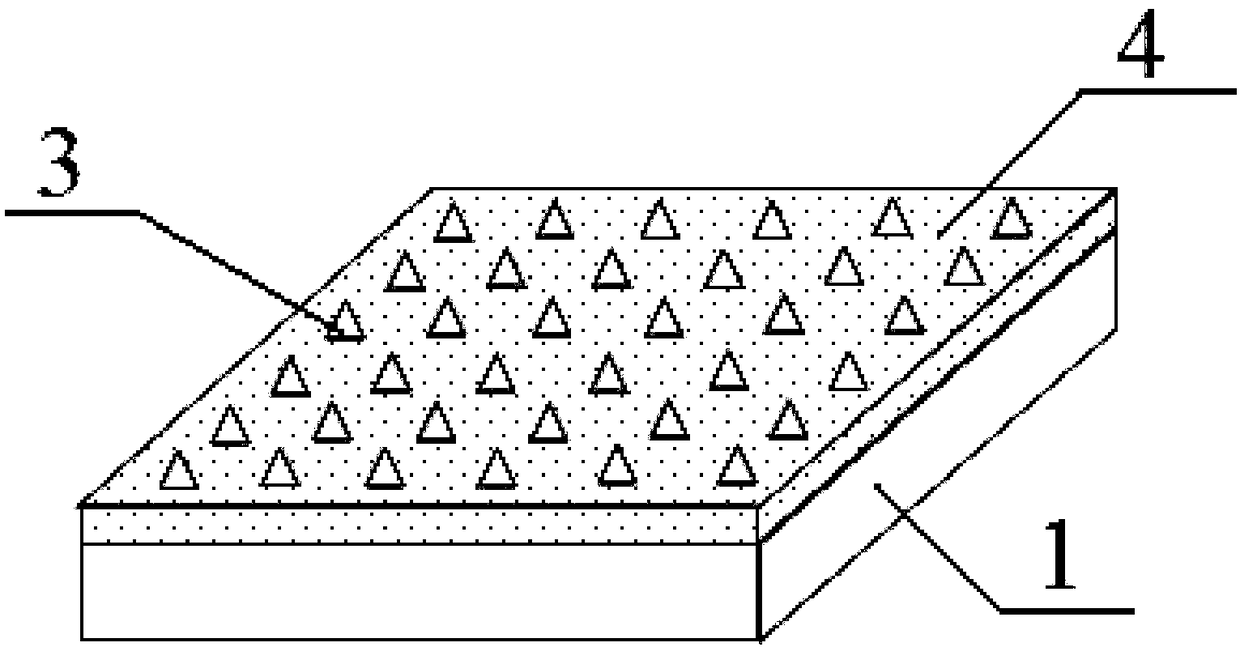

Tube type PERC single-sided solar cell, preparation method thereof and special equipment thereof

ActiveCN107256894AReduce the ratio of scratchesReduce impact forceFinal product manufactureSemiconductor/solid-state device manufacturingScratchingSilica membrane

The invention discloses a tube type PERC single-sided solar cell, which comprises a main silver back gate, an all-aluminum back electric field, a back-side composite film, a P-type silicon, an N-type emitting electrode, a front-side passivation film and a positive silver electrode. The back-side composite film is composed of one or more selected from an aluminum oxide film, a silicon dioxide film, a silicon oxynitride film and a silicon nitride film and is deposited at the back of a silicon chip by adopting tube type PECVD equipment. The tube type PECVD equipment comprises four gas pipelines of silane, ammonia, trimethyl aluminum and laughing gas. The appliance of the tube type PECVD equipment, used for loading and unloading silicon chips, is a graphite boat. The depth of a sticking point groove of the graphite boat is 0. 5-1 mm. The invention also discloses a preparation method and special equipment of the tube type PERC single-sided solar cell. According to the invention, the photoelectric conversion efficiency is high. Meanwhile, the appearance yield and the EL yield are high. The problems of scratching, winding and plating can be solved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH +1

Method for preparing substrate material with multilayer composite protective film

InactiveCN101974734APrecise thickness controlPrecise control ratioChemical vapor deposition coatingChemisorptionNitrogen gas

The invention relates to a method for preparing a substrate material with a multilayer composite protective film, which comprises the following steps: putting the substrate material into a reaction chamber, and heating the substrate material until the temperature thereof is 100 to 500 DEG C; introducing trimethyl aluminum or Al (CH3) N (CH2) 5CH3 precursor into the reaction chamber within 0.2 to 0.5 seconds under the pressure of 0.1 to 10 Torr; introducing nitrogen or inert gas into the reaction chamber so as to remove the trimethyl aluminum or Al (CH3) N (CH2) 5CH3 residual gas which is not subjected to chemisorption by a substrate; under the pressure of 0.1 to 10 Torr, introducing ozone or vapor reactive gas into the reaction chamber within 0.2 to 0.5 seconds so as to deposit an alumina atom layer on the substrate, wherein the thickness of the alumina atom layer on the substrate is 2 to 100nm; and replacing the trimethyl aluminum or Al (CH3) N (CH2) 5CH3 precursor by using chlorosilane, hexachlorodisilane or tetraethyl orthosilicate as silicon source, then repeating the steps above, and covering a silicon dioxide layer on an alumina layer, wherein the thickness of the alumina layer is 2 to 100nm; and finally, obtaining the substrate material with a composite inorganic protective film in a Al2O3 / SiO2 double-layer structure, wherein the thickness of the substrate material is 5 to 120nm. The method can precisely control the thickness of the film, wherein the thickness of the film can directly and precisely be controlled within a range of 1 to 100nm, and the film has excellent oxidation resistance and gas permeation resistance, and can control the ratio of Al2O3 to SiO2.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Olefin polymerization catalysts and olefin polymer production methods using said olefin polymerization catalysts

InactiveUS6525150B1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparation1-OcteneOctene

Olefins are homopolymerized or copolymerized in the presence of a catalyst containing a reaction product obtained from vanadium oxytrichloride and 2,2'-thiobis(6-t-butyl-4-methylphenyl), an organic aluminum compound, such as trimethylaluminum, and an ionized ionic compound, such as N,N-dimethylanilinium tetrakis(pentafluorophenyl)borate, and the like. By using this catalyst to polymerize ethylene with an alpha-olefin, such as propylene, 1-heptene, 1-octene, and the like, or a non-conjugated diene, such as 5-ethylidene-2-norbomene, and the like, a polymer having a high degree of copolymerization is obtained.

Owner:JSR CORPORATIOON

Polymethylaluminoxane preparation, method of producing the same, polymerization catalyst, and polymerization method of olefins

InactiveUS7910764B2Good storage stabilityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCarboxylic acidOxygen

A polymethylaluminoxane preparation exhibiting excellent storage stability with a high yield is provided. A polymethylaluminoxane preparation is formed by thermal decomposition of an alkylaluminum compound having an aluminum-oxygen-carbon bond, the alkylaluminum compound being formed by a reaction between trimethylaluminum and an oxygen-containing organic compound. In this preparation,(i) the oxygen-containing organic compound reacting with trimethylaluminum is an aliphatic or aromatic carboxylic acid represented by the general formula (I),R1—(COOH)n (I),wherein R1 represents a hydrocarbon group of C1-C20 straight or branched alkyl groups, alkenyl groups or aryl groups, and n represents an integer of 1 to 5;(ii) a mole fraction of methyl groups originating from trimethylaluminum, relative to the total moles of methyl groups existing in the generated polymethylaluminoxane preparation is not more than 26 mol %; and(iii) the generated polymethylaluminoxane preparation has a viscosity of not more than 2.1×10−3 Pa·sec at 40° C.

Owner:TOSOH FINECHEM CORP

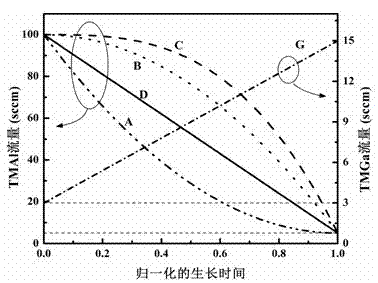

Gradient AlGaN layer preparation method and device prepared by same

ActiveCN103117209AChange rate of changeControl distributionSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorTrimethylgallium

The invention relates to the technical field of semiconductors, in particular to a gradient AlGaN layer preparation method and a device prepared by the same. When a gradient AlGaN layer is grown, flow of trimethylaluminum fed into a reaction chamber is gradually decreased, and flow of trimethylgallium is increased gradually. The function of the trimethylaluminum flow satisfies yTMAl=a-bx<m> or yTMAl=a(1-x)<m>+b, the function of the trimethylgallium flow satisfies yTMGa=cx<n>+d or yTMGa=c-d(1-x)<n>, x refers to normalization time of growing of the gradient AlGaN layer, and m and n are 1 asynchronously. By the aid of the different flow functions, change rates of TMAl and TMGa in different flows are changed, so that distribution of aluminum in the gradient AlGaN layer can be controlled effectively, further stress and crystalline quality of a GaN film growing on the gradient AlGaN layer are regulated and controlled, and a thick GaN film high in crystalline quality and free of crazing is grown.

Owner:SUN YAT SEN UNIV

Preparation method of trimethylaluminium

InactiveCN105175440AHigh yieldHigh purityGroup 3/13 element organic compoundsEvaporationMethyl group

The invention relates to a preparation method of trimethylaluminium. The method comprises steps as follows: (1) magnalium and haloalkane have a contact reaction in the presence of an ether solvent and in the inert atmosphere to produce a trimethylaluminium ether complex; (2) the trimethylaluminium ether complex and an amine and / or phosphine compound with the high boiling point have a contact reaction to produce a trimethylaluminium amine complex and / or a trimethylaluminium phosphine complex; (3) the complexes obtained in Step (2) are decomposed. With the adoption of the preparation method, the yield and the purity of the trimethylaluminium can be significantly increased, the yield of the trimethylaluminium can be higher than 80%, the purity can be 99.9999%, besides, a reaction kettle used in the method can be used as an evaporation kettle, the technology and equipment are simplified, the reaction process is easy to control, the prepared product can be separated from raw materials and byproducts more easily, the method is very applicable to industrial production, in addition, the byproducts can be used for synthesizing aluminum sulfate, and almost no waste is produced.

Owner:JIANGXI JIAYIN PHOTOELECTRIC MATERIAL

Trimethylaluminium preparation method

InactiveCN104774219ASave materialHigh yieldGroup 3/13 element organic compoundsEtherCoordination complex

A trimethylaluminium preparation method includes the steps of adding aluminium-magnesium alloy powder and ethers into a reactor under the protection of inert gas, dropwise adding alkyl halide under the stirring condition, keeping ether backflow in the dropwise alkyl halide adding process, continuing to keep the ether backflow for 4 hours to 5 hours after alkyl halide is dropwise added, regulating the temperature of the reactor to 45 DEG C to 100 DEG C, keeping the temperature for 1 hour to 4 hours, evaporating the ethers, regulating the temperature of the reactor to 45 DEG C to 70 DEG C, keeping the temperature, evaporating the coordination compound of trimethylaluminium and the ethers under the vacuum condition, moving the coordination compound of the trimethylaluminium and the ethers to a deolation kettle, adding tri-n-octylamine, conducting heating and backflow under the stirring condition, keeping for 2 hours to 3 hours, regulating the temperature of the deolation kettle to 85 DEG C to 89 DEG C again, keeping the temperature for 8 hours to 10 hours under the vacuum degree of 1 mmHg to 50 mmHg, evaporating the ethers, raising the temperature of the deolation kettle to 90 DEG C to 160 DEG C, keeping the temperature for 30 hours to 35 hours under the vacuum condition, and evaporating the trimethylaluminium.

Owner:HENAN CHENGMING PHOTOELECTRIC NEW MATERIAL CO LTD

Preparation method of high-purity trimethyl aluminum

ActiveCN104774218AEasy to operateImprove the purification effectGroup 3/13 element organic compoundsStationary phasePurification methods

The invention relates to a preparation method of high-purity trimethyl aluminum, belonging to the technical field of preparation of compounds of Group 3 metals in the periodic table. The preparation method comprises the following steps: (1) preparing a trimethyl aluminum crude product by using aether as a solvent; and (2) purifying the trimethyl aluminum crude product obtained in the step (1), wherein a first chromatographic column is utilized to purify the trimethyl aluminum crude product and adopts grafted silicon dioxide as a stationary phase, and the grafted silicon dioxide is silicon dioxide with tri-n-octyl amine grafted on the surface. The preparation method adopts the two steps of synthesis and separation to obtain the trimethyl aluminum of which the purity can reach 6N. The purification method combines the solid-liquid separation means to load the specific complexant onto the silicon dioxide; and thus, the method is simple to operate and further enhances the purification effect.

Owner:苏州普耀光电材料有限公司

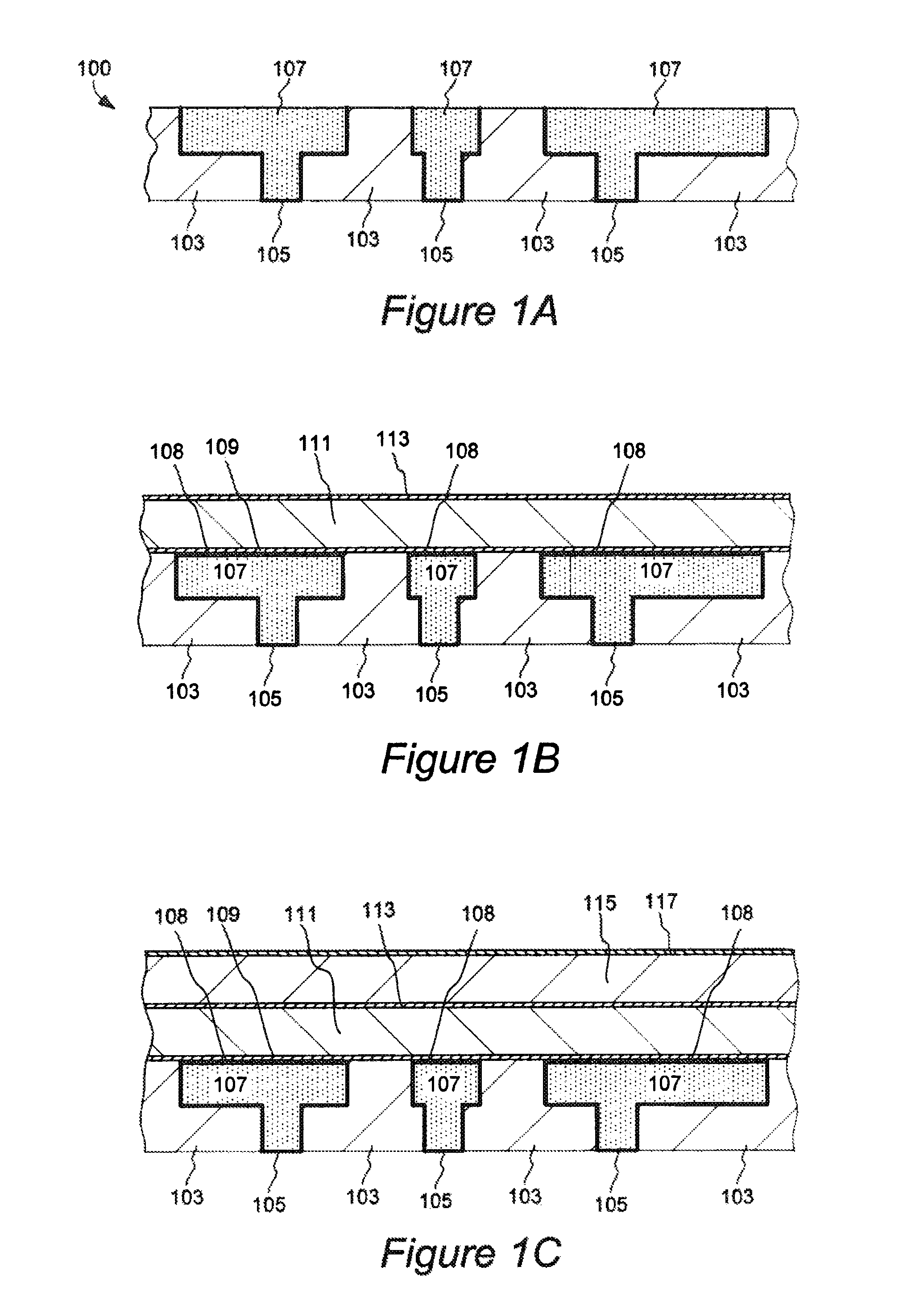

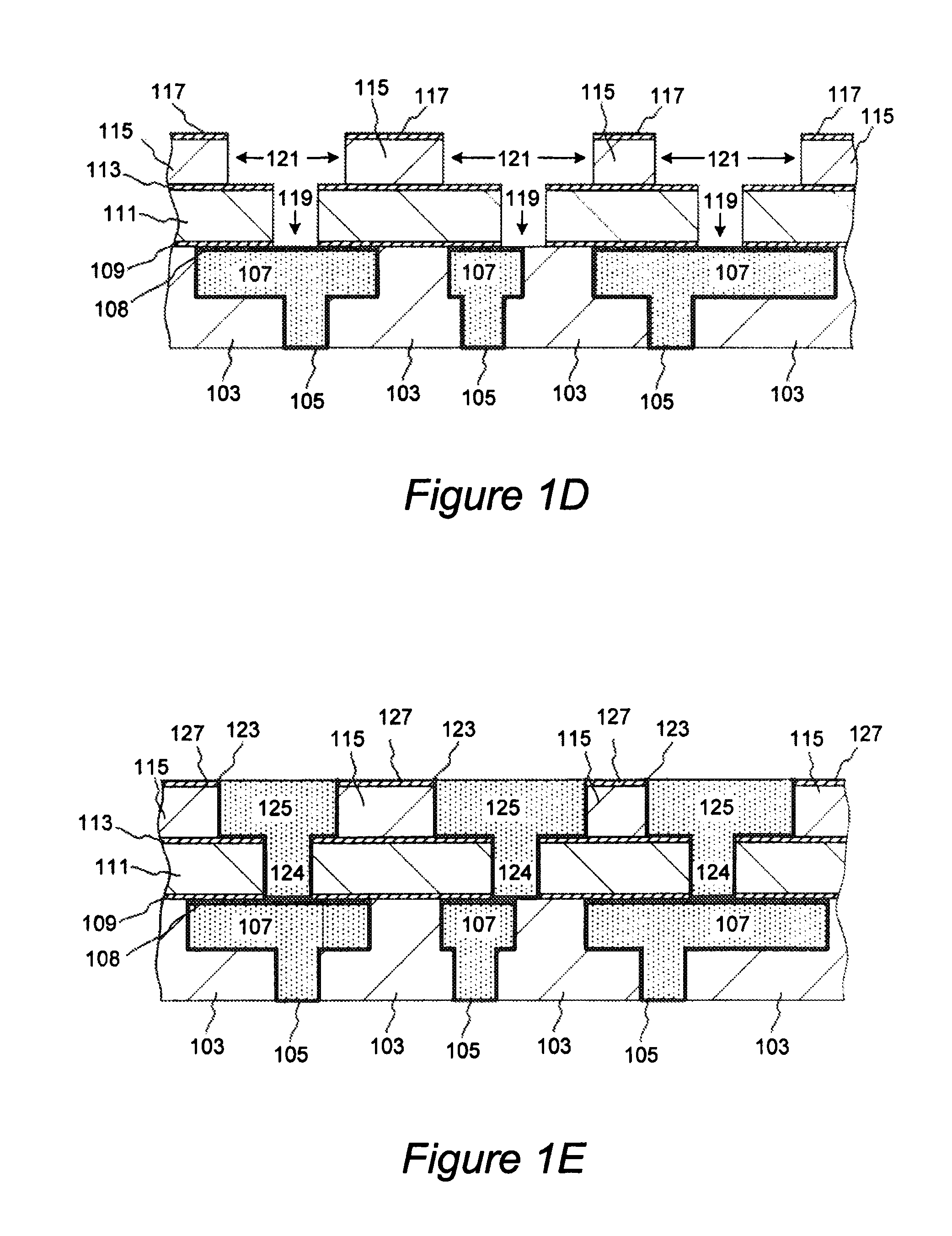

Interfacial capping layers for interconnects

ActiveUS8268722B2Improved electromigration performanceIncreasing interconnect resistanceSemiconductor/solid-state device detailsSolid-state devicesDielectricMetallic materials

Adhesive layers residing at an interface between metal lines and dielectric diffusion barrier (or etch stop) layers are used to improve electromigration performance of interconnects. Adhesion layers are formed by depositing a precursor layer of metal-containing material (e.g., material containing Al, Ti, Ca, Mg, etc.) over an exposed copper line, and converting the precursor layer to a passivated layer (e.g., nitridized layer). For example, a substrate containing exposed copper line having exposed Cu—O bonds is contacted with trimethylaluminum to form a precursor layer having Al—O bonds and Al—C bonds on copper surface. The precursor layer is then treated to remove residual organic substituents and to form Al—N, Al—H bonds or both. The treatment can include direct plasma treatment, remote plasma treatment, UV-treatment, and thermal treatment with a gas such as NH3, H2, N2, and mixtures thereof. A dielectric diffusion barrier layer is then deposited.

Owner:NOVELLUS SYSTEMS

Carried catalyzer for olefinic polymerization and preparation method

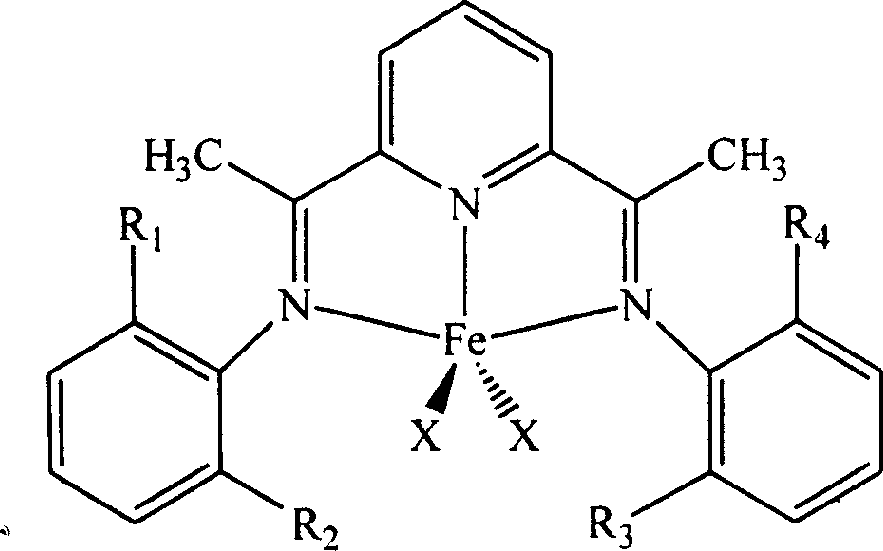

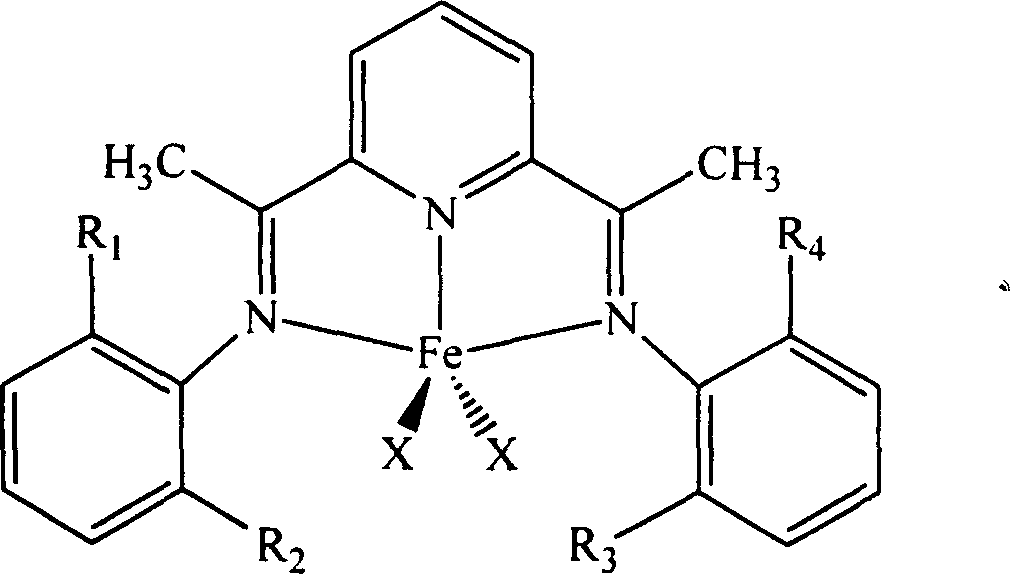

A carried metallocene catalyst or post-transition metal catalyst for the catalytic polymerization of ethylene and propylene contains Zr or Fe (0.05-1.00 wt. portions), aluminium alkylide chosen from trimethyl aluminium, triethyl aluminum and triisobutyl aluminum (1-50) and molecular sieve-like calcium silicon compound (100). Its preparing process is also disclosed. Its advantages are high catalytic activity and no adhesion to reactor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyethylene and process for production thereof

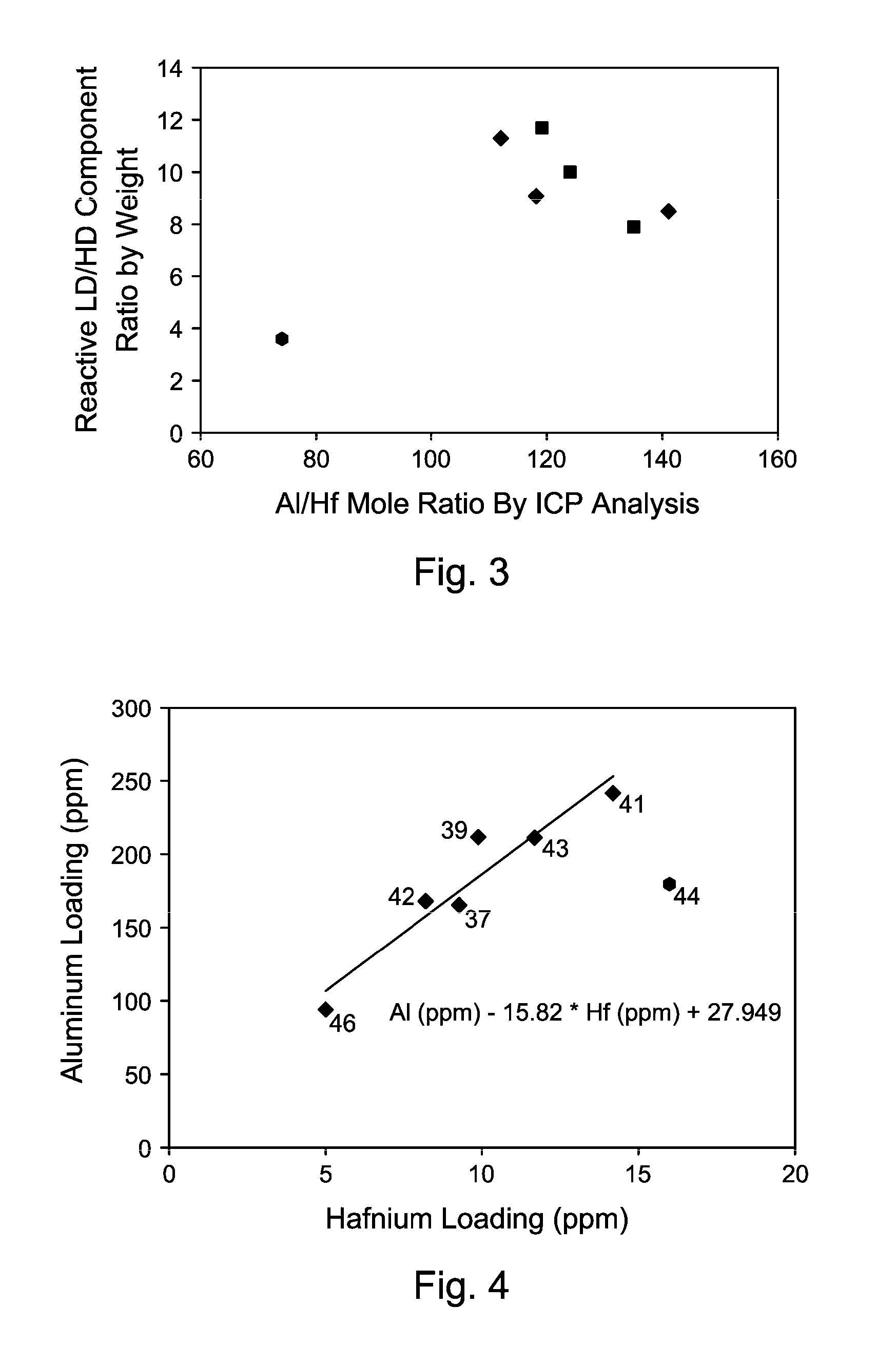

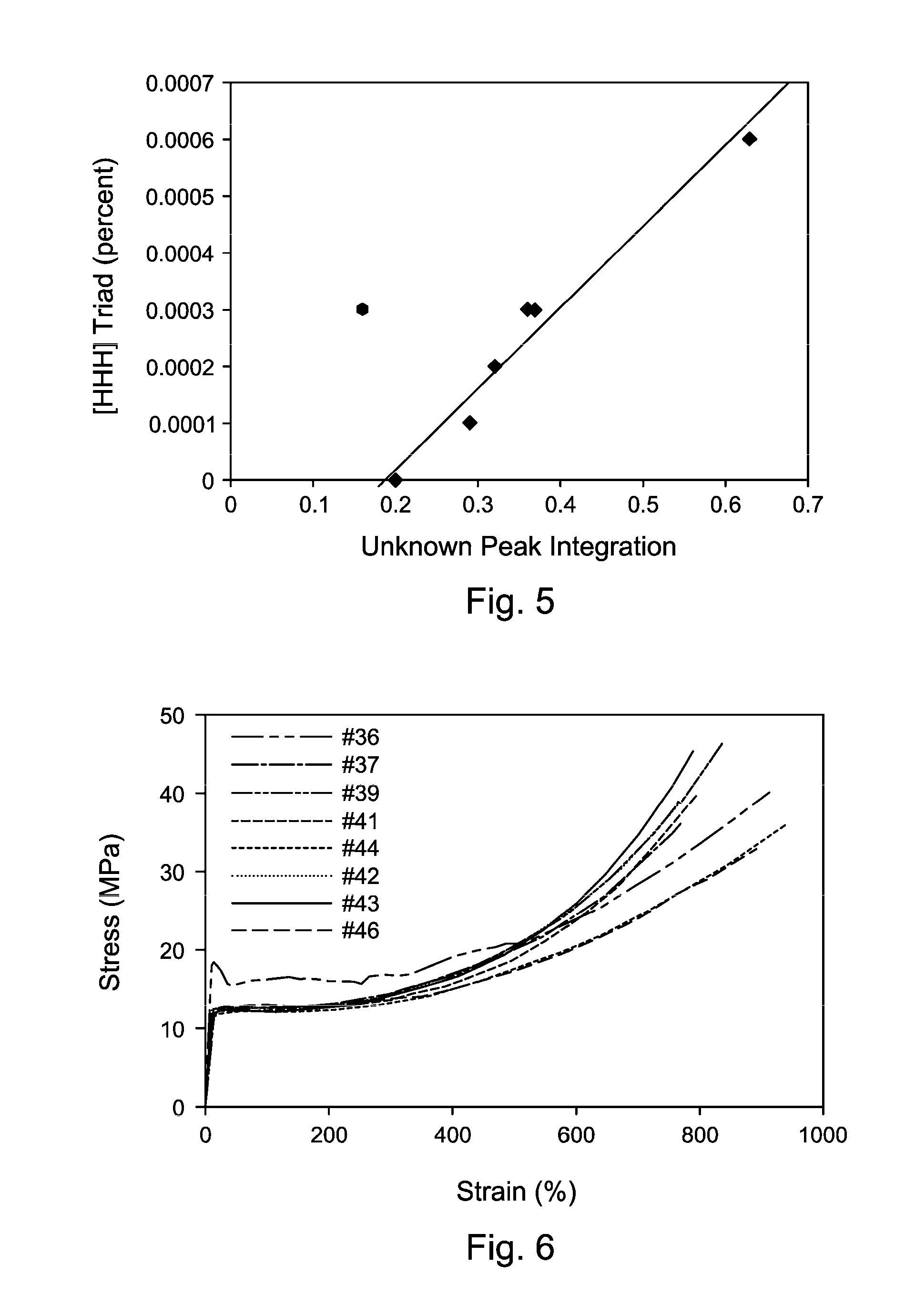

InactiveUS8431661B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceAluminoxane

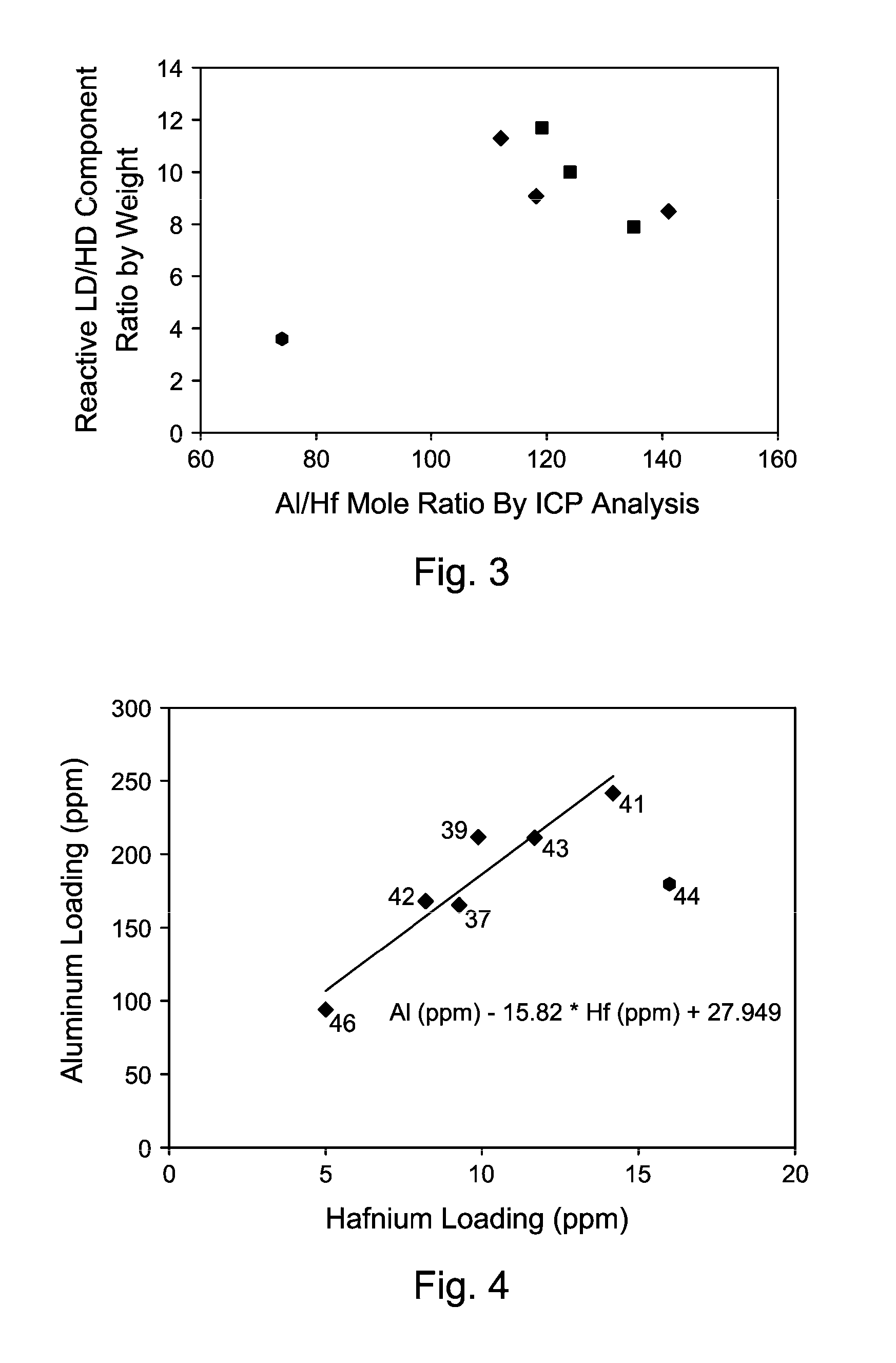

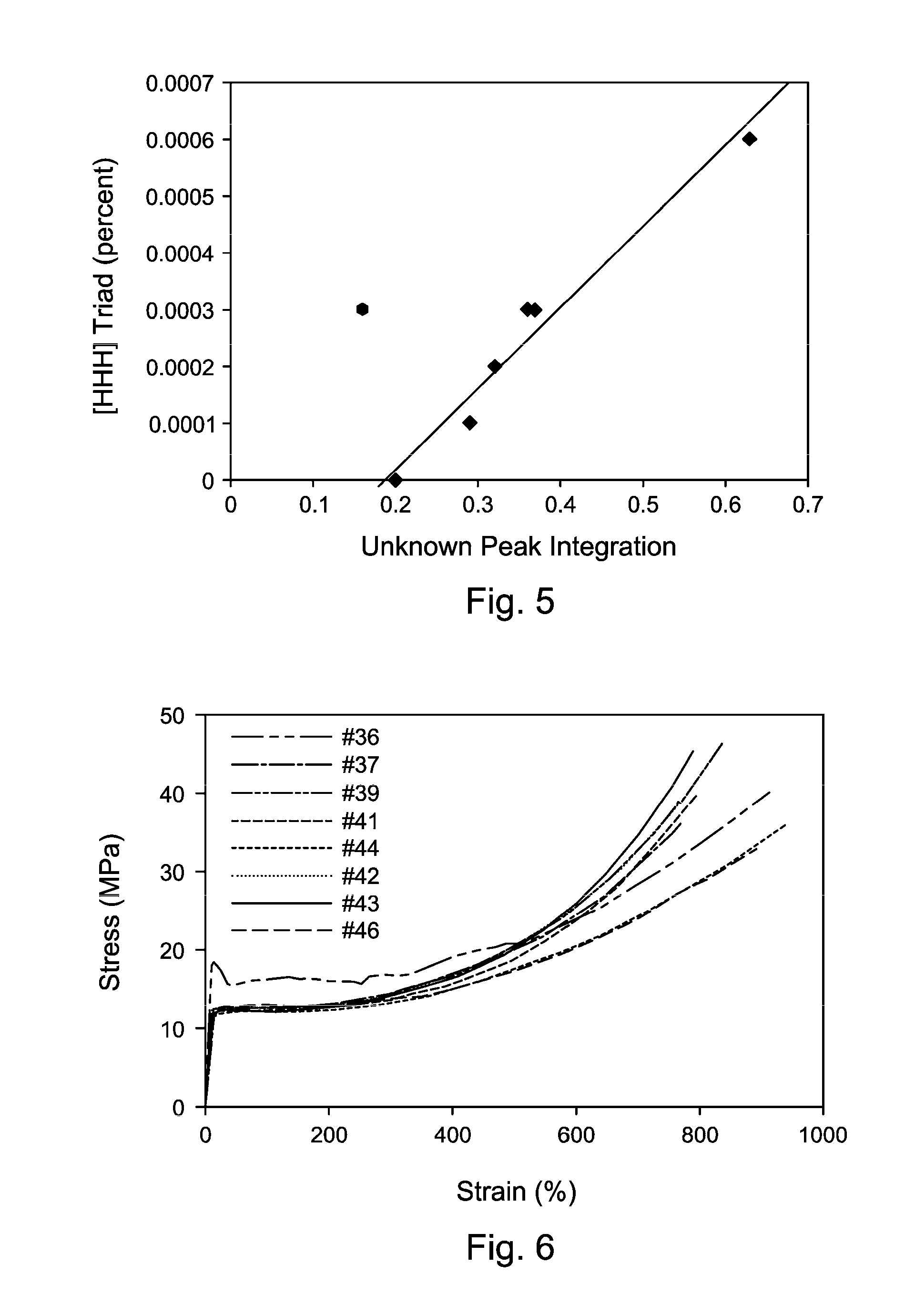

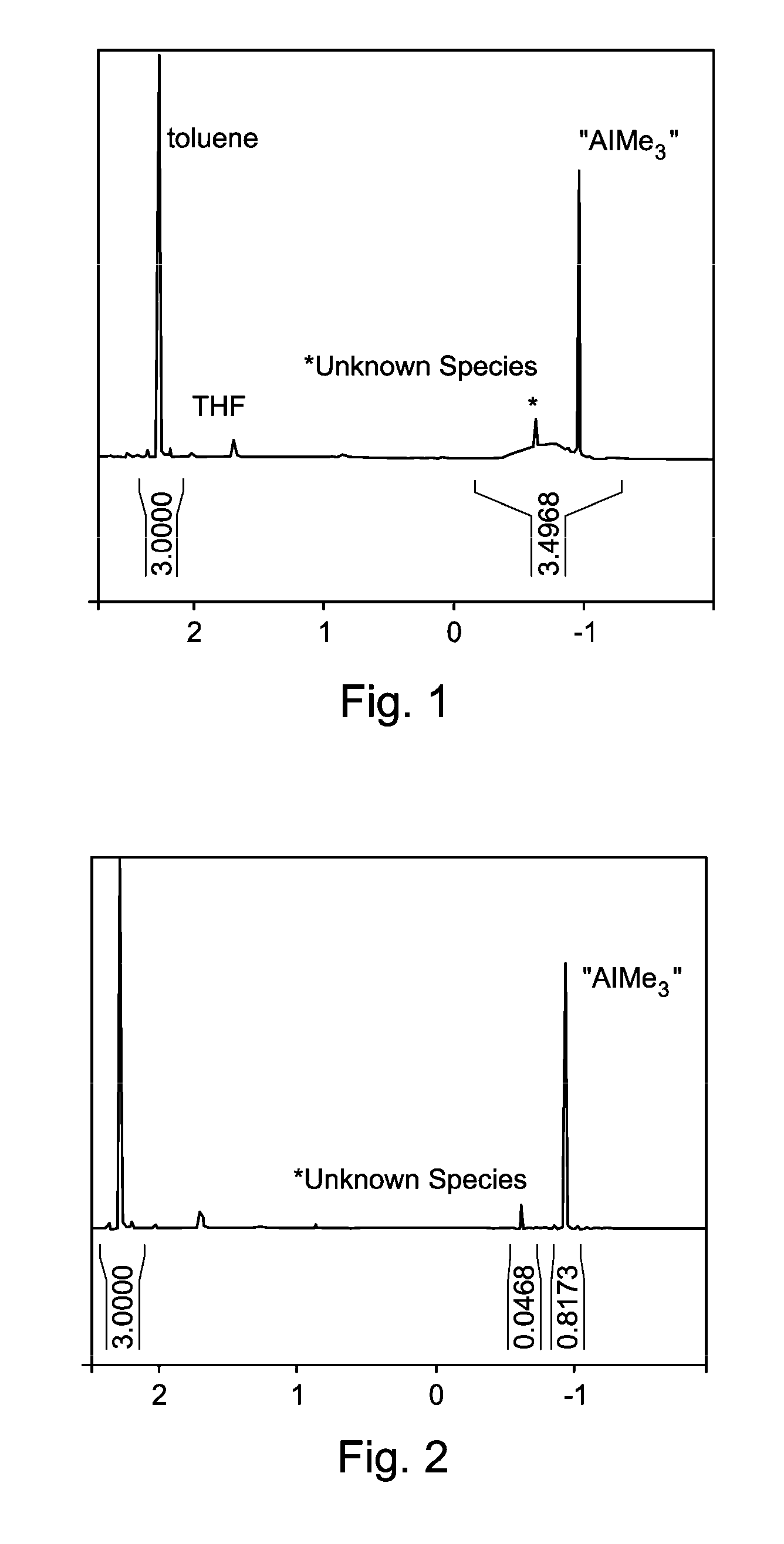

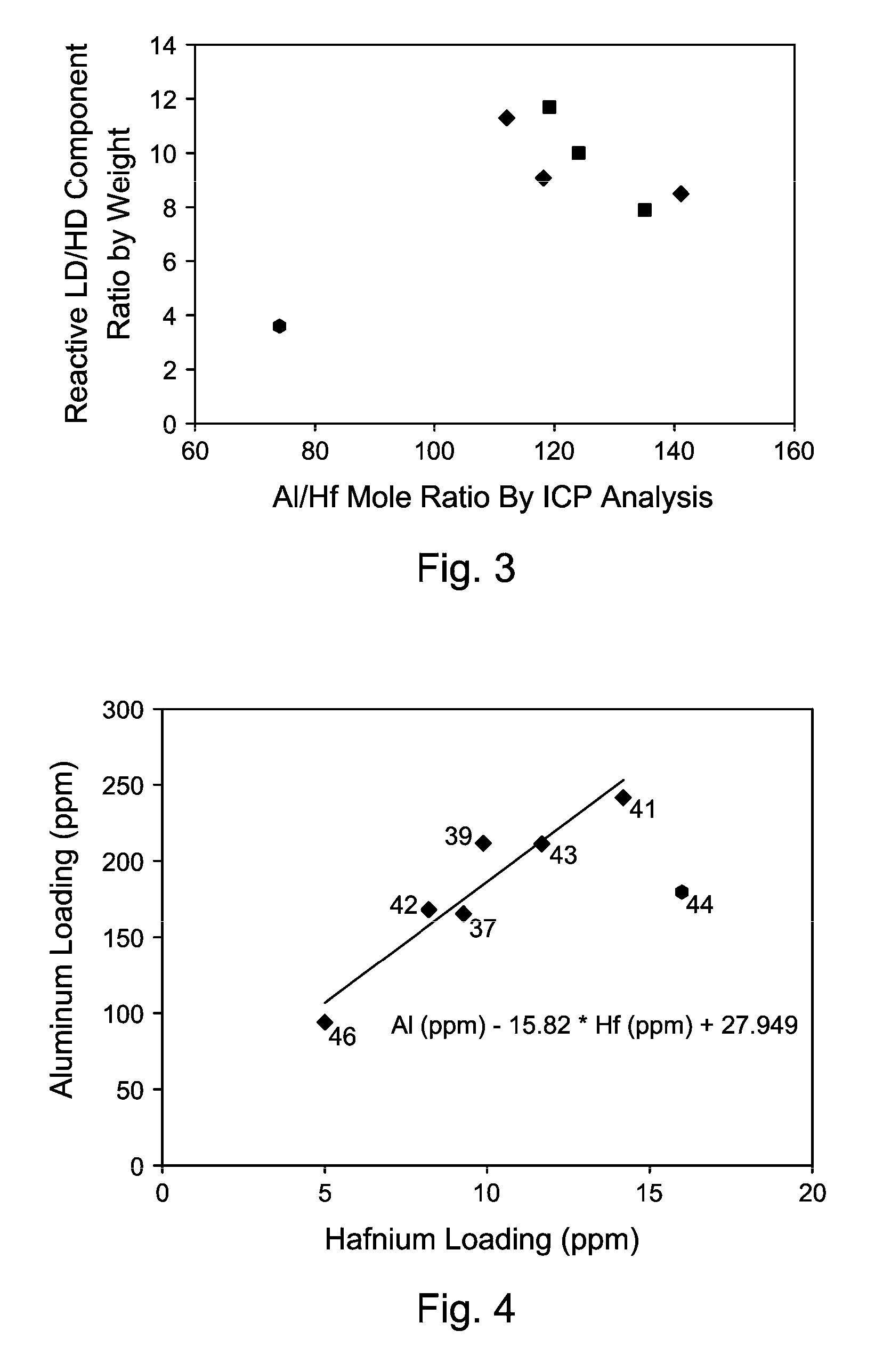

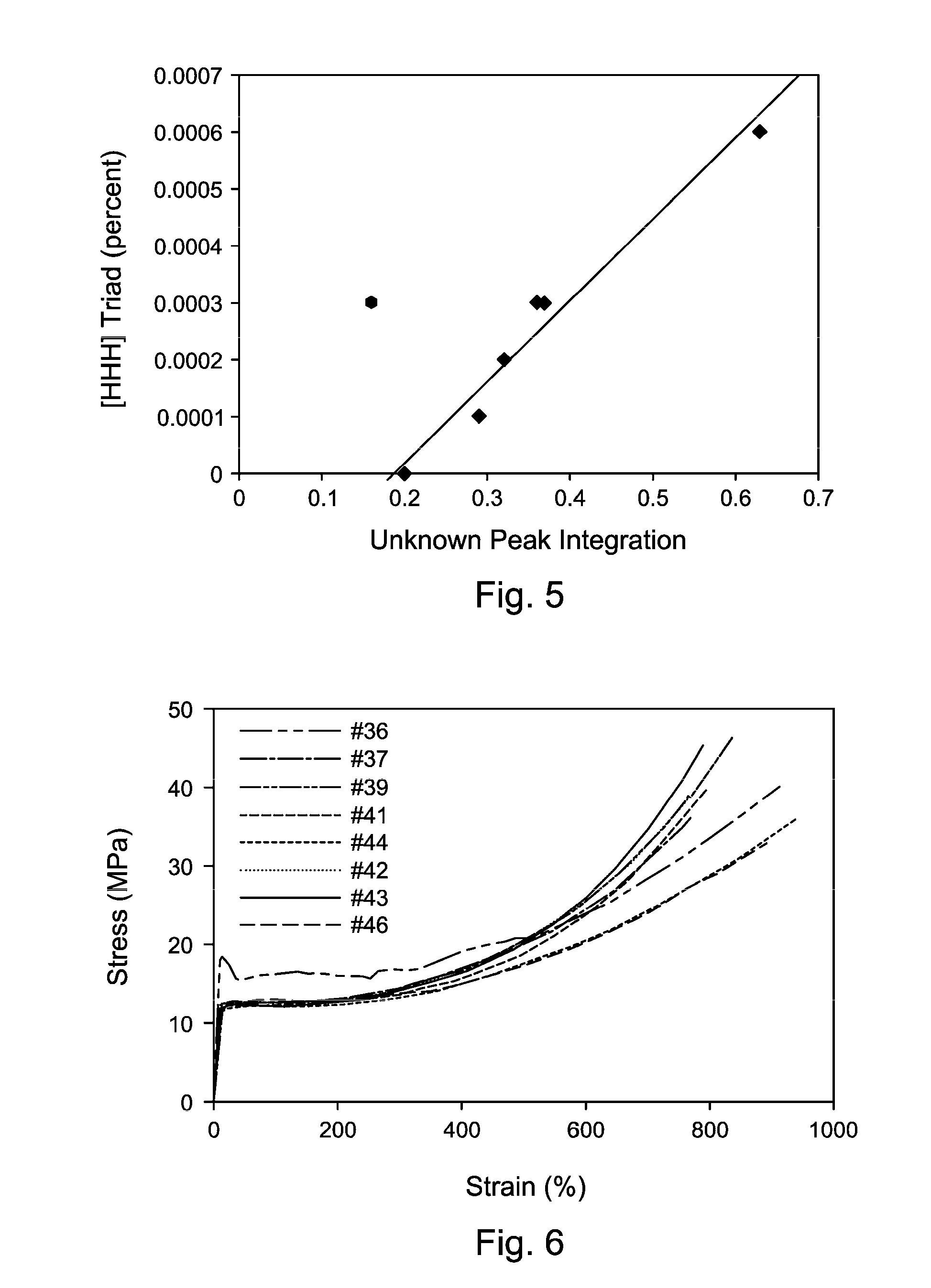

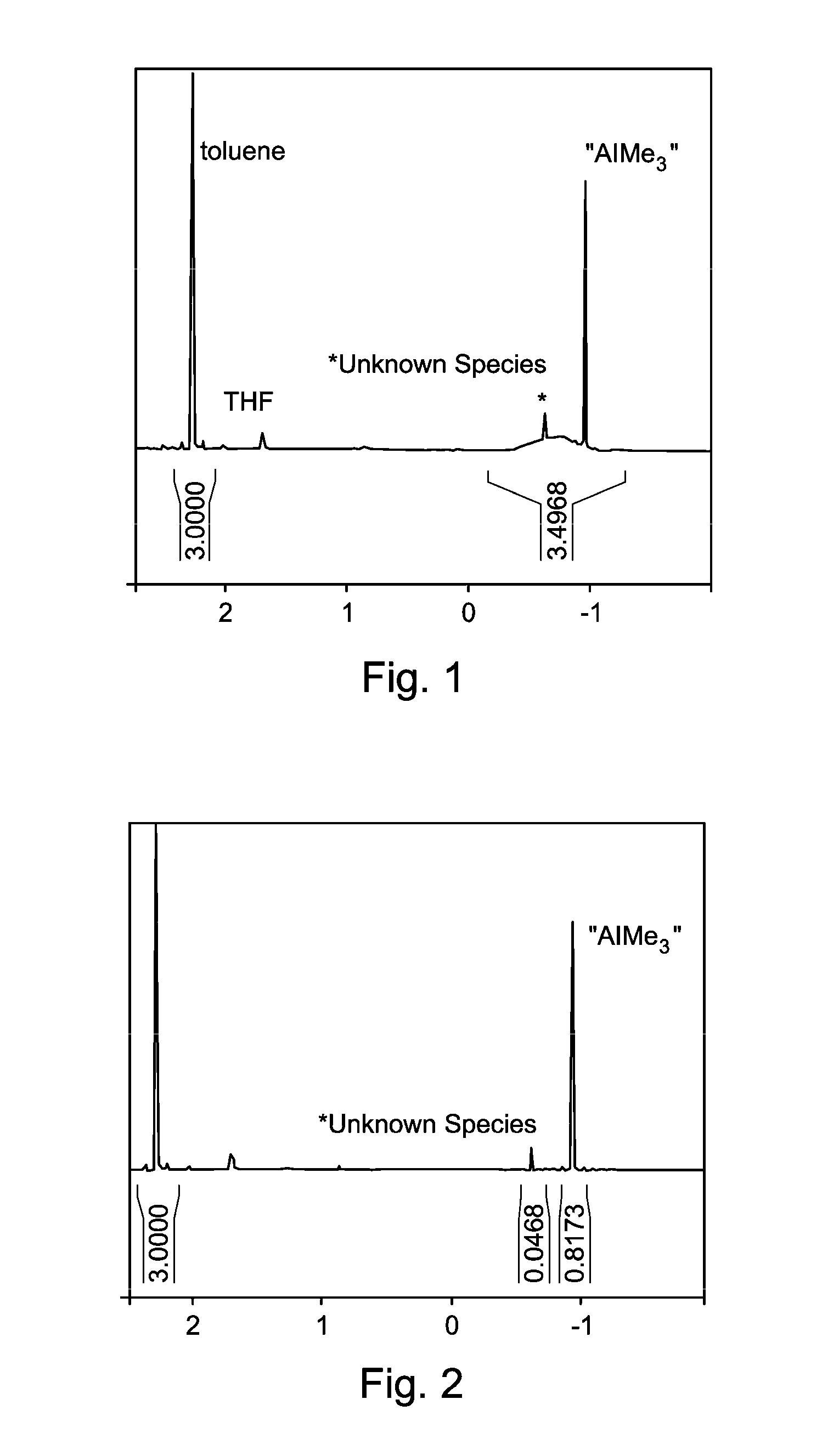

This invention relates to a process for polymerizing olefins in which the amount of trimethylaluminum in a methylalumoxane solution is adjusted to be from 6 to 25 mole %, prior to use as an activator, where the mole % trimethylaluminum is determined by 1H NMR of the solution prior to combination with any support. This invention also relates to a process for polymerizing olefins in which the amount of an unknown species present in a methylalumoxane solution is adjusted to be from 0.10 to 0.65 integration units prior to use as an activator, where the unknown species is the peak is identified in the 1H NMR spectra of the solution performed prior to combination with any support. Preferably, the methylalumoxane solution is present in a catalyst system also comprising a metallocene transition metal compound.

Owner:EXXONMOBIL CHEM PAT INC

Epitaxial structure of ultraviolet LED with aluminum nitride film and growth method of aluminum nitride film

ActiveCN108257853APromote growthEasy to implementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltravioletAmmonia gas

The present invention provides an epitaxial structure of an ultraviolet LED with an aluminum nitride film and a growth method of the aluminum nitride film. The growth method of the aluminum nitride film includes the following steps that: 1) a metal layer is grown on a substrate; 2) annealing treatment is performed on the substrate, so that the metal layer can form a metal ball-shaped object layer;3) etching treatment is performed on the substrate, so that a pitted substrate can be formed; 4) when temperature rises to 600 to 1200 DEG C, trimethylaluminum and ammonia gas are introduced into a reaction chamber, so that a buffer growth layer can be to grown; 5) when temperature rises to 1250 to 1450 DEG C, first growth mode / second growth mode alternate cyclic growth is carried out, so that anintermediate-state aluminum nitride layer can be formed; and 6) when temperature drops to 1100 to 1250 DEG C, the trimethylaluminum and ammonia are introduced into the aluminum nitride layer, so thatthird growth mode growth can be performed. The aluminum nitride film obtained by using the method has good crystal quality; and the surface cracks of the aluminum nitride film can be reduced.

Owner:MAANSHAN JASON SEMICON CO LTD

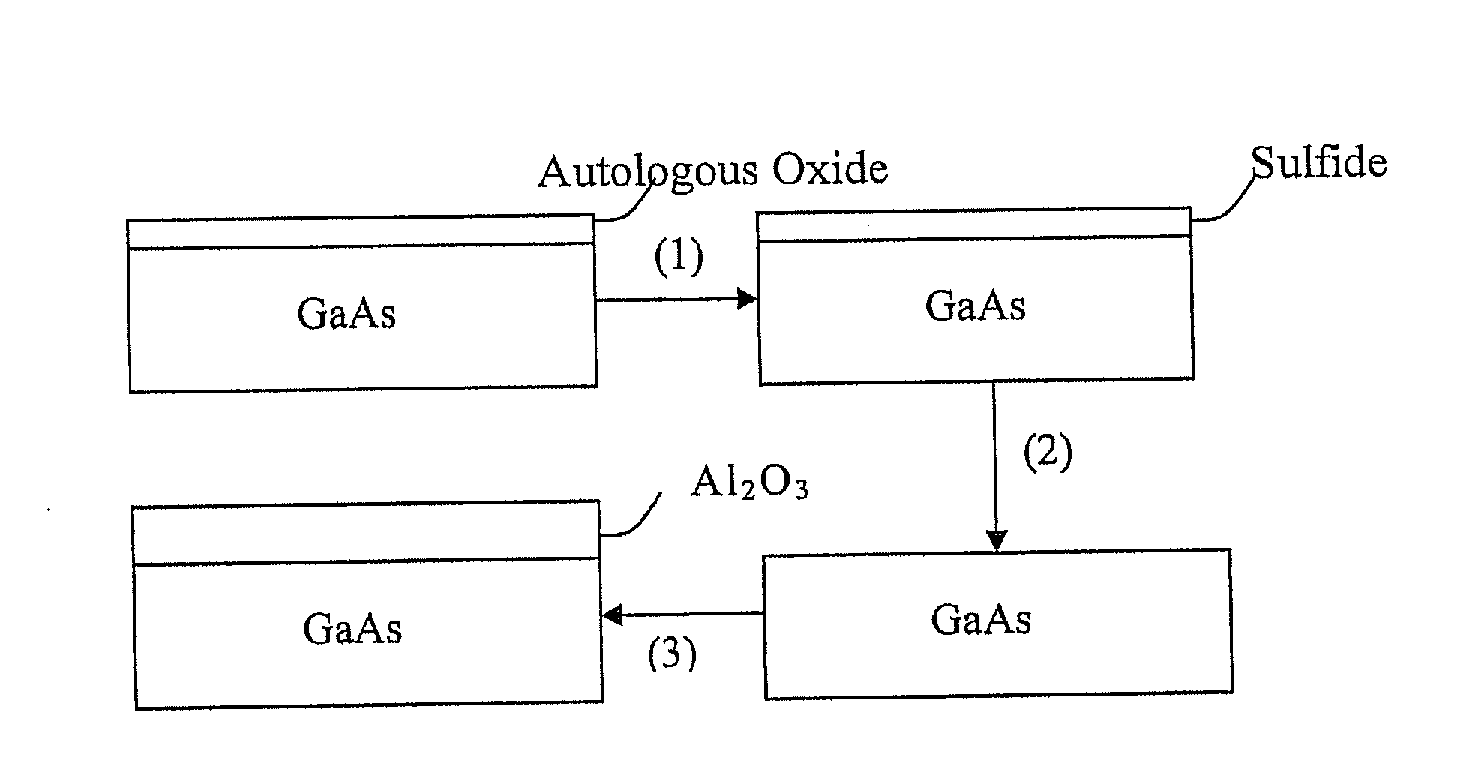

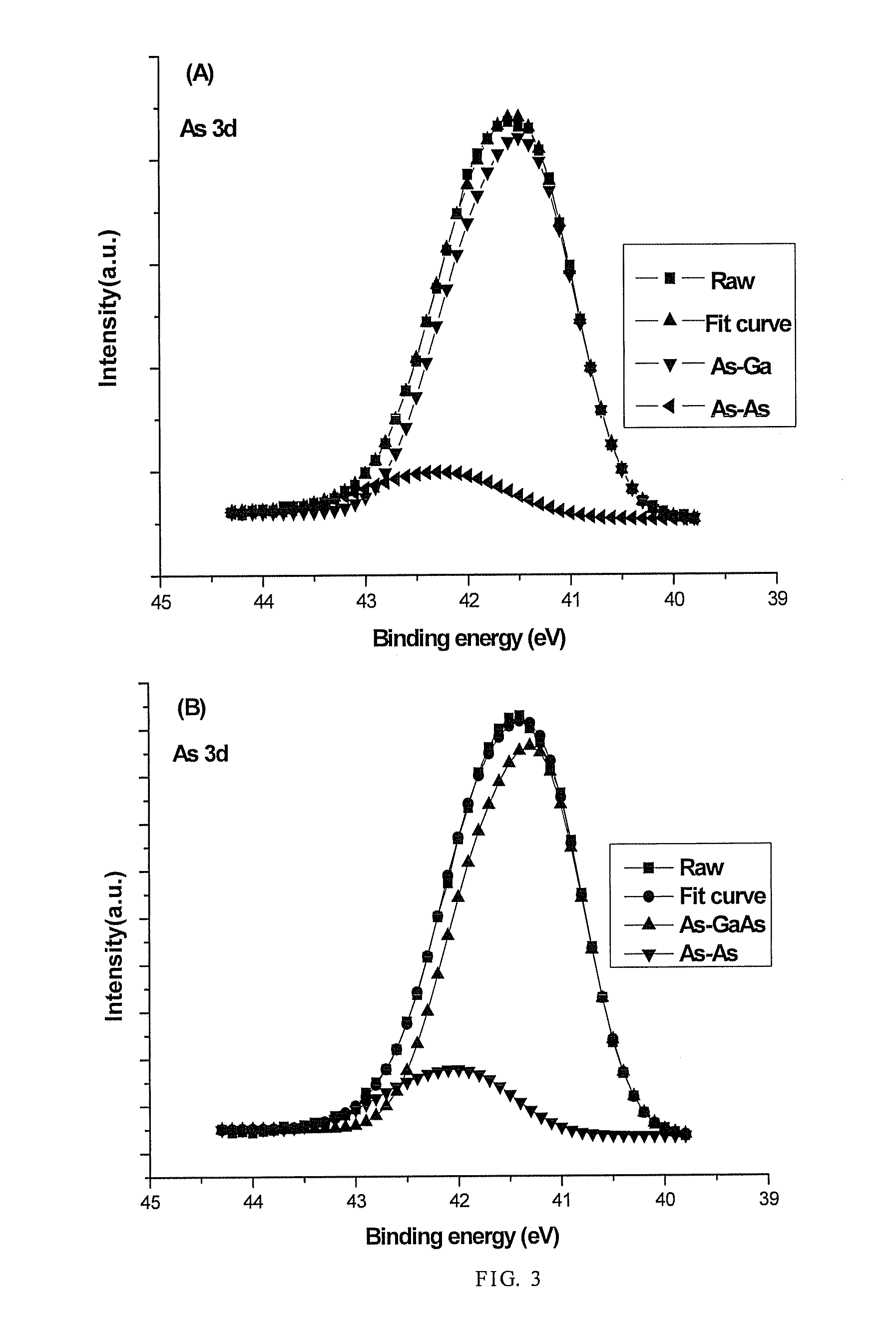

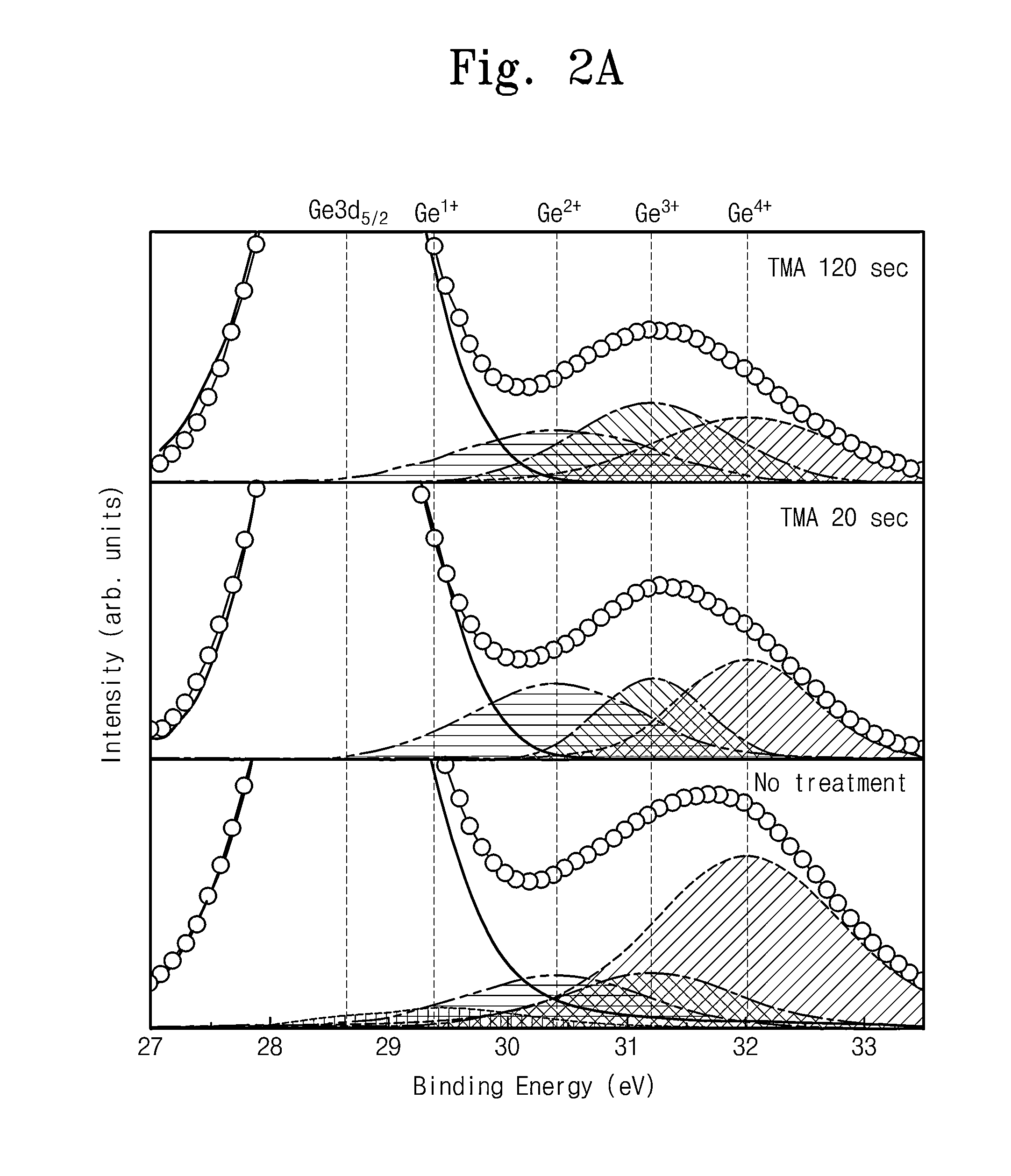

Method for cleaning & passivating gallium arsenide surface autologous oxide and depositing al2o3 dielectric

InactiveUS20130078819A1Quality improvementPreventing the GaAs from oxidatingPolycrystalline material growthPretreated surfacesDielectricGate dielectric

The present invention belongs to the technical field of semiconductor materials and specifically relates to a method for cleaning & passivizing gallium arsenide (GaAs) surface autologous oxide and depositing an Al2O3 dielectric. This method includes: use a new-type of sulfur passivant to react with the autologous oxide on the GaAs surface to clean it and generate a passive sulfide film to separate the GaAs from the outside environment, thus preventing the GaAs from oxidizing again; further cleaning the residuals such as autologous oxides and sulfides on the GaAs surface through the pretreatment reaction of the reaction source trimethyl aluminum (TMA) of the Al2O3 ALD with the GaAs surface, and then deposit high-quality Al2O3 dielectric through ALD as the gate dielectric which fully separates the GaAs from the outside environment. The present invention features a simple process and good effects, and can provide preconditions for manufacturing the GaAs devices.

Owner:FUDAN UNIV

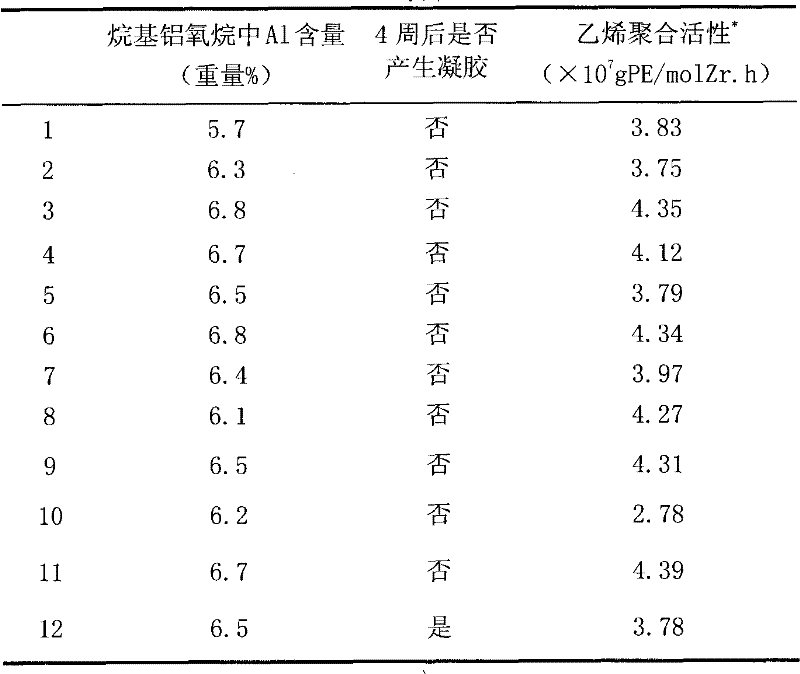

A kind of preparation method of alkyl aluminoxane solution

ActiveCN102286012AImprove anti-gel propertiesReduce manufacturing costGroup 3/13 element organic compoundsAlkaline earth metalAluminoxane

The invention provides a preparation method of an alkylaluminoxane solution, comprising the following steps: (1) mixing crystalline hydrate and alkali metal or alkaline earth metal anhydrous hydroxide, adding an organic solvent and stirring; (2) adding two or more different alkyl aluminums into silted size formed in the step (1) to react at low temperature; and (3) adding halogenated alkyl aluminum and stirring, and filtering solid substances out after reaction to obtain the alkylaluminoxane solution. One of the alkyl aluminums is trimethyl aluminium, and the other alkyl aluminum is high-carbon alkyl aluminum which contains 2-10 carbon atoms and has relative low price. The method has low cost, the obtained product has good gel resistance, and the analysis promotion activity of the alkylaluminoxane solution can be maintained.

Owner:PETROCHINA CO LTD

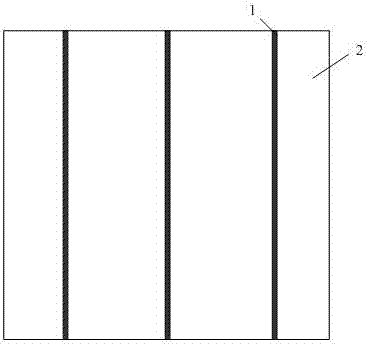

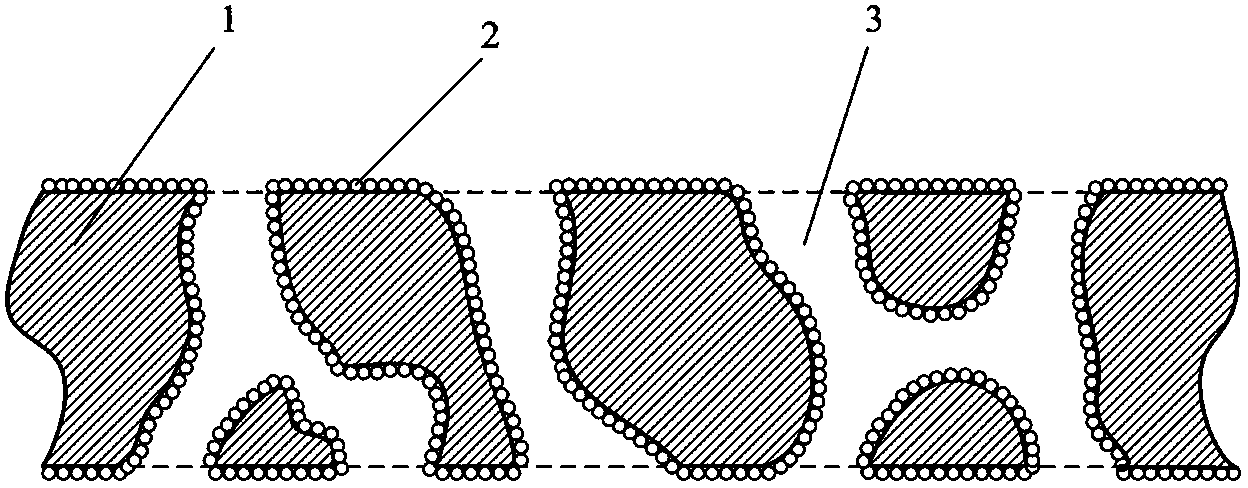

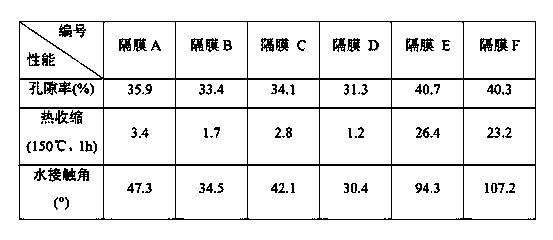

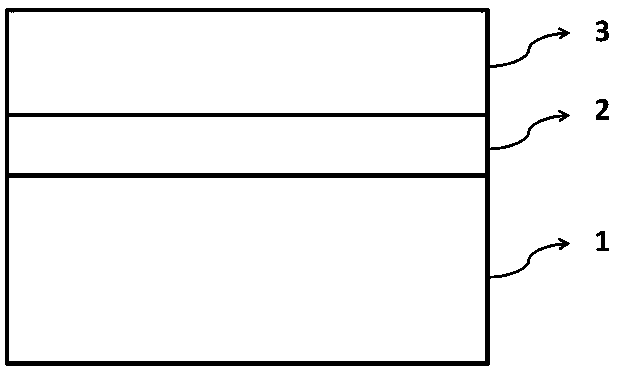

Separator for lithium ion battery and preparation method of separator

InactiveCN104377331ALower internal resistanceImprove performanceCell seperators/membranes/diaphragms/spacersElectrolytic agentNitrogen gas

The invention discloses a separator for a lithium ion battery and belongs to the technical field of lithium ion batteries. The separator comprises a polymer microporous film substrate, wherein the surface of the substrate and the internal wall of a micropore duct of the substrate are coated with nano-oxide layers. The preparation method comprises the following steps: (1) performing oxidation treatment on the polymer microporous film with an acid solution, then washing the film successively with an alkali solution and deionized water and drying the film; (2) putting the film on an atomic layer deposition apparatus or a continuous atomic layer deposition device, then vacuumizing, heating to 50-100 DEG C and keeping for 1-30min; (3) introducing trimethylaluminum as a first precursor; (4) adding nitrogen or inert gas for purging; (5) introducing a second precursor; (6) adding nitrogen or inert gas for purging; (7) repeating steps (3)-(6); and (8) performing heat setting treatment. The separator disclosed by the invention is small in thickness and heat shrinkage, and is good in wetting property with electrolyte. The preparation process temperature is low, a formed coating is dense, and the thickness of the coating can be precisely controlled.

Owner:XINXIANG ZHONGKE SCI&TECH

Homogeneous epitaxial growth method of high-quality aluminum nitride film

InactiveCN111188090AImprove performanceQuality improvementPolycrystalline material growthFrom chemically reactive gasesFilm baseThin membrane

The invention relates to a homogeneous epitaxial growth method of a high-quality aluminum nitride film. The homogeneous epitaxial growth method of the high-quality aluminum nitride film based on an aluminum nitride substrate is carried out in MOCVD equipment, and comprises the following steps: selecting an aluminum nitride substrate; putting the substrate into an MOCVD reaction cavity, and heatingto bake the substrate; introducing ammonia gas (NH3) to protect the substrate, further increasing the growth temperature, introducing trimethylaluminum (TMAl) and ammonia gas (NH3) at the same time,and growing a first aluminum nitride (AlN) optimization layer at a low growth rate; and then reducing the growth temperature, and increasing the growth rate to grow a second high-quality AlN epitaxialfilm. The method has the advantages that the method is simple and feasible, the growth period is short, the material performance is good, and the method is an effective solution for realizing high-quality and low-cost growth of the AlN epitaxial film.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Polyethylene and Process for Production Thereof

InactiveUS20120101235A1Improve tensile propertyOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsChemistryMethylaluminoxane

This invention relates to a process for polymerizing olefins in which the amount of trimethylaluminum in a methylalumoxane solution is adjusted to be from 1 to 25 mol %, prior to use as an activator, where the mol % trimethylaluminum is determined by 1H NMR of the solution prior to combination with any support. This invention also relates to a process for polymerizing olefins in which the amount of an unknown species present in a methylalumoxane solution is adjusted to be from 0.10 to 0.65 integration units prior to use as an activator, where the amount of the unknown species is determined by the 1H NMR spectra of the solution performed prior to combination with any support. Preferably, the methylalumoxane solution is present in a catalyst system also comprising a metallocene transition metal compound.

Owner:EXXONMOBIL CHEM PAT INC

Polyethylene and Process For Production Thereof

This invention relates to a process for polymerizing olefins in which the amount of trimethylaluminum in a methylalumoxane solution is adjusted to be from 6 to 25 mole %, prior to use as an activator, where the mole % trimethylaluminum is determined by 1H NMR of the solution prior to combination with any support. This invention also relates to a process for polymerizing olefins in which the amount of an unknown species present in a methylalumoxane solution is adjusted to be from 0.10 to 0.65 integration units prior to use as an activator, where the unknown species is the peak is identified in the 1H NMR spectra of the solution performed prior to combination with any support. Preferably, the methylalumoxane solution is present in a catalyst system also comprising a metallocene transition metal compound.

Owner:EXXONMOBIL CHEM PAT INC

Preparation method of surface acoustic wave filter in AlN/GAZO/self-supporting diamond film structure

InactiveCN103014653AHigh crystallinityMeet high frequencyImpedence networksChemical vapor deposition coatingSurface acoustic waveNitrogen gas

The invention belongs to the field of piezoelectric thin-film materials, and particularly relates to a preparation method of a surface acoustic wave filter in an AlN / GAZO / self-supporting diamond film structure. The method comprises the following steps: cleaning a self-supporting diamond film used as a substrate, sending the self-supporting diamond film into a vapor deposition reaction chamber, introducing nitrogen gas, trimethyl aluminum, trimethyl gallium and diethyl zinc into the reaction chamber to deposit a GAZO film with the thickness of 80-120nm on the substrate, introducing trimethyl aluminum to deposit an AlN thin film with the thickness of 800nm on the substrate carrying the GAZO film, cooling the inside of the vapor deposition reaction chamber to room temperature, and opening the deposition chamber to obtain the surface acoustic wave filter in an AlN / GAZO / self-supporting diamond film structure. The method provided by the invention is simple, the technique is easy to control, and the prepared piezoelectric thin-film device has the advantages of favorable uniformity and excellent acoustic speed transmission performance and can be used for manufacturing high-power high-frequency surface acoustic wave filters.

Owner:SHENYANG INST OF ENG +1

Method of removing oxide from substrate and method of manufacturing semiconductor device using the same

ActiveUS20150194300A1The overall thickness is thinImprove mobilityTransistorSolid-state devicesDevice materialPhysical chemistry

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

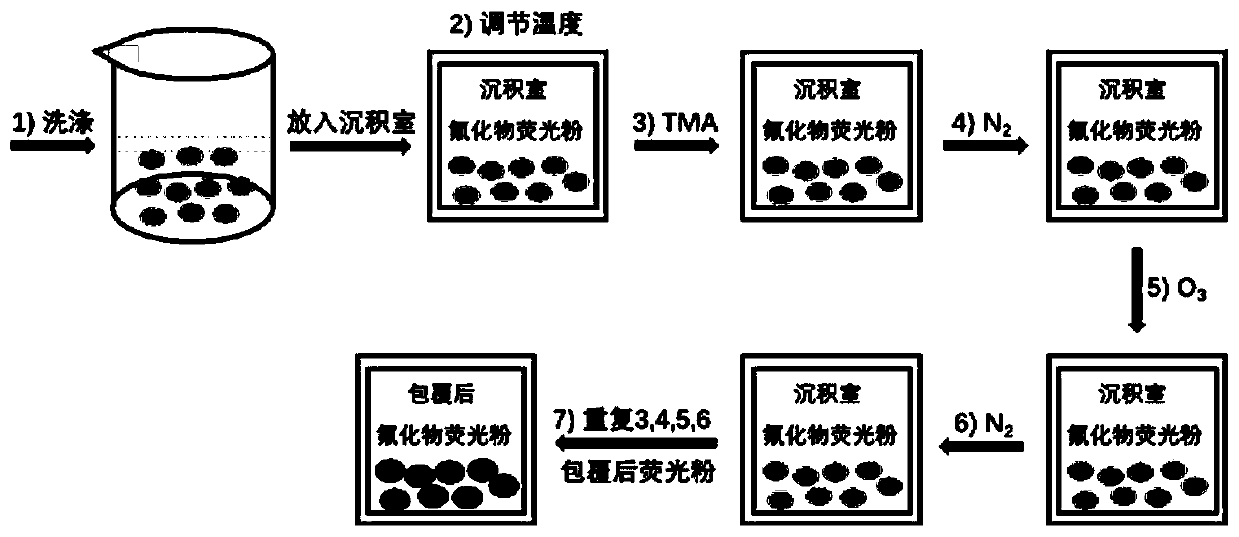

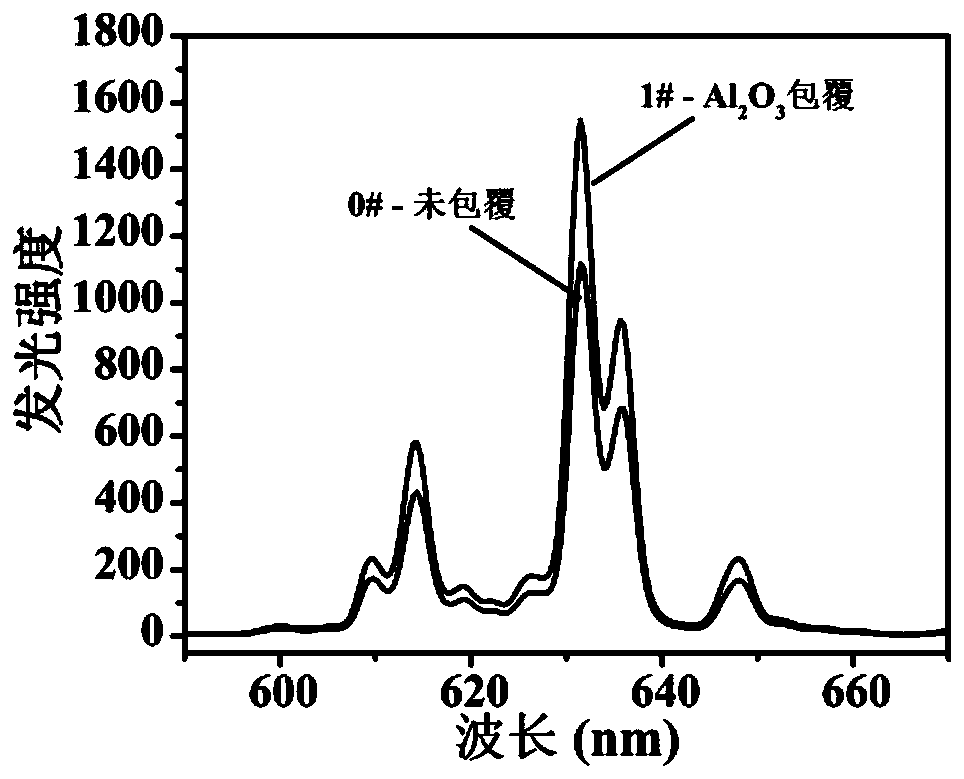

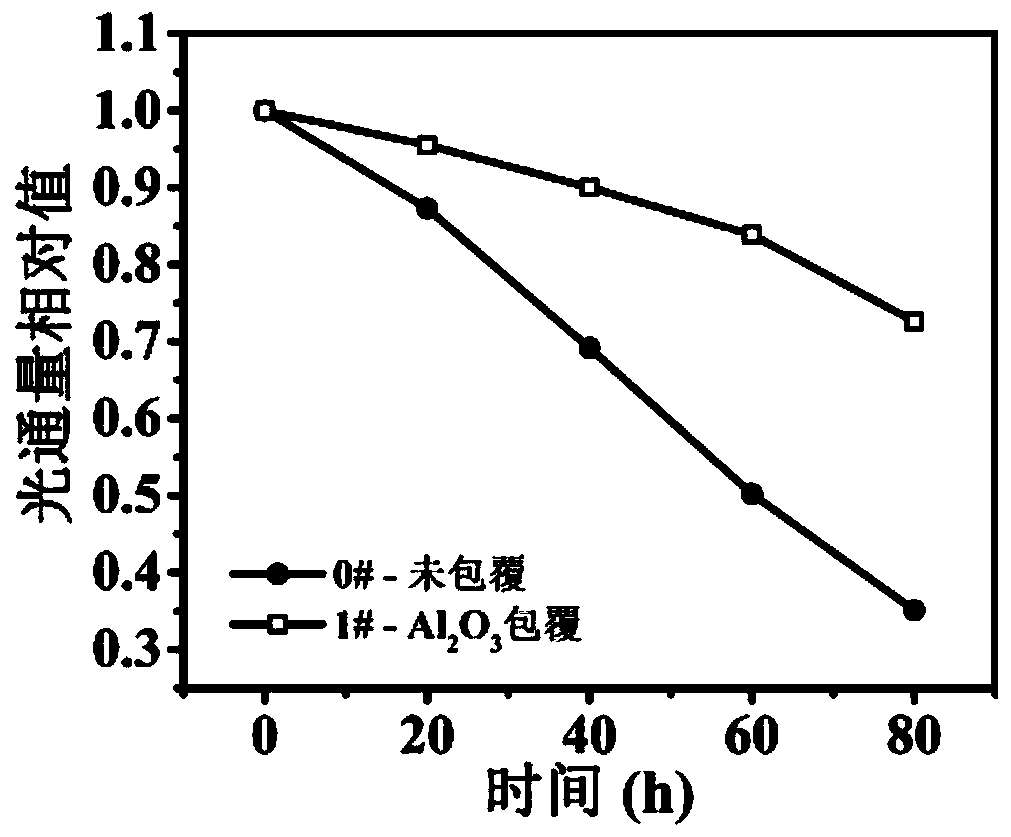

Fluoride phosphor powder coating method based on atomic layer deposition technology

InactiveCN110343518AReduce consumptionBlocking attackLuminescent compositionsSemiconductor devicesNitrogen gasAtomic layer deposition

The invention relates to a fluoride phosphor powder coating method based on an atomic layer deposition technology, and relates to material surface treatment. The method comprises the following steps:1) carrying out pre-treatment on fluoride phosphor powder and placing the treated fluoride phosphor powder into a deposition chamber; 2) adjusting the temperature of the deposition chamber; 3) introducing trimethyl aluminum into the deposition chamber with nitrogen as a carrier gas, and purging the mixture; 4) stopping loading of trimethyl aluminum, introducing nitrogen gas into that deposition chamber, and purging the mixture; 5) stopping introduction of nitrogen gas, introducing ozone into the deposition chamber, and purging the mixture; 6) stopping introduction of ozone, introducing nitrogen gas into the deposition chamber, and purging the mixture; 7) repeating the steps 3) to 6); and 8) stopping introducing of nitrogen gas and naturally cooling the deposition chamber to obtain the coated fluoride phosphor powder. The reactant purging time is adjusted according to the repetition times so that the total reaction time does not exceed 2h, the temperature of the atomic layer depositioncoating operation is 50-90 DEG C and the time does not exceed 2h, and the coating adopts trimethyl aluminum and ozone as precursors.

Owner:XIAMEN UNIV

Chromite catalyst for trimerization of ethylene into 1-hexene and preparation and application thereof

InactiveCN113083373ALow running costLow selectivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsAluminoxanePtru catalyst

The invention provides a chromite catalyst for trimerization of ethylene into 1-hexene and preparation and application thereof, raw materials for preparing the chromite catalyst comprise chromite organic acid salt, an electron donor, 2, 5-dimethyl pyrrole and a polydentate PNP compound, and at least one of trimethyl aluminum, triethyl aluminum, triisobutyl aluminum, trioctyl aluminum, diethyl aluminum monochloride, ethyl aluminum dichloride, ethyl aluminum sesquichloride, methylaluminoxane, modified methylaluminoxane and ethyl aluminoxane. According to the chromite catalyst, a chromite source is adopted to synthesize a chromite organic metal compound, and the step of reducing trivalent chromium into chromite by aluminum alkyl is reduced by the generated catalyst, so that the active center is ensured to be + 2 valence, the loss of the catalyst is avoided, and meanwhile, the situation that the reaction selectivity is reduced and the product yield is influenced by excessive aluminum alkyl is avoided. Therefore, 1-hexene with high activity and good selectivity is developed, and the operation cost of the 1-hexene device is greatly reduced.

Owner:BEIJING CORETEAM ENG & TECH

Method for growing GaN-based luminous crystal film by metal organic chemical vapor deposition

InactiveCN101736400AImprove lattice distortionImprove luminous performancePolycrystalline material growthFrom chemically reactive gasesRare-earth elementMethyl group

The invention discloses a method for growing a GaN-based luminous crystal film by metal organic chemical vapor deposition. The method is characterized in that: trimethylborine or trimethylaluminium are doped in a raw material formula of the GaN crystal film in proportion, and boron or aluminum enter a GaN crystal lattice in a mode of trivalent ion in a growing process to regulate the ionic radius difference between rare-earth ions and Ga3+; the molar ratio of the raw material formula is that: Ga (CH3)3 to rare-earth organic complex to A(CH3)3 is (1-x-y):x:y, wherein the rare-earth organic complex is Re(TMHD)3 or Re (i-PrCp)3 taking rare-earth element Re as a core; A represents III group element boron or aluminum; x is more than or equal to 0.1 percent and less than or equal to 10.0 percent; and y is more than or equal to 0.1 time of the x and less than or equal to x. Because the organic complex of the III group element boron or aluminum and the rare-earth organic complex are co-doped in a certain proportion, the method can improve lattice distortion of the GaN crystal film caused by larger radius mismatch between Re3+ and Ga3+ to a large extent so as to improve the luminous performance of the GaN crystal film.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

An aluminum nitride film growing method and application thereof

ActiveCN108538968AReduce defect concentrationImprove crystal qualityNanotechnologySemiconductor devicesThin membraneTrimethylaluminium

The invention provides an aluminum nitride film growing method and application thereof. The growing method comprises the steps of: 1) injecting trimethylaluminum and ammonia gas and growing a first aluminum nitride layer on a substrate; 2) performing nanoscale column body etching processing on the first aluminum nitride layer to obtain a column body recess aluminum nitride layer which has a plurality of nanoscale column body recesses; 3) controlling the temperature and the pressure of a reaction chamber and injecting trimethylaluminum and ammonia gas to grow a second aluminum nitride layer onthe column body recess aluminum nitride layer; 4) controlling the temperature and the pressure of the reaction chamber and injecting trimethylaluminum and ammonia gas to grow a third aluminum nitridelayer on the second aluminum nitride layer. The Mole-flow ratio of ammonia gas to trimethylaluminum in the step 3) is less than that in the step 4); the aluminum nitride film is the integration of thefirst aluminum nitride layer, the second aluminum nitride layer and the third aluminum nitride layer. The AlN thin film crystalline quality is remarkably improved.

Owner:MAANSHAN JASON SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com