Preparation of high melt strength polypropylene

A high-melt-strength polypropylene technology, applied in the field of high-melt-strength polypropylene preparation, can solve the problems of high cost of catalysts and co-catalysts, limited practical value, and low melting point of polymers, and achieve good processability and melting The effect of high body strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the reactor fully replaced by the inert gas, 12g of magnesium chloride, 25mL of ethanol, 200mL of white petrolatum oil, and 5mL of silicone oil were successively added, heated and stirred, reacted at 100-135°C for 2-4 hours, cooled to 20-80°C and added to give The electron compound is added dropwise within 2 to 3 hours, stirred for 1 to 2 hours at a temperature of -25 to -20°C, then heated to 110 to 130°C, and an electron donor is added, and the solid filtered after 2 to 4 hours of reaction is used Titanium tetrachloride is treated at 100-135 DEG C for 2-4 hours, filtered and washed with anhydrous hexane, and dried under vacuum to obtain a solid titanium catalyst.

[0027] 2. Preparation of high melt strength polypropylene

Embodiment 2

[0029] In a vacuum state, propylene was charged into a 500mL reaction kettle, followed by adding 100ml heptane, 3.6×10 -3 mol triethylaluminum in heptane, add 3.6 x 10 -2 mol of dimethoxydiphenylsilane (DDS) and 1.0×10 -2 mol of 1,7-octadiene, stir, add 0.05g TiCl 4 / DIBP / MgCl 2(Titanium tetrachloride / diisobutyl phthalate / magnesium chloride, the same below) Ziegler-Natta catalyst, react at 30° C. and 0.5MPa for 1 hour to obtain 20.2g of high melt strength polypropylene. DSC test showed that the melting point of the obtained product was 160°C, 1 H-NMR showed that the content of unsaturated ethylene double bonds in the copolymer was 0.15mol%. GPC test results: the weight average molecular weight was 9.9×10 4 , the molecular weight distribution is 4.80. And the polymer is in granular form with good shape.

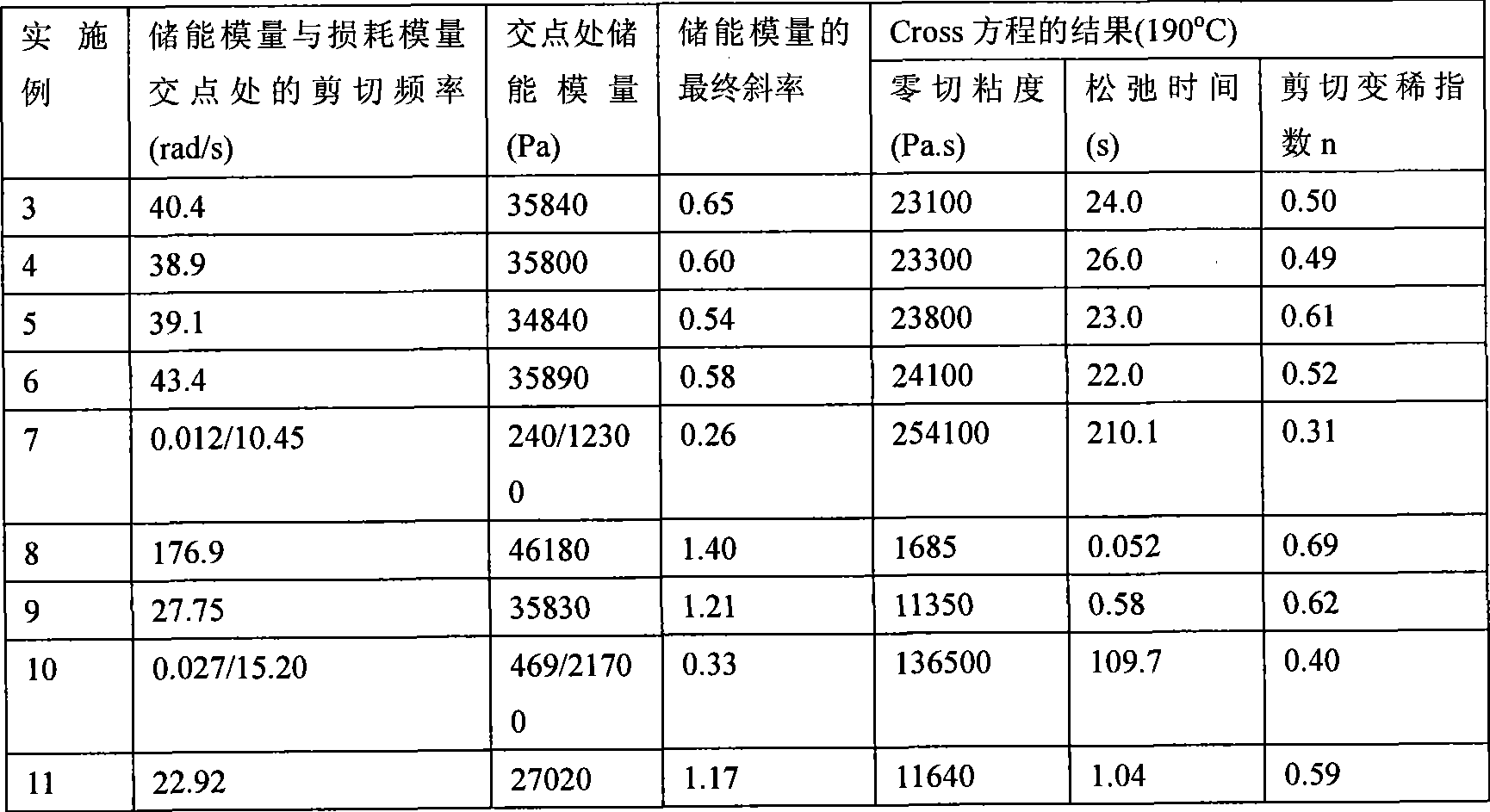

Embodiment 3—11

[0031] Examples 3-11, otherwise the same as in Example 2, the operating conditions and the properties of the resulting high melt strength polypropylene are listed in Table 1.

[0032] Table 1 Examples 3-11

[0033] implement

example

1,7-Syn

mmol pressure

(MPa)

Degree (℃)

Yield

(g)

melting point

(°C)

terminal double bond

(mol%)

Wait

regulations

Spend

% weighted average

Molecular weight (×

10 -4 ) Melt Index

(g / 10min)

3 Hexane 10.0 0.5 30 17.6 160 0.13 97.0 47.0 0.30 4 Toluene 10.0 0.5 30 23.8 160 0.14 96.3 47.2 0.25 5 Heptane 10.0 0.5 70 34.1 155 0.10 96.5 43.7 0.09 6 Heptane 10.0 0.5 50 28.9 156 0.12 96.1 46.8 0.14 7 Heptane 70.0 0.5 70 23.7 150 0.49 93.2 50.0 0.41 8 Heptane 3.0 0.5 70 46.0 161 --- 98.2 40.9 0.86 9 Heptane 7.0 0.5 70 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com