Catalyst of ethylene trimerization, and application

A technology of ethylene trimerization and catalyst, applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., to achieve the effect of good selectivity, less polyethylene and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

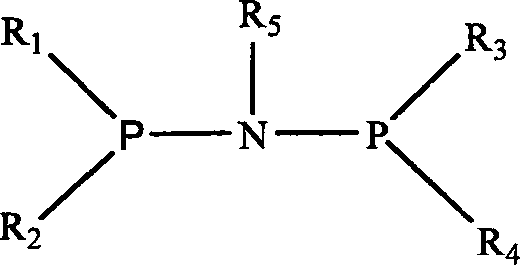

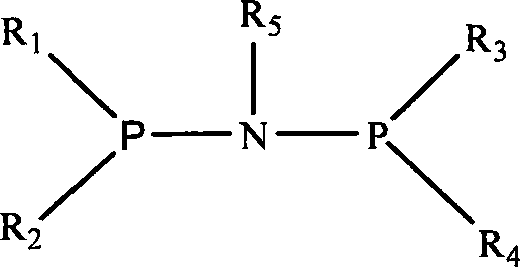

Image

Examples

Embodiment 1

[0021] 1. Preparation of (diphenyl) phosphorus nitrogen (cyclopropyl) phosphorus (diphenyl) ligand

[0022] (1) Preparation of N, N-diisopropyl dichlorophosphoramide

[0023] in the N 2 Add dehydrated toluene (100mL) into a fully replaced stirred 250mL reactor, add PCl 3 (21.87mL, 0.25mol), and cooled to -20°C. Diisopropylamine (70 mL, 0.5 mol) was slowly added while stirring at room temperature, stirred for 3 hours, raised to room temperature and continued to react for 2 hours, then filtered and dried to obtain 38.1 g (0.19 mol, 74%) of the product.

[0024] (2) Preparation of phenylmagnesium bromide lattice reagent

[0025] in the N 2 Add dehydrated THF (100 mL) and magnesium powder (9.11 g, 0.375 mol) into a fully replaced stirred 250 mL reactor, cool down in an ice bath and slowly add bromobenzene (11.775 g, 0.075 mol) dropwise. After 2 hours, heat to reflux and continue the reaction for 2 hours to obtain the lattice reagent.

[0026] (3) Preparation of diphenyl phos...

Embodiment 2

[0035] 1. Preparation of (diphenyl) phosphorus nitrogen (cyclopentyl) phosphorus (diphenyl) ligand

[0036] (1) Preparation of N, N-diisopropyl dichlorophosphoramide

[0037] With embodiment 1.

[0038] (2) Preparation of phenylmagnesium bromide lattice reagent

[0039] With embodiment 1.

[0040] (3) Preparation of diphenyl phosphorus chloride

[0041] With embodiment 1.

[0042] (4) Preparation of (diphenyl) phosphorus nitrogen (cyclopentyl) phosphorus (diphenyl)

[0043] in the N 2 Add dehydrated dichloromethane (20mL), triethylamine (3.75mL), and diphenylphosphine chloride (1.326mL, 7.2mol) into a fully replaced stirred 100mL reactor, cool to 0°C, and slowly Add cyclopentylamine (0.415 mL, 3.5 mmol). After stirring for 30 minutes, the reaction was continued at room temperature for 12 hours. Filtration and drying gave the product (0.55 g, 32.68%).

[0044] 2. Preparation of catalyst

[0045] in the N 2 Add dehydrated cyclohexane (10mL), trimethylaluminum (10mL), ...

Embodiment 3

[0049] 1. Preparation of (diphenyl) phosphorus nitrogen (fluorenyl) phosphorus (diphenyl) ligand

[0050] (1) Preparation of N, N-diisopropyl dichlorophosphoramide

[0051] With embodiment 1.

[0052] (2) Preparation of phenylmagnesium bromide lattice reagent

[0053] With embodiment 1.

[0054] (3) Preparation of diphenyl phosphorus chloride

[0055] With embodiment 1.

[0056] (4) Preparation of (diphenyl) phosphorus nitrogen (fluorenyl) phosphorus (diphenyl)

[0057] in the N 2 Add dehydrated dichloromethane (20mL), triethylamine (3.75mL), and diphenylphosphine chloride (1.326mL, 7.2mol) into a fully replaced stirred 100mL reactor, cool to 0°C, and slowly Fluorenamine (0.652 g, 3.6 mmol) was added. After stirring for 30 minutes, the reaction was continued at room temperature for 12 hours. Filtration and drying gave the product (0.48g, 24.3%).

[0058] 2. Preparation of catalyst

[0059] in the N 2 Add dehydrated cyclohexane (10mL), tripropylaluminum (10mL), (diph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com