Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

271 results about "1-Hexene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1-Hexene (hex-1-ene) is an organic compound with the formula C₆H₁₂. It is an alkene that is classified in industry as higher olefin and an alpha-olefin, the latter term meaning that the double bond is located at the alpha (primary) position, endowing the compound with higher reactivity and thus useful chemical properties. 1-Hexene is an industrially significant linear alpha olefin. 1-Hexene is a colourless liquid.

Catalytic process for the oligomerization of olefinic monomers

InactiveCN101351424AGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilylene1-Octene

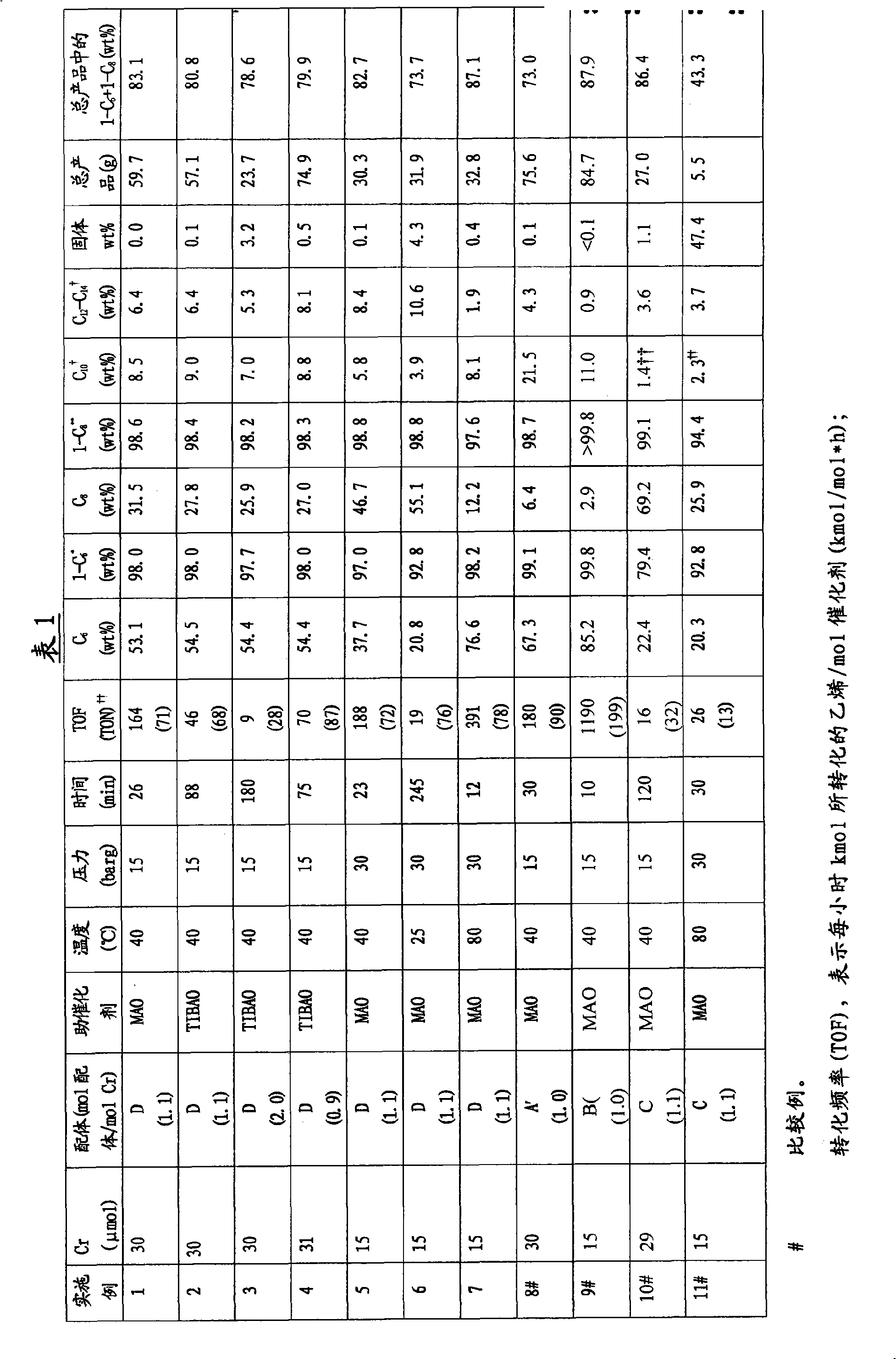

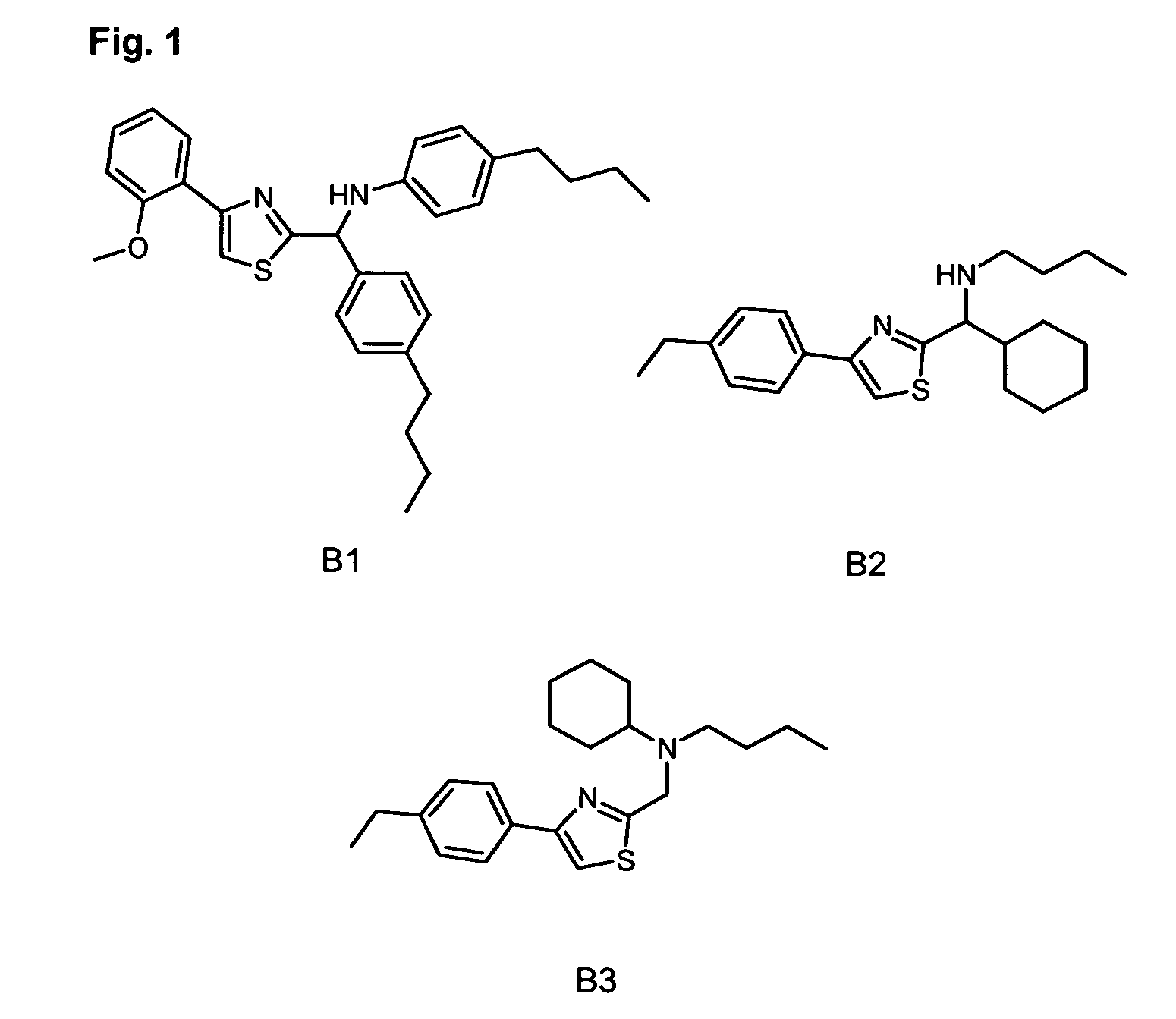

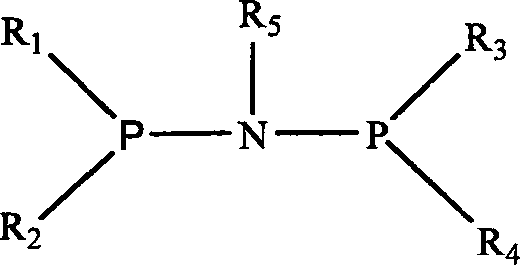

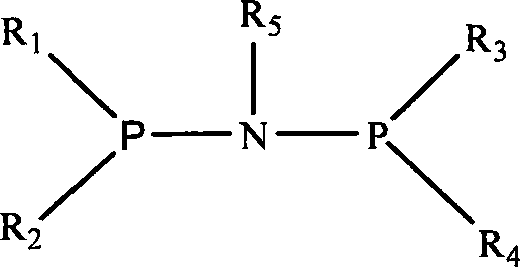

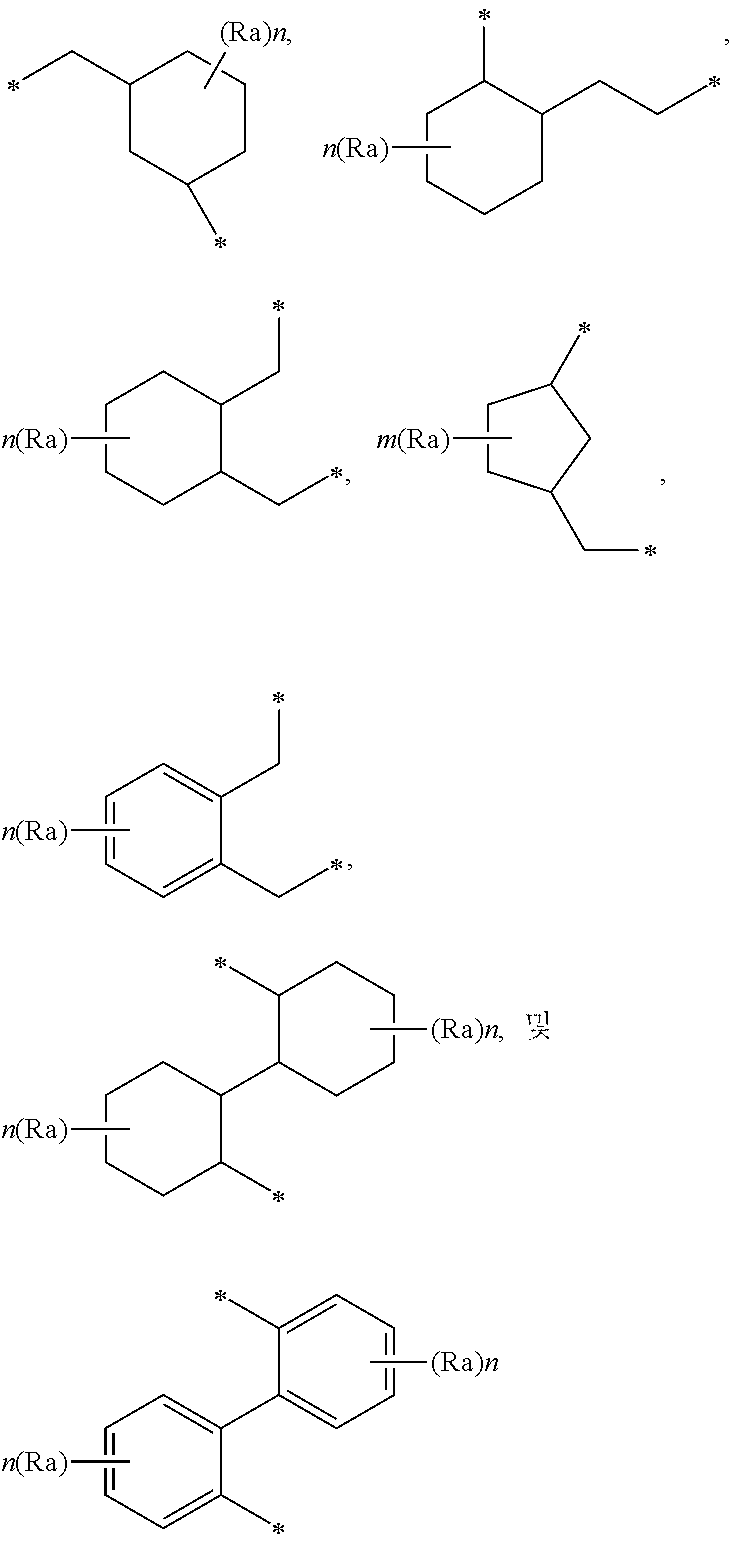

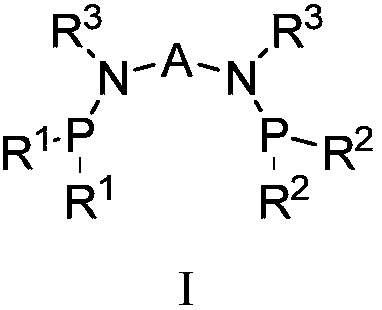

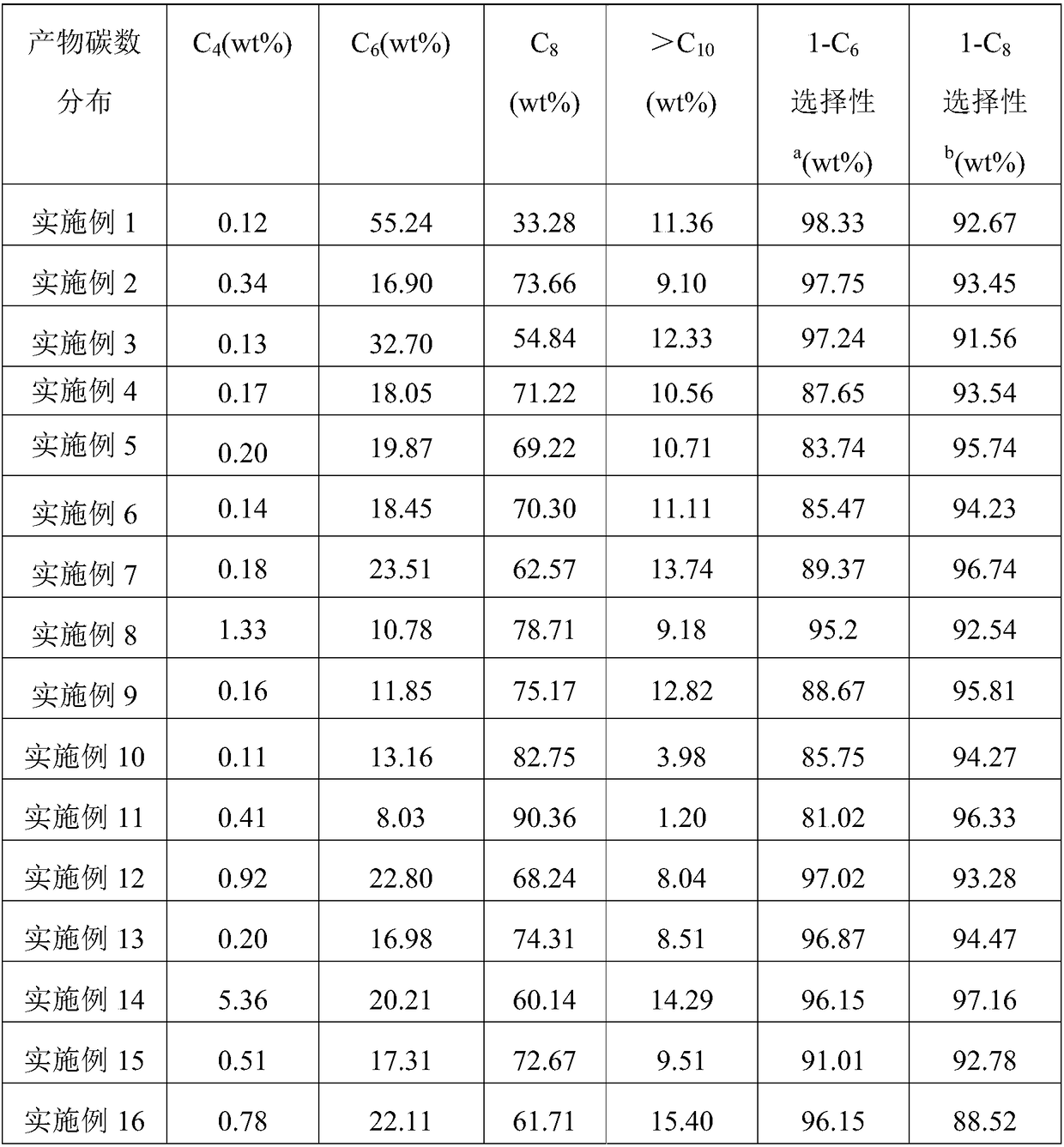

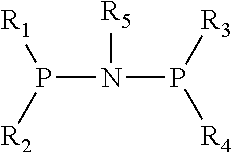

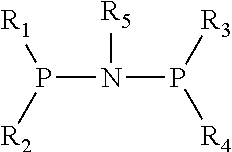

A process for the simultaneous trimerization and tetramerization of olefinic monomers , wherein the process comprises contacting at least one olefinic monomer with catalyst system comprising : a) a source of chromium, molybdenum or tungsten; b) a ligand having the general formula (I) ; (R<1>)2P-X-P (R<1>)m(R<2>)n wherein : X is a bridging group of the formula -N(R<3>)-, wherein R<3> is selected from hydrogen, a hydrocarbyl group, a substituted hydrocarbyl group, a heterohydrocarbyl group, a substituted heterohydrocarbyl group, a silyl group or derivative thereof; the R<1> groups are independently selected from an optionally substituted aromatic group bearing a polar substituent on at least one of the ortho-positions; and the R<2> groups are independently selected from hydrocarbyl, substituted hydrocarbyl, heterohydrocarbyl and substituted heterohydrocarbyl groups and c) a cocatalyst. The present invention further relates to a process for the simultaneous trimerization and tetramerization of ethylene to 1-hexene and 1-octene.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Low viscosity PAO based on 1-tetradecene

ActiveUS7544850B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcohol1-Hexene

Disclosed herein is a method of making a PAO using tetradecene and particularly mixtures comprising 1-hexene, 1-decene, 1-dodecene, and 1-tetradecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol and an ester. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

Process for producing 1-hexene

InactiveUS6521806B1Organic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsKetoneCarboxylic acid

A process for preparing 1-hexene which comprises trimerizing ethylene in a 1-hexene solvent in the presence of a catalyst system prepared by contacting in a 1-hexene solvent the following components (A), (B), (C) and (D):(A) a chromium-containing compound represented by the general formula: CrXkYm wherein X is a residue of a carboxylic acid, a residue of a 1,3-diketone, a halogen atom or an alkoxyl group, k is an integer of 2 to 4, Y in Ym is an amine compound, a phosphine compound, a phosphine oxide compound, a nitrosyl group or an ether compound and m is an integer of 0 to 6, with the proviso that any two Y's may be same or different;(B) trialkylaluminum or dialkylaluminum hydride;(C) a pyrrole compound or a derivative thereof;(D) a group 13 (IIIB)-halogen compound represented by the general formula: MTtU3-t or a group 14 (IVB)-halogen compound represented by the general formula: M'Tt'U4-t' wherein M is an atom from the group 13 (IIIB), M' is an atom from the group 14(IVB), T is an alkyl group, an aryl group, an allyl group or a hydrogen atom, U is a halogen atom, t is a real number of 0 or more and less than 3 and t' is a real number of 0 or more and less than 4.

Owner:SUMITOMO CHEM CO LTD

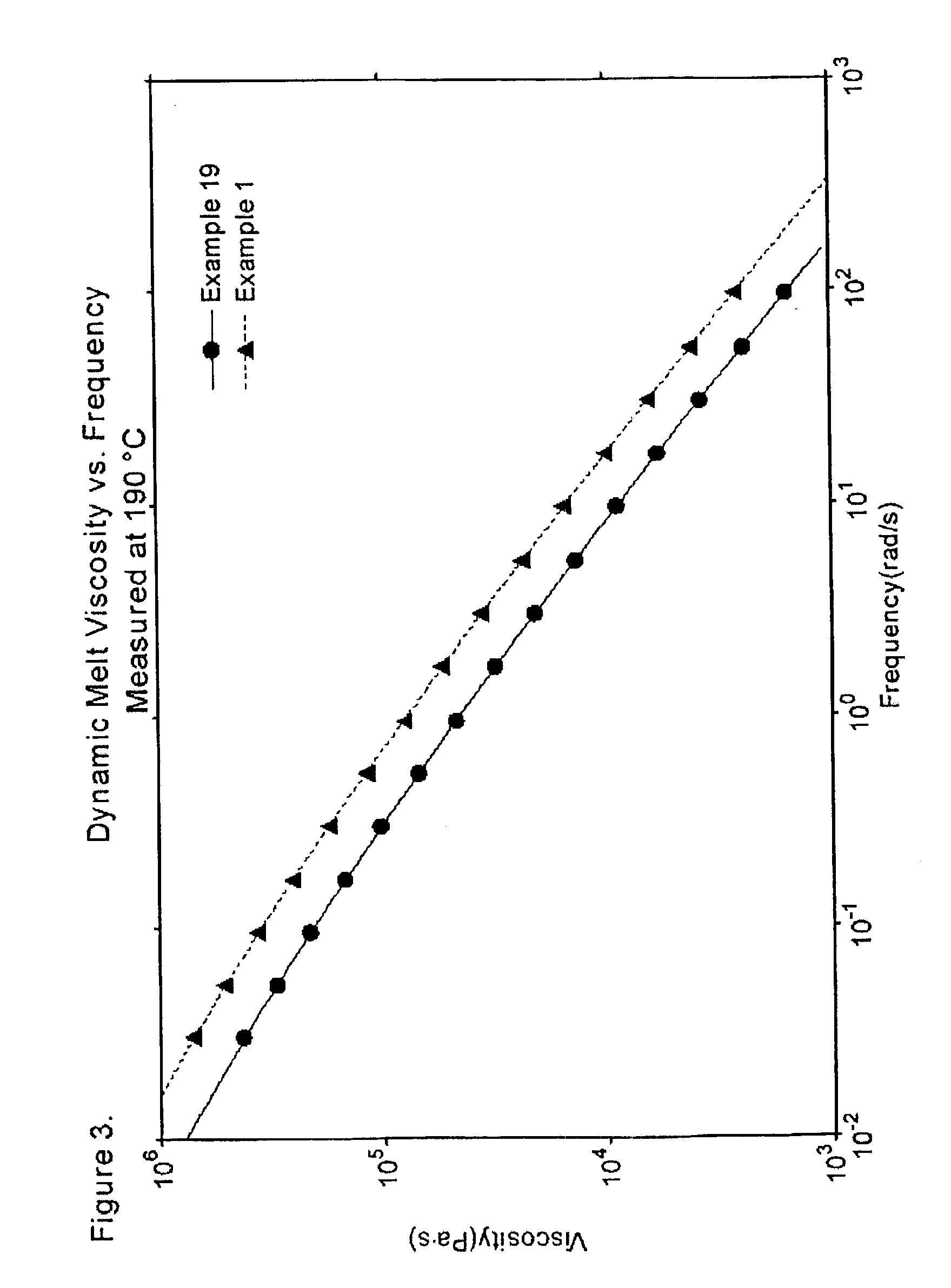

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS7547811B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

Methods for oligomerizing olefins

ActiveUS20060247399A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsChromium Compounds1-Octene

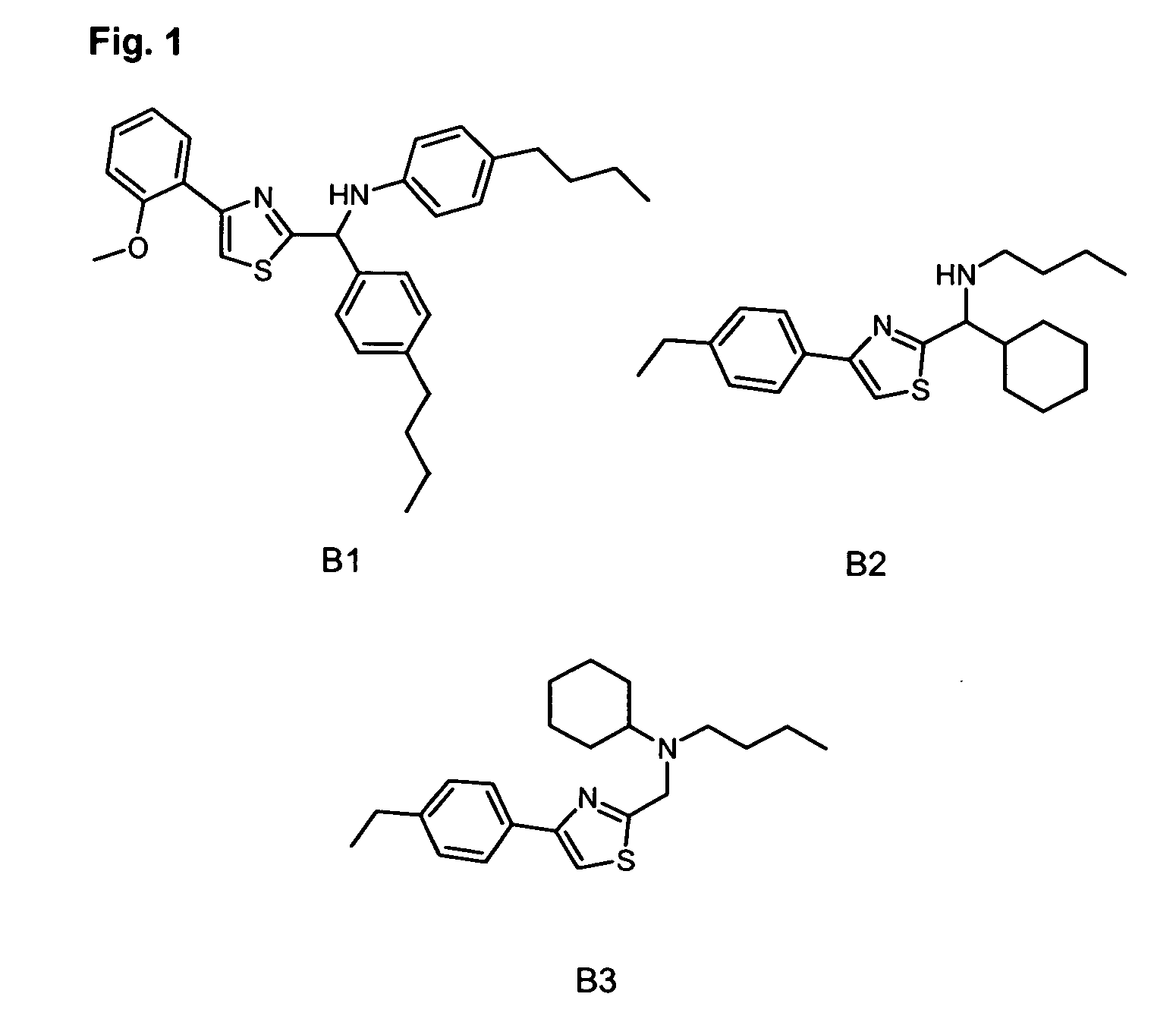

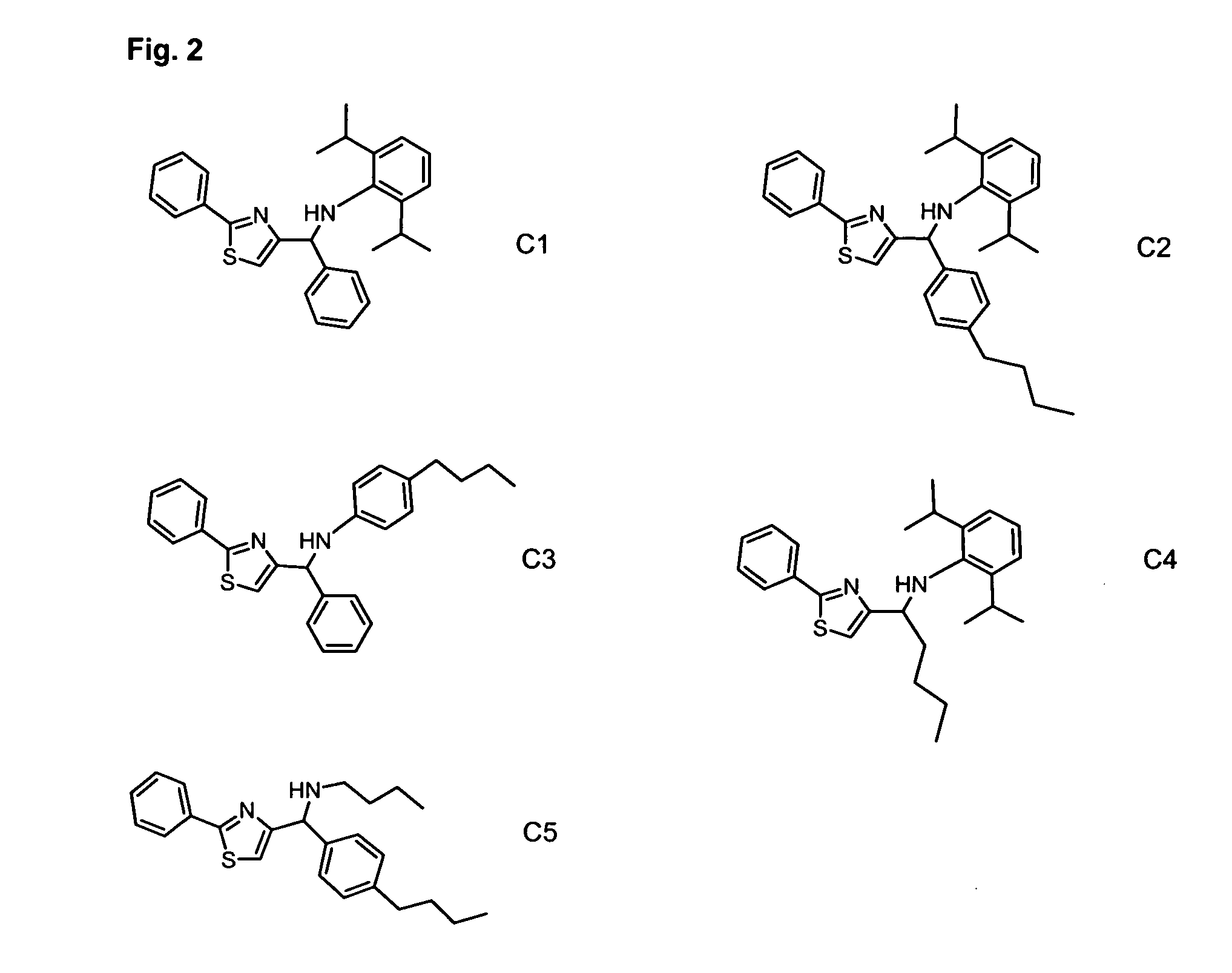

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

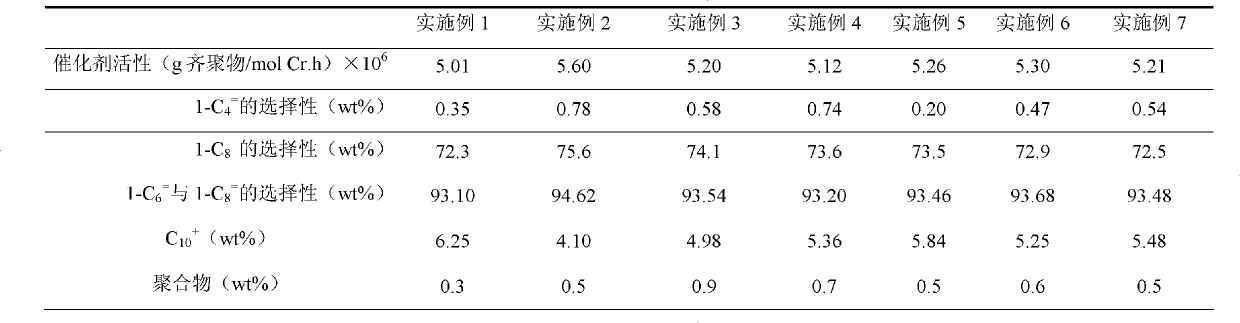

Ethylene oligomerization catalyst composition and application thereof

InactiveCN103285926AHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsArylAluminoxane

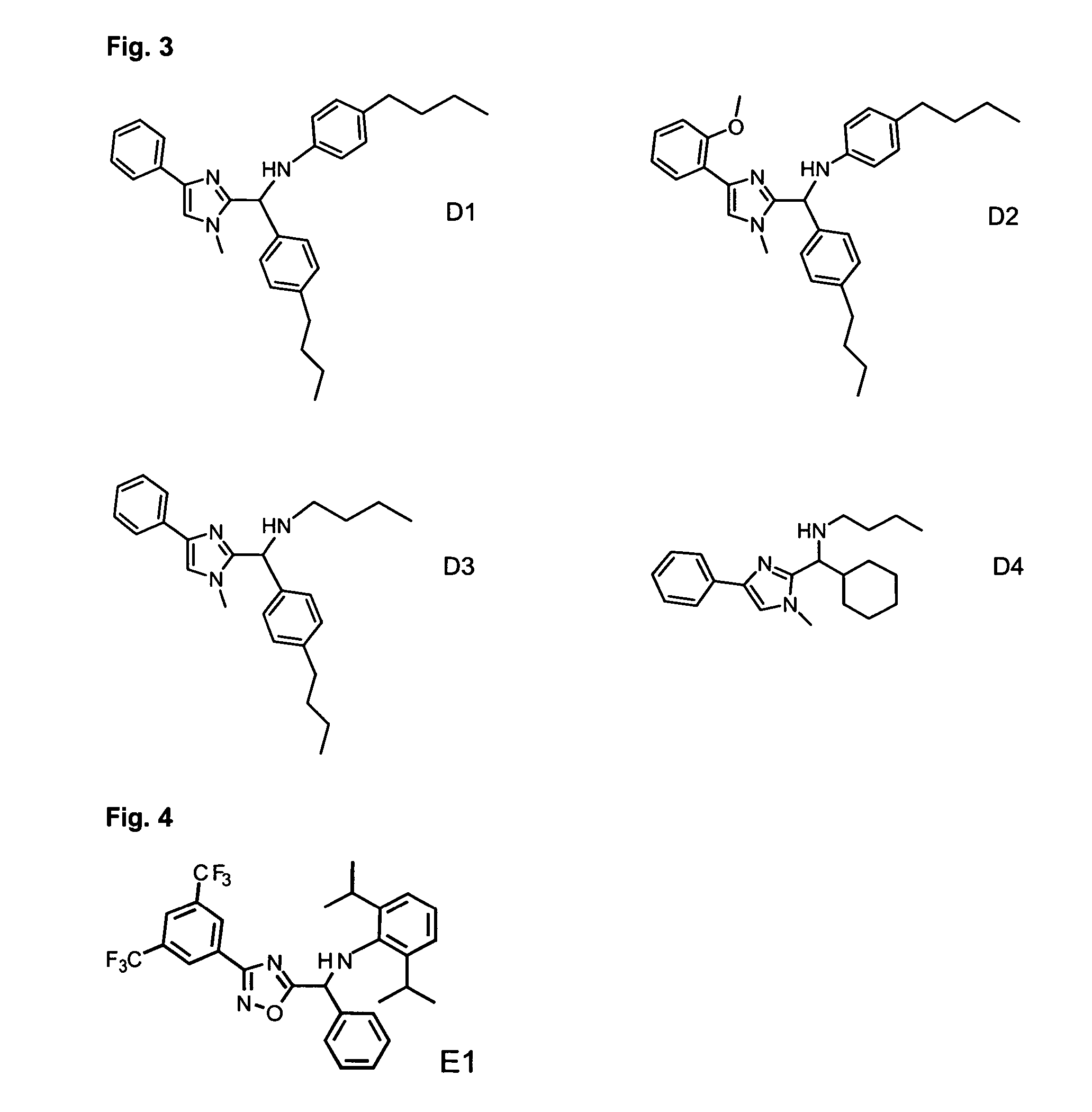

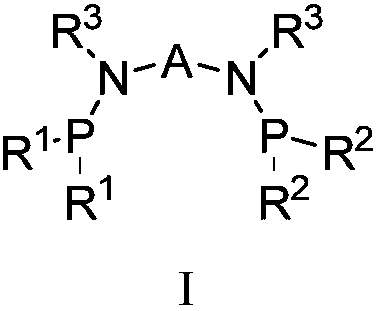

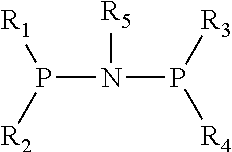

The invention relates to an ethylene oligomerization catalyst composition and an application thereof. The composition comprises the following components: a component a contains chromium acetylacetonate, tetrahydrofuran chromium chloride and / or chromium 2-ethylhexanoate; in the formula of a component b, R1, R2, R3 and R4 are phenyl, benzyl or naphthyl; and R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; a component c contains methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; a component d has a formula X1R6X2, wherein X1 and X2 are F, Cl, Br, I or alkoxy, and R6 is alkyl or aryl; in the formula of a component e, R is a linking group and selected from alkyl and derivatives thereof as well as aryl and derivatives thereof; and the molar ratio is 1: (0.5-10): (50-3000): (0.5-10): (0.5-10). The catalyst has the catalytic activity being more than 5.0*10<6>g mol<-1>Cr.h<-1>, and the mass of 1-hexene and 1-octylene is more than 93%.

Owner:PETROCHINA CO LTD

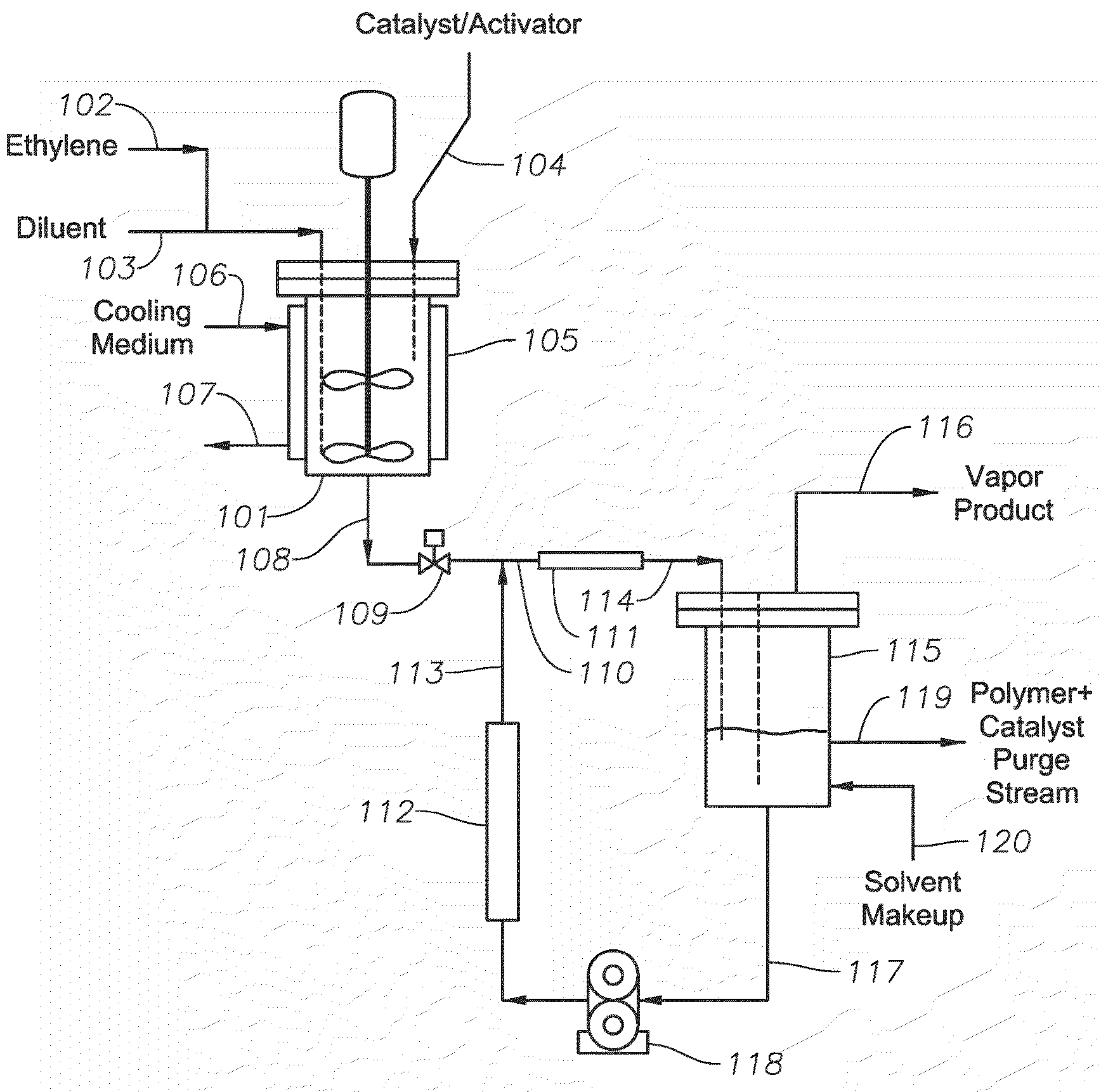

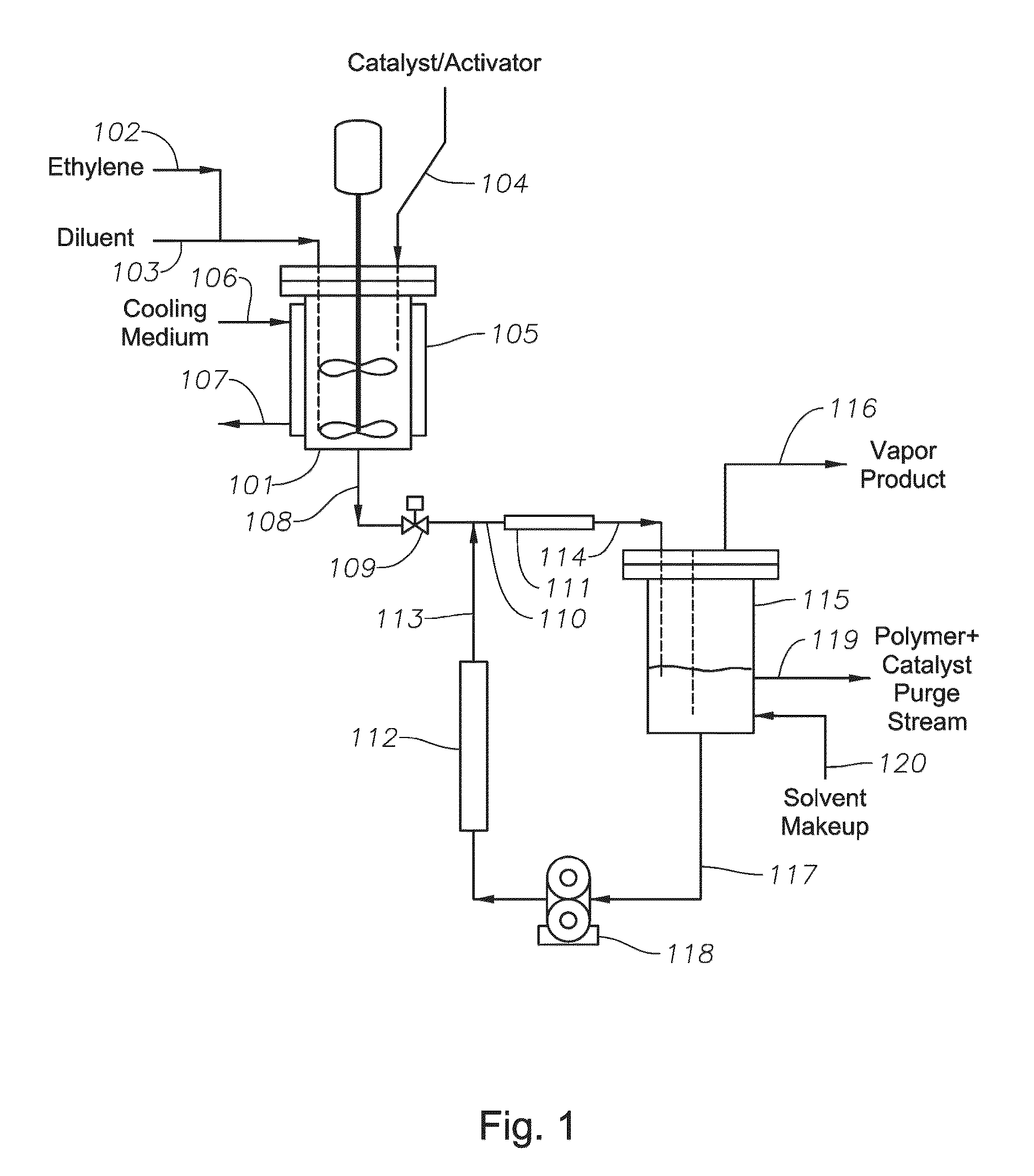

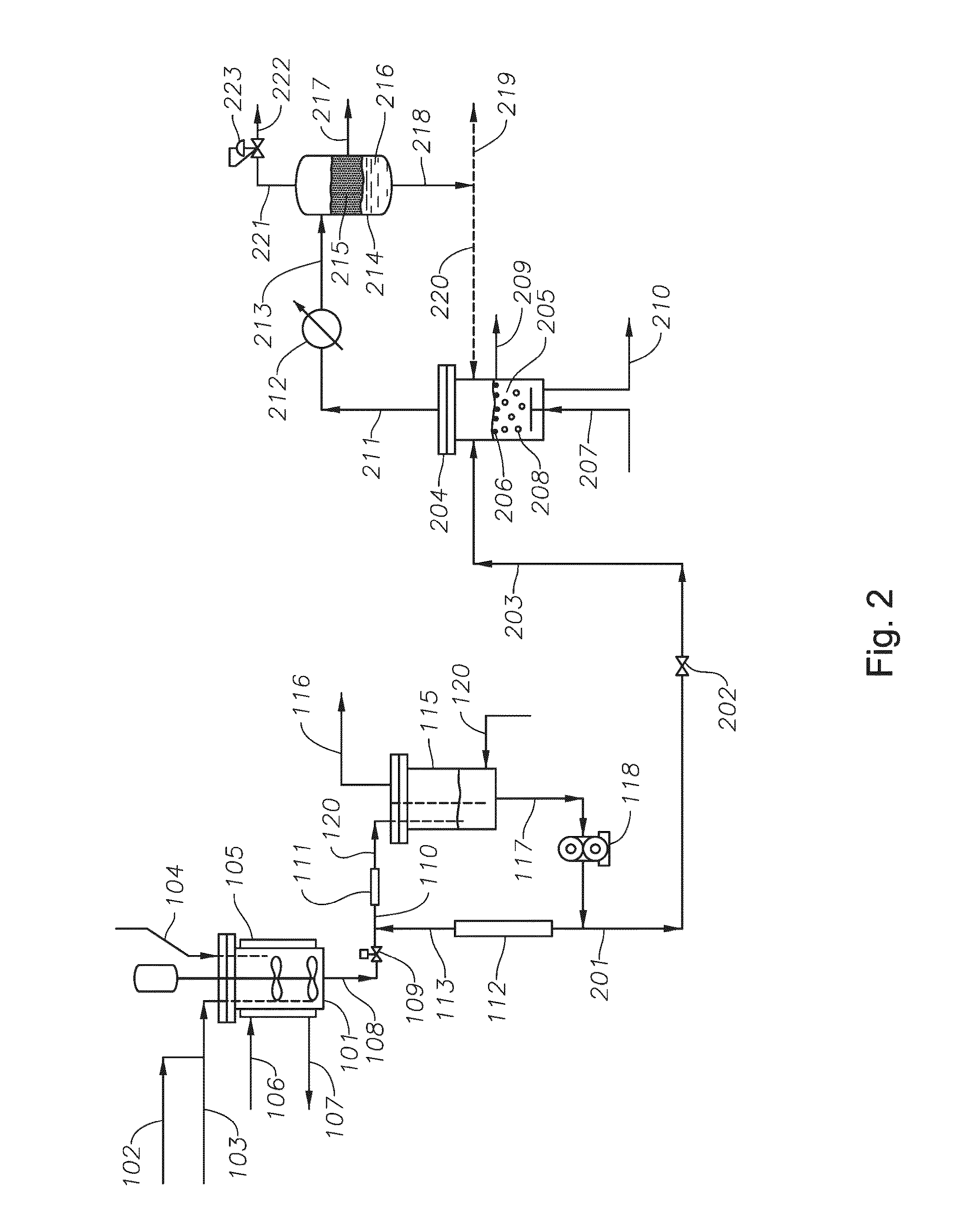

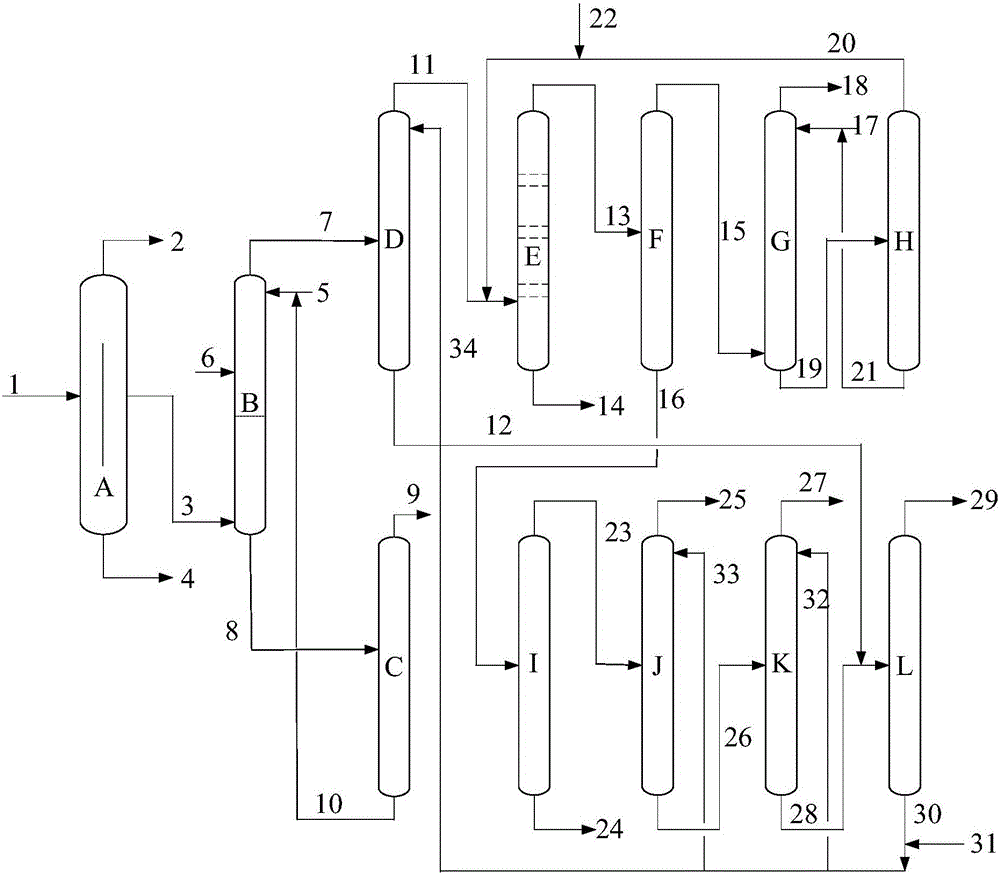

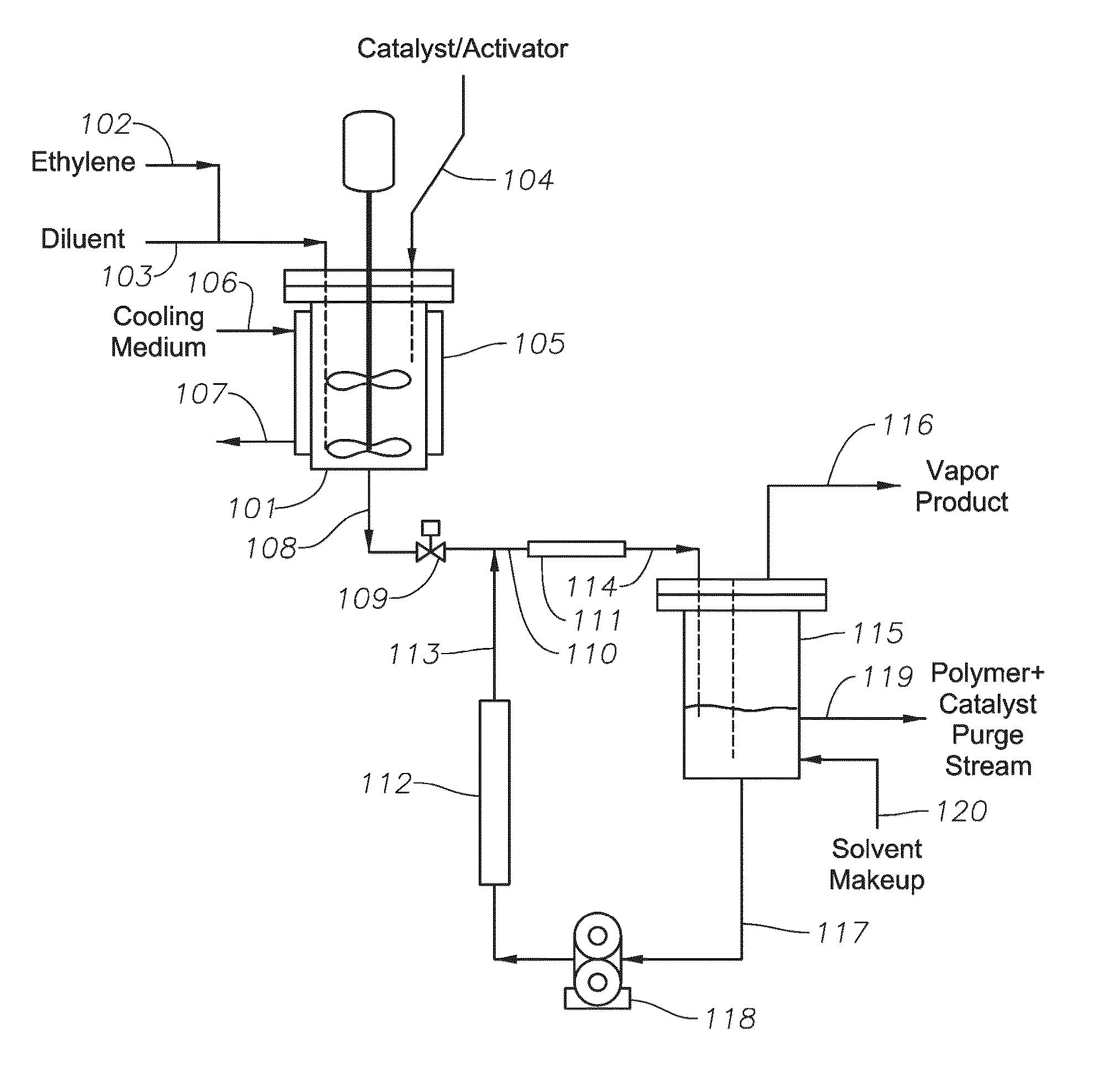

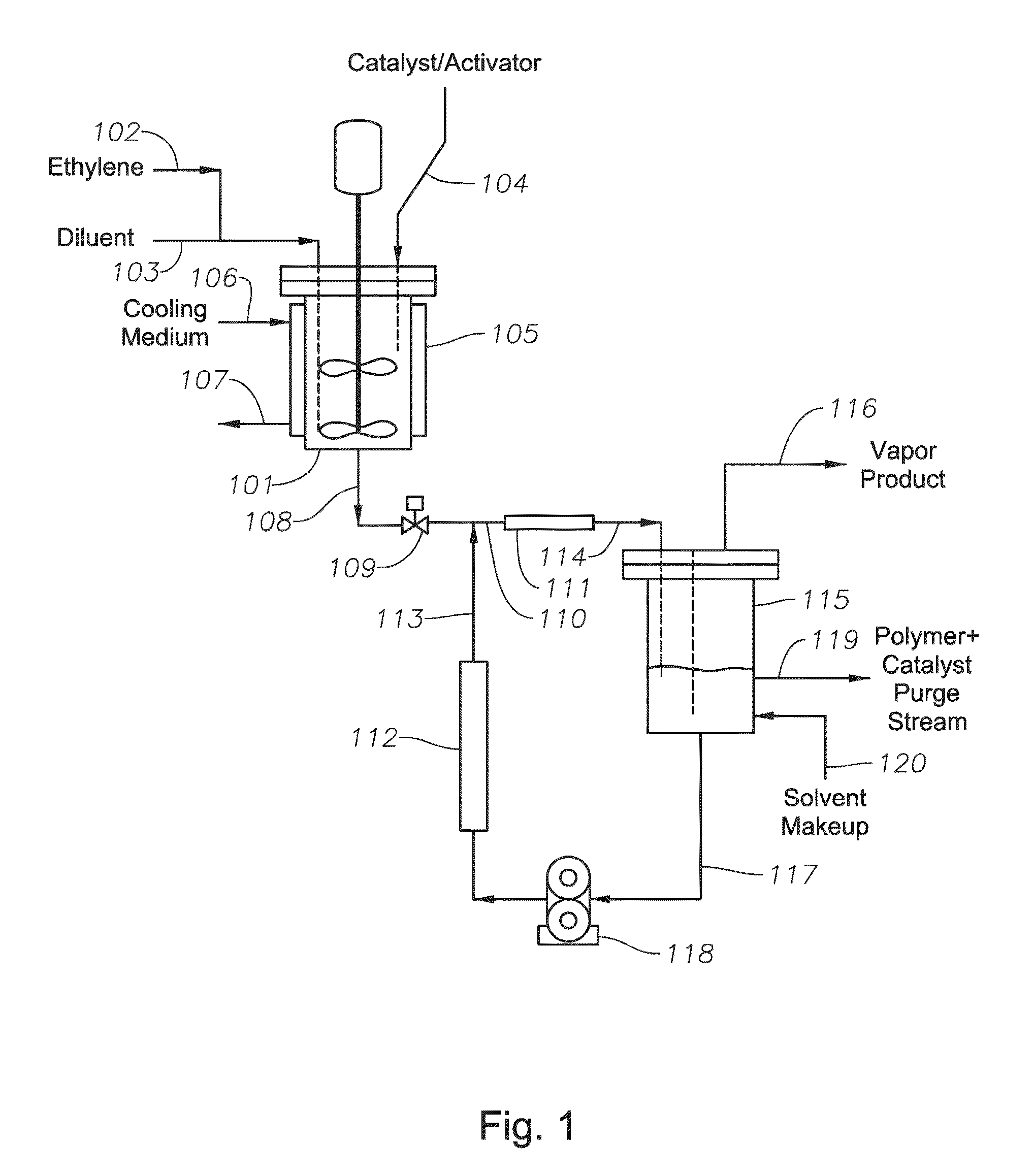

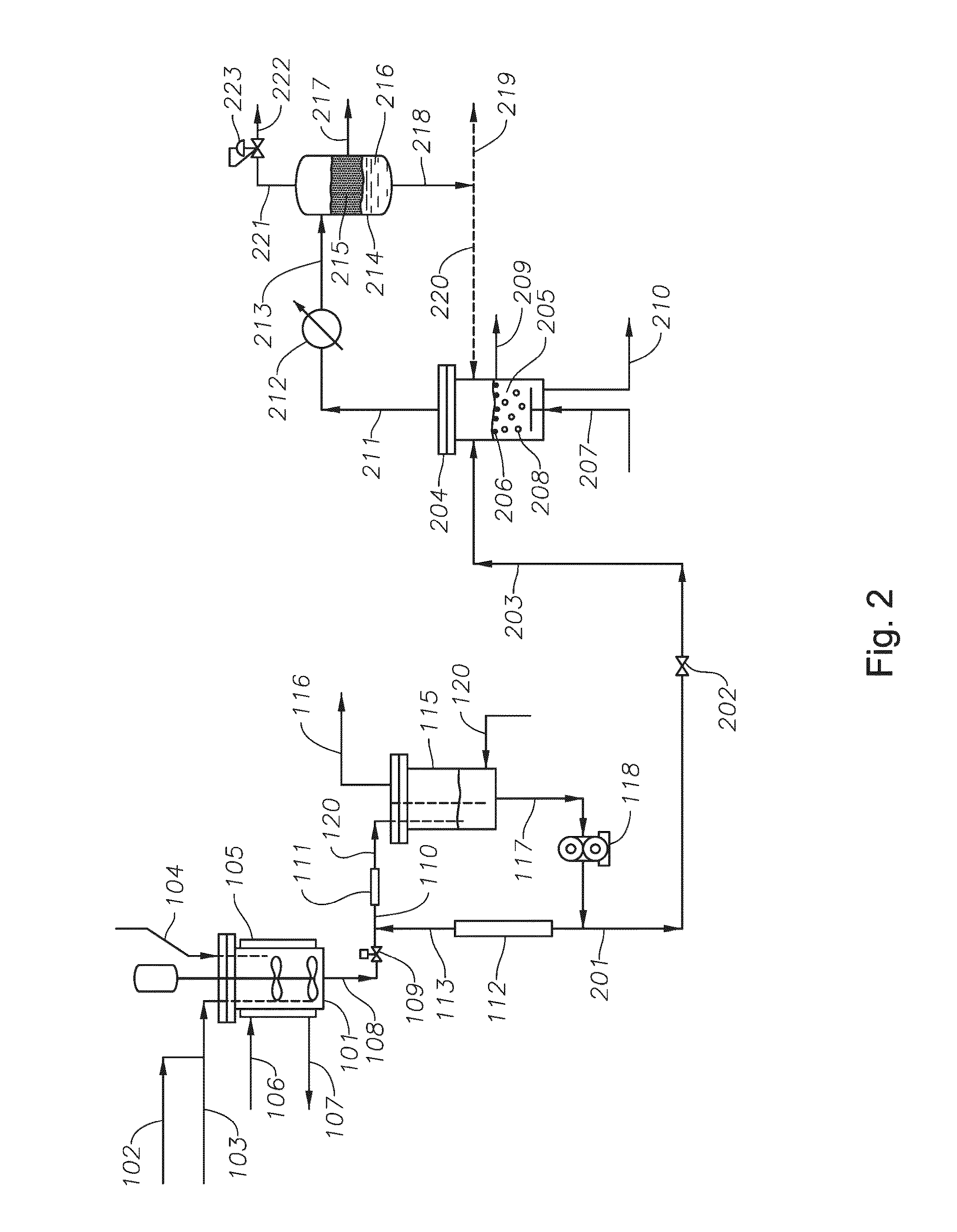

System and method for selective trimerization

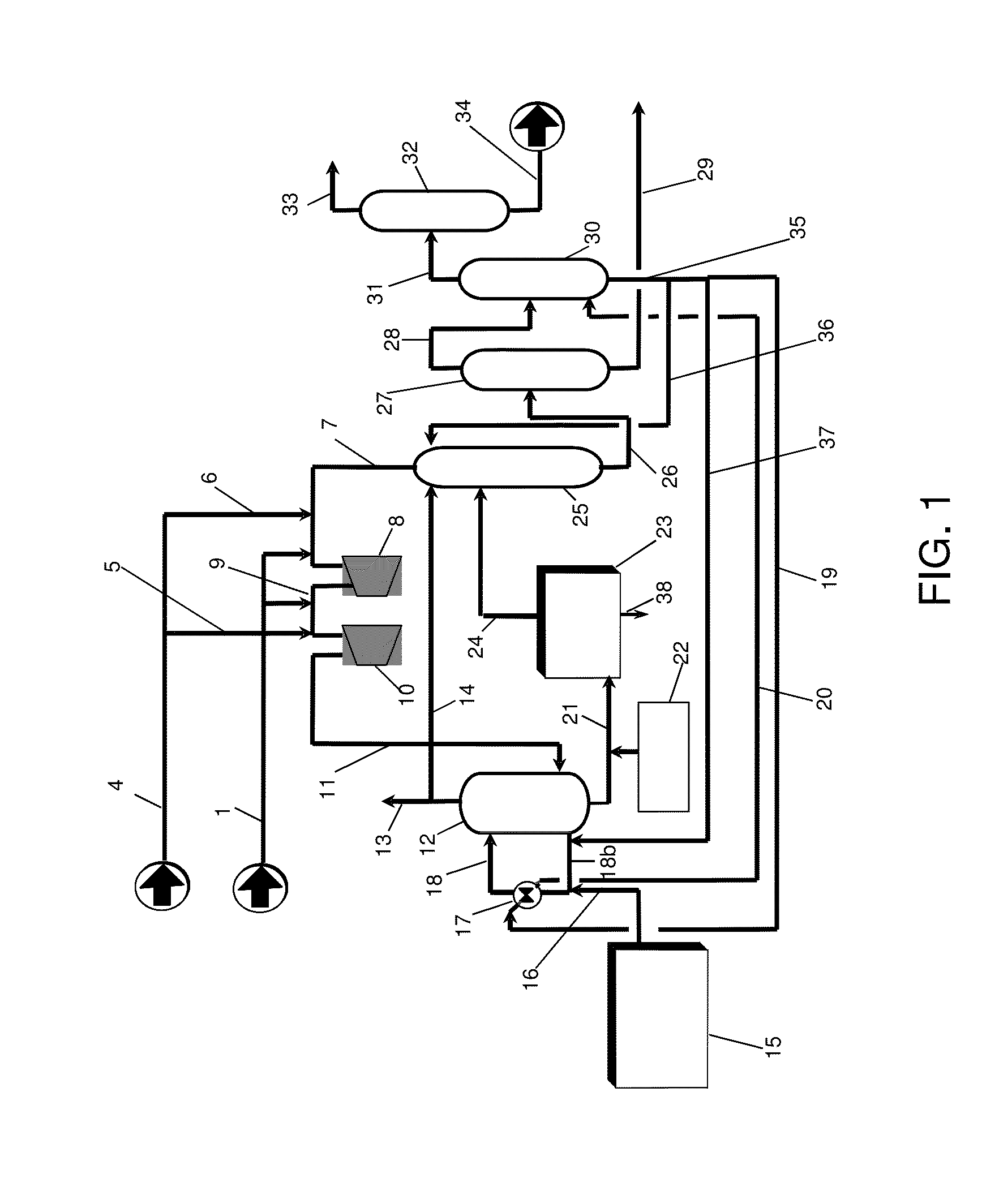

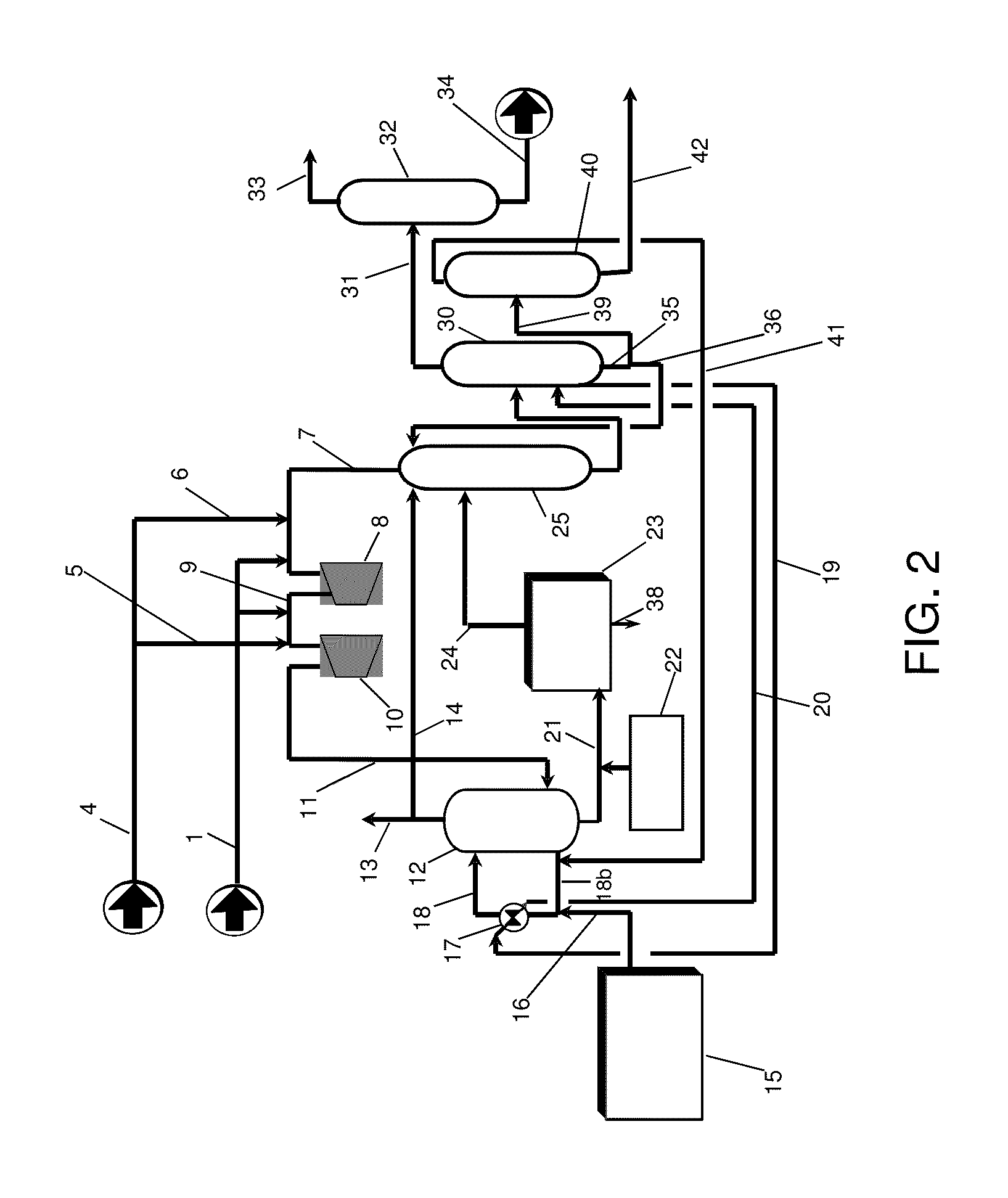

ActiveUS8658750B2Distillation purification/separationMolecular sieve catalystsReactor systemDownstream processing

Disclosed herein is a method for separating from the reactor effluent of an olefin oligomerization procedure those catalyst materials and polymeric by-products which can cause difficulties in the downstream processing of such effluent. Polymer by-products and catalyst in the effluent are separated from reaction products by flash vaporization utilizing an in-situ hot solvent which is contacted with the effluent and serves as the heating medium to promote this flash vaporization step. Subsequent processing of a liquid portion of the effluent which is left after flash vaporization involves recovery of catalyst and polymeric by-products therefrom in a steam stripping vessel. Also disclosed is a multiple reactor system which can be used for continuous trimerization of ethylene to 1-hexene while at the same time washing polymeric by-products from one of the reactors in the series using a wash oil solvent.

Owner:EXXONMOBIL CHEM PAT INC

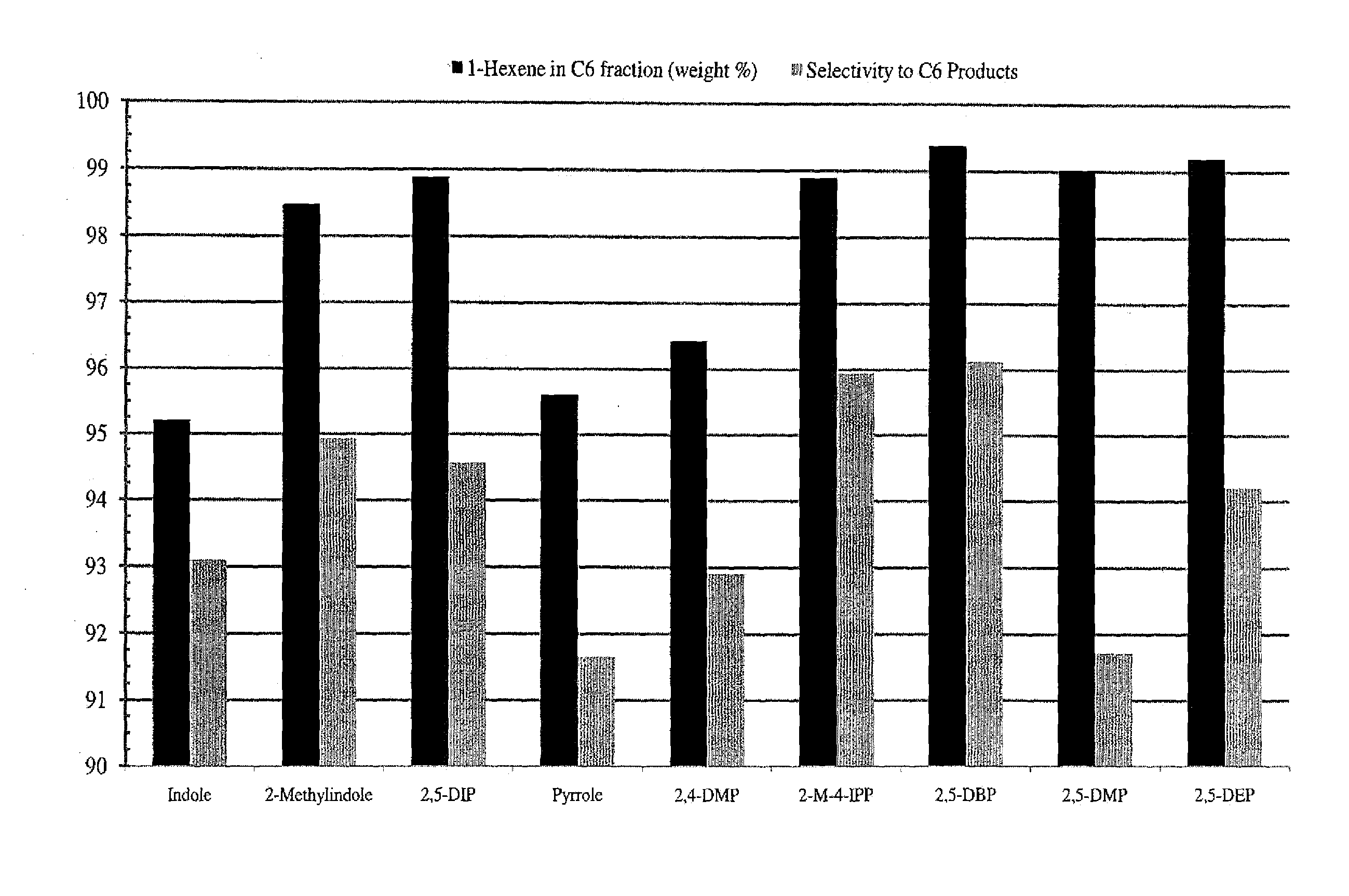

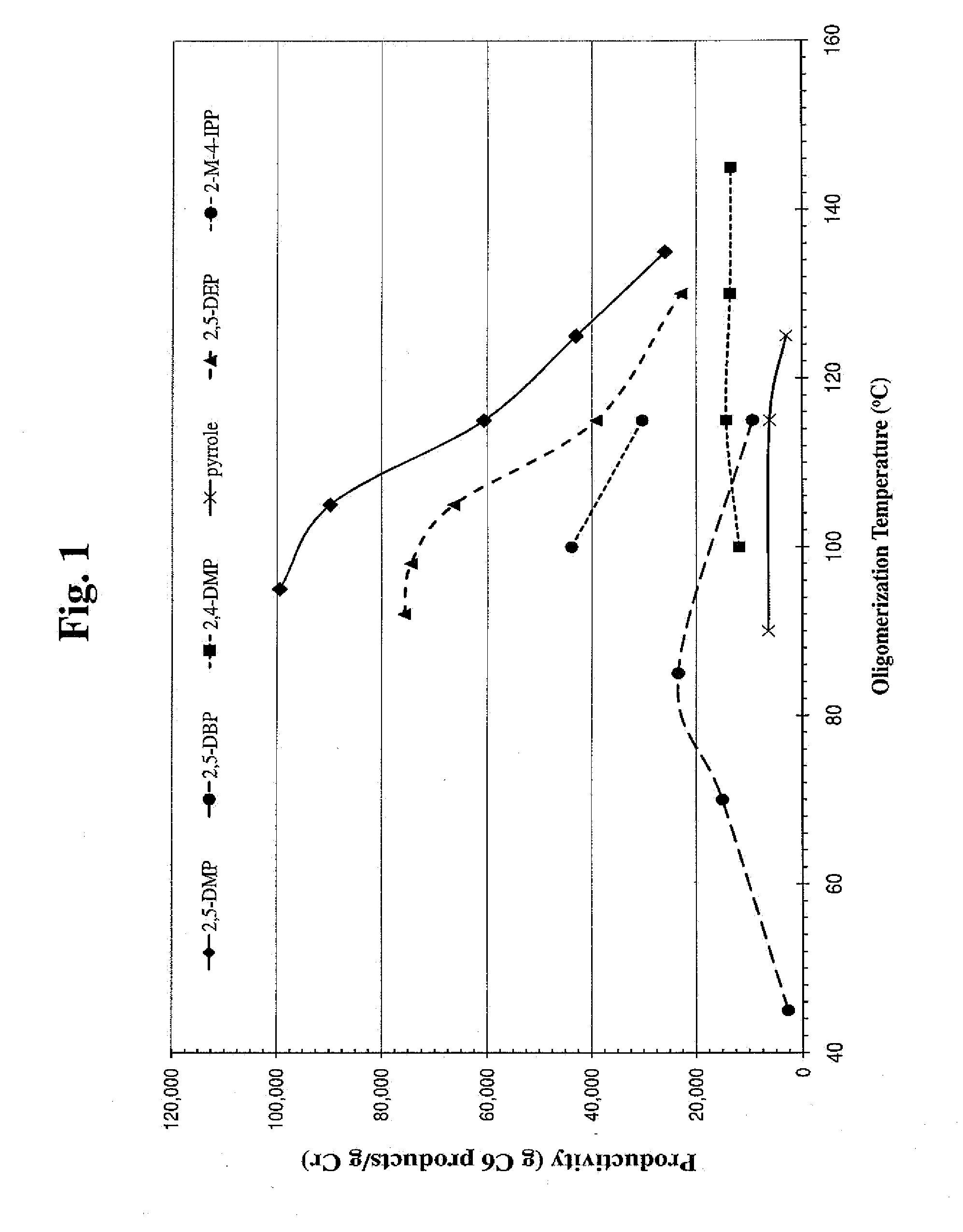

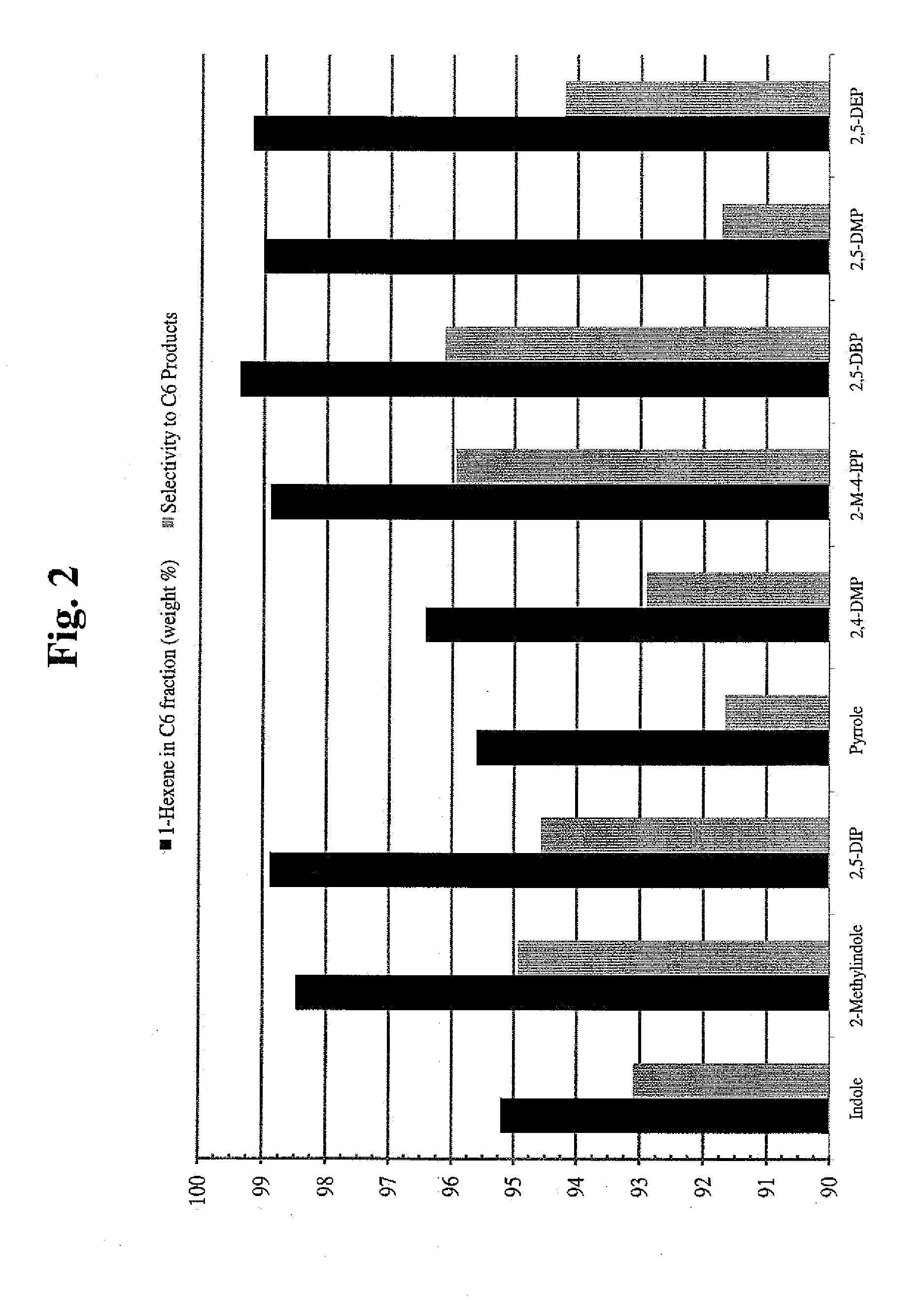

Oligomerization catalyst system and process for oligomerizing olefins

ActiveUS20100274065A1High catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionProduction rateHydrogen atom

Among other things, this disclosure provides an olefin oligomerization system and process, the system comprising: a) a transition metal compound; b) a pyrrole compound having a hydrogen atom on at the 5-position or the 2- and 5-position of a pyrrole compound and having a bulky substituent located on each carbon atom adjacent to the carbon atom bearing a hydrogen atom at the 5-position or the 2- and 5-position of a pyrrole compound. These catalyst system have significantly improved productivities, selectivities to 1-hexene, and provides higher purity 1-hexene within the C6 fraction than catalyst systems using 2,4-dimethylpyrrole.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Methods for oligomerizing olefins

ActiveUS7414006B2Organic-compounds/hydrides/coordination-complexes catalystsCatalystsChromium Compounds1-Octene

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

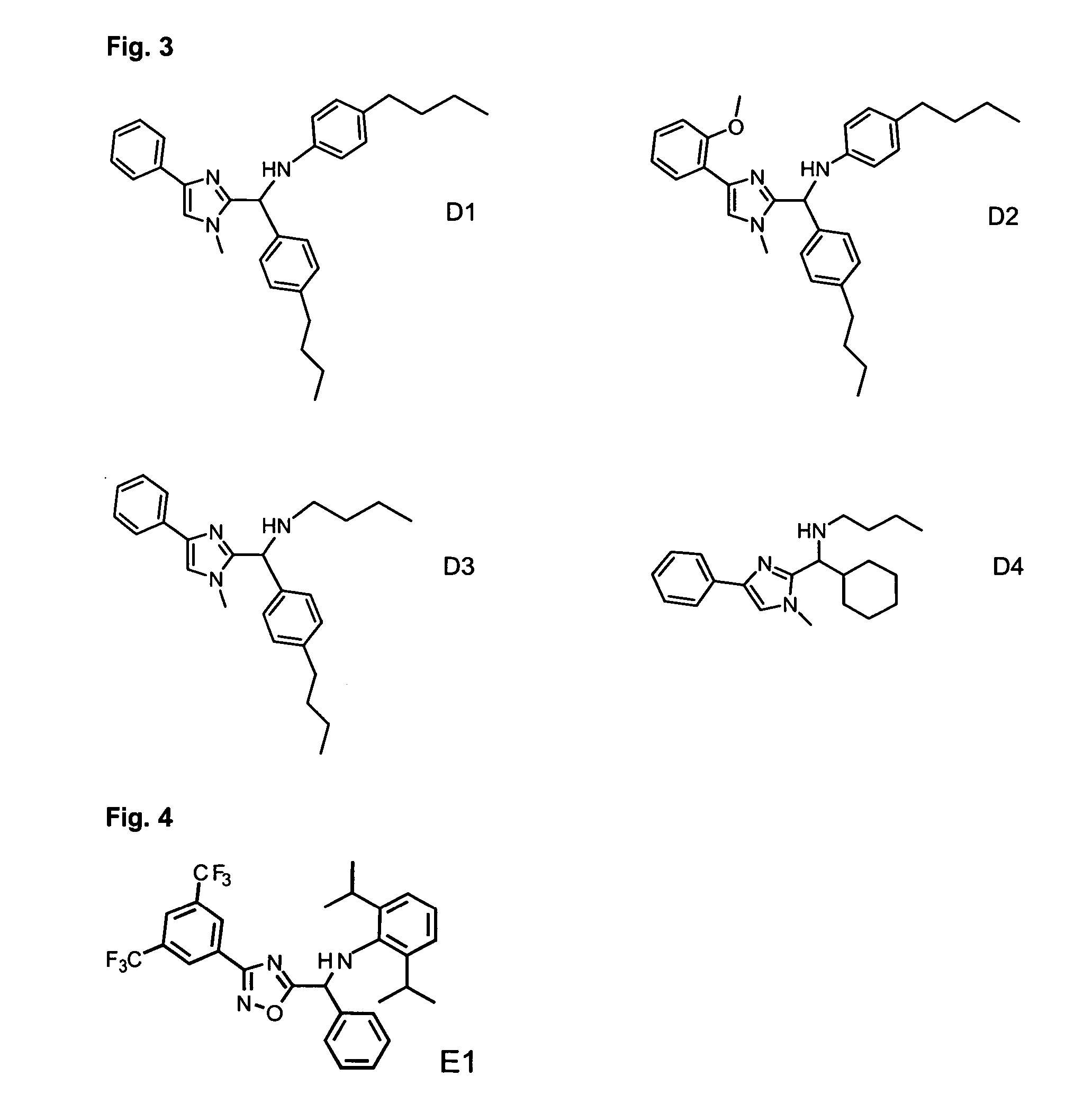

High-selectivity catalyst system used in trimerization and tetramerization of ethylene and use method thereof

ActiveCN104511311AIncreased co-selectivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChromium Compounds1-Octene

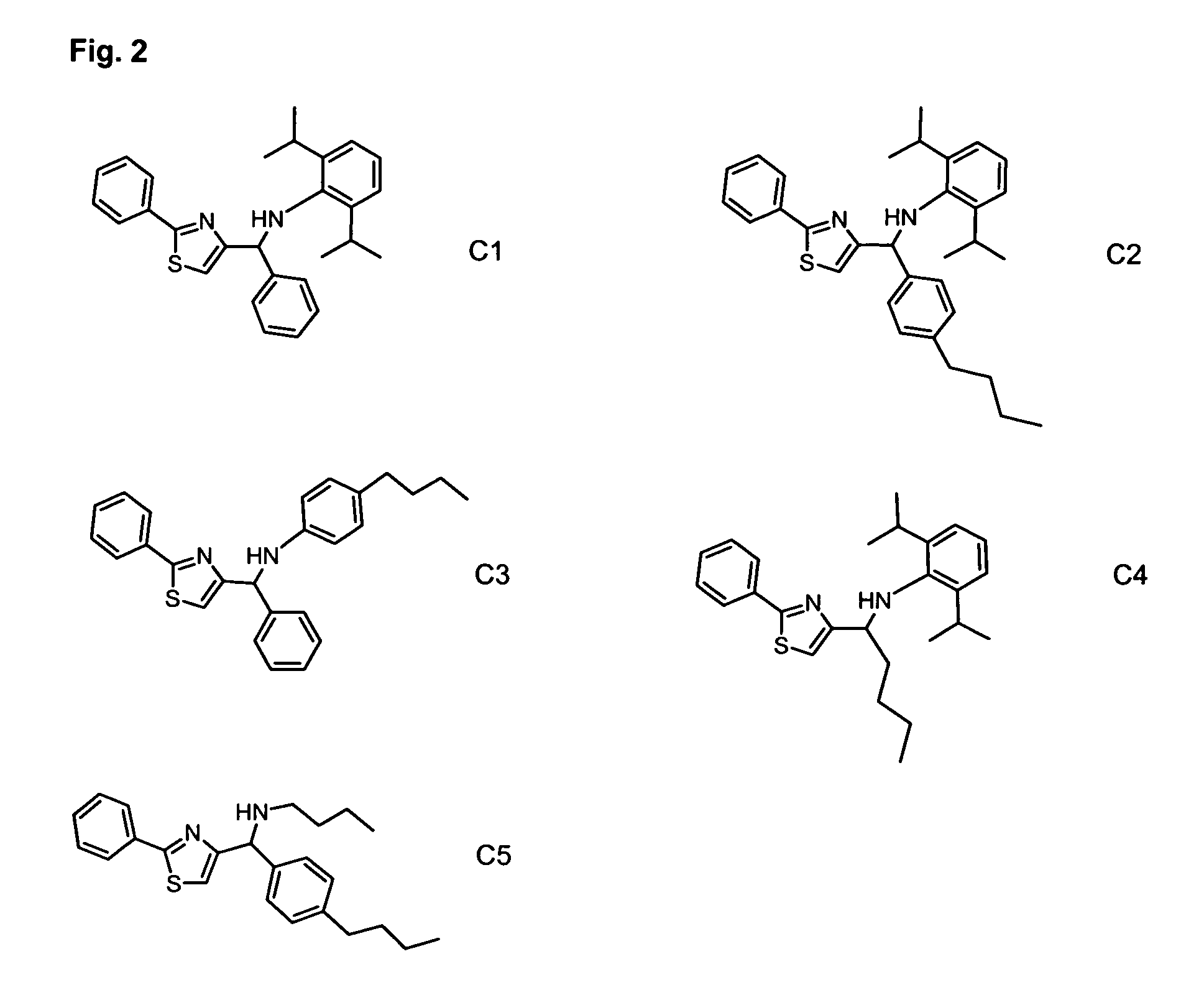

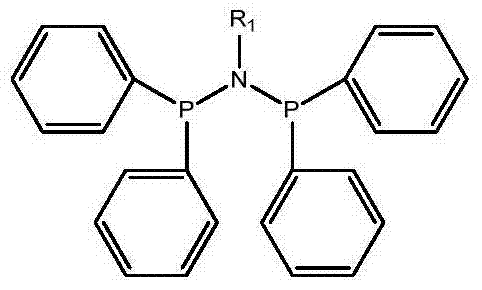

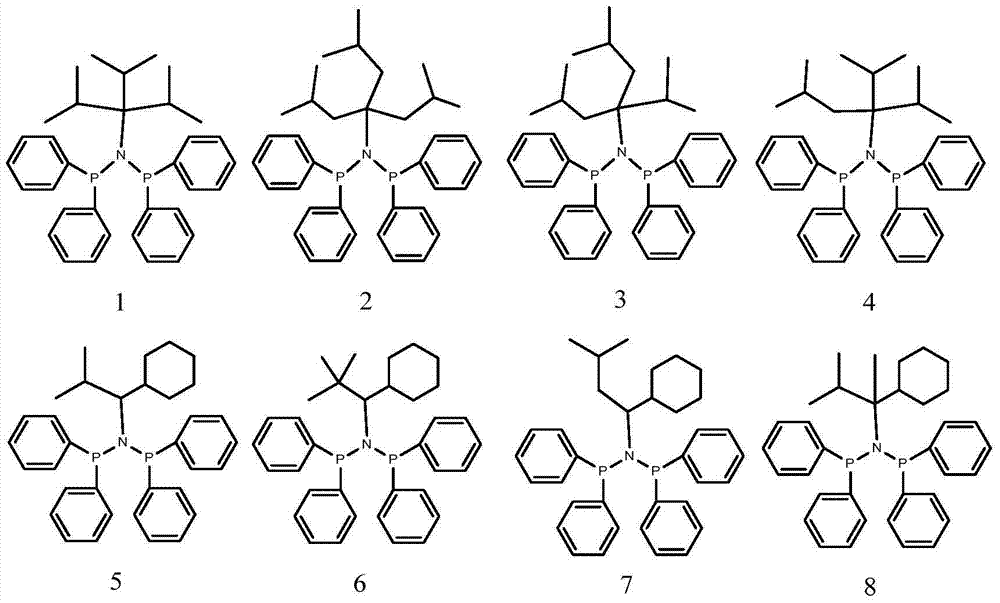

The invention provides a high-selectivity catalyst system used in trimerization and tetramerization of ethylene and a use method thereof. The catalyst system includes three components: (1) a chromium compound, (2) a ligand, of which a general structure formula is (Ph2)P-N(R1)-P(Ph2), wherein R1 is a synthetic phenyl group, alkyl group or cycloalkyl group; and (3) an activating agent or a co-catalyst. According to the catalyst system, a conventional PNP chromium-series catalyst is improved so that a co-selectivity of 1-hexane and 1-octylene is increased, wax-like products are reduced and a high activity is maintained.

Owner:EAST CHINA UNIV OF SCI & TECH

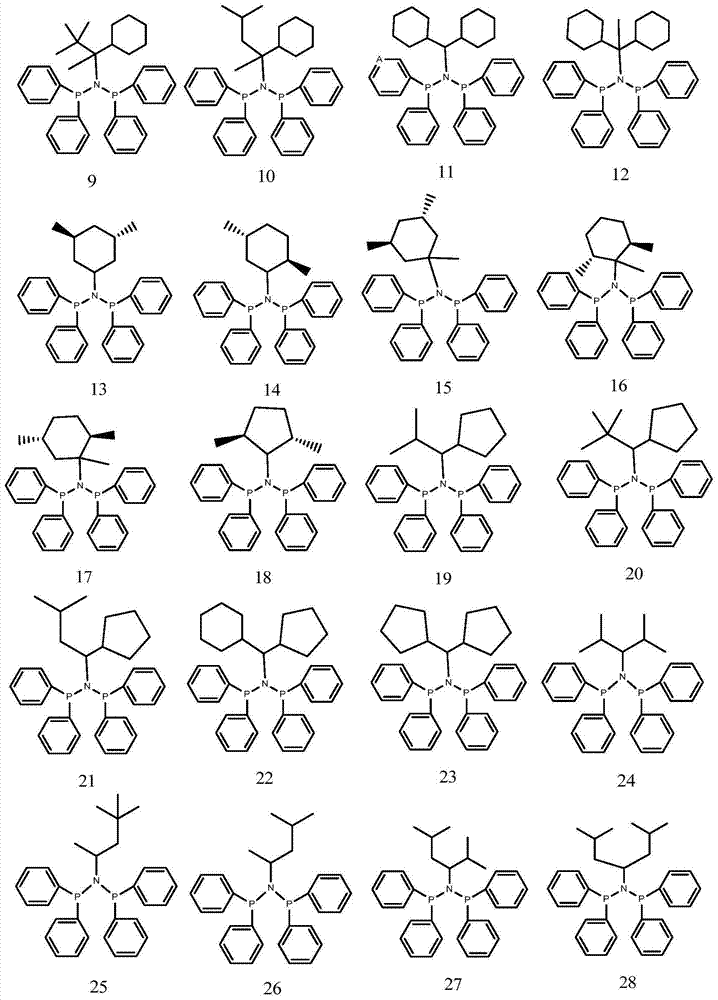

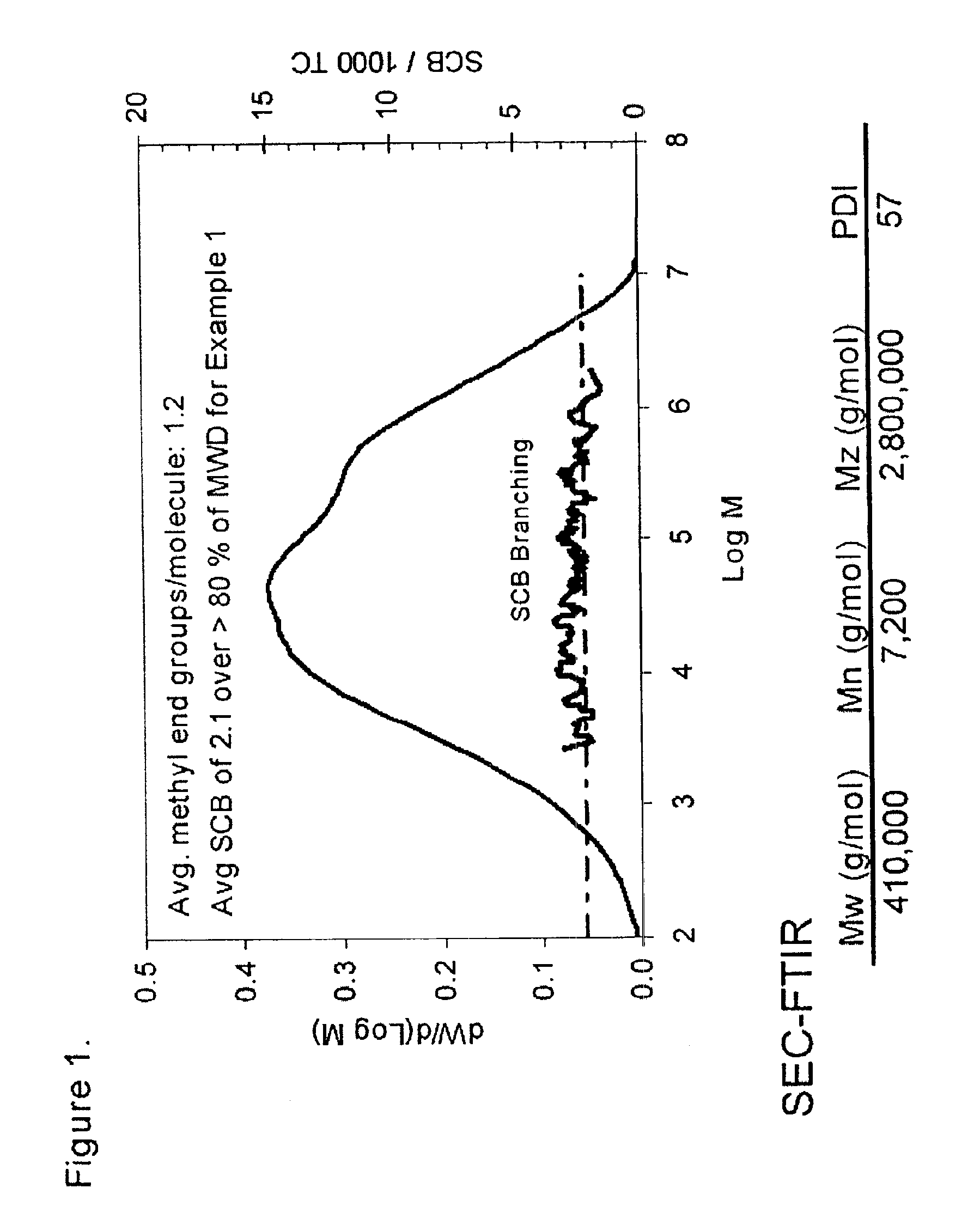

Olefin polymers, method of making, and use thereof

The present invention is directed to homo-polymers and copolymers of mono-1-olefins, a method of making such polymers,and uses of such polymers. Polymers of the present invention are formed by contacting at least one mono-1-olefin having from 2 to about 20 carbon atoms per molecule and at least one mono-1-olefin co-monomer having from 2 to about 10 carbon atoms per molecule in a reaction zone under polymerization conditions in the presence of a hydrocarbon diluent, a catalyst system, and a cocatalyst. In another aspect of the present invention, ethylene copolymers are employed to produce PE-100 pipe. Further, these ethylene copolymers may be employed to produce PE-100 pipe having both small diameters and diameters in excess of 42 inches substantially without sagging or other gravitational deformation. Copolymers of ethylene and 1-hexene are disclosed which are used to produce PE-100 pipe.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

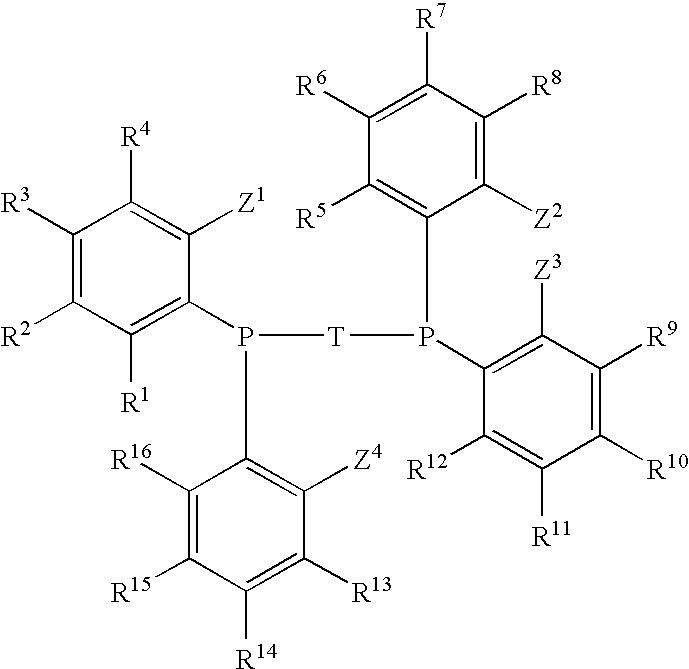

Phosphine Ligand-Metal Compositions, Complexes, and Catalysts For Ethylene Trimerizations

This invention relates to a method to selectively oligomerize olefins comprising contacting olefins with: 1) at least one diaryl-substituted diphosphine ligand; 2) a chromium metal precursor; and 3) optionally, one or more activators. In a particular embodiment, the method for selectively oligomerizing olefins includes trimerizing ethylene to selectively form 1-hexene.

Owner:EXXONMOBIL CHEM PAT INC

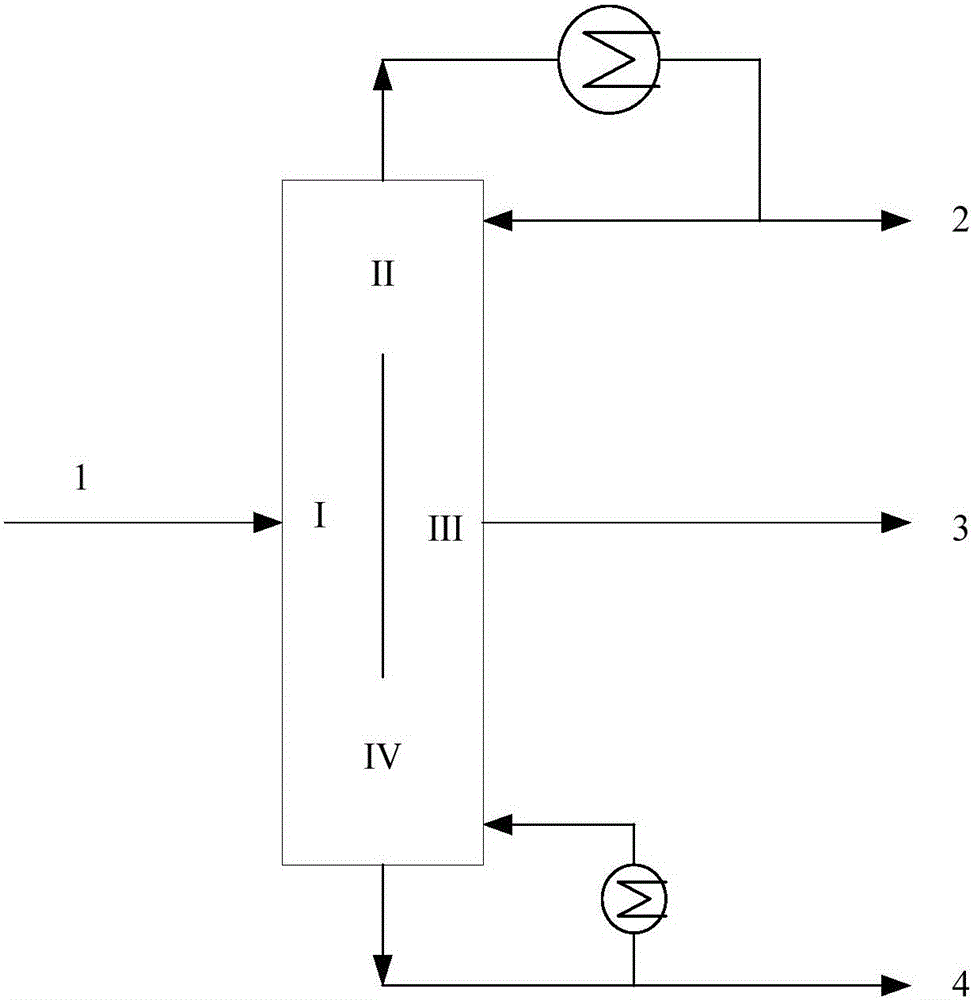

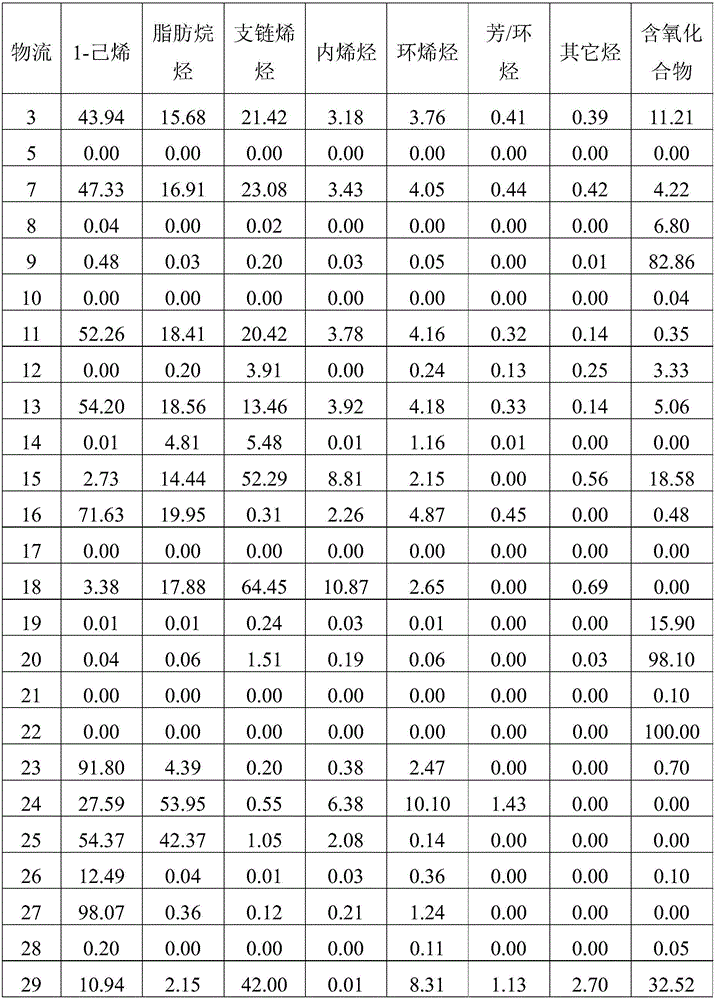

Method for separating oxygenated chemicals and 1-hexene from Fischer-Tropsch synthesis oil product

ActiveCN105777467AIncrease productionExpand product rangeOrganic compound preparationDistillation purification/separationAlkaneAlcohol

The invention relates to a method for separating oxygenated chemicals and 1-hexene from a Fischer-Tropsch synthesis oil product.The method comprises the steps that C6 fraction material flow is obtained through distillation in a predistillation tower by taking the Fischer-Tropsch synthesis oil product as a raw material, and two streams of extraction agents are fed to remove oxygenated chemicals in an extraction tower to obtain material flow rich in the oxygenated chemicals and crude C6 hydrocarbon material flow; the oxygenated chemicals contained in the crude C6 hydrocarbon material flow are further removed through a third extraction agent, tertiary olefins are converted into corresponding ethers through methyl alcohol under the action of an etherification catalyst to be removed, further purification is performed through rectification, and then C6 isoparaffin components and cycloolefin components are removed sequentially through a fourth extraction agent and a fifth extraction agent respectively to obtain 1-hexene product material flow.Compared with the prior art, the method has the advantages of being simple in technological process, low in cost and the like, and not only is 1-hexene separated and purified from the Fischer-Tropsch synthesis oil, but also the oxygenated chemicals can be separated.

Owner:YANKUANG ENERGY R&D CO LTD

Catalytic oligomerization of olefinic monomers

A catalyst precursor composition comprising: a source of chromium, molybdenum or tungsten; a first ligand having the general formula (R1)(R2P—X—P(R3)(R4); and a second ligand having the general formula (R1′)(R2′)P—X′—P(R3′)(R4′). The present invention also relates to a catalyst system comprising the catalyst precursor composition of the present invention and a cocatalyst. The present invention further relates to a process for the trimerization and tetramerization of olefinic monomers, particularly the trimerization and tetramerization of ethylene to 1-hexene and 1-octene, wherein the process comprises contacting at least one olefinic monomer with the catalyst system of the present invention.

Owner:SHELL OIL CO

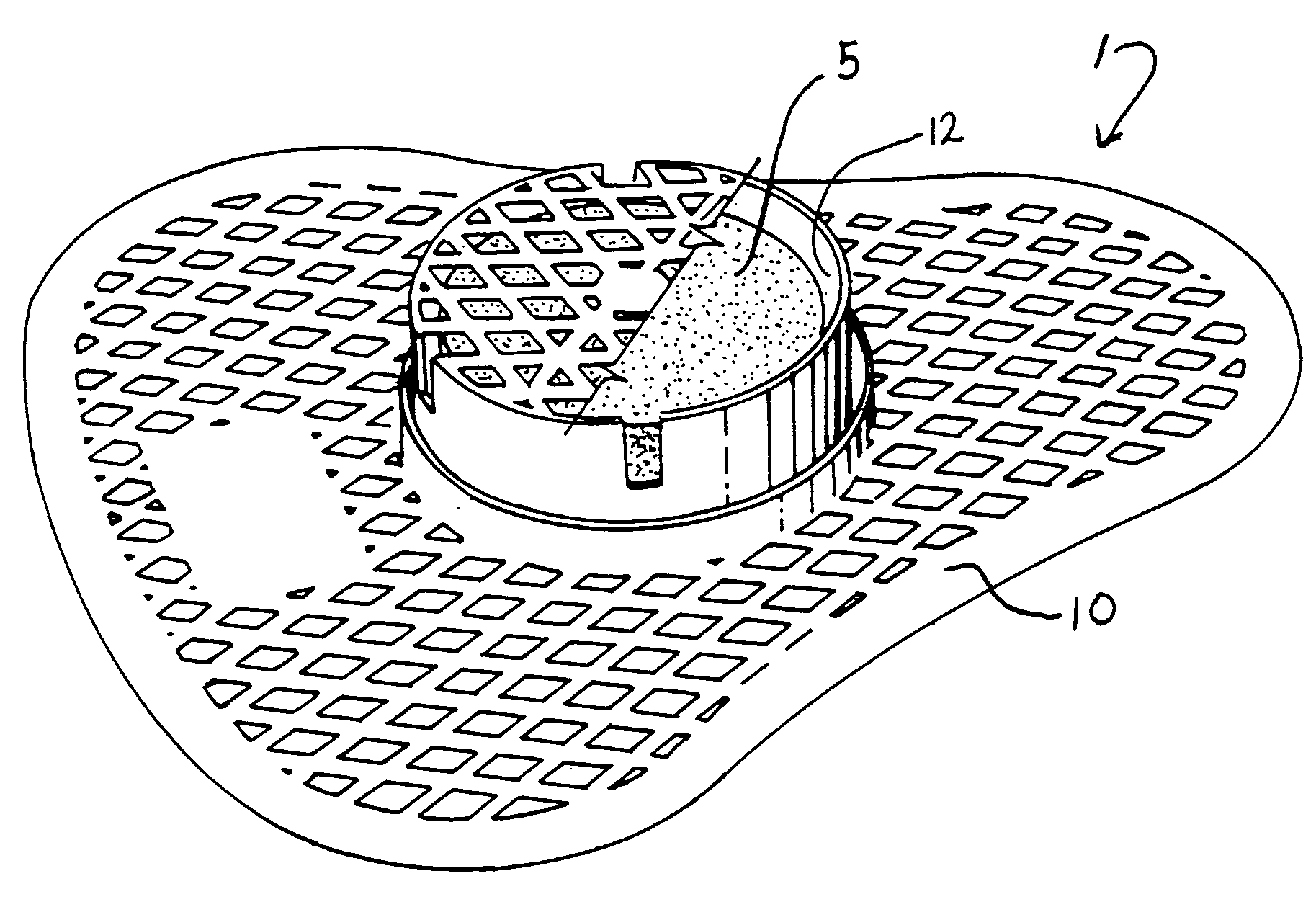

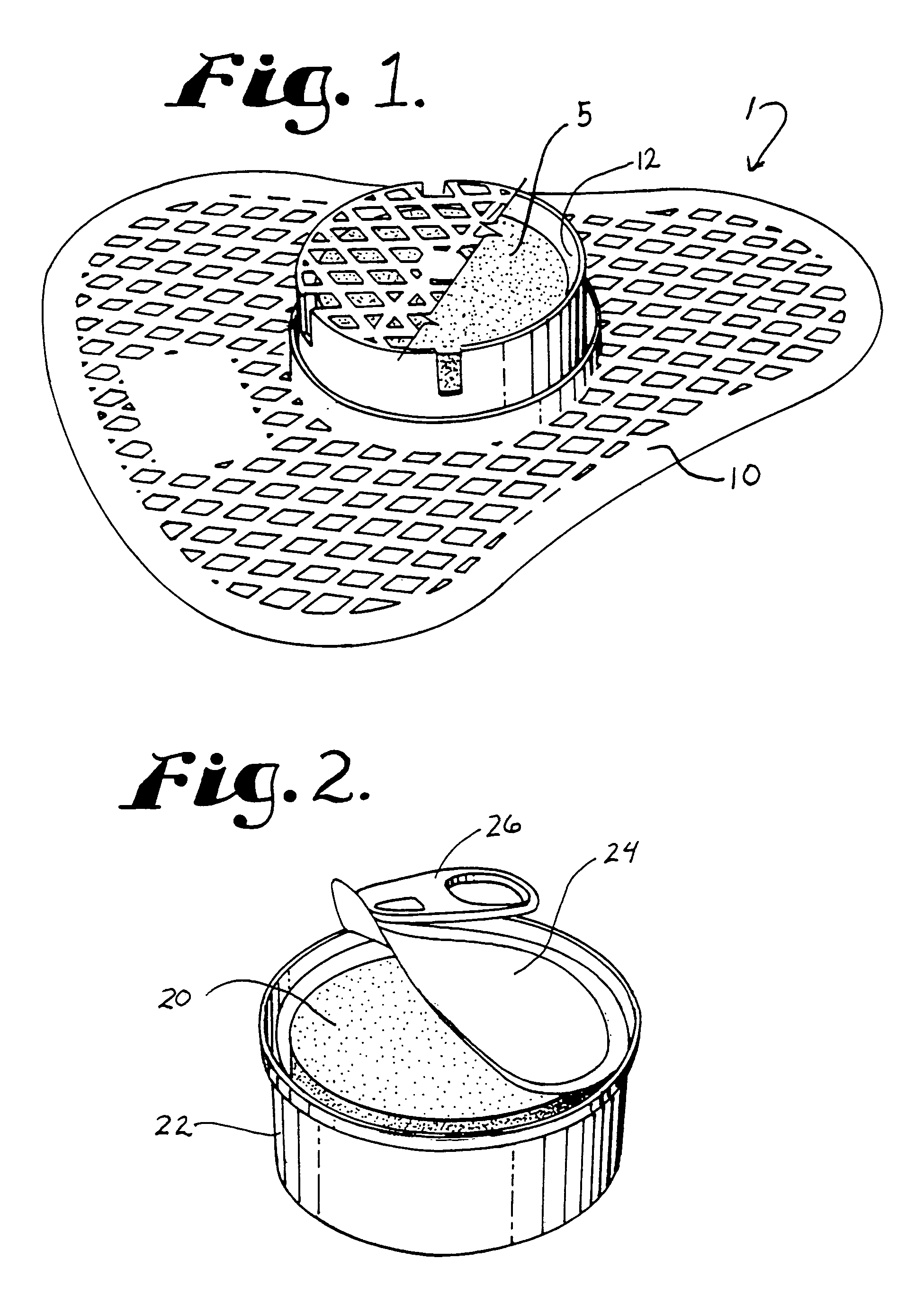

Fragrance emitting compositions and products

InactiveUS7202201B1Low production costReadily and easilyUrinalsCosmetic preparationsPotassium1-Hexene

Compositions and products for emitting fragrance include at least one fragrance, perlite, and sodium silicate or water glass. Compositions used to make urinal blocks and other products may further include at least one of: lime (calcium oxide), gypsum, enzymes and colorant agents. Chlorophyl and alfalfa may also be included, as well as calcium chloride, sodium chloride, potassium chloride, bicarbonate of soda, sodium sulfate, sodium talloate, nonionic surfactants, ethyl alcohol, hexylene glycol (1-hexene) ethylene glycol, propylene glycol and isopropyl alcohol.

Owner:UNITED LAB INT LLC +1

Compositions comprising 3,3,4,4,5,5,6,6,6-nonafluoro-1-hexene

Disclosed herein are 3,3,4,4,5,5,6,6,6-nonafluoro-1-hexene compositions for use in refrigeration and air conditioning systems, particularly in centrifugal compressor systems. Also disclosed are 3,3,4,4,5,5,6,6,6-nonafluoro-1-hexene in combination with at least one bromofluorocarbon, ketones, alcohols, chlorocarbons, ethers, esters, 4-chloro-1,1,2,3,3,4-hexafluorobutene, N-(difluoromethyl)-N,N-dimethylamine, or mixtures thereof, which are azeotropic or near azeotropic.

Owner:EI DU PONT DE NEMOURS & CO

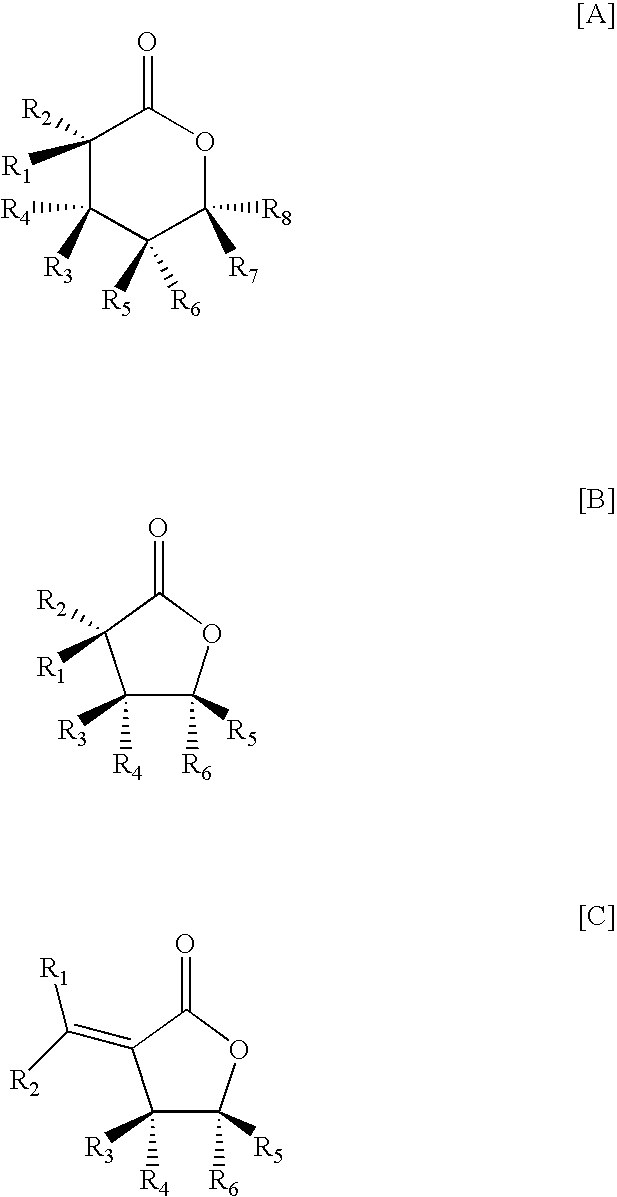

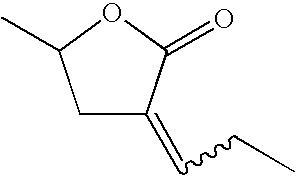

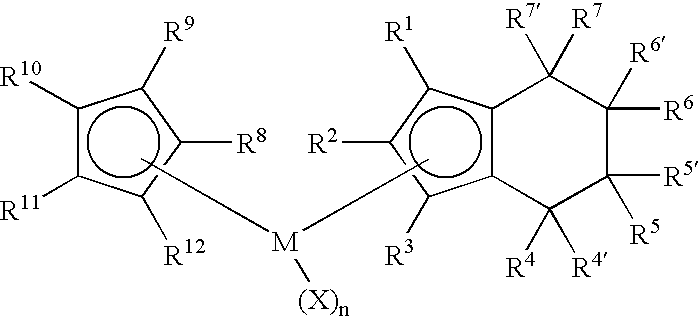

Class of metallocenes and method of producing polyethylene

ActiveUS6911508B2Change densityOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingHalogen1-Hexene

The invention provides a catalyst system and a method of making polyethylene using the catalyst system, the method comprising combining ethylene; an activator; and a metallocene catalyst compound; wherein in one embodiment the metallocene catalyst compound is selected from: wherein M is a Group 4 atom; X is a leaving group; n is an integer from 0 to 3; and R1 to R12 are independently selected from hydrides, halogens, hydroxy, C1 to C6 alkoxys, C1 to C6 alkenyls, and C1 to C10 alkyls; characterized in that when the comonomer is 1-hexene, and the mole ratio of 1-hexene to ethylene combined is varied between 0.015 to 0.05, the density of the resultant polyethylene changes by less than 5% and the I21 / I2 varies from 10 to 150.

Owner:EXXONMOBIL CHEM PAT INC

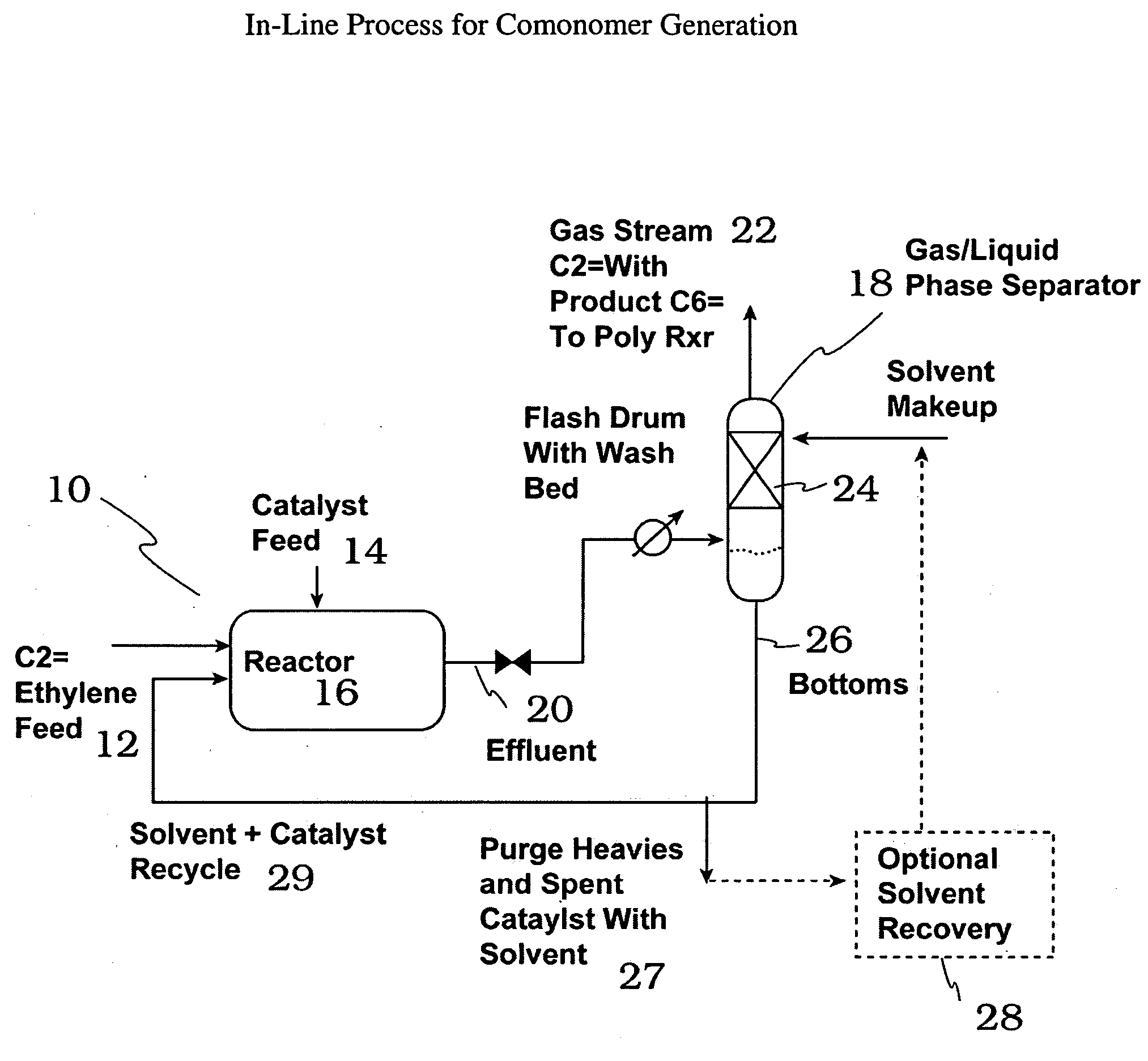

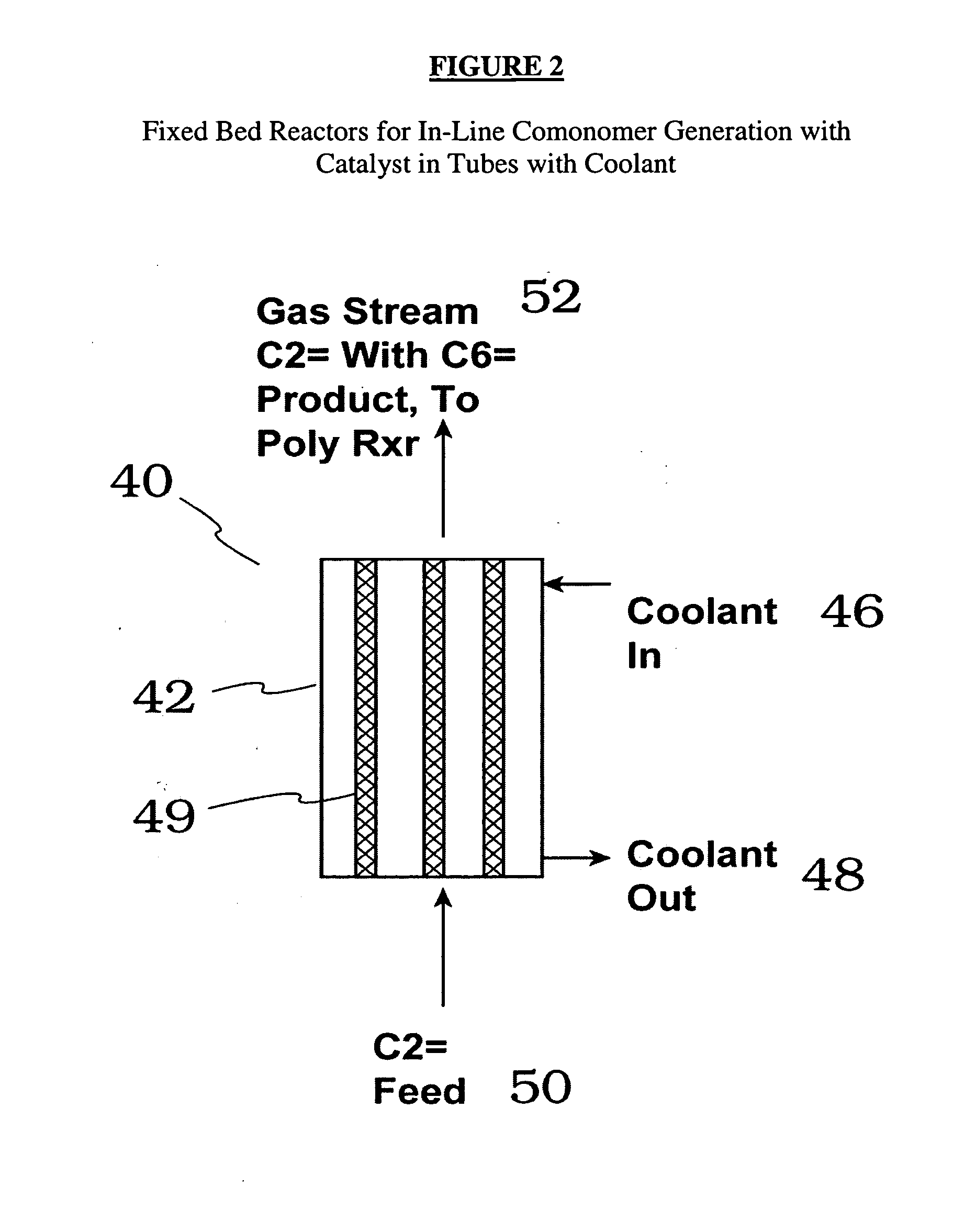

In-line process for generating comonomer

InactiveUS20070185364A1Substantial capitalSubstantial operational cost savingHydrocarbons from unsaturated hydrocarbon additionHydrocarbons1-OcteneSolvent

The present invention relates to an in-line method for generating comonomer, such as 1-hexene or 1-octene, from monomer, such as ethylene. The comonomer generated is directly transported, without isolation or storage, to a polyethylene polymerization reactor. The in-line method for generating comonomer includes the steps of providing an in-line comonomer synthesis reactor and a downstream gas / liquid phase separator prior to a polyethylene polymerization reactor; feeding ethylene monomer and a catalyst in a solvent to the comonomer synthesis reactor; reacting the ethylene monomer and the catalyst in solvent under reaction conditions to produce an effluent stream including ethylene monomer and comonomer; passing the effluent stream from the comonomer synthesis reactor to the downstream gas / liquid phase separator to separate a gas stream from a bottom stream, wherein the gas stream is a mixture of ethylene monomer, and comonomer; and passing the gas stream to the polyethylene polymerization reactor to provide the necessary comonomer input. The in-line method is useful in the production of LLDPE, and other branched polyethylene based polymers. Some benefits include process simplification and reduced capital and operating costs.

Owner:EXXONMOBIL CHEM PAT INC

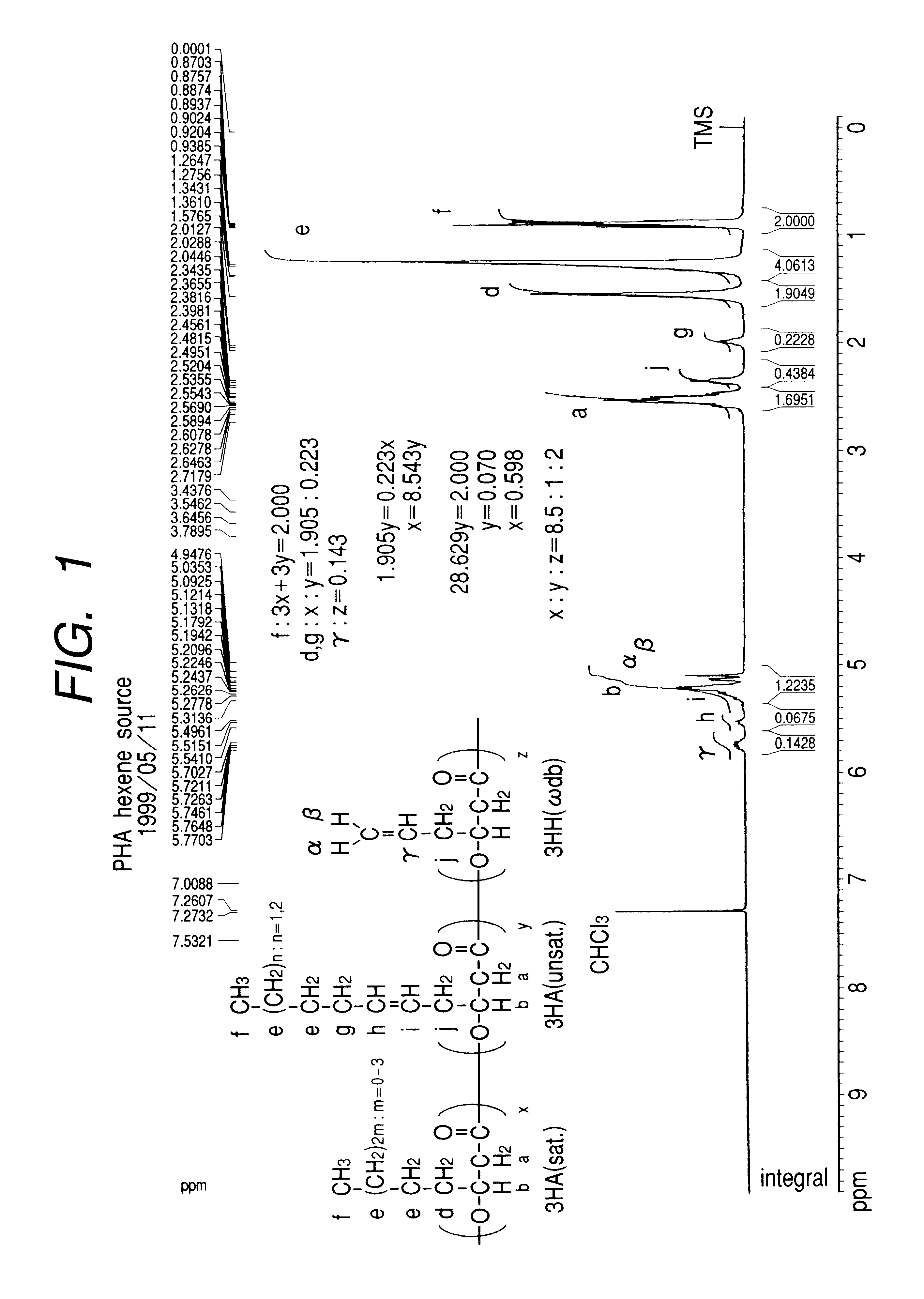

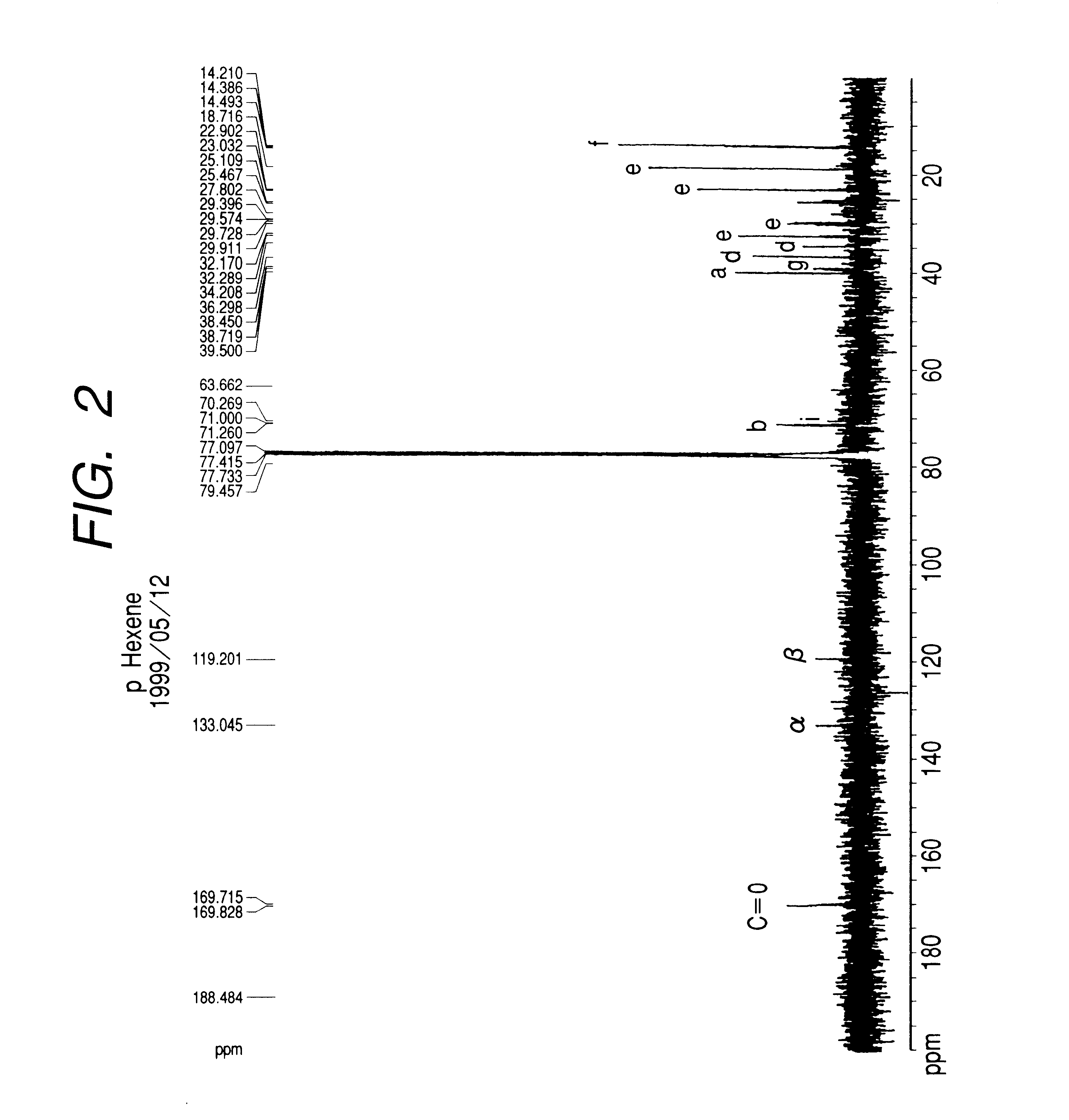

Method for producing microbial polyester

A method for producing a microbial polyester by culturing a microorganism being capable of producing a poly hydroxyalkanoate polyester in a culture medium containing 1-hexene as a sole carbon source.

Owner:CANON KK

Catalyst for trimerization of ethylene and process for trimerizing ethylene using the catalyst

InactiveUS6900152B2Good handling characteristicsHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionInorganic compoundCompound (substance)

A catalyst used for trimerization of ethylene into 1-hexene is descrobed, which comprises (i) a specific organometallic complex having a neutral multidentate ligand having a tripod structure, (ii) an alkylaluminoxane, and an optional ingredient selected from: (iii) a halogenated inorganic compound, (iv) a specific alkyl group-containing compound, (v) a combination of a halogenated inorganic compound with a specific alkyl group-containing compound, (vi) an amine compound and / or an amide compound, and (vii) a combination of an amine compound and / or an amide compound with a specific alkyl group-containing compound.

Owner:TOSOH CORP

Methods for oligomerizing olefins

ActiveUS20060247483A1Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium CompoundsOligomer

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a pyridyl amine or a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

Methods for oligomerizing olefins

ActiveUS7425661B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionOligomer1-Octene

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a pyridyl amine or a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS20070225533A1Improve low temperature performanceHigh viscosityLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

System and Method for Selective Trimerization

ActiveUS20130144024A1Distillation purification/separationMolecular sieve catalystsDownstream processingReactor system

Disclosed herein is a method for separating from the reactor effluent of an olefin oligomerization procedure those catalyst materials and polymeric by-products which can cause difficulties in the downstream processing of such effluent. Polymer by-products and catalyst in the effluent are separated from reaction products by flash vaporization utilizing an in-situ hot solvent which is contacted with the effluent and serves as the heating medium to promote this flash vaporization step. Subsequent processing of a liquid portion of the effluent which is left after flash vaporization involves recovery of catalyst and polymeric by-products therefrom in a steam stripping vessel. Also disclosed is a multiple reactor system which can be used for continuous trimerization of ethylene to 1-hexene while at the same time washing polymeric by-products from one of the reactors in the series using a wash oil solvent.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst of ethylene trimerization, and application

ActiveCN1872416AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChromium(III) acetylacetonateTriisobutylaluminium

A catalyst for the self-polymerization of the ethene with three molecule to selectively generate 1-hexene is prepared from the Cr compound, the ligand containing P and / or N, aluminum alkylide, and promoter in the mole ratio of 1: (0.5-100): (50-5000): (0.5-100).

Owner:PETROCHINA CO LTD +1

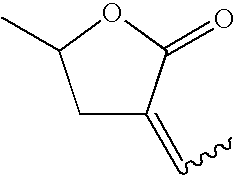

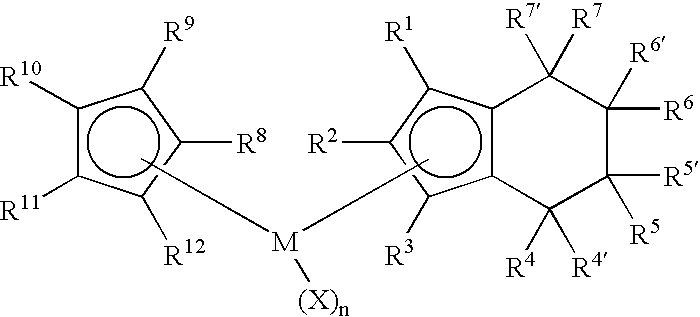

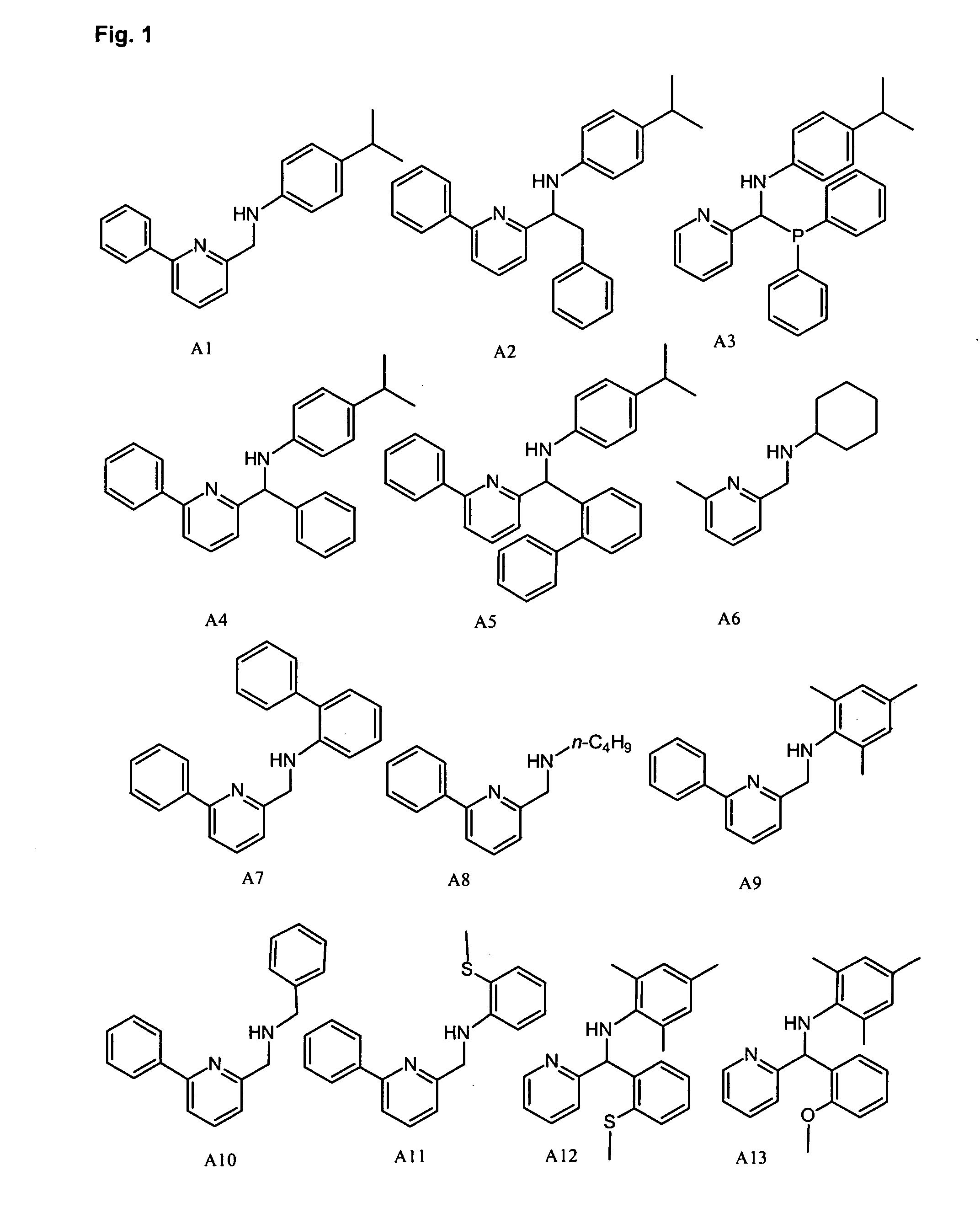

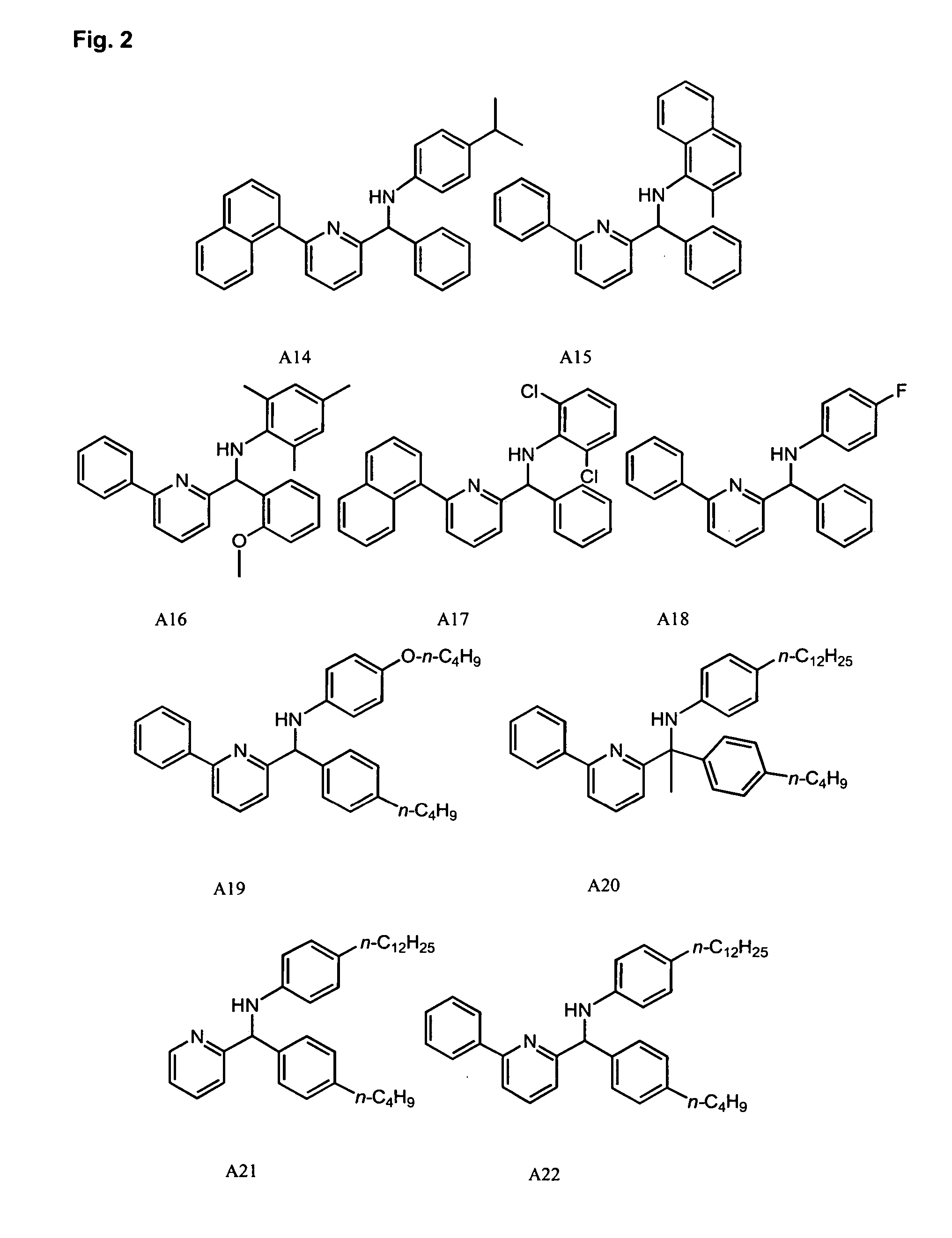

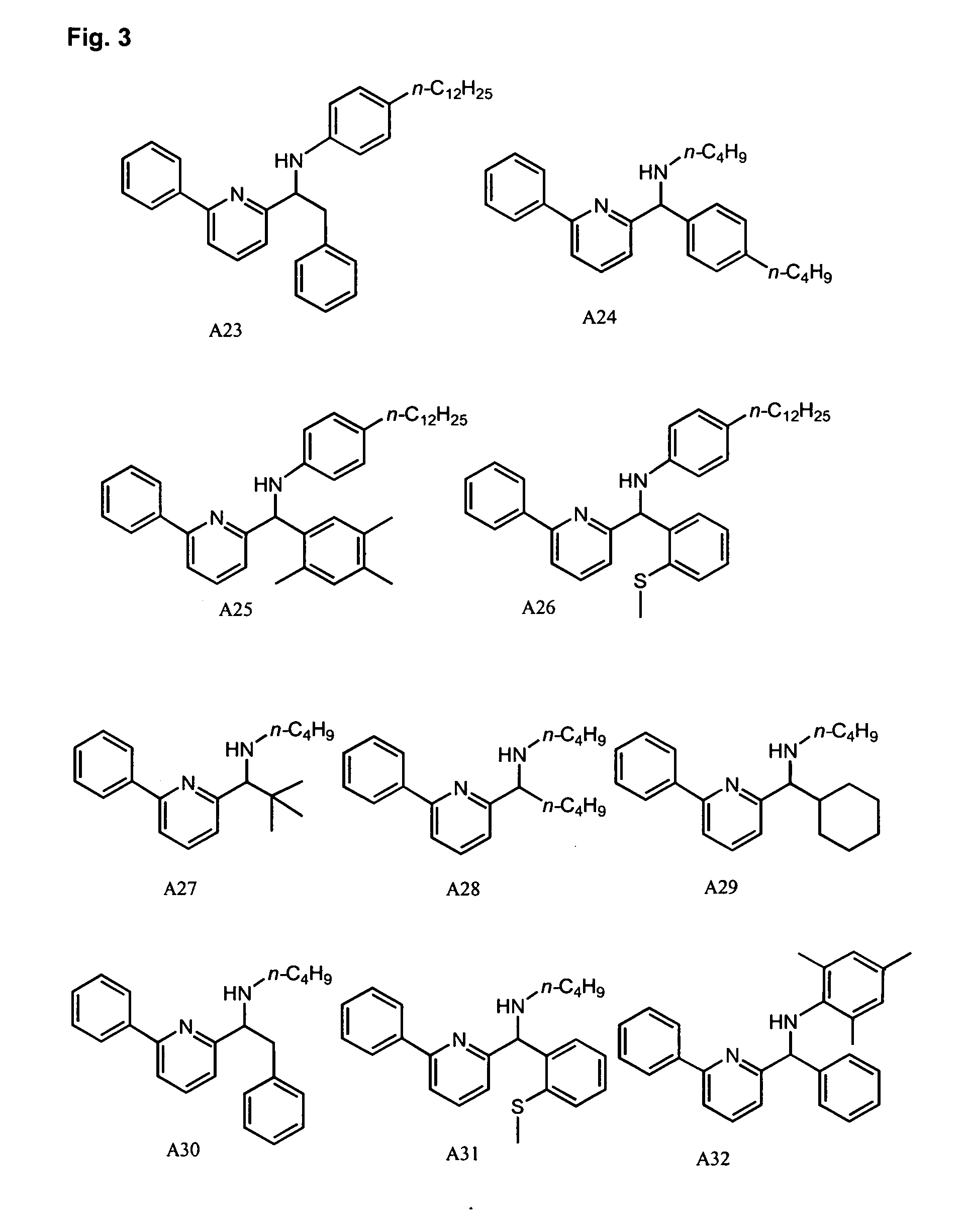

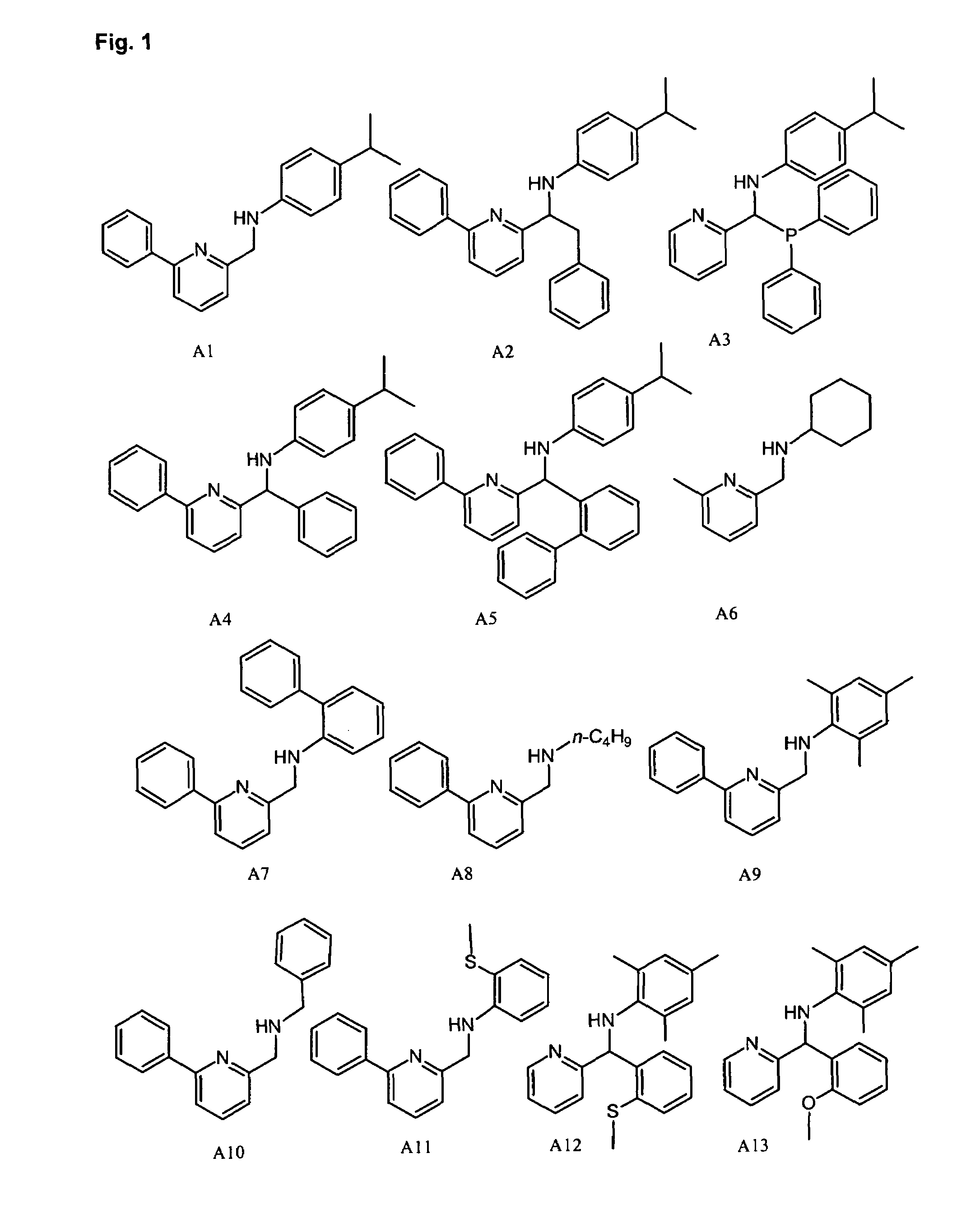

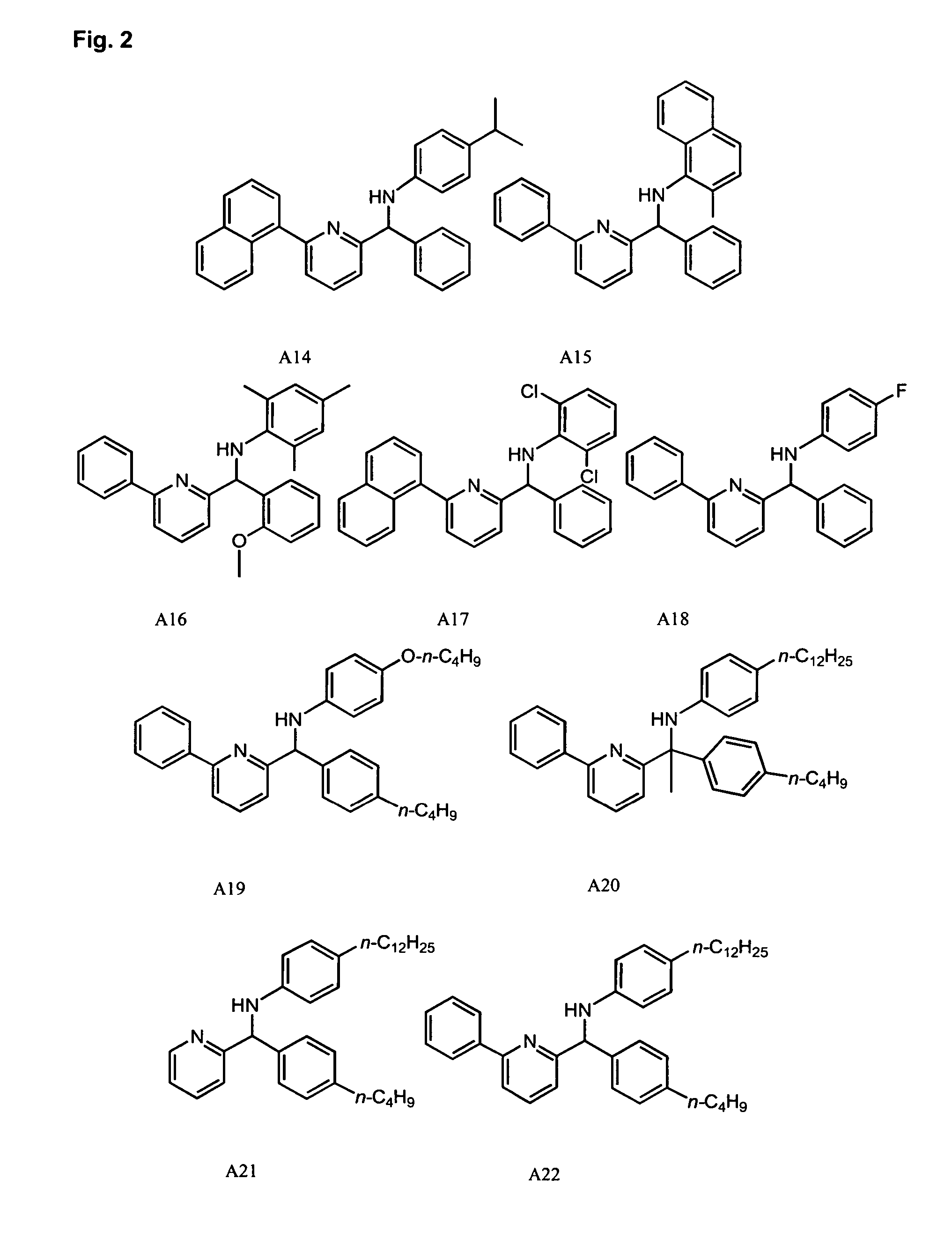

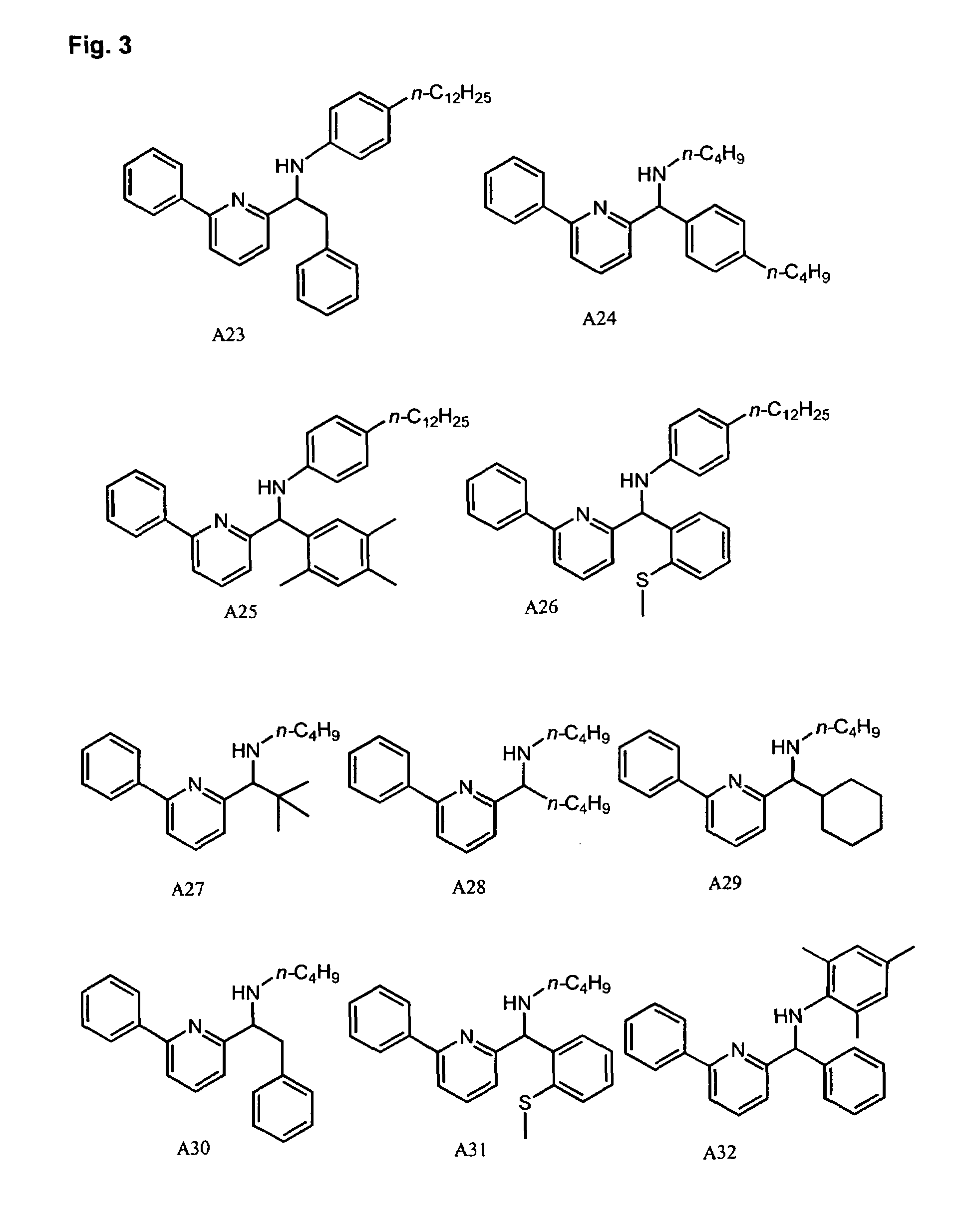

Ligand compound, catalyst system for olefin oligomerazation, and method for olefin oligomerization using the same

ActiveUS20160122371A1High catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-Octene1-Hexene

This disclosure relates to a ligand compound, a catalyst system for olefin oligomerization, and a method for olefin oligomerization using the same. The catalyst system for olefin oligomerization according to the present invention has excellent catalytic activity, and yet, exhibits high selectivity to 1-hexene and 1-octene, thus enabling efficient preparation of alpha-olefin.

Owner:LG CHEM LTD

Catalyst system for ethylene selective oligomerization and ethylene oligomerization method

ActiveCN108097322ASolution to short lifeEasy to synthesizeGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsBackbone chain1-Hexene

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low viscosity PAO based on 1-tetradecene

ActiveUS20070225534A1Low viscosityLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcohol1-Hexene

Disclosed herein is a method of making a PAO using tetradecene and particularly mixtures comprising 1-hexene, 1-decene, 1-dodecene, and 1-tetradecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol and an ester. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst for Synthesizing 1-Hexene from Ethylene Trimerization and Application Thereof

ActiveUS20120310025A1Improve coordinationWell formedOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsElectron donor1-Hexene

A catalyst for synthesizing 1-hexene from ethylene trimerization and its application are provided. Said catalyst consists of (a) the compound containing P and N, (b) electron donor, (c) Cr compound, (d) carrier and (e) accelerator. The molar ratio of (a), (b), (c), (d) and (e) is 0.5-100:0.5-100:1:0.5-10:50-5000. The catalyst is prepared by mixing the components of (a)-(e) in an ethylene trimerization apparatus in situ and ethylene is introduced into the apparatus continuously. The prepared catalyst can be used to synthesize 1-hexene from ethylene trimerization in the inert solvents. The trimerization is performed at 30-150° C. and 0.5-10.0 MPa for 0.1-4 hours. The catalyst has high catalytic activity and high 1-hexene selectivity. During the process of ethylene trimerization, by-product polyethylene does not stick to the apparatus.

Owner:PETROCHINA CO LTD

Process for separating 1-hexene from a mixture of products obtained from an ethylene trimerization zone

A process for recovering 1-hexene comprising: a) separating the mixture obtained from the ethylene trimerization reaction into a top fraction comprising ethylene and a bottom fraction, b) separating a portion of the bottom fraction obtained from step a) into a top fraction comprising 1-hexene and 1-butene and a bottom fraction, c) separating a portion of the fraction comprising 1-hexene and 1-butene obtained from step b) into a top fraction principally comprising 1-butene and into a bottom fraction principally comprising 1-hexene, and in said process: a portion of the bottom fraction obtained from step b) is returned to the reaction section and another portion of said bottom fraction obtained from step b) is used in a recirculation loop connecting the reaction section and the column of said step b), said recirculation loop being used to cool the reaction section and to reboil said column of step b).

Owner:AXENS SA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com