Catalytic process for the oligomerization of olefinic monomers

A technology of olefin monomer and catalyst, applied in the field of olefin monomer oligomerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

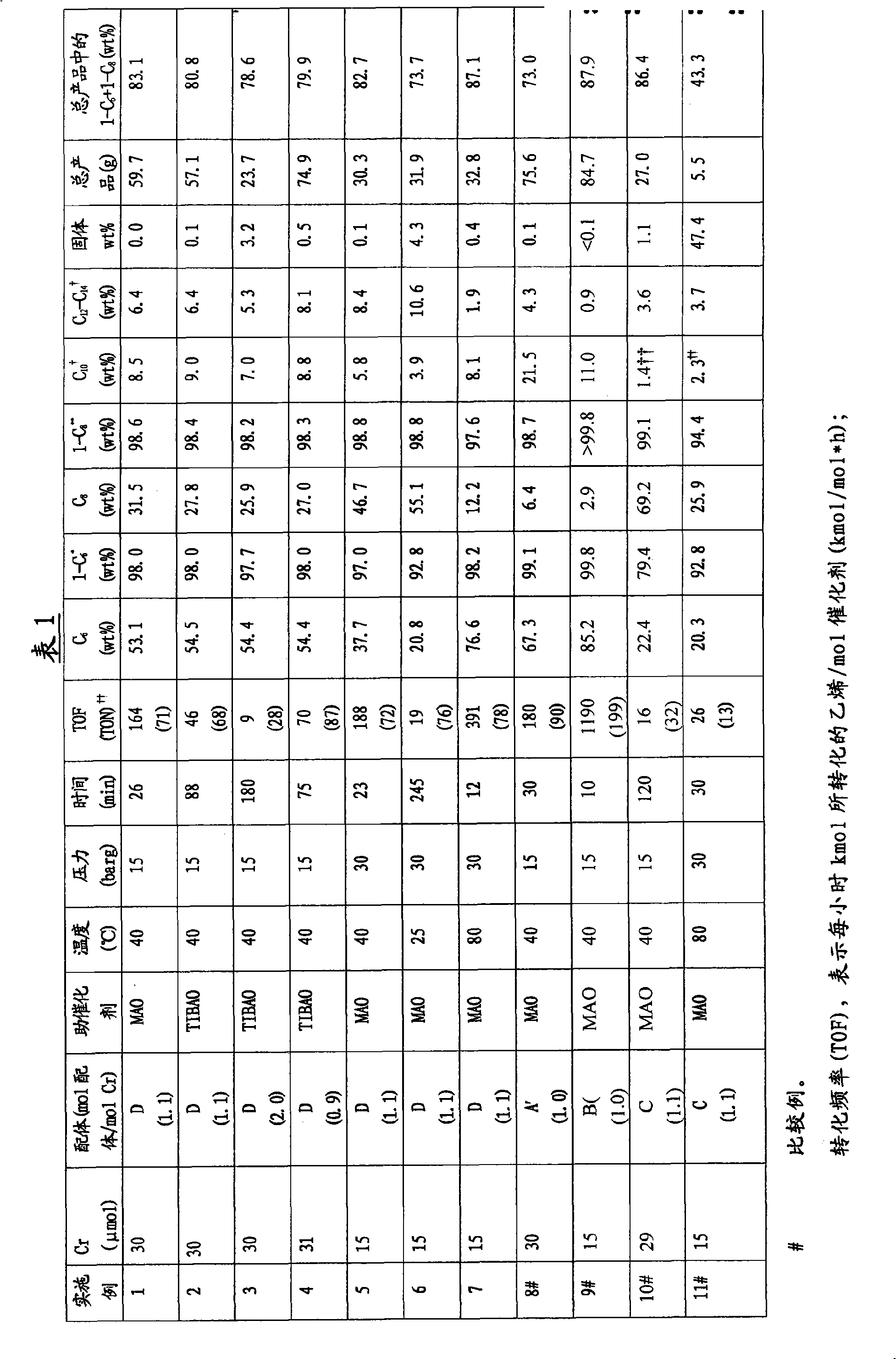

Embodiment 1-11

[0167] Catalyst system preparation for simultaneous trimerization and tetramerization in a batch autoclave

[0168] CrCl in a Braun MB 200-G drying oven 3 The 1:1 complexes with Ligand A or B (ie composition A' or B' indicated in Table 1) were placed in glass vials. The catalyst precursor composition was converted to a catalyst solution by adding a 3 or 1.5 mmol solution of MAO in toluene (approximately 1.6 g or 0.8 g MAO solution), followed by typically 4 g of anhydrous toluene. Finally the bottle is sealed with a septum cap.

[0169] These catalyst solutions or part of these solutions are used for the simultaneous trimerization and tetramerization of ethylene.

[0170] Alternatively, tris(acetylacetonate)chromium (typically 30 μmol) and the amount of ligand component C or D as shown in Table 1 were placed in a glass bottle, anhydrous toluene (typically 4 g) was added thereto, to obtain a catalyst precursor solution. Finally the bottle is sealed with a septum cap.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com