Supported non-metallocene single site catalyst component and preparation method thereof and use

An active center, non-single-free technology, which is applied in the field of components of non-single-cene active center catalysts, can solve the problems of increasing fine powder, inability to adapt to industrial equipment, affecting the distribution of polymer particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

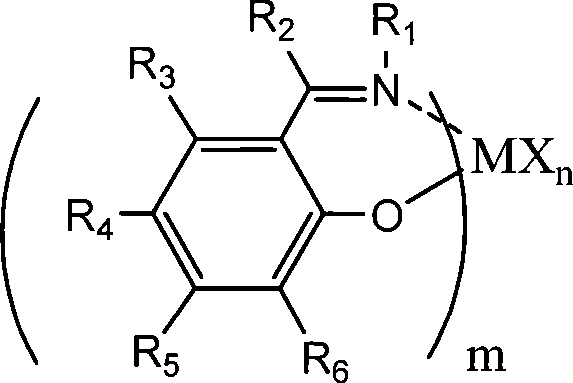

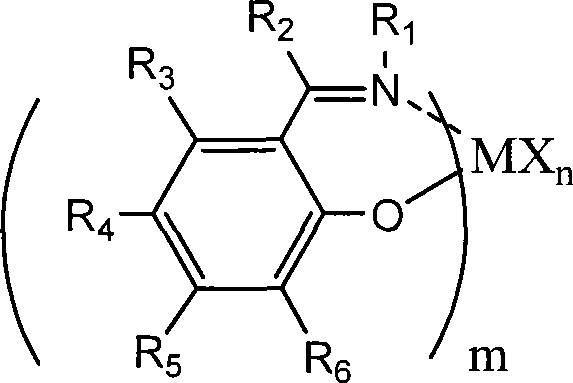

Method used

Image

Examples

Embodiment 1

[0072] 1) Preparation of magnesium chloride / silica gel carrier

[0073] Under the protection of nitrogen, in a glass reactor, add 0.50 g of anhydrous magnesium chloride at room temperature, then add 350 ml of dried tetrahydrofuran, start stirring, 13.2 g of silica gel (GRACE 955, under nitrogen, roast at 150 ° C for 2.5 hours, heat up to 300°C for 2 hours, then at 600°C for 5 hours) into the reactor, heated to 65°C, stirred and dissolved for 2 hours, then evaporated at 80°C to remove the solvent to obtain a white solid powder. The white solid powder was vacuum-dried at 100°C for 2 hours, and then vacuum-dried at 300°C for 10 hours to obtain a solid powder with good fluidity. According to gas chromatography analysis, no tetrahydrofuran was detected.

[0074] 2), preparation of alkylaluminoxane / magnesium chloride / silica gel carrier

[0075] Under the protection of nitrogen, take 5.13 grams of the above-mentioned magnesium chloride / silica gel carrier and add it to a glass reacto...

Embodiment 2

[0085] 1), preparation of alkylaluminoxane / silica gel carrier

[0086] Same as in Example 1 1)

[0087] 2), preparation of alkylaluminoxane / magnesium chloride / silica gel carrier

[0088] With embodiment 1 in 2)

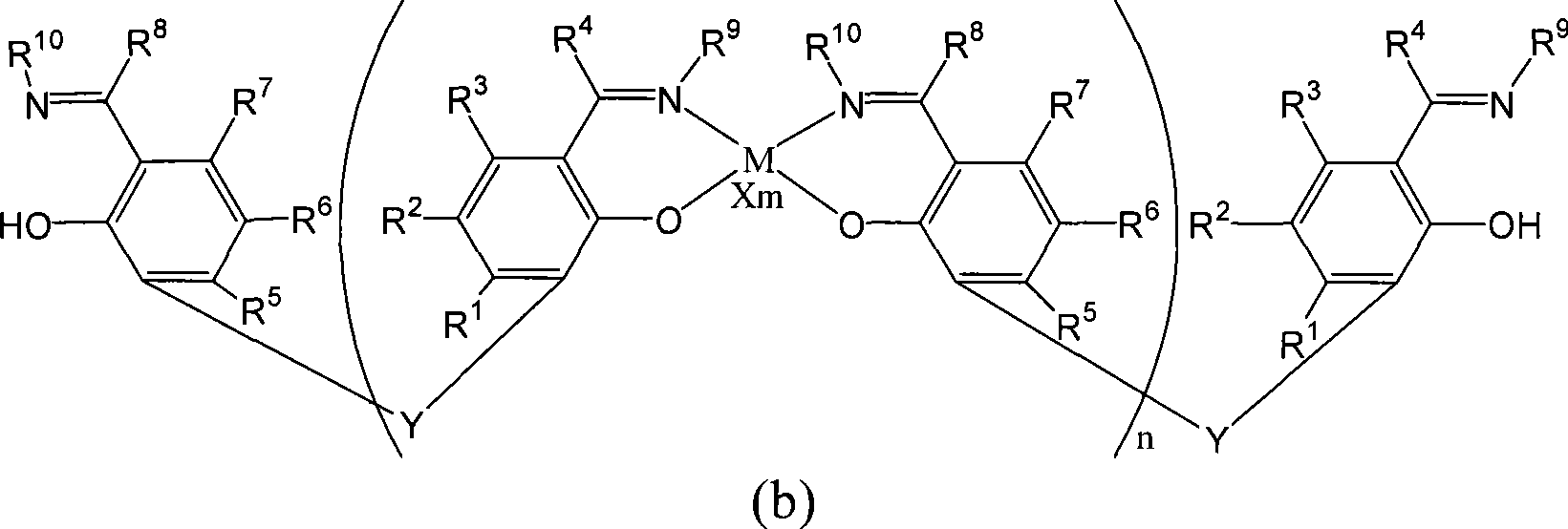

[0089] 3) Preparation of supported non-cene catalyst B

[0090] Under nitrogen protection, 4.23 grams of the above-mentioned prepared alkylaluminoxane / magnesium chloride / silica gel carrier were added in a glass reactor, 50 milliliters of dried toluene was added to make a slurry, and 0.364 grams of ( L2) 3 Zr 2 Cl 4 (Its structure is as follows, see Chinese patent application 200410086388.8 for synthesis) solution was added dropwise into the reactor, reacted at 30° C. for 30 minutes, then washed with 50 ml of toluene, and dried in vacuum to obtain supported non-cene catalyst B. Characterized by ICP, in catalyst B, the weight content of Mg is 1.15%, the weight content of Zr is 0.43%, and the weight content of Al is 13.28%.

[0091]

Embodiment 3

[0093] 1) Preparation of magnesium chloride / silica gel carrier

[0094] Under nitrogen protection, in a glass reactor, add 14.4 grams of anhydrous magnesium chloride at room temperature, then add 400 milliliters of tetrahydrofuran after drying, after starting to stir, 22.0 grams of silica gel (Cabot company CAB-O- TS-610, average particle size 0.2-0.3 microns, dried at 50°C for 4 hours) was added into the reactor, heated to 65°C, stirred and dissolved for 5 hours, and then solid powder was prepared using a closed spray dryer. The particle size of solid powder is D 50 19 microns.

[0095] The solid powder was vacuum-dried at 100° C. for 2 hours, and then vacuum-dried at 300° C. for 10 hours to obtain a solid powder with good fluidity. Through gas chromatography analysis, no tetrahydrofuran was detected.

[0096] 2), preparation of alkylaluminoxane / magnesium chloride / silica gel carrier

[0097] Under the protection of nitrogen, take 7.10 grams of the magnesium chloride / silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com