Polypropylene, preparation method and applications thereof

A polypropylene, dimethoxypropane technology, applied in the field of olefin polymerization, can solve the problems of intractability, unstable organic peroxides, and increased processing steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] According to a specific embodiment of the present invention, the melt flow index MFR of the polypropylene is 70-90g / 10min, the isotactic index is 97.5-98.5wt%, and the molecular weight distribution index M W / Mn is 4-5.

[0018] The melt flow index MFR of polypropylene provided by the present invention can be greater than 30g / min, preferably greater than 50g / min, more preferably 70-90g / 10min, for example, can be 70-75g / 10min, 75-80g / 10min, 80 Any value between -85g / 10min or 85-90g / 10min.

[0019] The isotactic index of the polypropylene provided by the present invention can be 96-99.5wt%, preferably 96.5-98.5wt%, more preferably 97.5-98.5wt%, for example can be between 97.5-98wt% or 98-98.5wt% any value of .

[0020] The molecular weight distribution index of the polypropylene provided by the present invention can be properly selected according to the specific application of the polypropylene, subject to meeting the requirements of use, it can be 3-5.5, preferably 3.5...

Embodiment 1

[0060] This example serves to illustrate the polypropylene according to the invention and the process for its preparation.

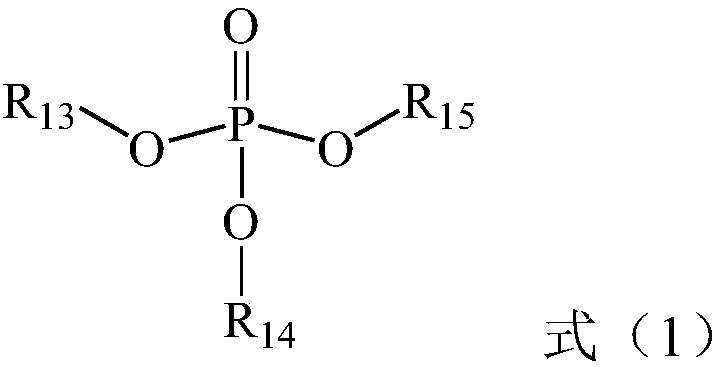

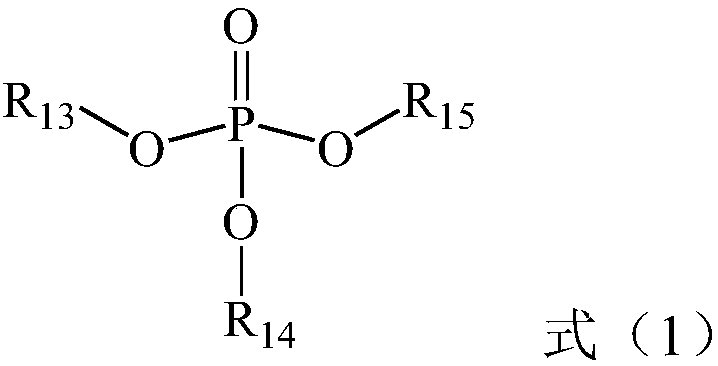

[0061] (1) Preparation of catalyst components

[0062] In a 300ml glass reaction bottle, add 90ml (820mmol) of titanium tetrachloride and cool to -20°C, add 37mmol of magnesium halide carrier (prepared according to the method disclosed in CN1330086A Example 1) in terms of magnesium element, wherein, Then the temperature was raised to 110°C, and 0.3mmol of tributyl phosphate and 7.3mmol of 2-isopropyl-2-isopentyl-1,3-dimethoxypropane were added during the temperature rise, and maintained at 110°C After 30 minutes, the liquid was filtered off, washed twice with titanium tetrachloride and five times with hexane, and dried in vacuum to obtain the catalyst component Cat-1 for olefin polymerization.

[0063] As measured by X-ray fluorescence spectroscopic analysis, the phosphorus content in the catalyst component Cat-1 for olefin polymerization is 0.011% by w...

Embodiment 2

[0067]This example serves to illustrate the polypropylene according to the invention and the process for its preparation.

[0068] Prepare the catalyst component and prepare polypropylene according to the method of Example 1, the difference is that tributyl phosphate and 2-isopropyl-2-isopentyl-1,3-dimethoxy were added during the heating process The amounts of propane were 1 mmol and 10 mmol, respectively, to obtain catalyst component Cat-2 for olefin polymerization.

[0069] As measured by X-ray fluorescence spectroscopic analysis, the phosphorus content in the catalyst component Cat-2 for olefin polymerization is 0.025% by weight calculated as phosphorus element, and the titanium content is 2.5% by weight calculated as titanium element.

[0070] The obtained propylene homopolymer was weighed and analyzed after drying, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com