Controllable preparation method of alkylaluminoxane

A technology of alkylaluminoxane and alkylaluminum, which is applied in the field of controllable preparation of alkylaluminoxane, can solve the problems of target product composition and performance influence, and achieves safe and controllable reaction process, flexible operation and simple method workable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

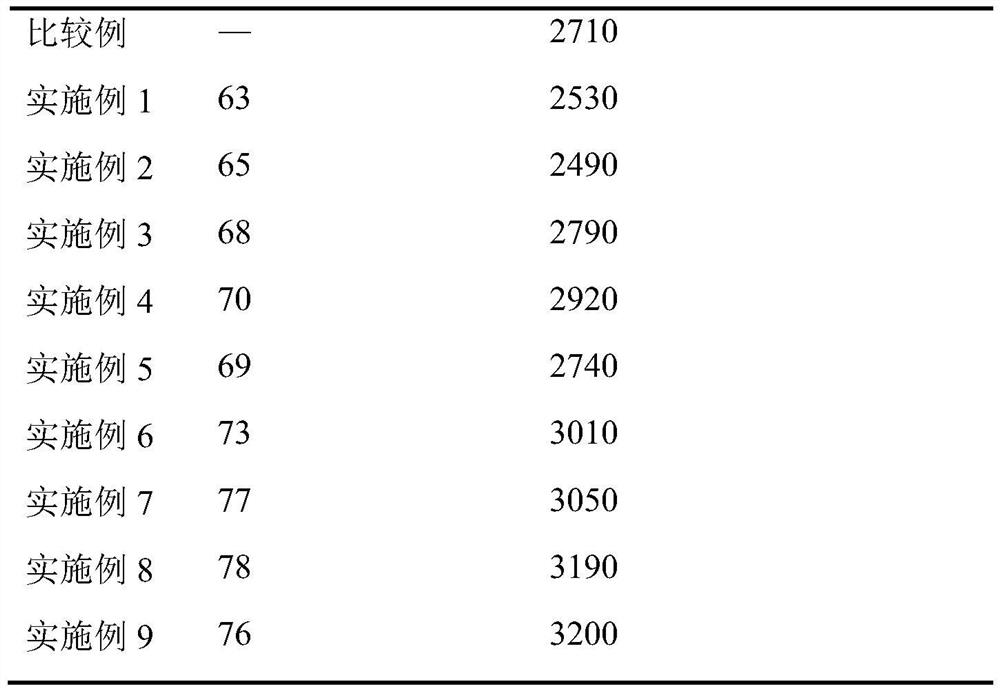

Examples

Embodiment 1

[0034] A circular hole with a diameter of 1 cm was opened at the position where the side wall of the 250mL reaction kettle was level with the mechanical stirring paddle, and a stainless steel tube with a 45° upward inclination was connected with the kettle body. is 10 μm. The reaction kettle was equipped with a nitrogen inlet, a vent valve and a cooling jacket. Under nitrogen protection, 100 mL of trimethylaluminum toluene solution (10wt%) was added to the reaction kettle, and the temperature of the reaction kettle was controlled to be 0°C. A certain amount of distilled deionized water was put into the stainless steel tube to make [H 2 O] / [AlMe 3 ] The molar ratio is 0.7, the other end of the steel pipe is filled with nitrogen, and the pressure of nitrogen is adjusted to apply a driving force to the reaction water in the pipe, and the temperature of the reaction water in the stainless steel pipe is controlled to be 5 °C.

[0035] When starting the reaction, the trimethylalum...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the orifice is embedded in the sand core, and the diameter of the sand core is 2-4 μm.

[0039] Other reaction processes, conditions, and device parameters are the same as in Example 1. After the reaction was completed, the yield of methylaluminoxane was 65%.

Embodiment 3

[0041] Insert a stainless steel tube with an inner diameter of 1cm from the top of the 250mL reaction kettle. The end of the tube is close to the upper part of the stirring paddle, and a screen is fixed at the end of the tube as a support. A molecular sieve membrane is installed on the screen in the tube, with an average pore size of 0.5nm. The reaction kettle was equipped with a nitrogen inlet, a vent valve and a cooling jacket. Under nitrogen protection, 100 mL of trimethylaluminum toluene solution (10wt%) was added to the reaction kettle, and the temperature of the reaction kettle was controlled to be 5°C. A certain amount of distilled deionized water was put into the stainless steel tube to make [H 2 O] / [AlMe 3 ] The molar ratio is 0.7, the other end of the steel pipe is filled with nitrogen, and the driving force is applied to the reaction water in the pipe by adjusting the nitrogen pressure.

[0042] When starting the reaction, the trimethylaluminum solution was stirred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com