Multi-level solid fuel drying system

A technology of solid fuel and drying system, which is applied in the directions of drying solid materials, heating to dry solid materials, and drying gas layout, etc., which can solve the problem that low-grade heat sources cannot be directly utilized, particles are back mixed in the fluidized bed, and the water content of products is not high. Equal problems, to achieve the effect of reducing drying energy consumption, improving drying quality, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

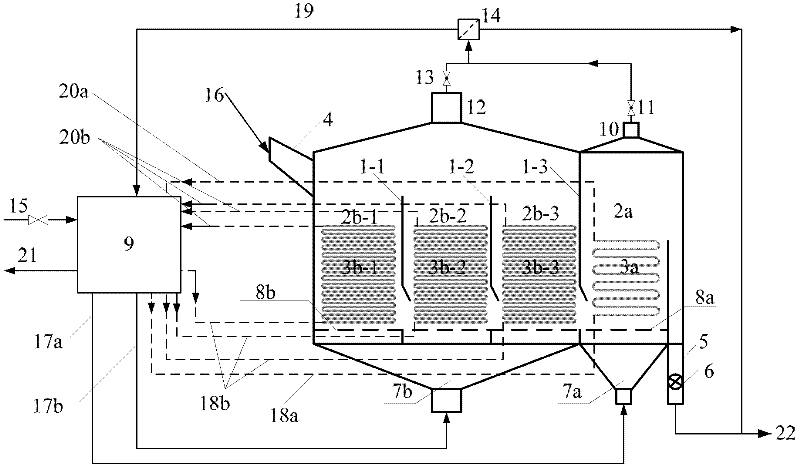

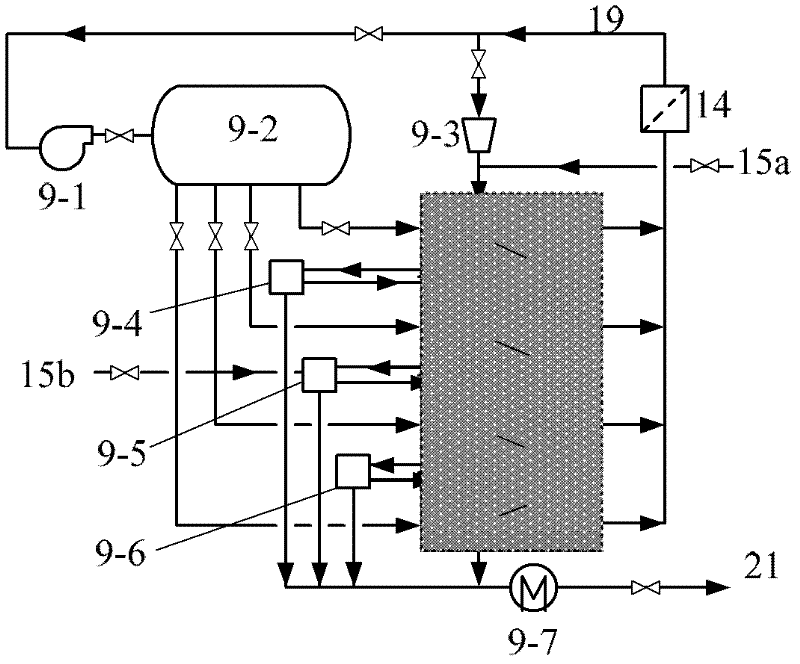

[0029] As wrong! Reference source not found. As shown in the horizontal fluidized bed and its process, the horizontal fluidized bed 1 is provided with three partitions with lower openings: a partition 1-1, a partition 1-2, and a partition 1-3, and the fluidized bed It is divided into four small fluidized chambers connected at the lower end: fluidized chamber 2b-1, fluidized chamber 2b-2, fluidized chamber 2b-3 and fluidized chamber 2a. Among them, the fluidization chamber 2b-1, the fluidization chamber 2b-2 and the fluidization chamber 2b-3 are drying fluidization chambers, and the fluidization chamber 2a is a temperature-regulating fluidization chamber. A steam coil heat exchanger 3b-1 for heating, a heat exchanger 3b-2 and a heat exchanger 3b-3 are installed in the drying fluidization chamber. The temperature-regulating fluidized chamber is used for cooling and temperature-regulating the particles, which requires less heat, so a heat exchanger 3a with a smaller heat-exchan...

Embodiment 2

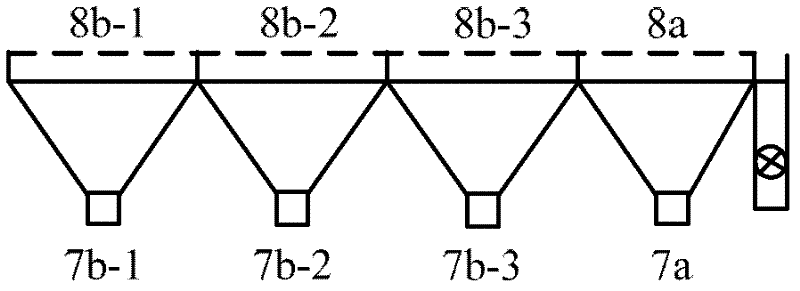

[0032] Such as image 3 As shown, the gas distribution method in the drying fluidization chamber is as follows: each drying fluidization chamber is provided with a separate gas distributor: gas distributor 7b-1, gas distributor 7b-2 and gas distributor 7b-3, and gas distribution plate 8b -1, gas distribution plate 8b-2, gas distribution plate 8b-3), the amount of fluidizing gas in each drying fluidization chamber is controlled by pipeline valves, and the rest are the same as in embodiment 1.

Embodiment 3

[0034] One partition is provided in the horizontal fluidized bed to divide the horizontal fluidized bed into two fluidized chambers, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com