Device and method for synthesizing polymethoxy dimethyl ether with medium concentration formaldehyde and methylal

A polymethoxydimethyl ether and methylal technology, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of unfavorable industrialized continuous production, high operation and maintenance cost, complex structure and the like, Achieve the effect of reducing high production cost problems, solving high energy consumption problems, and large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

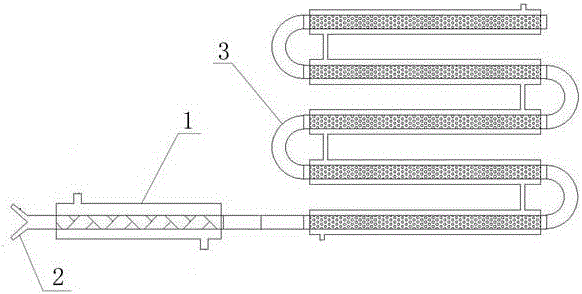

[0016] Embodiment one: the method for synthesizing polyoxymethylene dimethyl ether with medium concentration formaldehyde and methylal, comprises the following operation steps: a, in the straight pipe section of pipeline reactor, fill super strong solid acid catalyst; b, mass fraction is 55 % formaldehyde aqueous solution and methylal are added to the static mixer through two raw material input pipes according to the molar ratio of 1:1 and mixed evenly; c, the uniformly mixed reaction raw materials are transported into the pipeline reactor through pipelines, and the pipeline reaction is controlled The temperature throughout the reactor is constant at 100°C, the reaction pressure is 1.0MPa, and the feed flow rate is adjusted so that the liquid volume space velocity in the pipe reactor is 0.3h -1 ; d, after the material is reacted in the pipeline reactor, it is transported from the upper mouth of the pipeline reactor to the refining separation equipment for separation and refinin...

Embodiment 2

[0017] Embodiment two: the method for synthesizing polyoxymethylene dimethyl ether with medium-concentration formaldehyde and methylal, comprises the following operation steps: a, in the straight pipe section of pipeline reactor, fill super strong solid acid catalyst; b, mass fraction is 55 % formaldehyde aqueous solution and methylal are added to the static mixer through two raw material input pipes according to the molar ratio of 1:2 and mixed evenly; c, the uniformly mixed reaction raw materials are transported into the pipeline reactor through pipelines, and the pipeline reaction is controlled The temperature throughout the reactor is constant at 150°C, the reaction pressure is 0.4MPa, and the feed flow rate is adjusted so that the liquid volume space velocity in the pipeline reactor is 0.4h -1 ; d, after the material is reacted in the pipeline reactor, it is transported from the upper mouth of the pipeline reactor to the refining separation equipment for separation and ref...

Embodiment 3

[0018] Embodiment three: the method for synthesizing polyoxymethylene dimethyl ether with moderate concentration formaldehyde and methylal, comprises the following operation steps: a, in the straight pipe section of pipeline reactor, fill super strong solid acid catalyst; b, mass fraction is 55 % formaldehyde aqueous solution and methylal are added to the static mixer through two raw material input pipes according to the molar ratio of 1:4 and mixed evenly; c, the uniformly mixed reaction raw materials are transported into the pipeline reactor through pipelines, and the pipeline reaction is controlled The temperature throughout the reactor is constant at 70°C, the reaction pressure is 0.7MPa, and the feed flow rate is adjusted so that the liquid volume space velocity in the pipe reactor is 0.2h -1 ; d, after the material is reacted in the pipeline reactor, it is transported from the upper mouth of the pipeline reactor to the refining separation equipment for separation and refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com