Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

643results about "Granulation by powder suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrocatalyst powders, methods for producing powders and devices fabricated from same

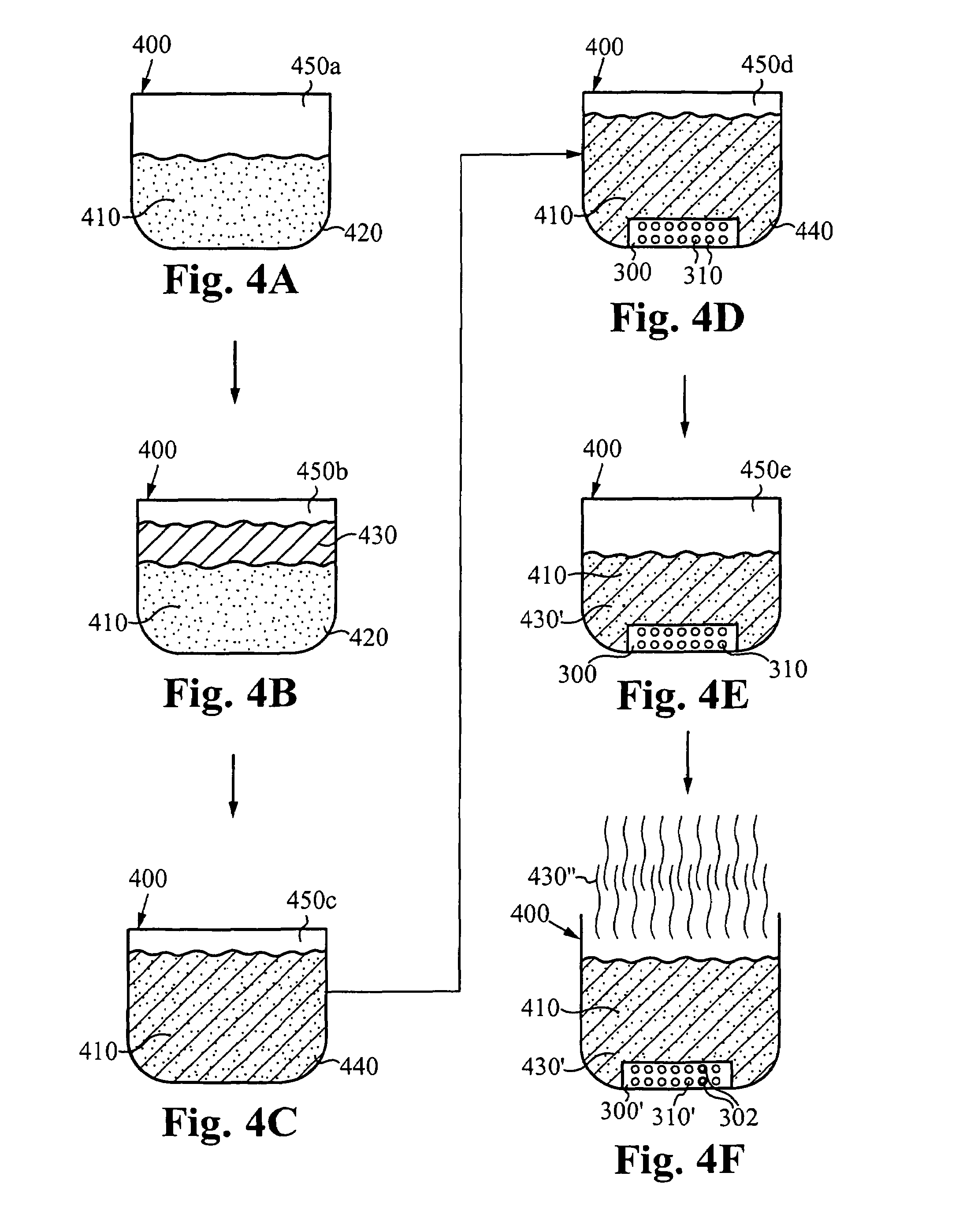

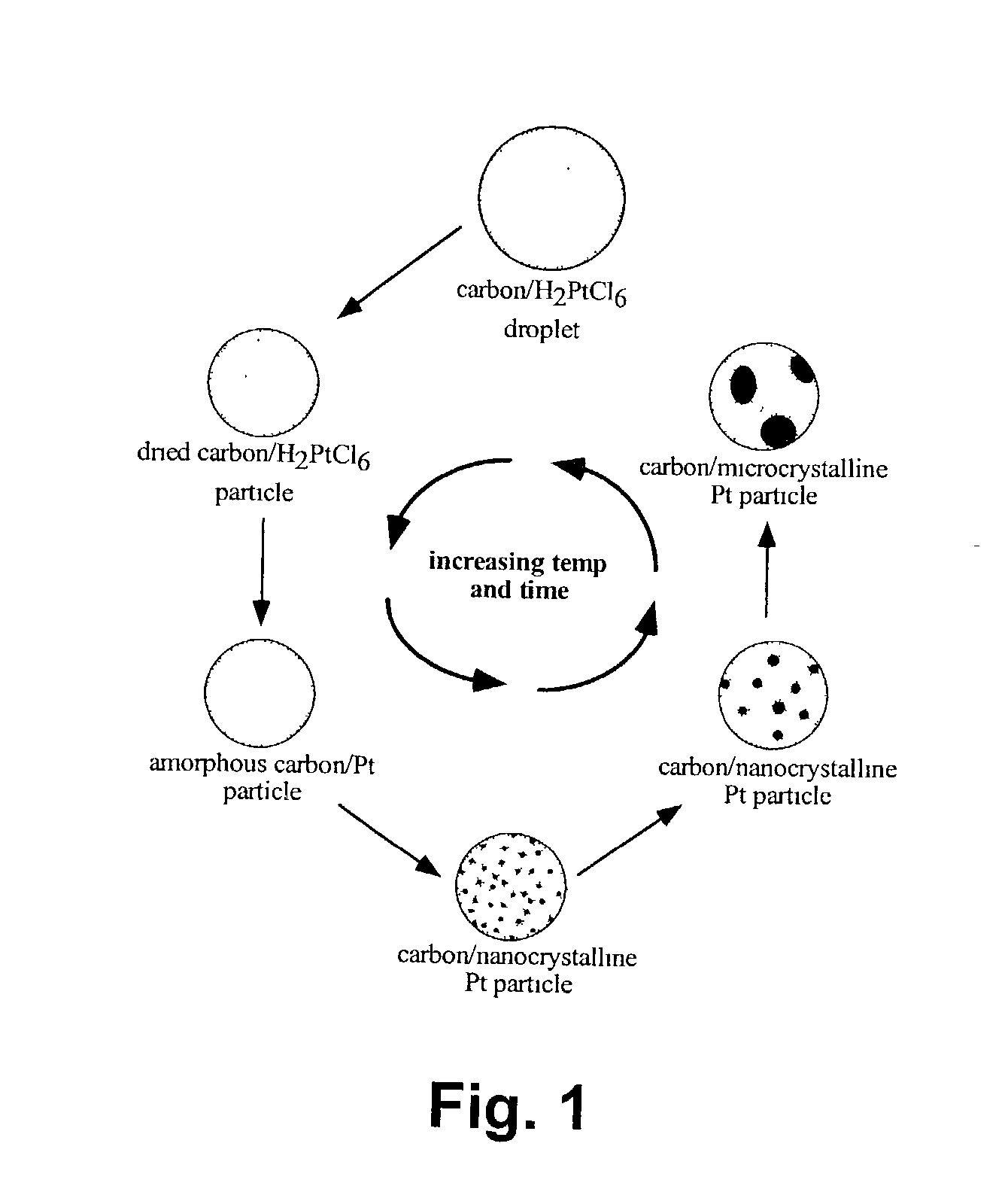

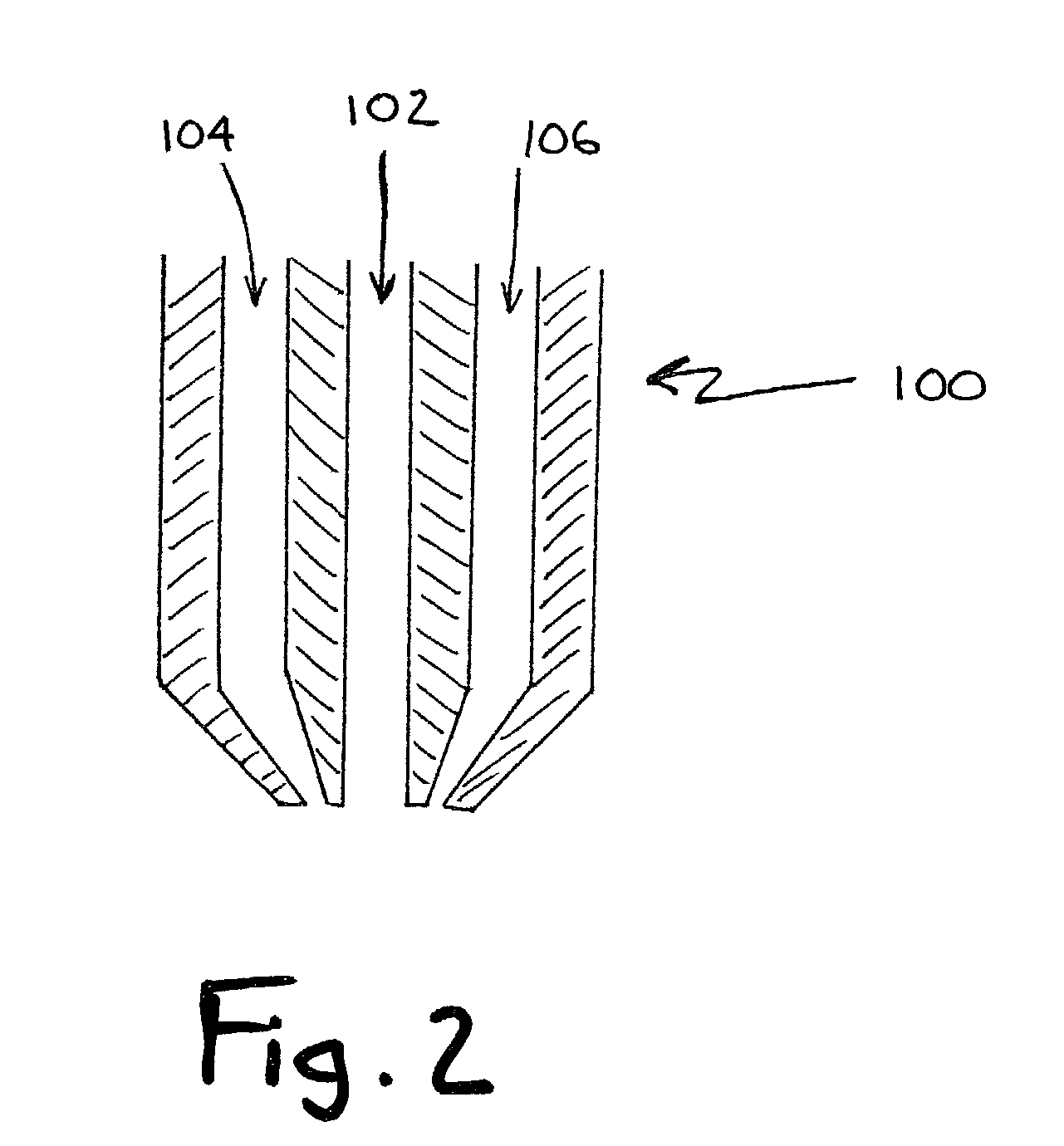

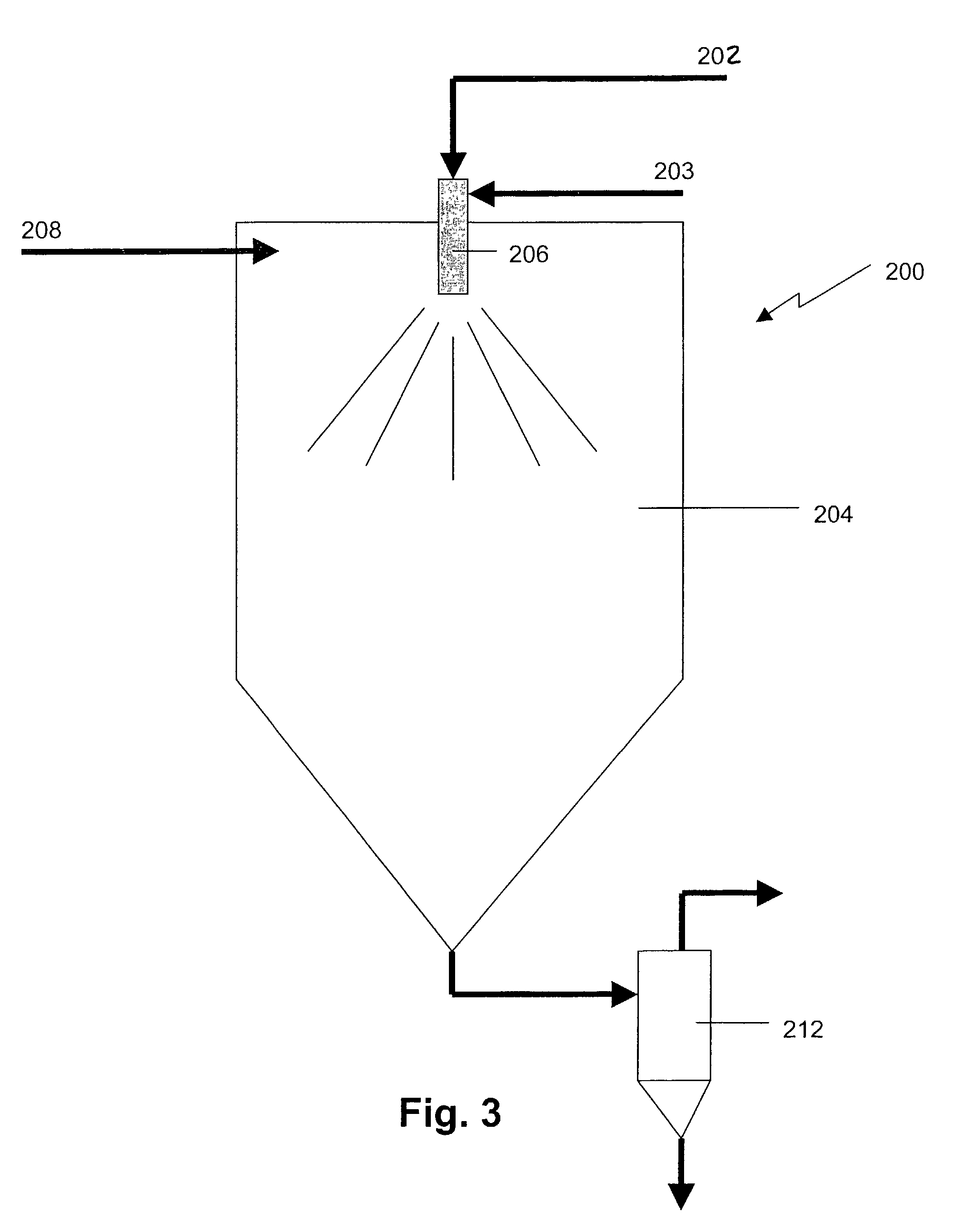

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

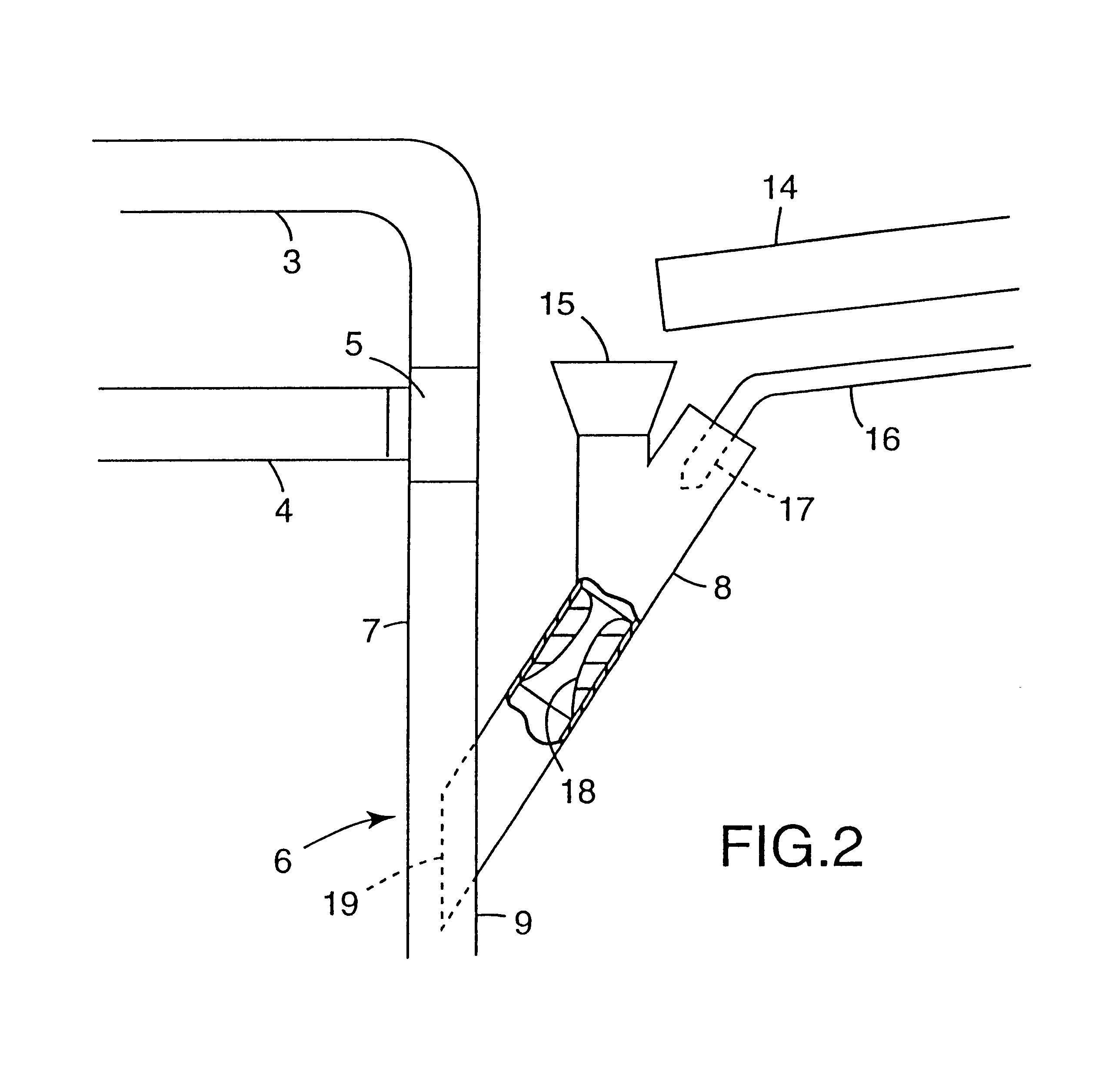

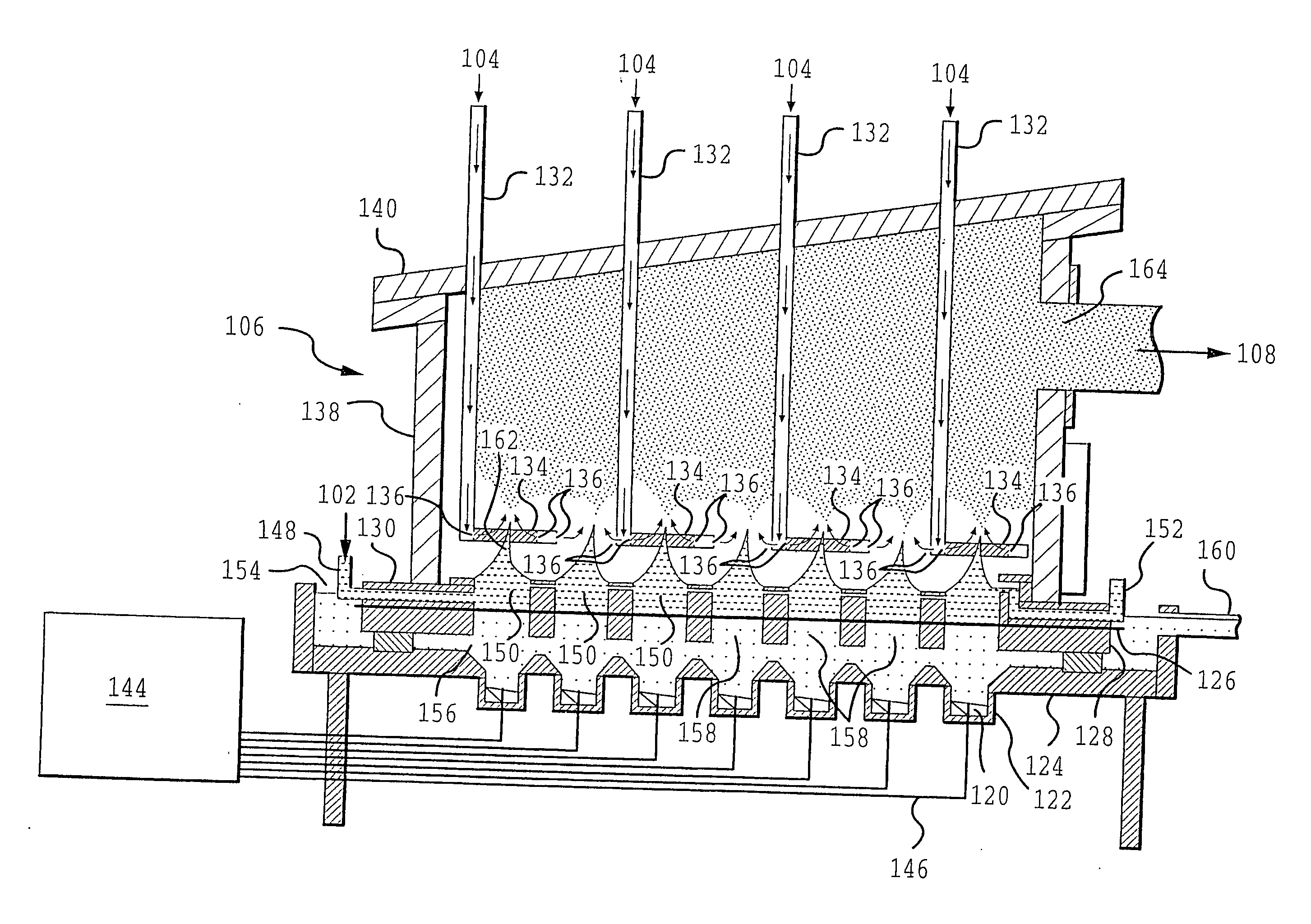

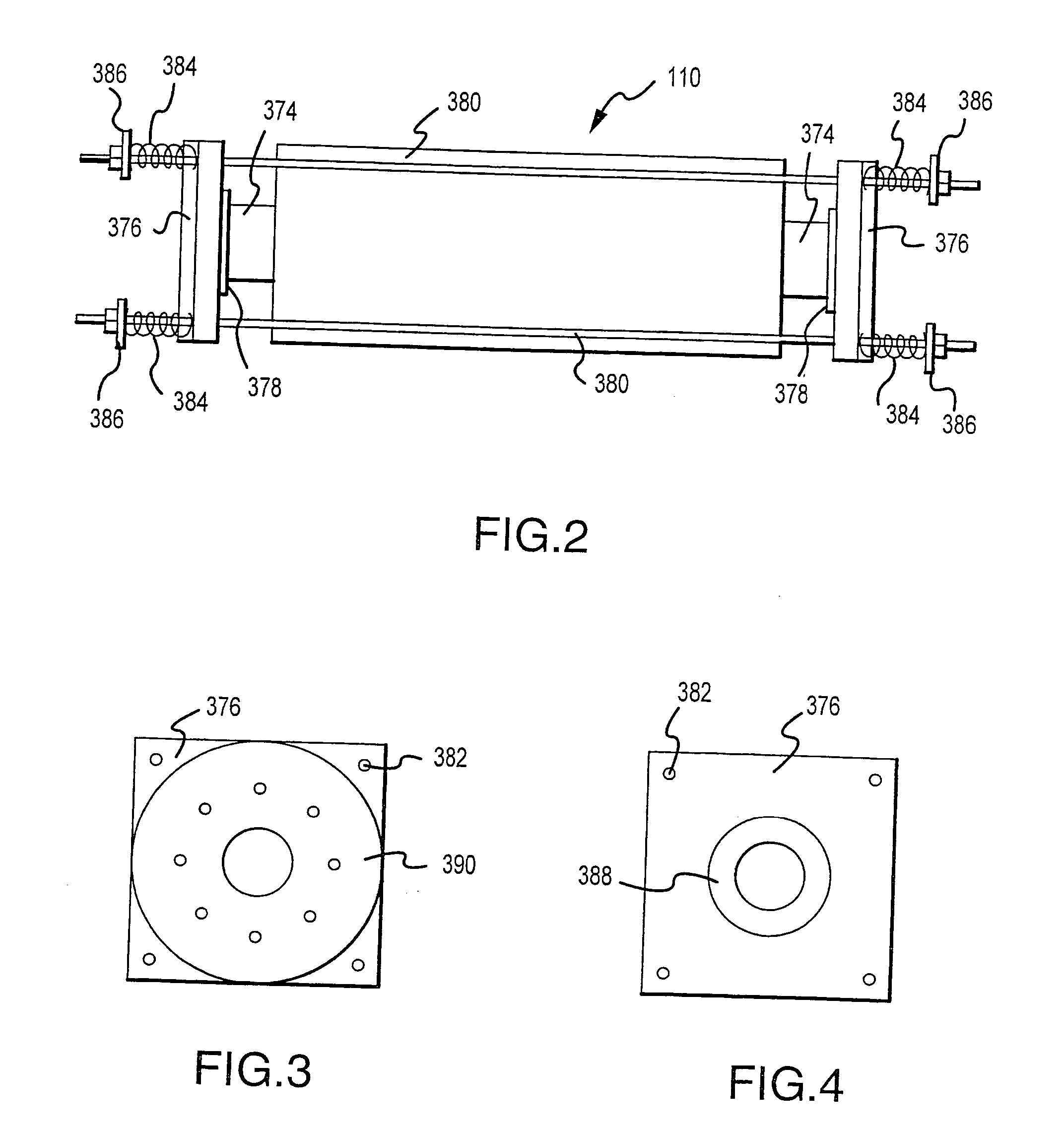

Fused glassy particulates obtained by flame fusion

InactiveUS6254981B1Efficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsParticulatesSuspended particles

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

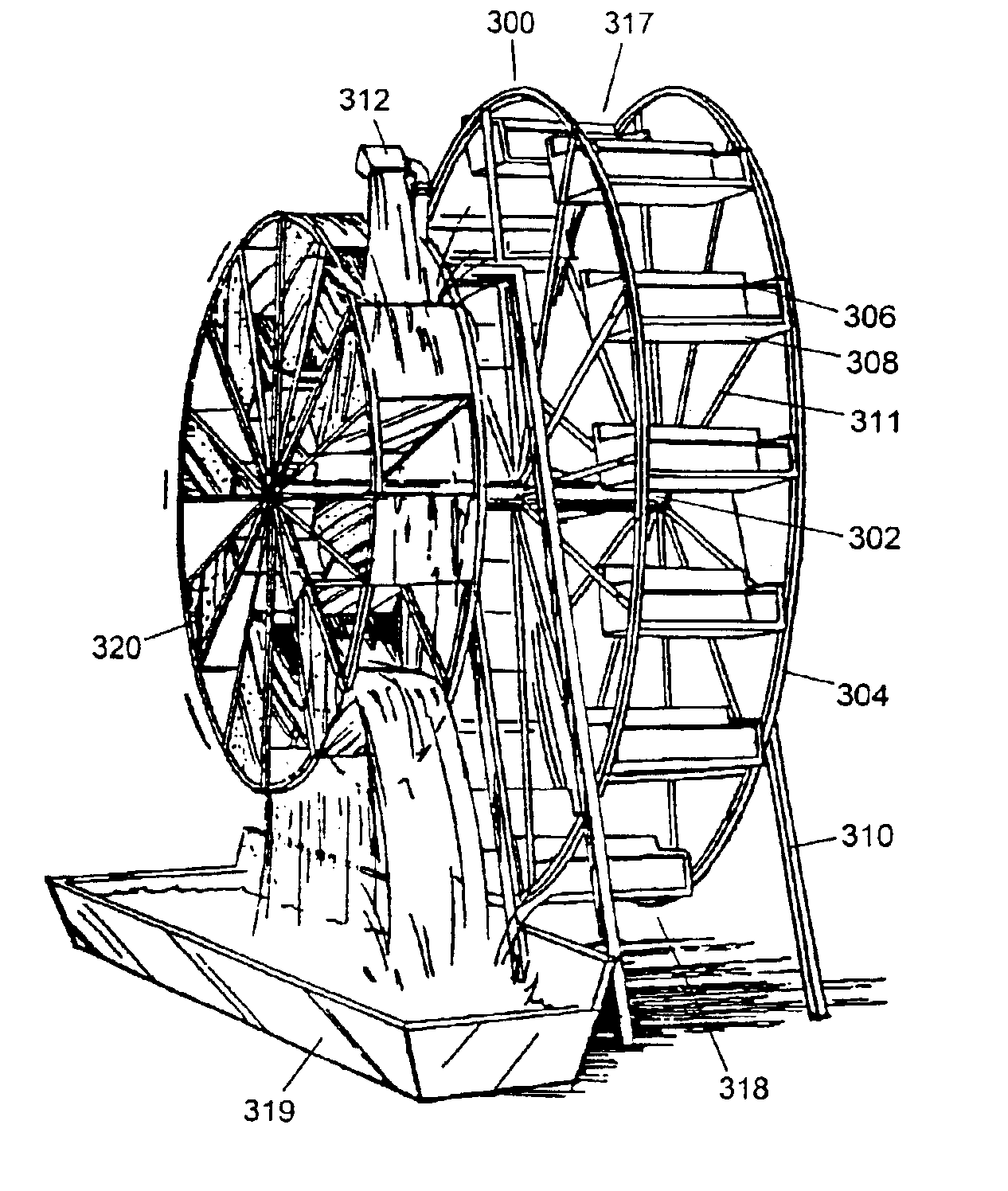

Water amusement system and method

Owner:WATER RIDE CONCEPTS

Process for the granulation of an animal feedstuff additive

The invention relates to a process for the granulation of an animal feedstuffs additive comprising amino acids or vitamins in a circulating fluidized bed, wherein the additive is preferably a fermentation product and optionally comprises further constituents from the fermentation broth.

Owner:EVONIK DEGUSSA GMBH

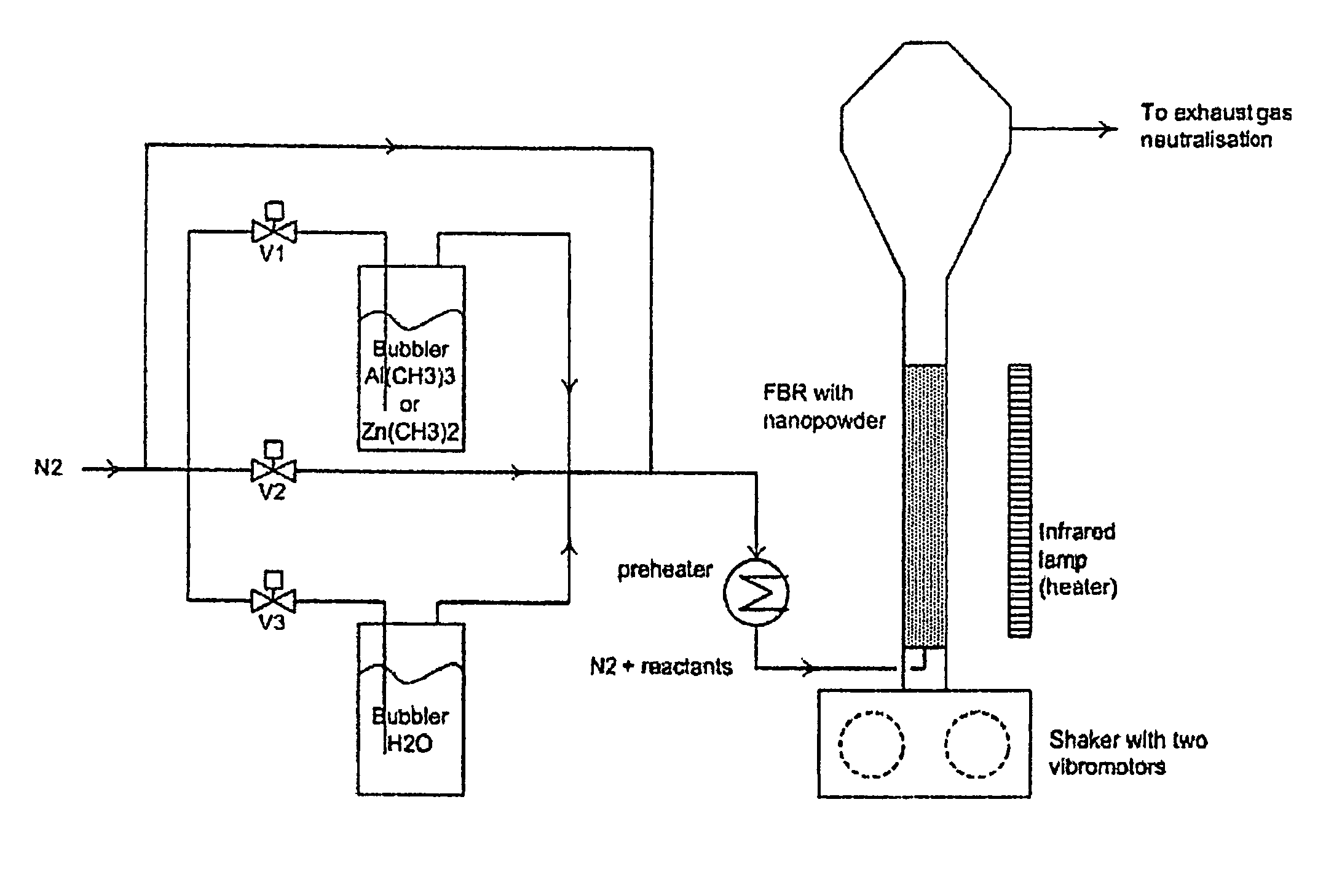

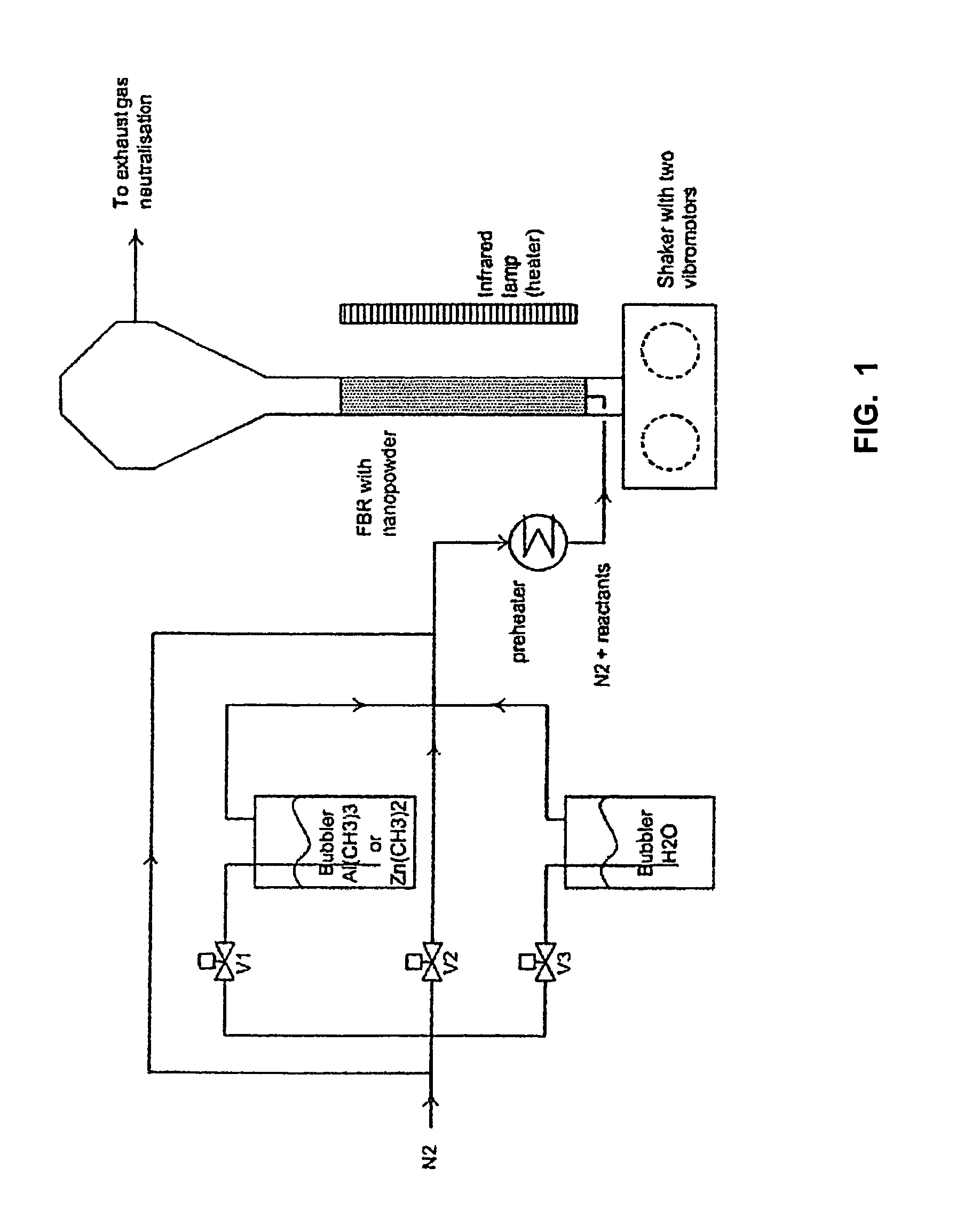

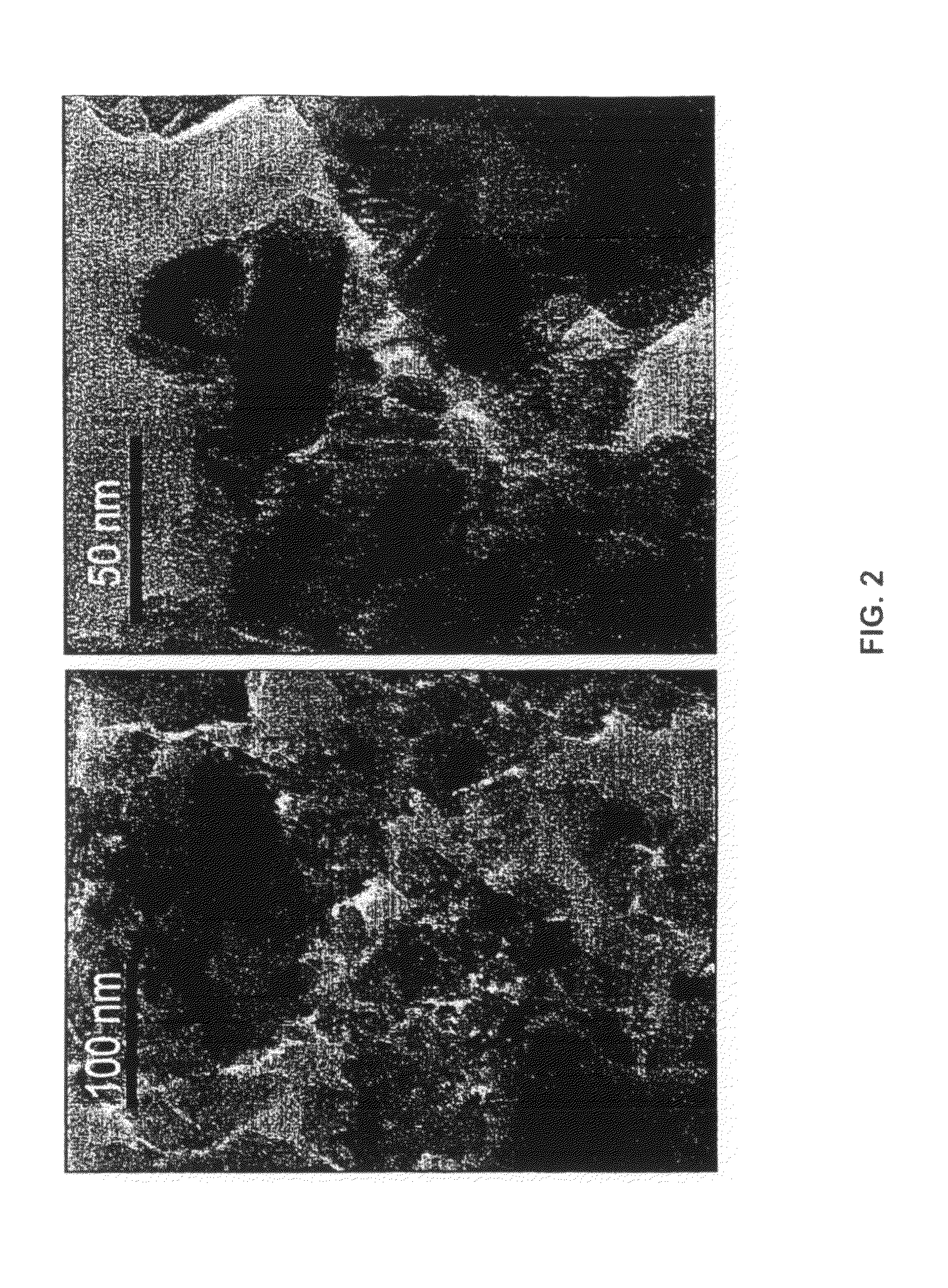

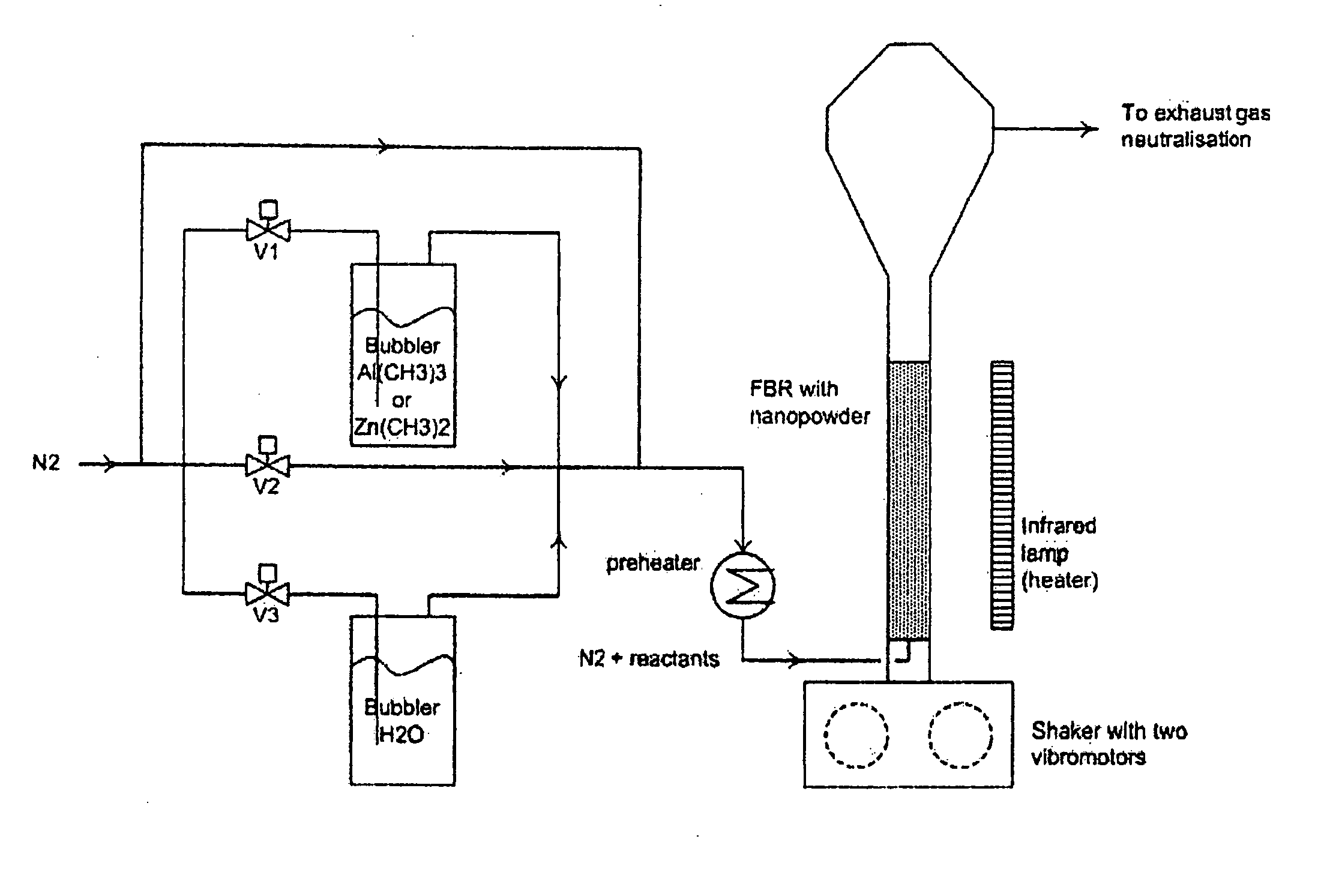

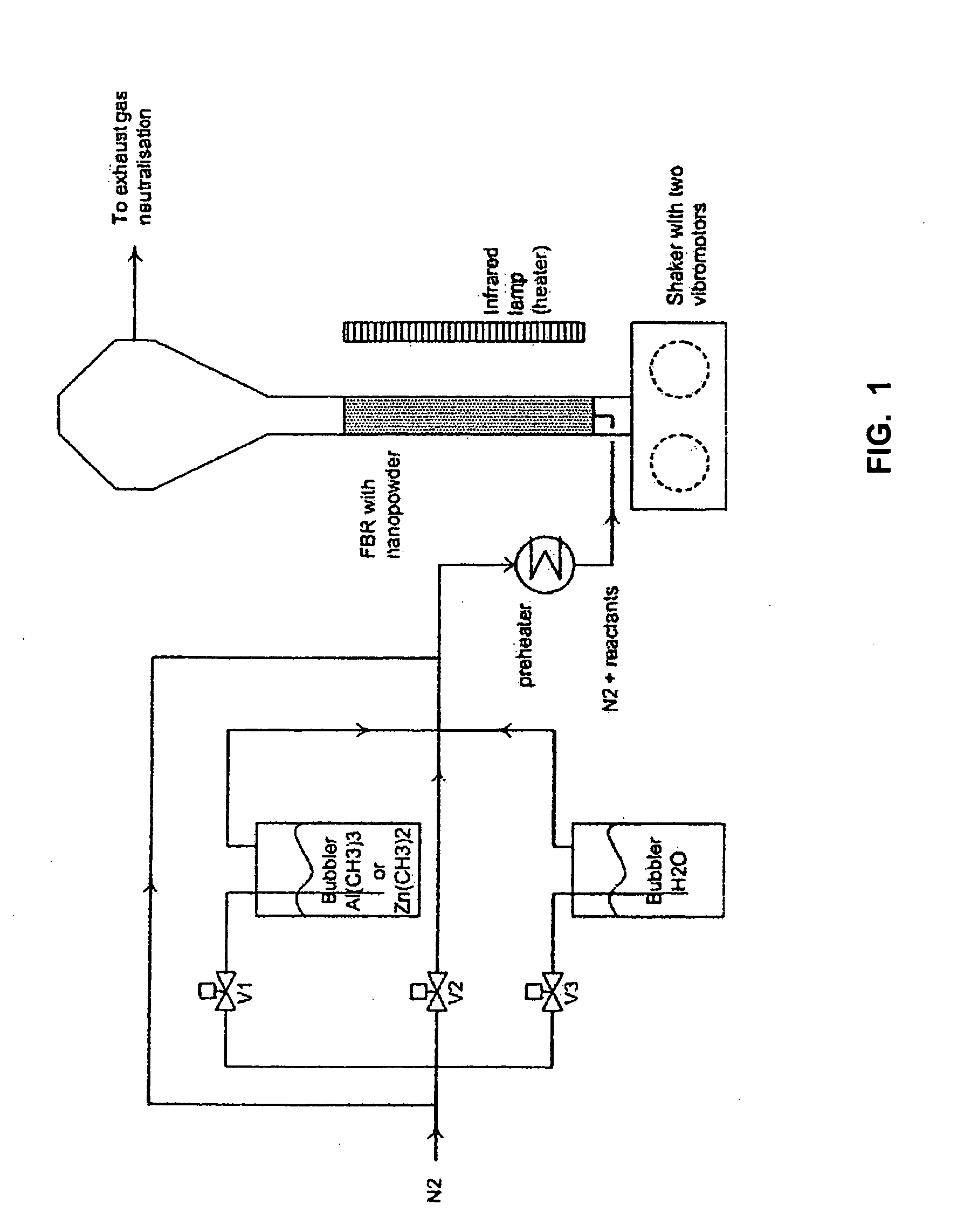

Method for covering particles, especially a battery electrode material particles, and particles obtained with such method and a battery comprising such particle

A method for covering particles having a diameter of maximally 60 μm by means of atomic layer deposition, whereby said method comprises the step of fluidizing said particles in a fluidized bed reactor using a first reactant gas comprising a first reactant for substantially completely covering said particles with a monolayer of said first reactant.

Owner:PNEUMATICOAT TECH LLC

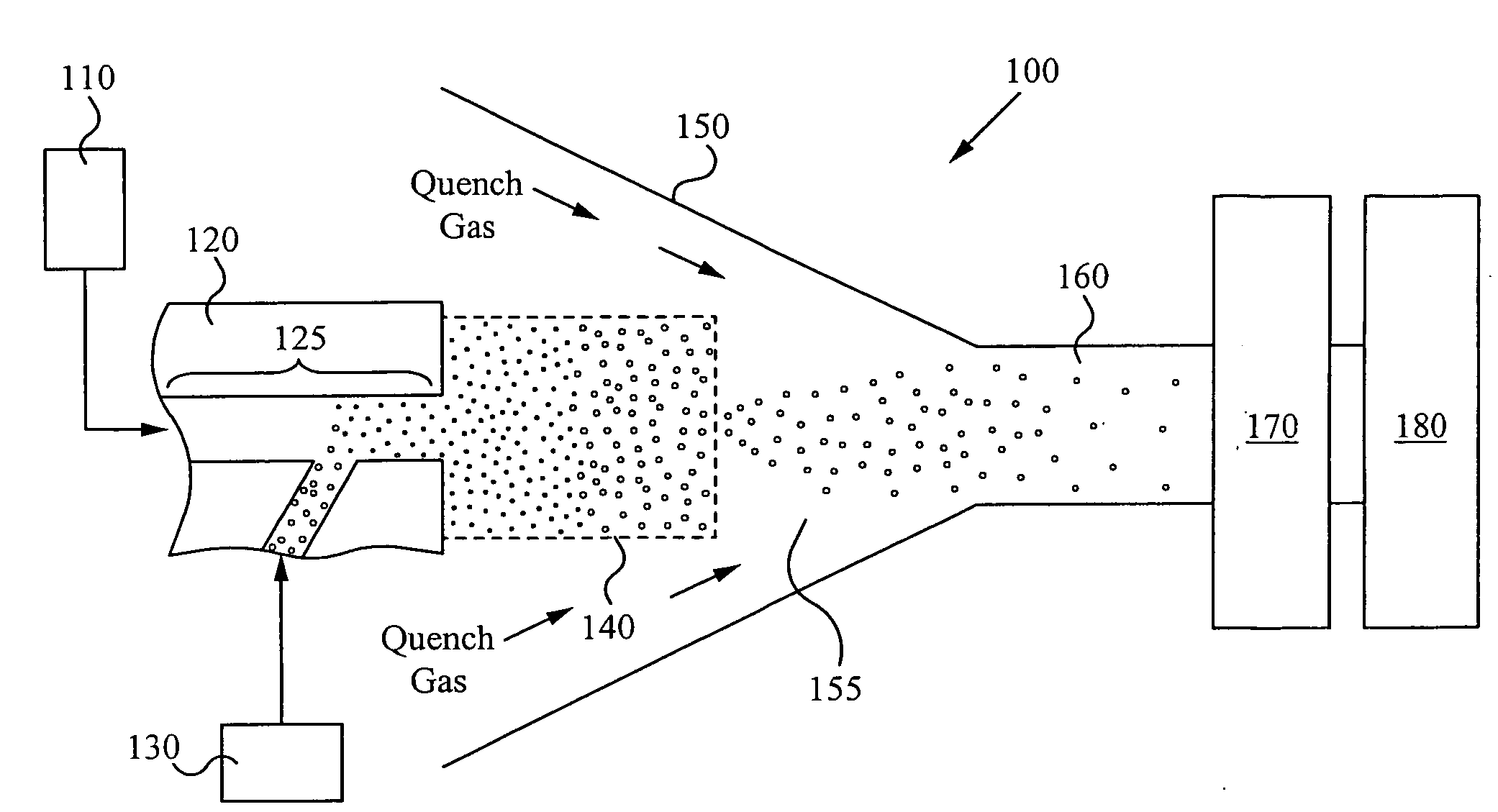

Method and apparatus for making uniform and ultrasmall nanoparticles

ActiveUS20080277270A1Catalyst activation/preparationDirect contact heat exchangersNanoparticleEngineering

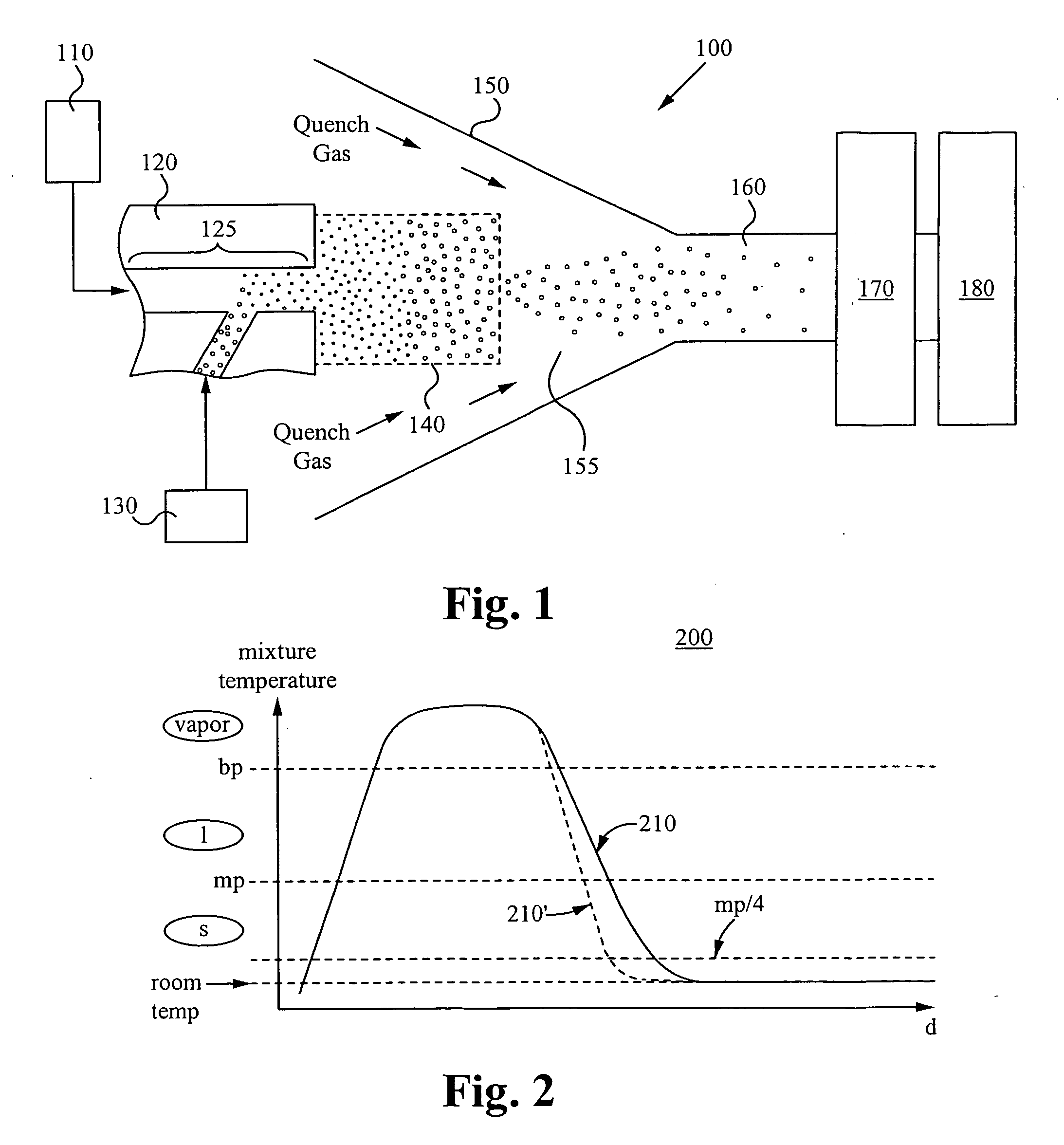

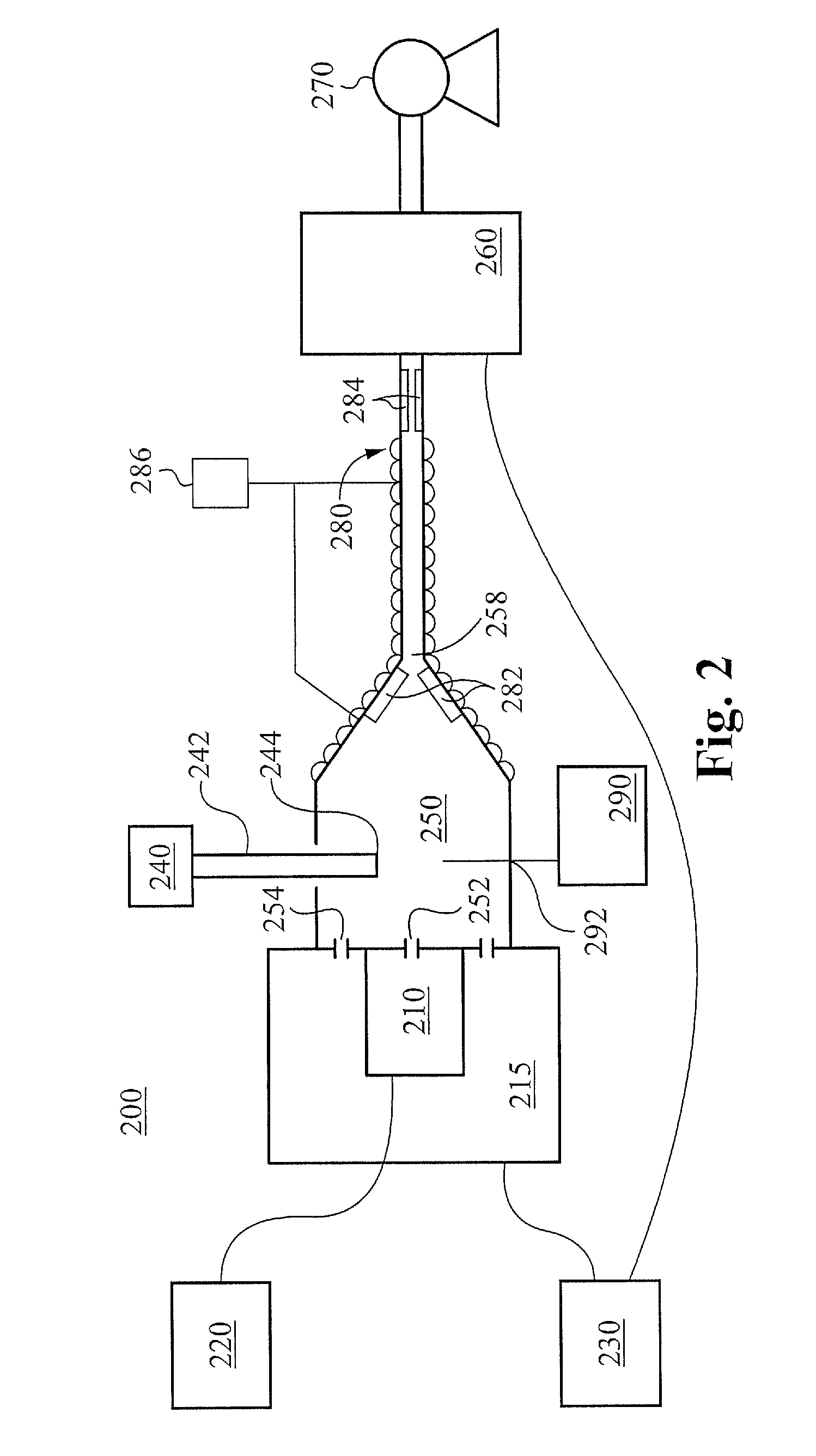

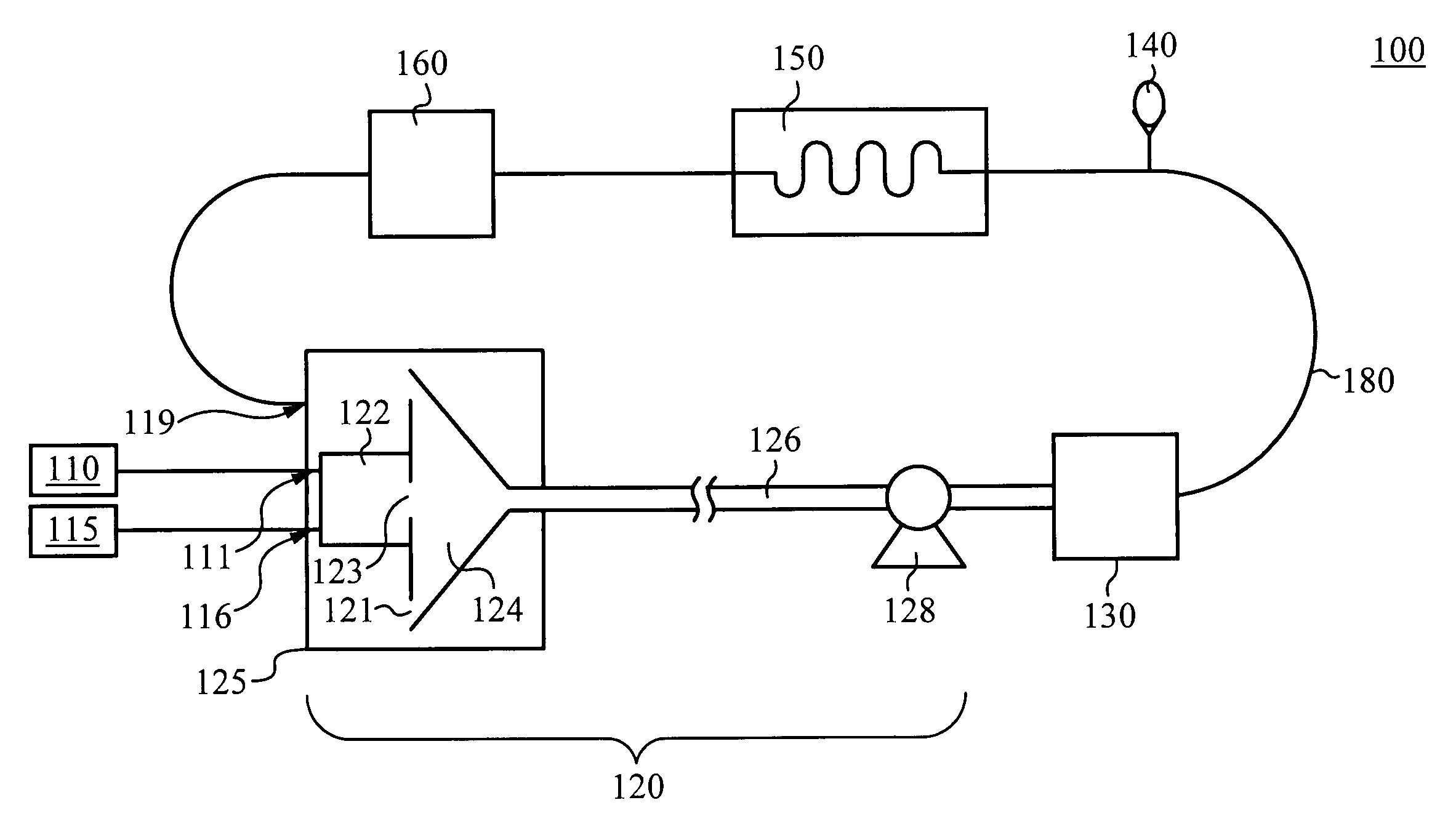

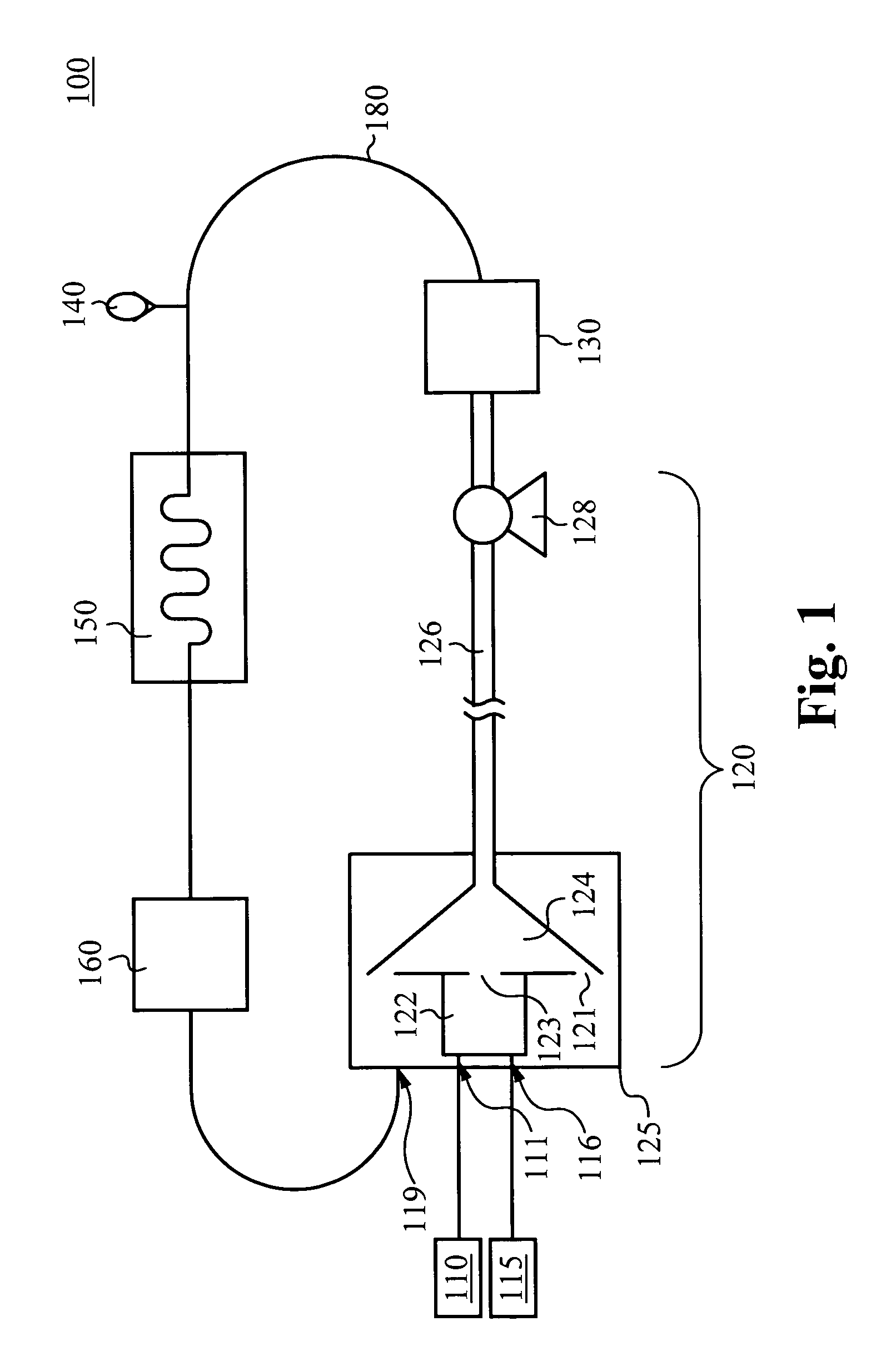

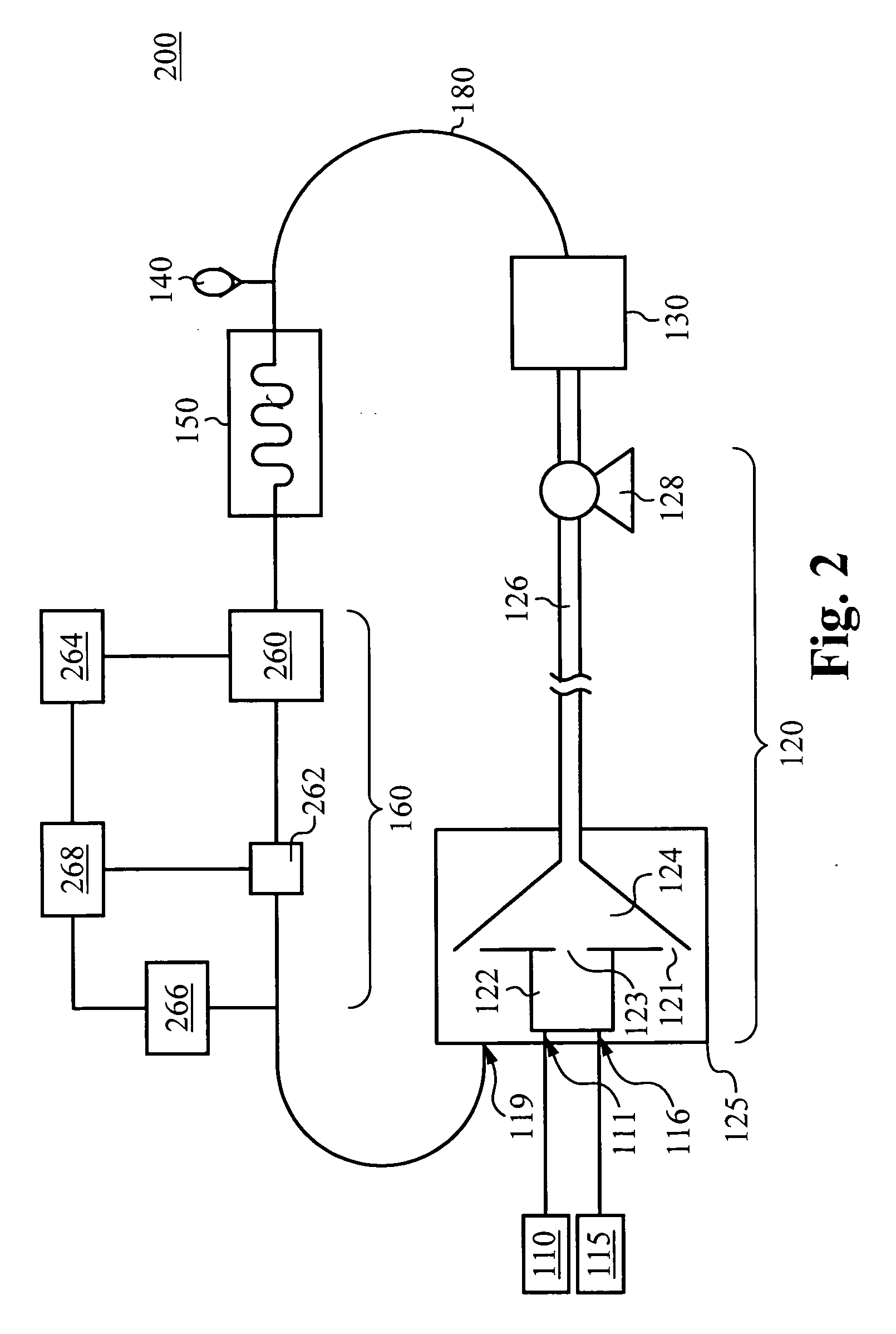

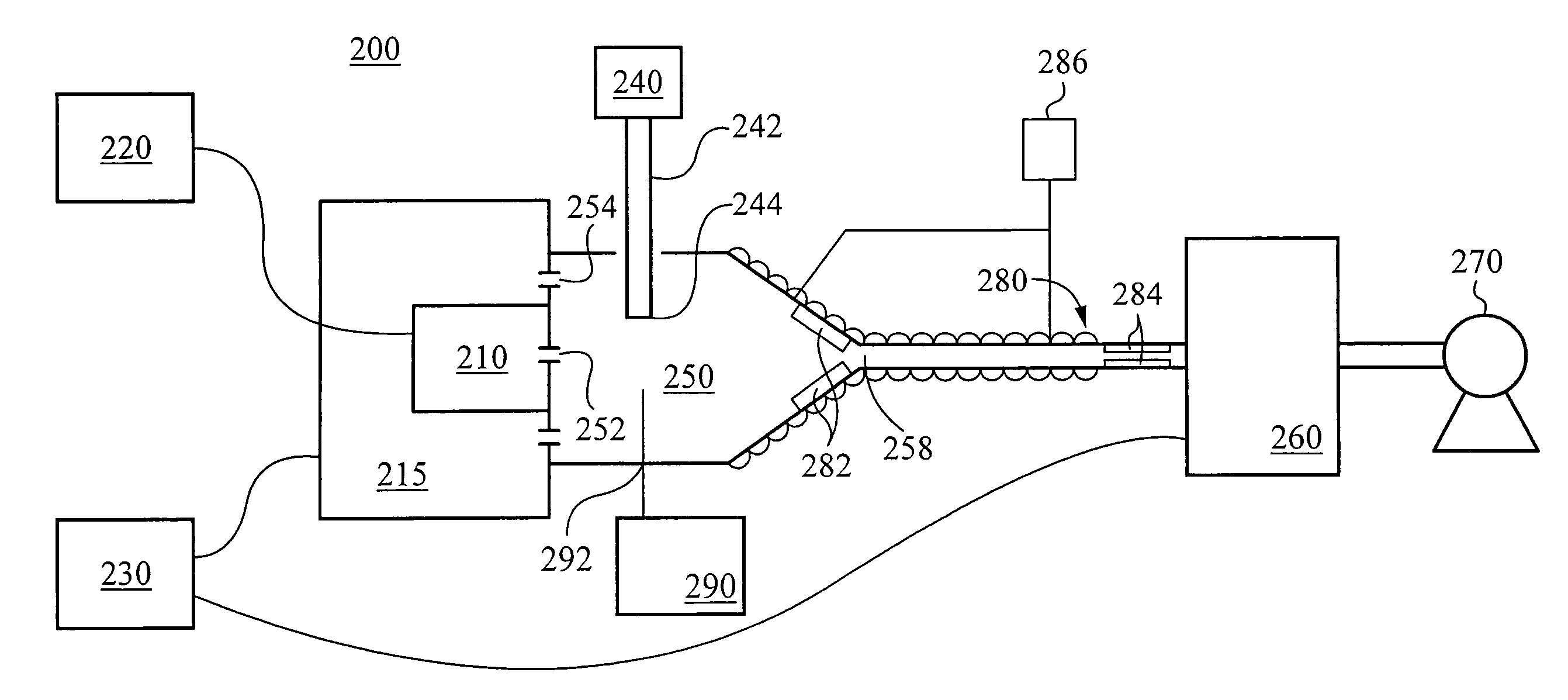

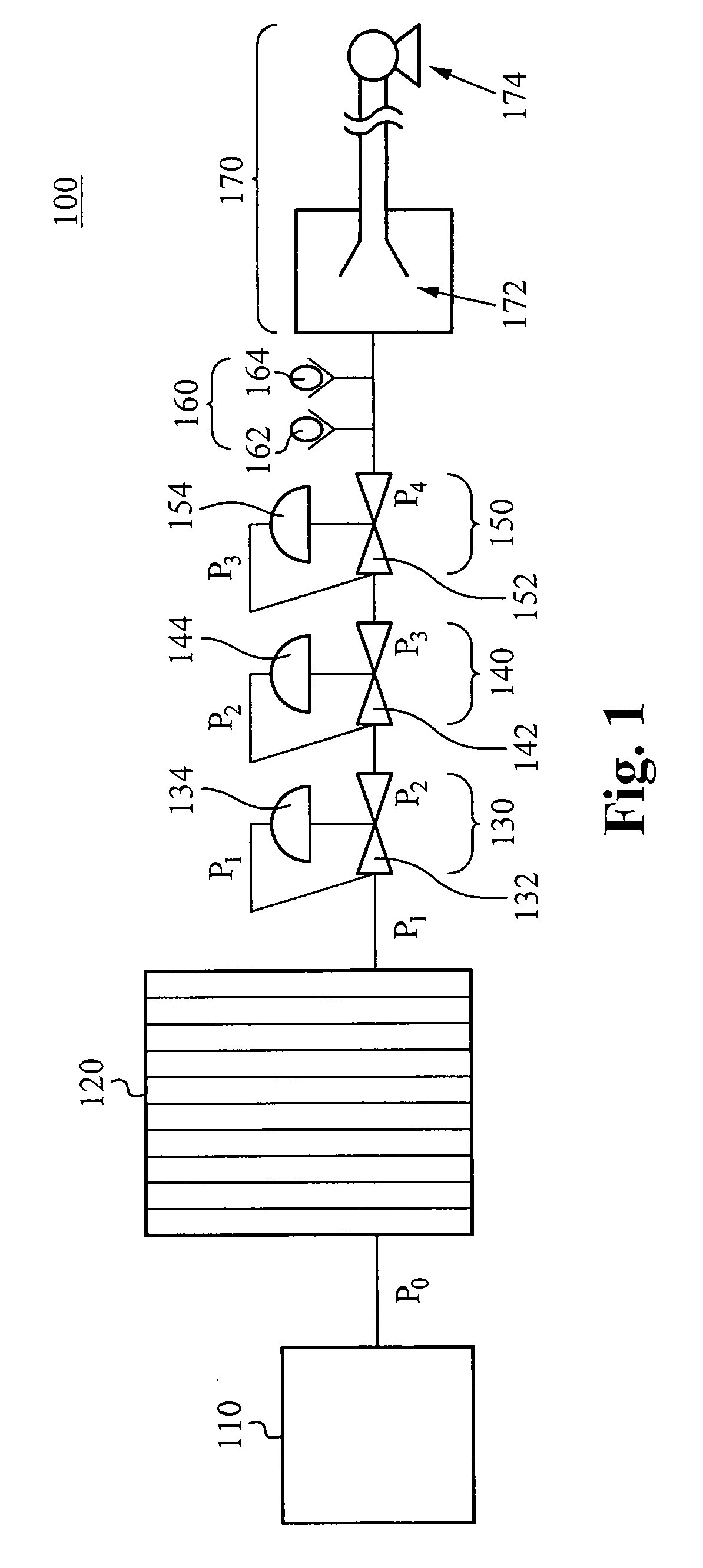

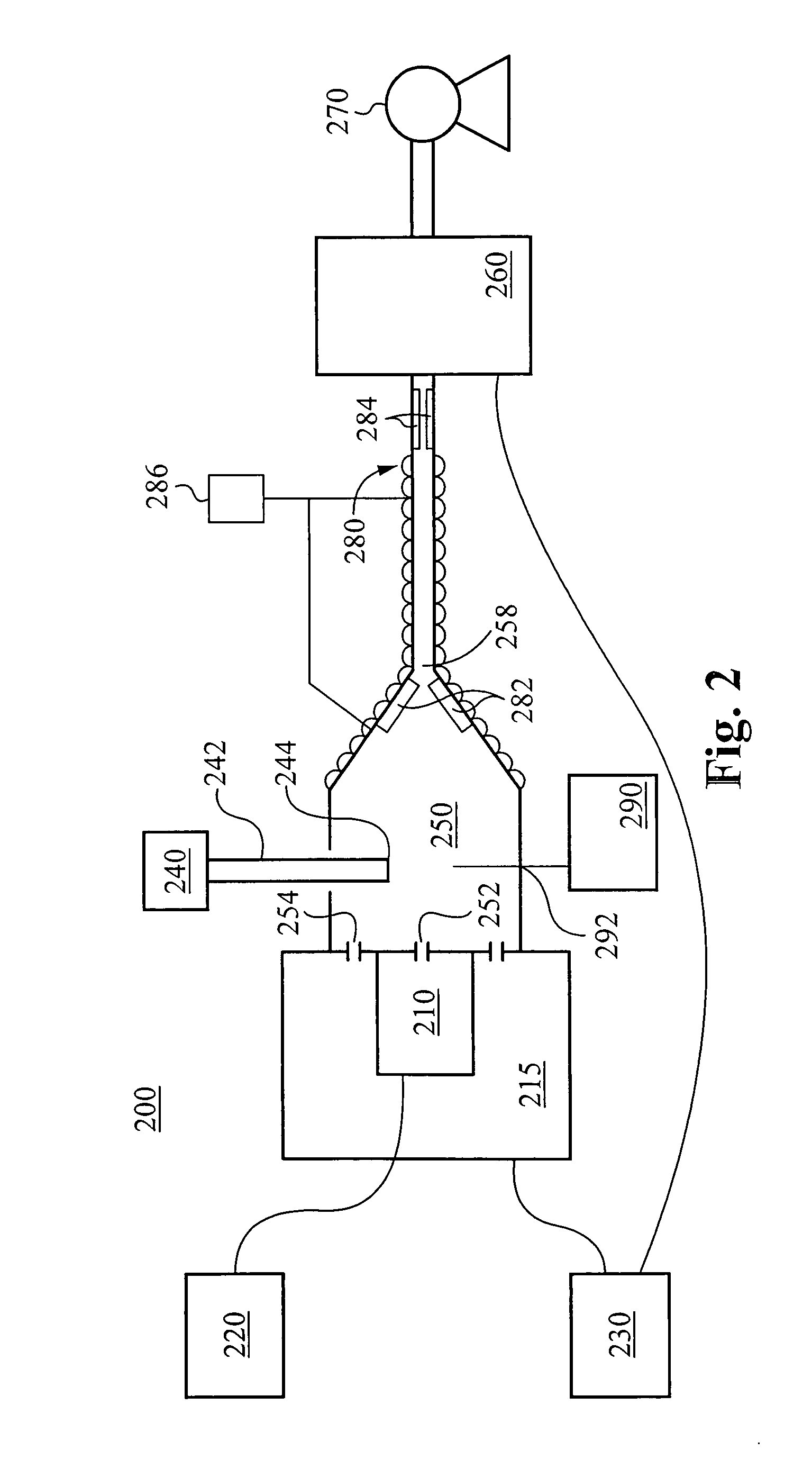

A system comprising: a plasma production chamber configured to produce a plasma; a reaction chamber vaporize a precursor material with the plasma to form a reactive mixture; a quench chamber having a frusto-conical surface and a quench region formed within the quench chamber between an ejection port of the reaction chamber and a cooled mixture outlet, wherein the quench region configured to receive the reactive mixture from the ejection port, to cool the reactive mixture to form a cooled mixture, and to supply the cooled mixture to the cooled mixture outlet; and a conditioning fluid injection ring disposed at the ejection port and configured to flow a conditioning fluid directly into the reactive mixture as the reactive mixture flows through the ejection port, thereby disturbing the flow of the reactive mixture, creating turbulence within the quench region and cooling the reactive mixture to form a cooled mixture comprising condensed nanoparticles.

Owner:SDC MATERIALS +1

Highly turbulent quench chamber

ActiveUS20080277267A1Temperature controlDirect contact heat exchangersStationary tubular conduit assembliesEngineeringQuenching

An apparatus for cooling a reactive mixture, comprising: a reactor configured to form the reactive mixture; a quench chamber comprising a frusto-conical body having a wide end, a narrow end, and a quench region formed between the wide and narrow end, wherein the quench chamber is configured to receive the reactive mixture from the plasma reactor through a reactive mixture inlet into the quench region, to receive a conditioning fluid through at least one fluid inlet, and to flow the conditioning fluid into the quench region, wherein the frusto-conical body is configured to produce a turbulent flow within the quench region with the flow of the conditioning fluid into the quench region, thereby promoting the quenching of the reactive mixture to form a cooled gas-particle mixture; and a suction generator configured to force the cooled gas-particle mixture out of the quench chamber.

Owner:UMICORE AG & CO KG +1

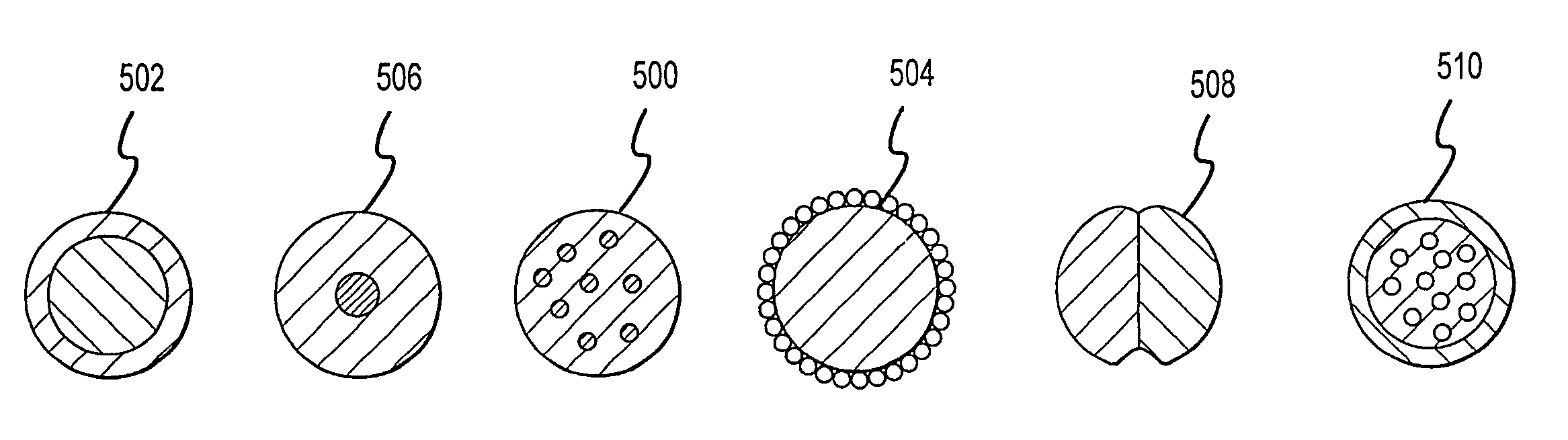

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

Pharmaceutical excipient having improved compressibility

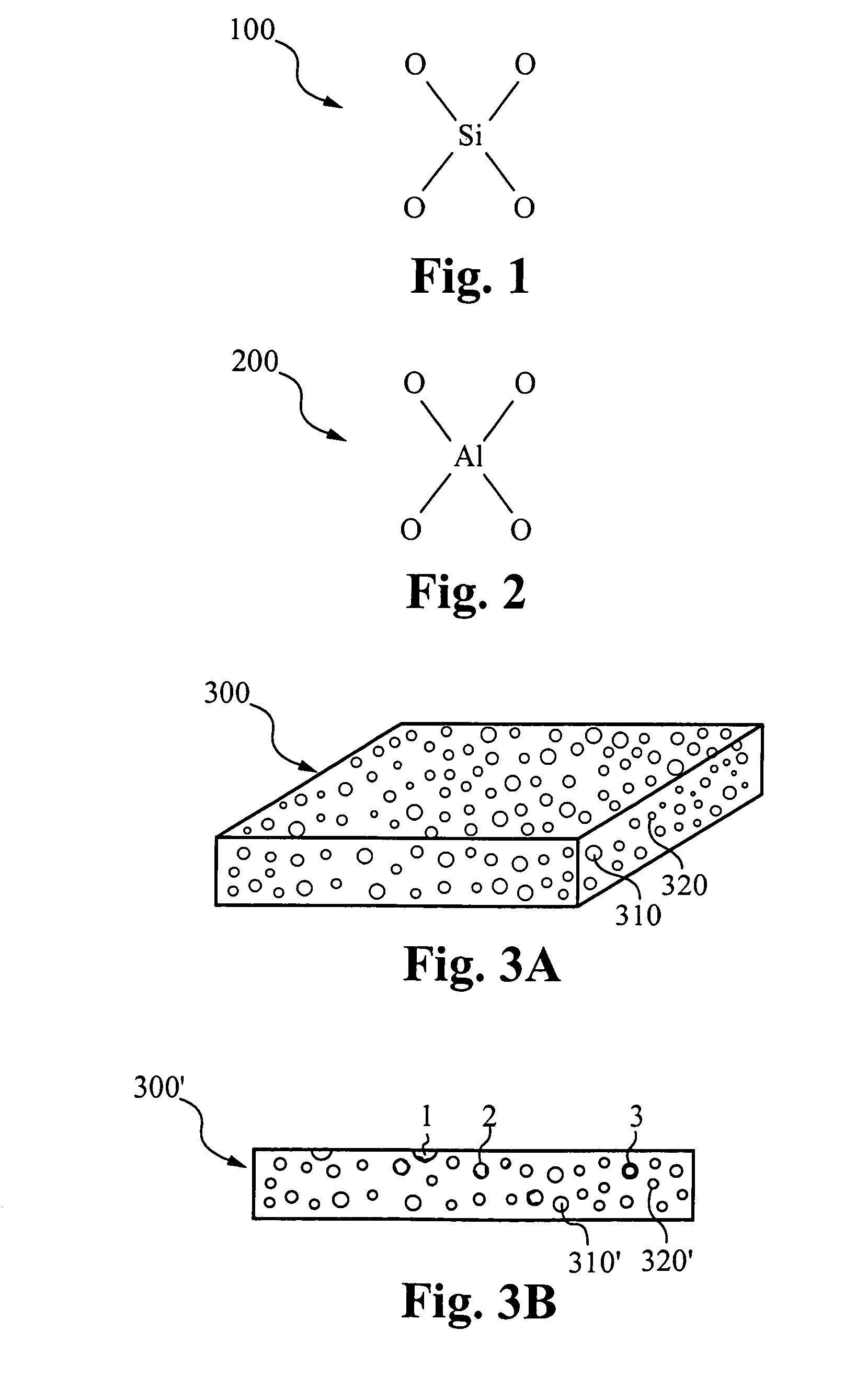

InactiveUS6217909B1Improve compression performanceReduce the amount requiredInorganic/elemental detergent compounding agentsPowder deliverySilica particleSilicon dioxide

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Granular fertilizer coated with decomposable coating film and process for producing the same

A coated granular fertilizer which comprises a degradable film containing 10% by weight or more of a polyolefin and / or petroleum wax having a weight-average molecular weight of 300-10,000 and an inorganic filler and / or a surface active agent and a granular fertilizer coated with said degradable film.

Owner:JCAM AGRI

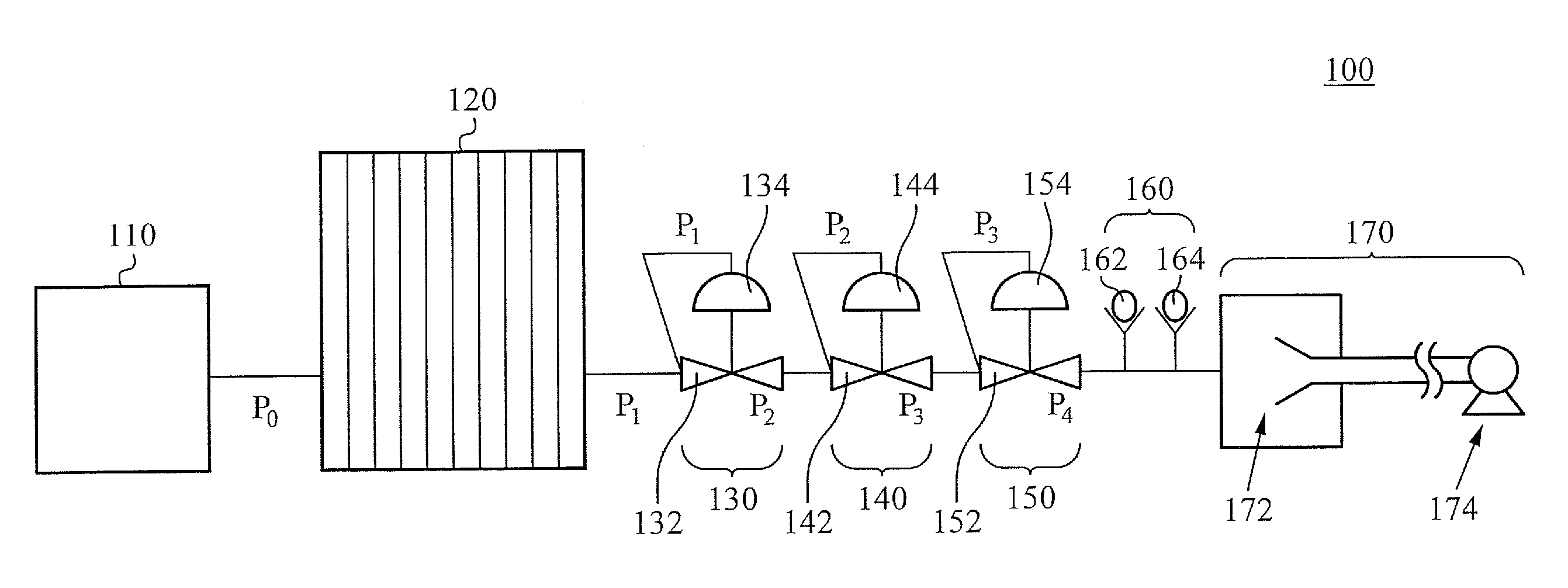

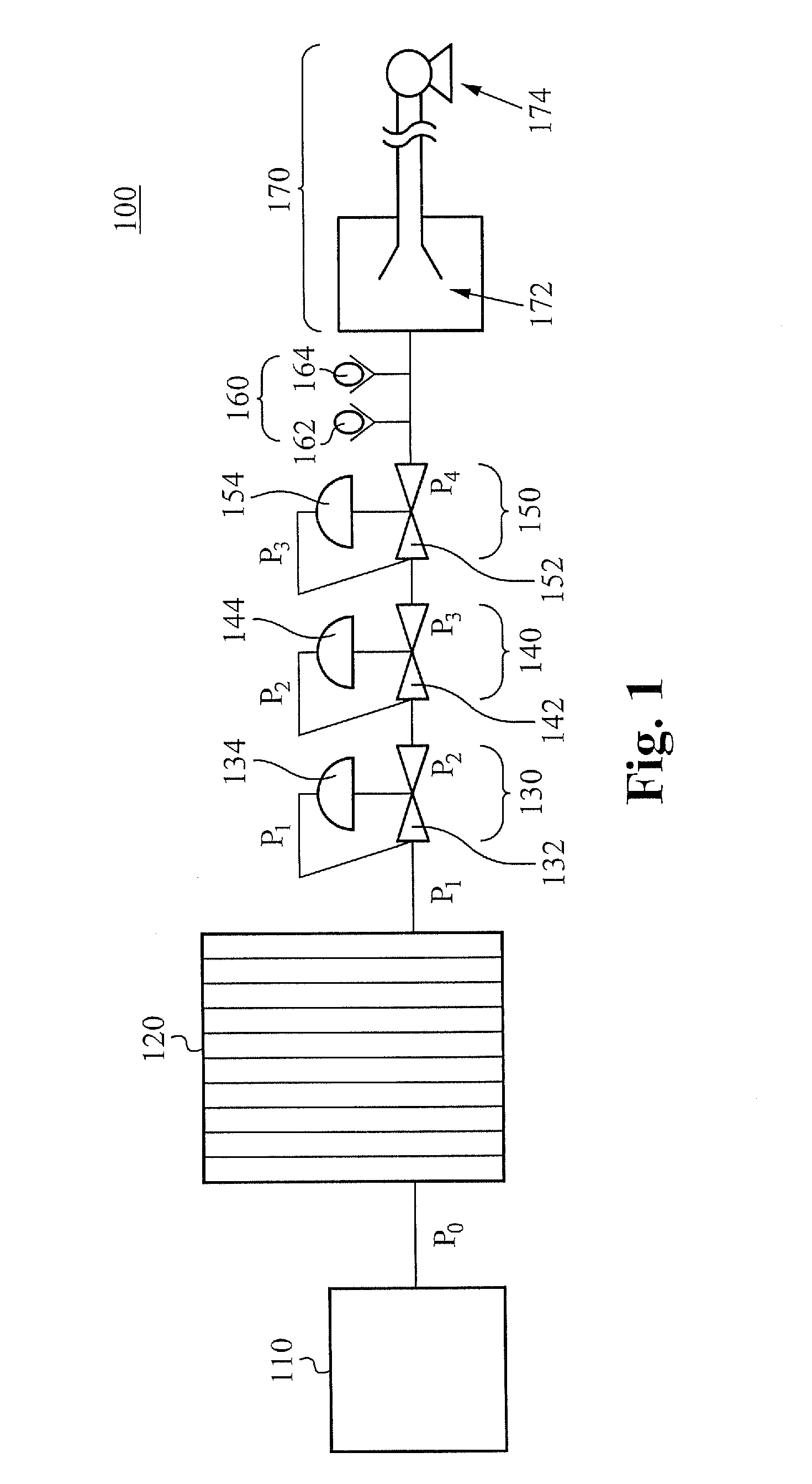

Gas delivery system with constant overpressure relative to ambient to system with varying vacuum suction

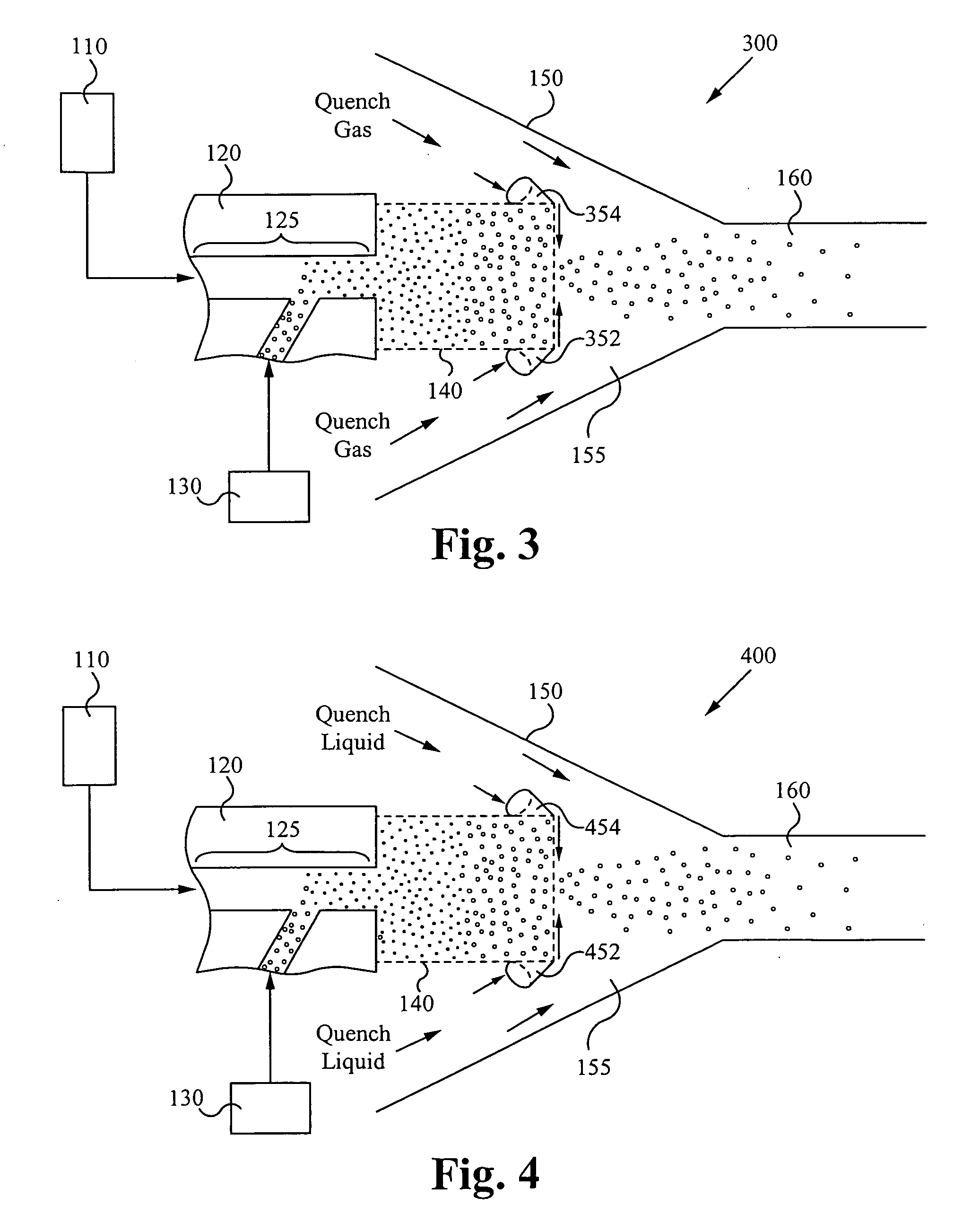

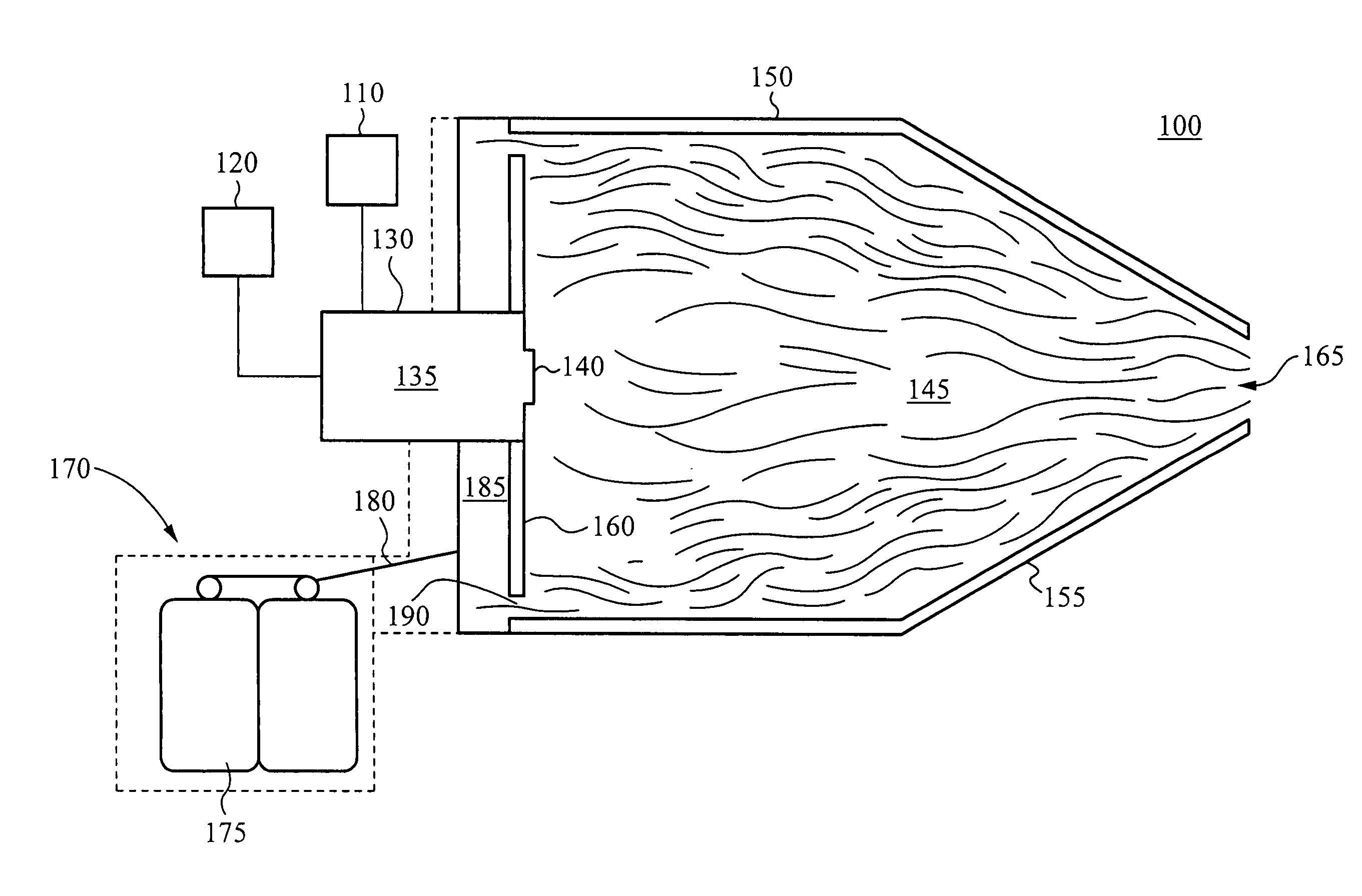

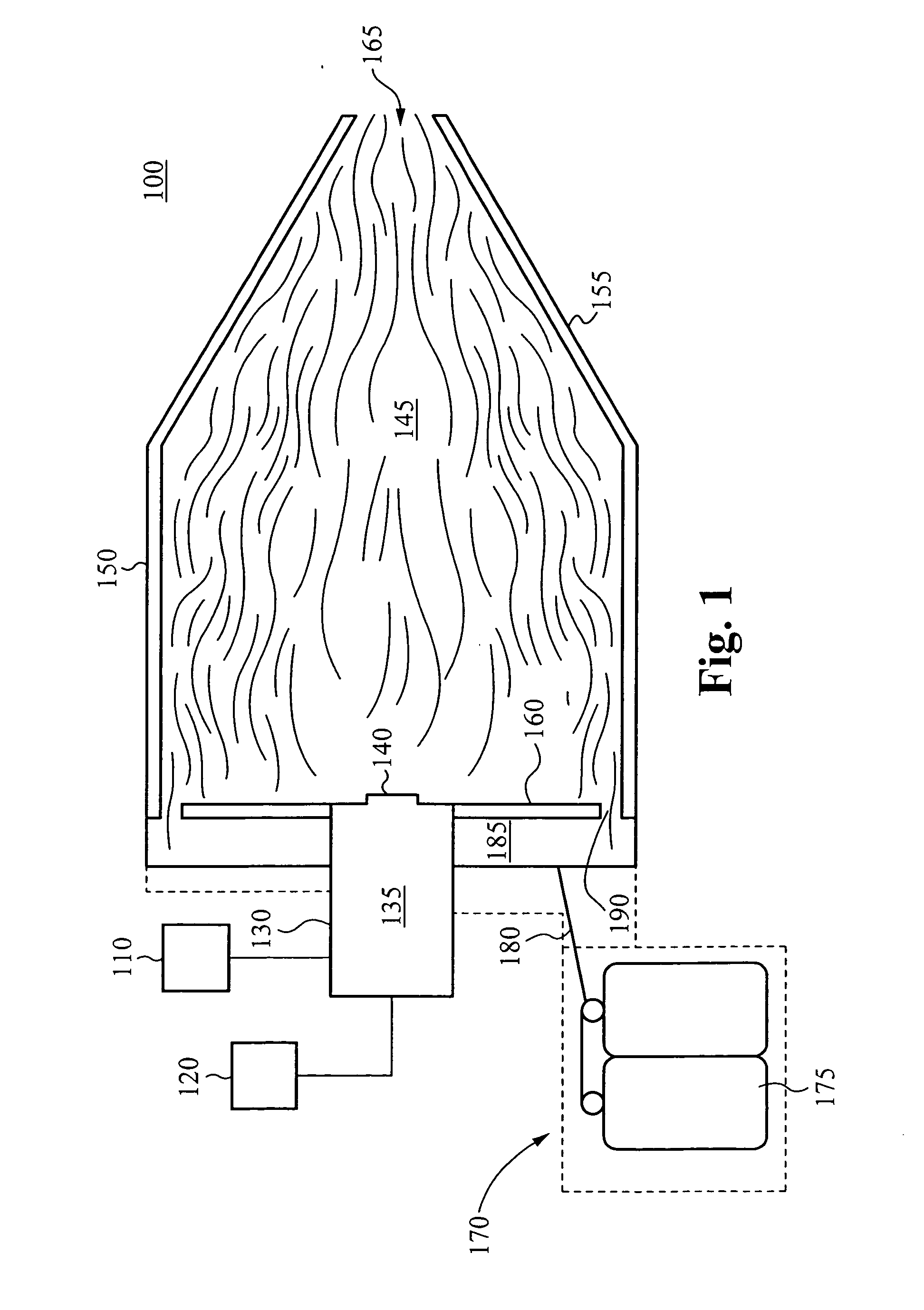

ActiveUS20110006463A1Reduce pressureMinimizes pressure differentialCatalyst activation/preparationDirect contact heat exchangersSuction forceComputer module

A system operating in an environment having an ambient pressure, the system comprising: a reactor configured to combine a plasma stream, powder particles and conditioning fluid to alter the powder particles and form a mixture stream; a supply chamber coupled to the reactor; a suction generator configured to generate a suction force at the outlet of the reactor; a fluid supply module configured to supply the conditioning fluid at an original pressure; and a pressure regulation module configured to: receive the conditioning fluid from the fluid supply module, reduce the pressure of the conditioning fluid from the original pressure to a selected pressure relative to the ambient pressure regardless of any changes in the suction force at the outlet of the reactor, and supply the conditioning fluid at the selected pressure to the supply chamber.

Owner:UMICORE AG & CO KG +1

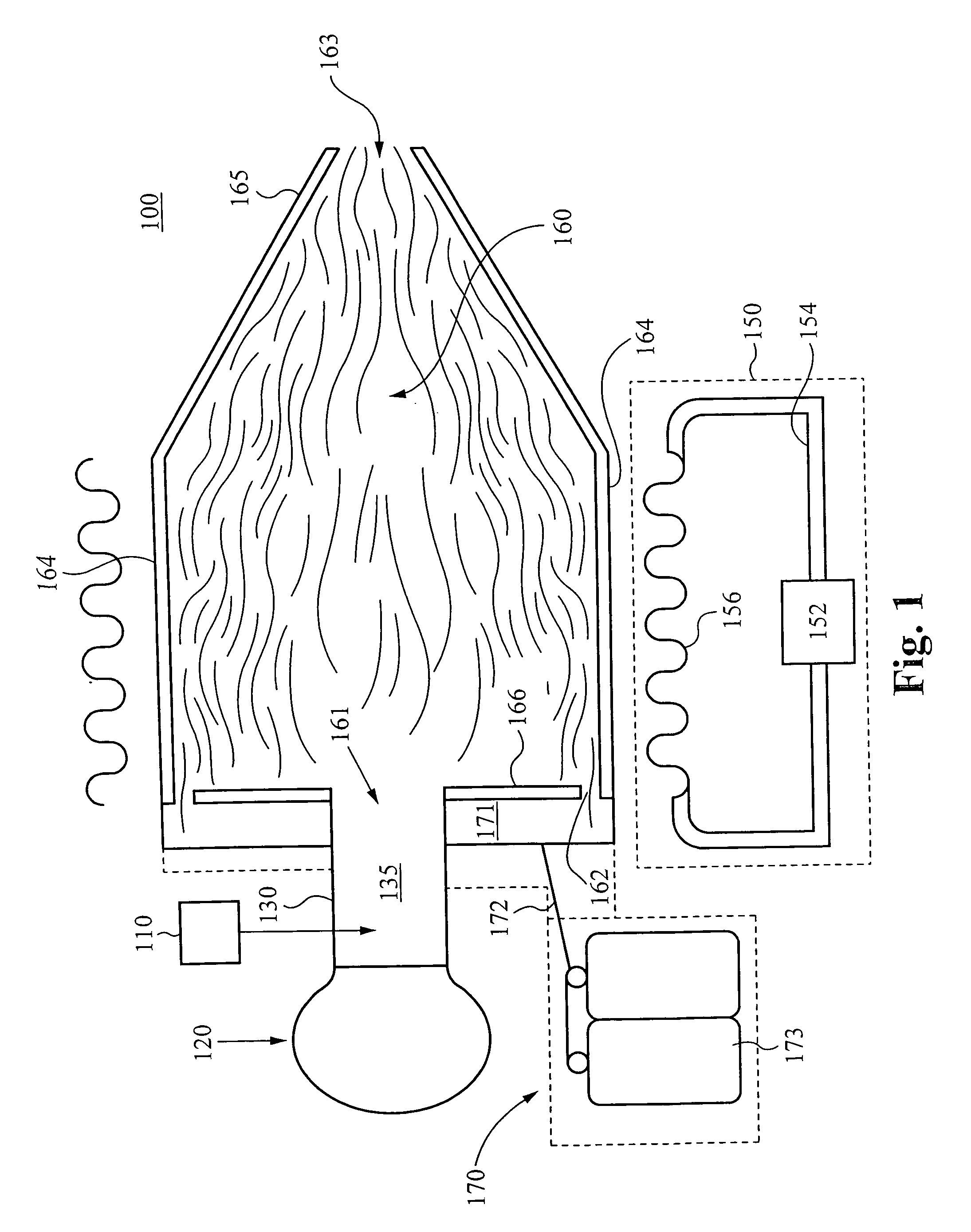

Fluid recirculation system for use in vapor phase particle production system

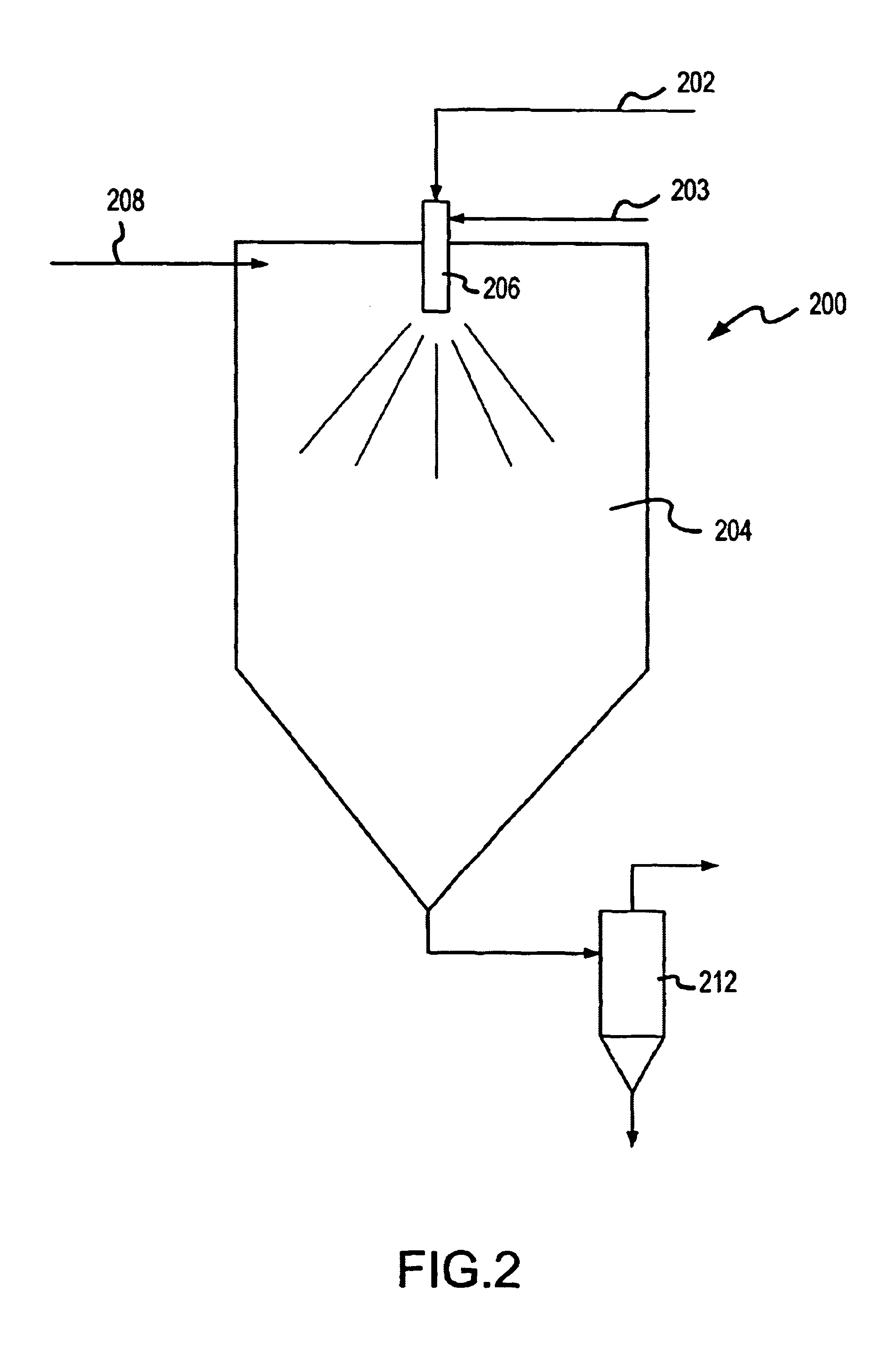

ActiveUS20080277268A1Reduce pressureDispersed particle filtrationDirect contact heat exchangersTemperature controlProduct gas

A method of and system for recirculating a fluid in a particle production system. A reactor produces a reactive particle-gas mixture. A quench chamber mixes a conditioning fluid with the reactive particle-gas mixture, producing a cooled particle-gas mixture that comprises a plurality of precursor material particles and an output fluid. A filter element filters the output fluid, producing a filtered output. A temperature control module controls the temperature of the filtered output, producing a temperature-controlled, filtered output. A content ratio control module modulates the content of the temperature-controlled, filtered output, thereby producing a content-controlled, temperature-controlled, filtered output. A channeling element supplies the content-controlled, temperature-controlled, filtered output to the quench chamber, wherein the content-controlled, filtered output is provided to the quench chamber as the conditioning fluid to be used in cooling the reactive particle-gas mixture.

Owner:SDC MATERIALS +1

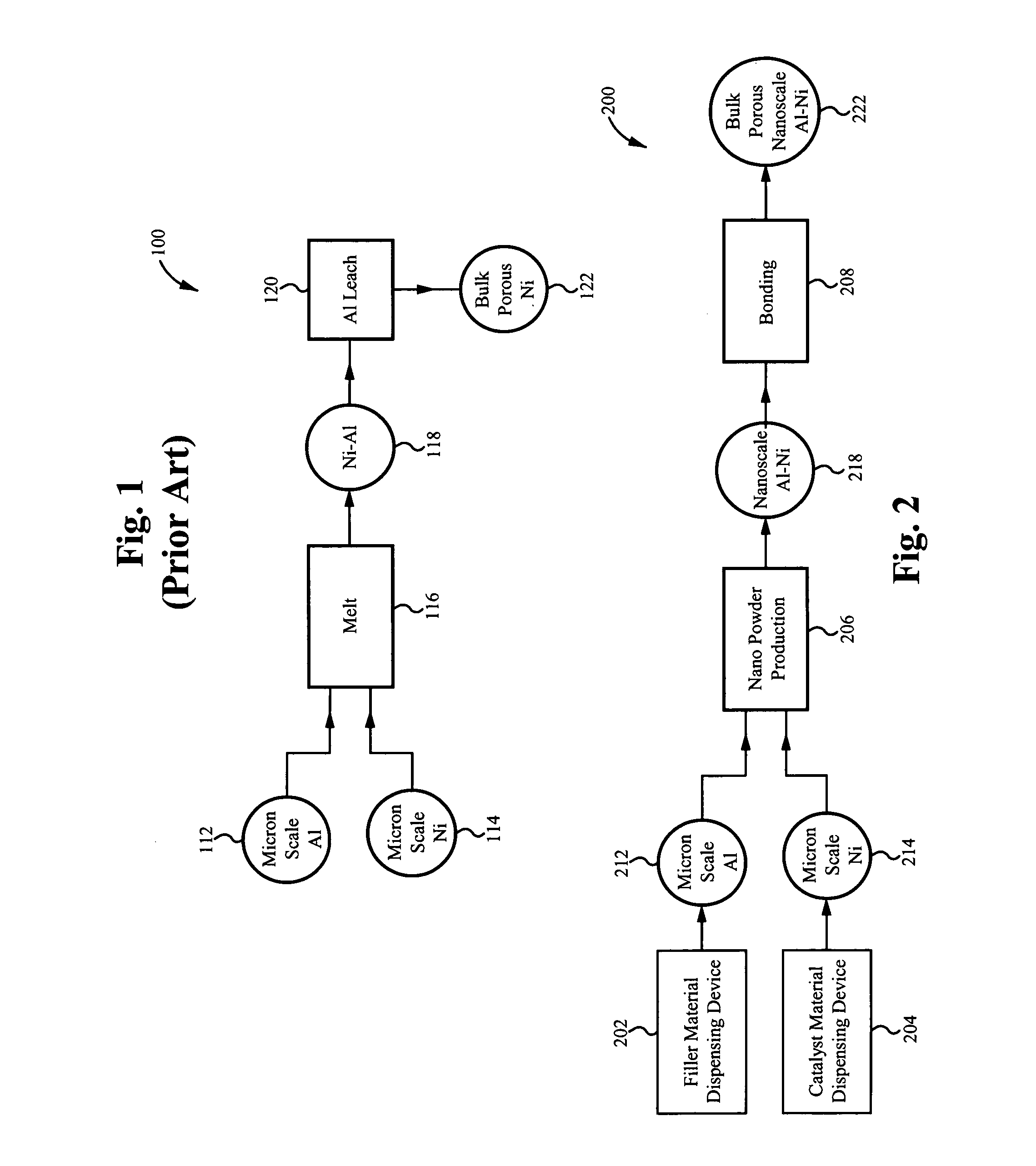

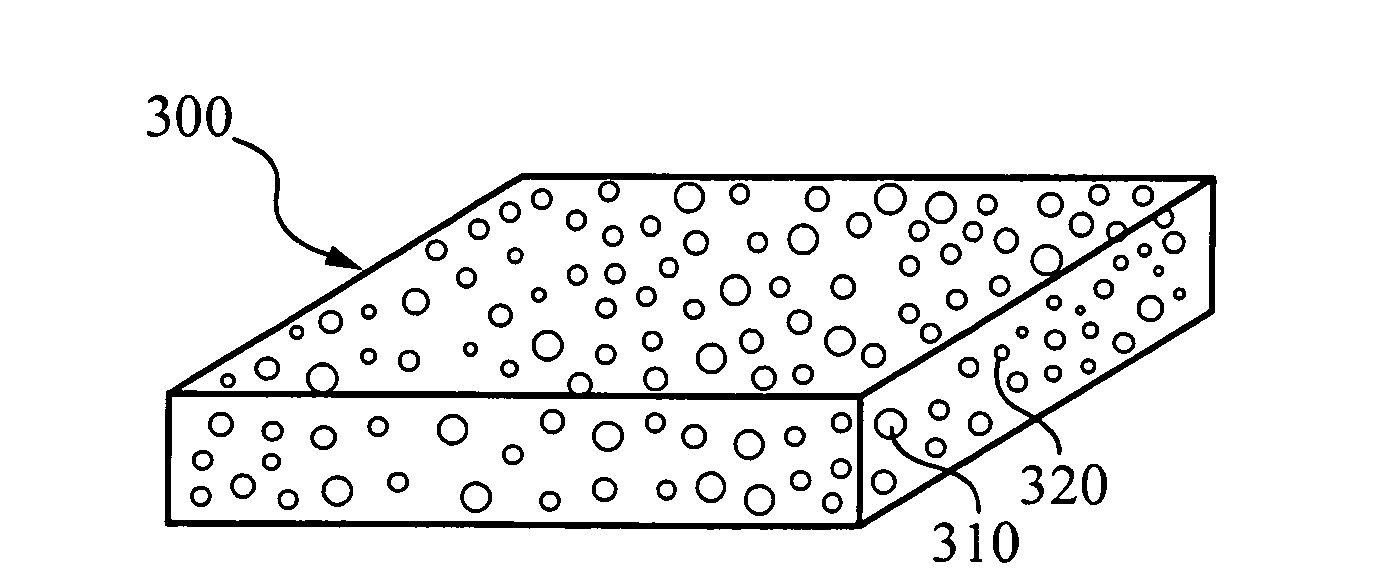

Nano-skeletal catalyst

ActiveUS20080280756A1Increase surface areaMassive costMechanical working/deformationSemiconductor/solid-state device manufacturingPolymer scienceScale structure

A method of producing a catalyst material with nano-scale structure, the method comprising: introducing a starting powder into a nano-powder production reactor, the starting powder comprising a catalyst material; the nano-powder production reactor nano-sizing the starting powder, thereby producing a nano-powder from the starting powder, the nano-powder comprising a plurality of nano-particles, each nano-particle comprising the catalyst material; and forming a catalyst precursor material from the nano-powder, wherein the catalyst precursor material is a densified bulk porous structure comprising the catalyst material, the catalyst material having a nano-scale structure.

Owner:SDC MATERIALS +1

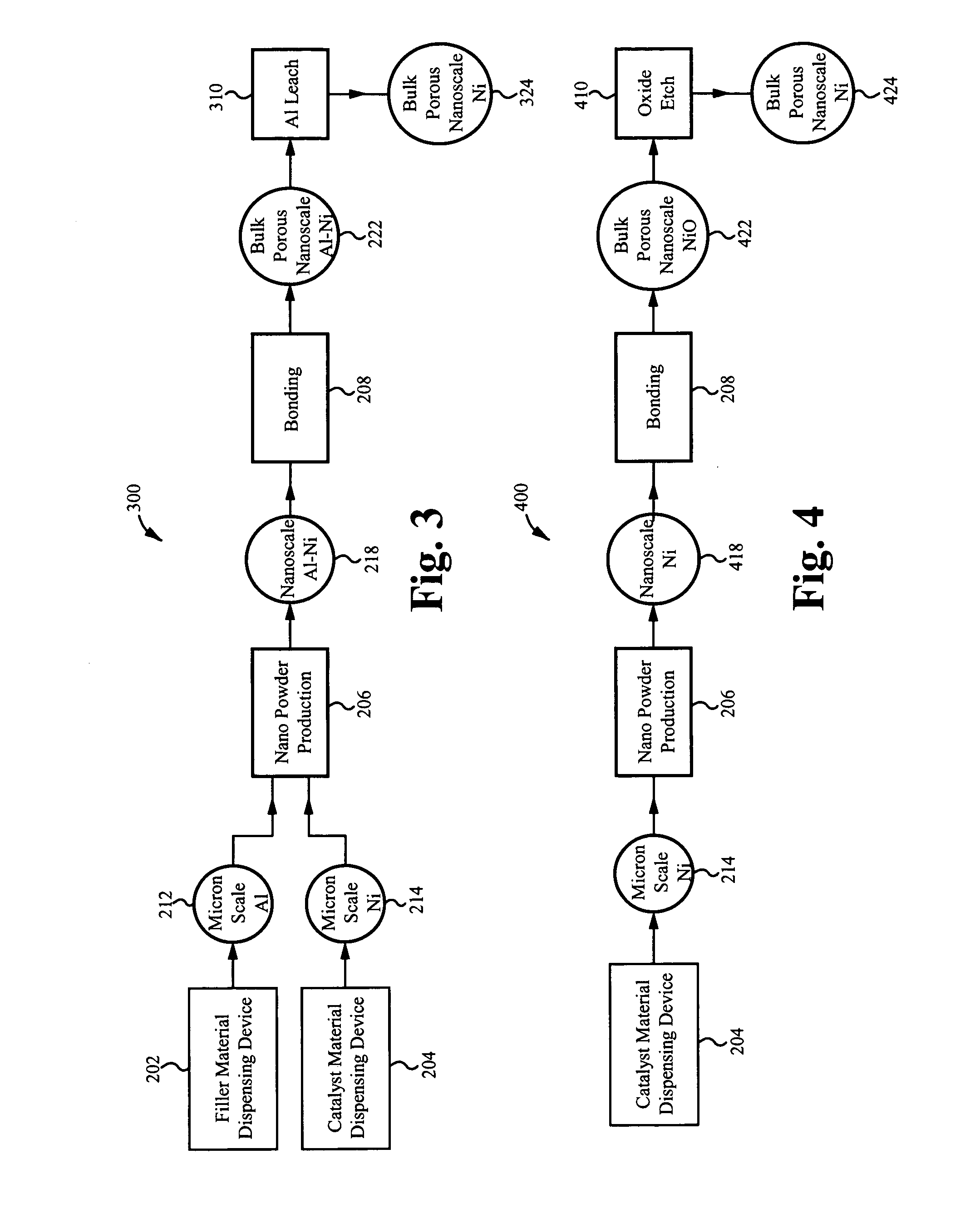

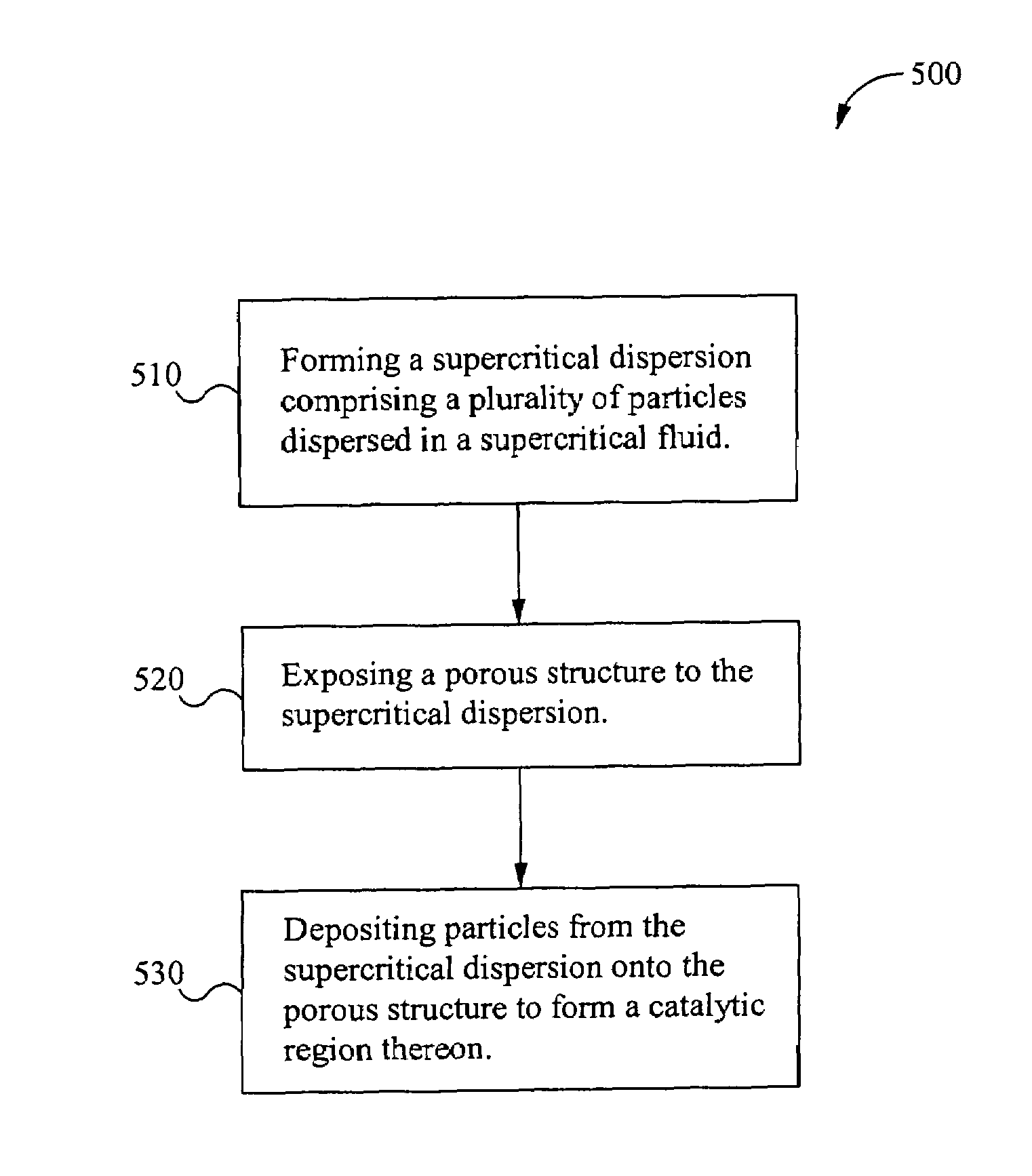

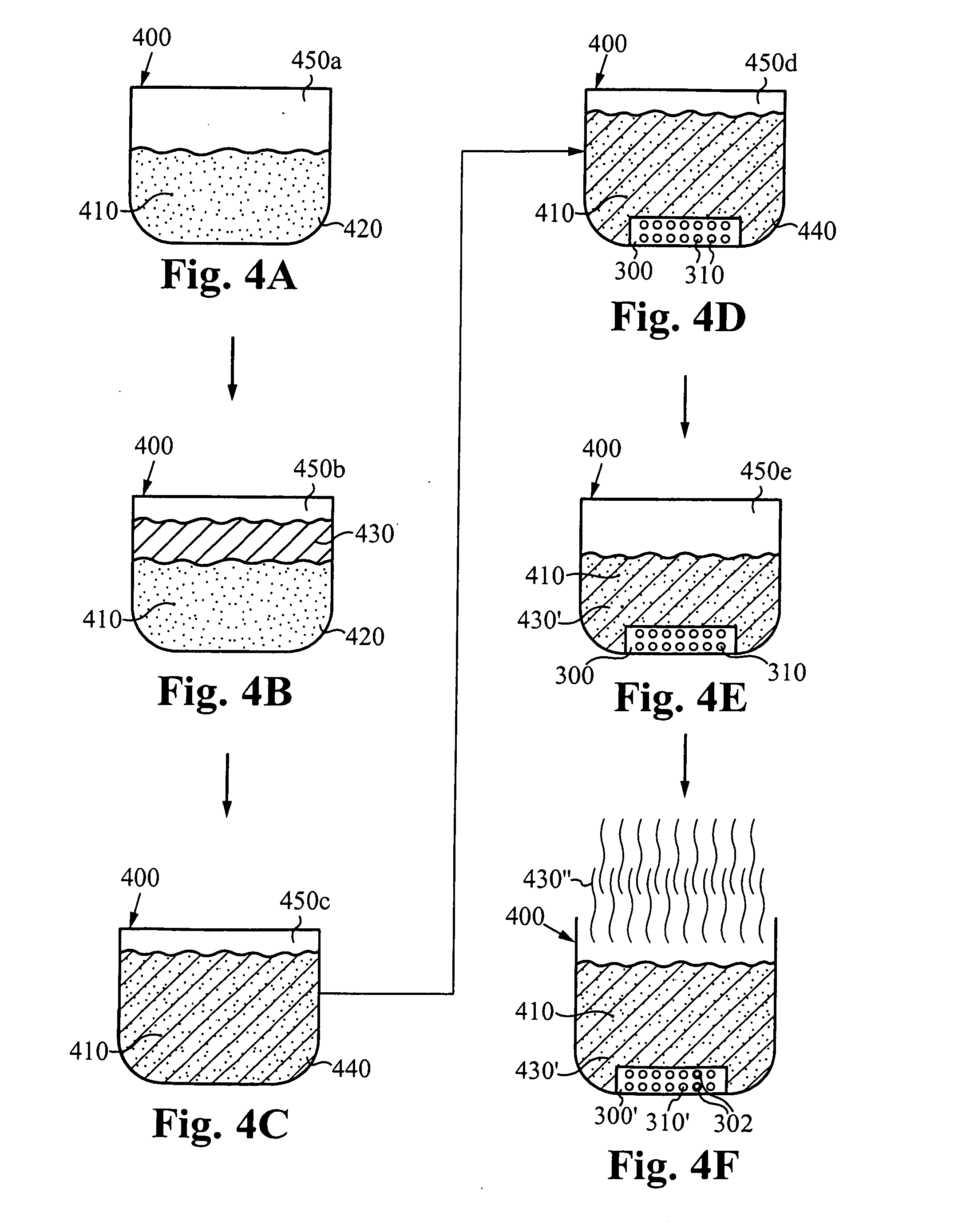

Formation of catalytic regions within porous structures using supercritical phase processing

InactiveUS7678419B2Pretreated surfacesDirect contact heat exchangersMaterials scienceSupercritical fluid

A method of forming a catalytic region on a porous structure having an exterior surface and a plurality of pores, the method comprising: forming a supercritical dispersion, wherein the supercritical dispersion comprises a plurality of particles dispersed in a supercritical fluid; exposing the porous structure to the supercritical dispersion; and depositing the plurality of particles from the supercritical dispersion onto the porous structure, wherein each one of the deposited plurality of particles is catalytic, thereby forming one or more catalytic regions on the porous structure. The method is particularly well suited for creating catalytic regions within pre-formed microporous structures.

Owner:UMICORE AG & CO KG +1

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

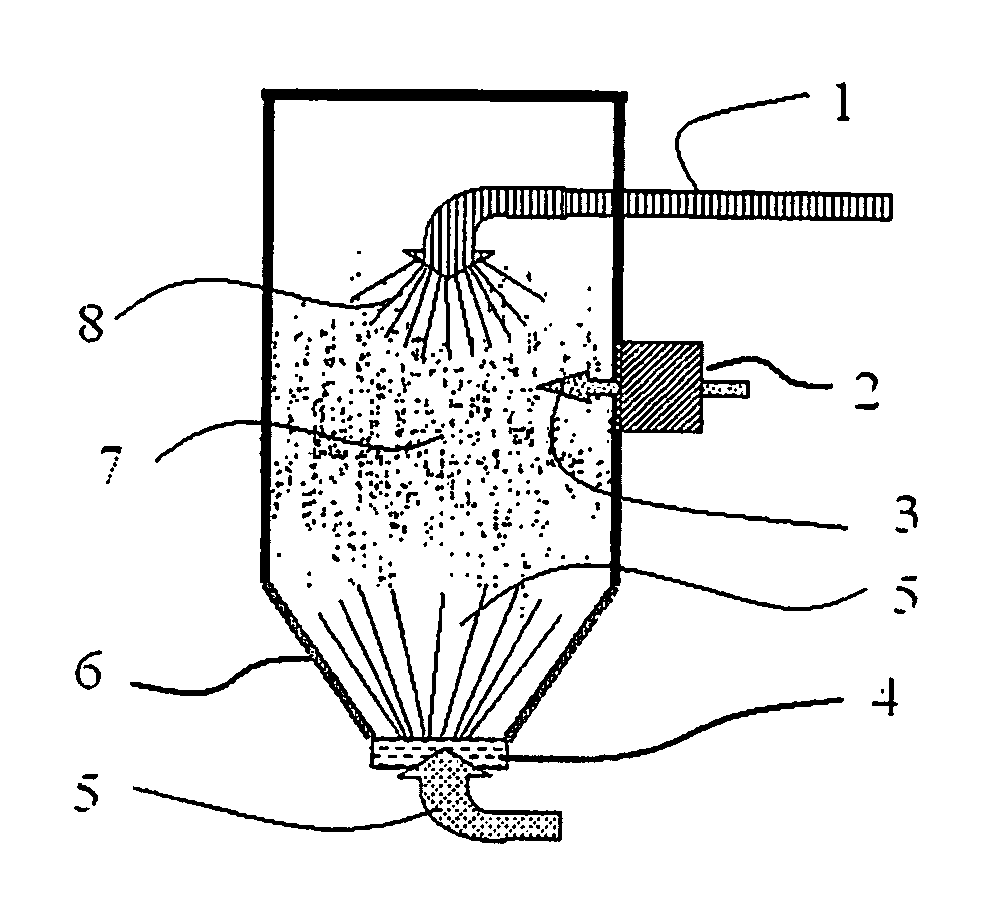

Spherical single-substance particles, medicines and foodstuffs containing the particles, and method of production thereof

The present invention relates to a process for producing a spherical particle comprising an aggregate of particles containing at least 95% of a water-soluble single substance having a viscosity of 10 mPa.s or less as determined in the form of a saturated aqueous solution, the process comprising: preparing moist spherical particles of the single substance by charging, as cores, crystalline particles or granulated particles of the single substance on a rotary disc in a processing vessel of a centrifugal tumbling granulating apparatus, wherein the granulated particles are prepared by granulating a powder of the single substance, and dispersing over the cores a powder of the single substance and simultaneously spraying on the cores a liquid such as water or the like while supplying slit air to provide a fluidized condition; and then fixation treating the moist spherical particles by drying them while spraying an aqueous solution of the single substance or the like on the spherical particles in a fluidized bed apparatus; to the spherical particle produced by the process; and to a pharmaceutical preparation and a food containing the spherical particle.

Owner:FREUNT IND +1

Method for coating particles for generative prototyping processes

InactiveUS20060251826A1Good storage stabilityImprove handlingAdditive manufacturing apparatusGranule coatingOrganic fluidMetal

The invention relates to a method for coating particles of a plastic, metal and / or ceramic powder material for producing an adhesive-containing coating material, in particular for producing appropriate particles by compressing a 3D binder. Said coating is applied to fluidised particles in a gaseous phase by means of a coating solution, at least the particles and / or coated particles being exposed to ionised particles. A method for producing bodies or sintered bodies from organic liquid binders by compressing the 3D binder and the use thereof are also disclosed.

Owner:DAIMLER AG

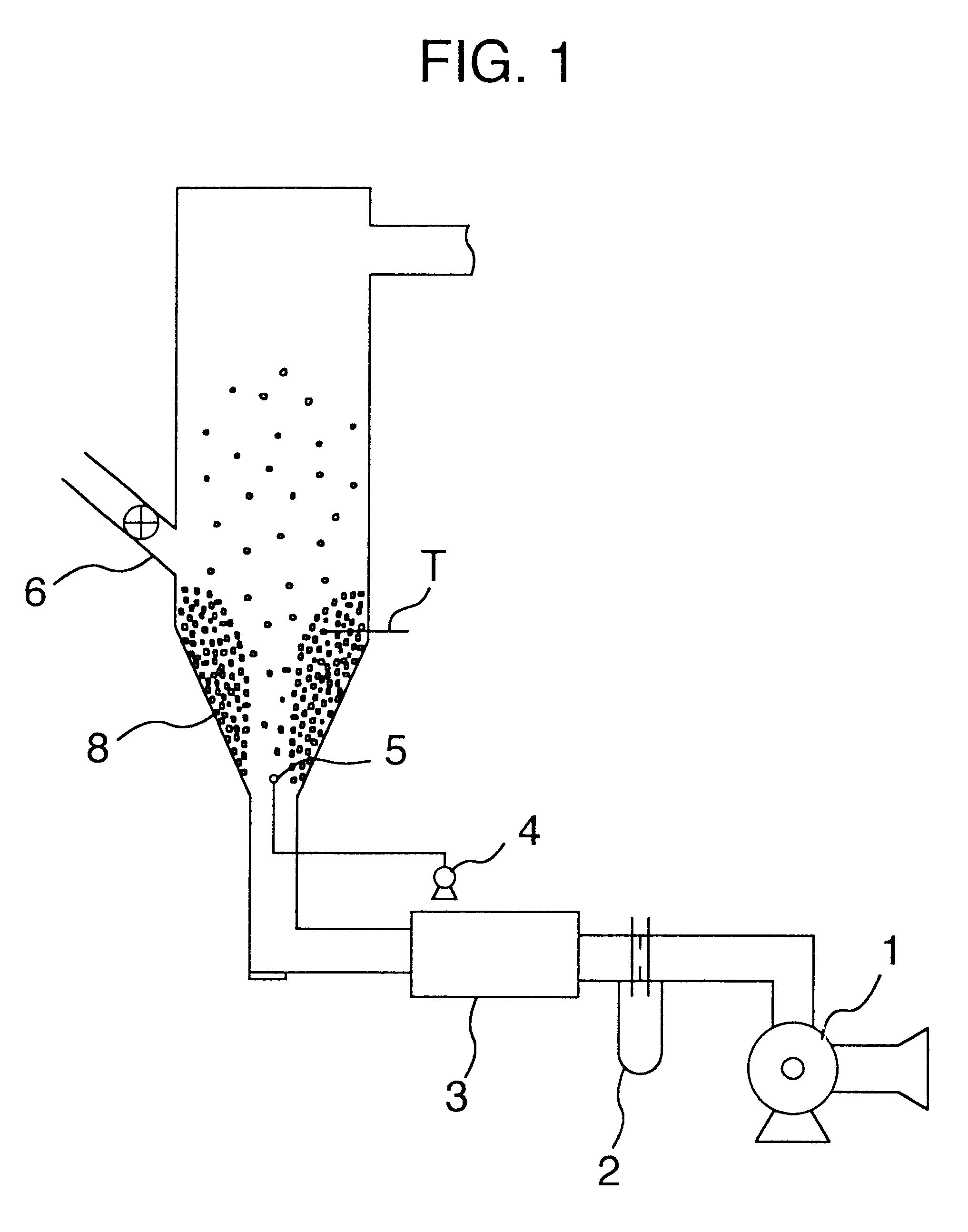

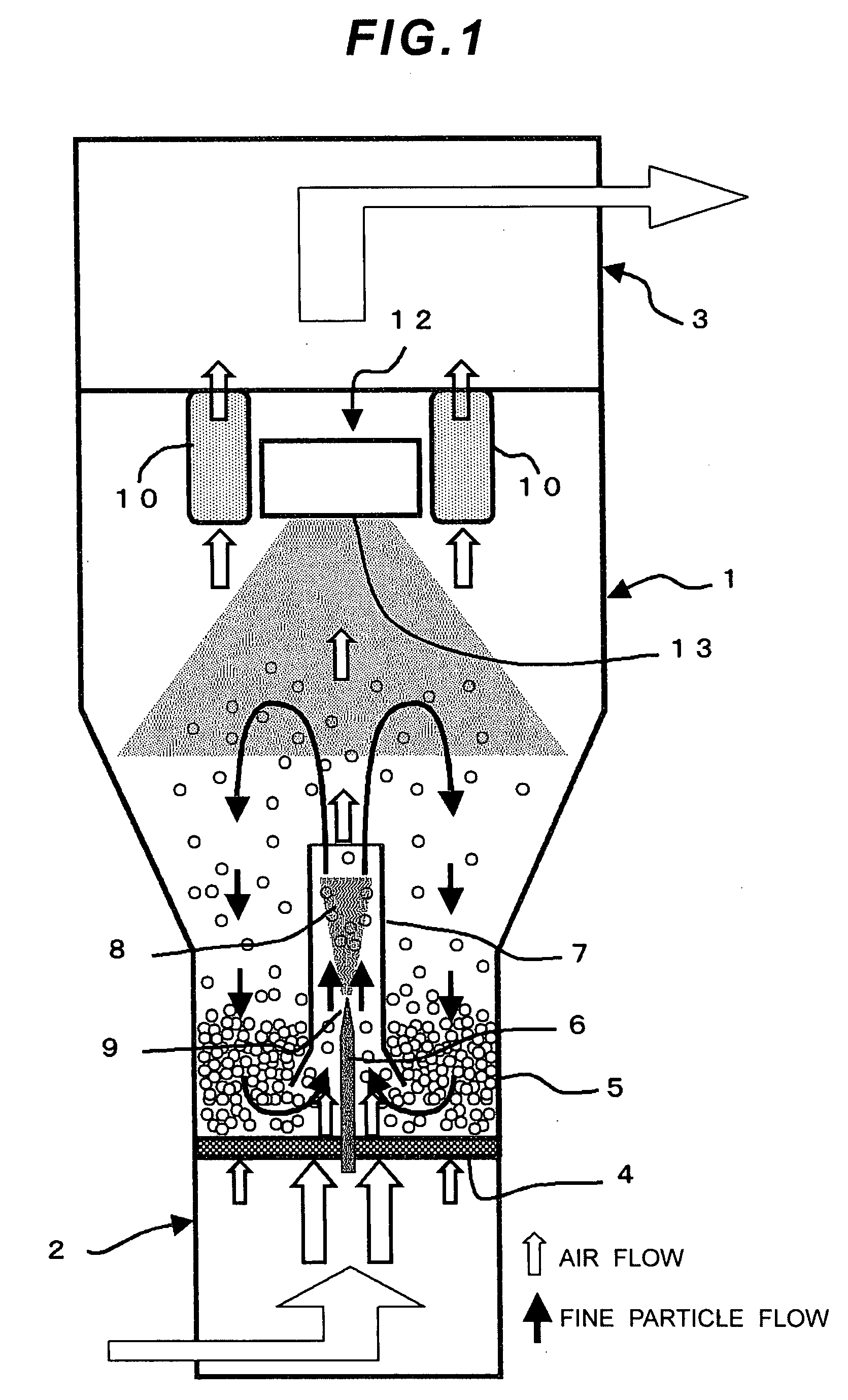

Fluidized Bed Device

InactiveUS20090123665A1Good hygroscopicityVulnerable to moistureLiquid surface applicatorsVacuum evaporation coatingFluidized bedX-ray

Owner:EISIA R&D MANAGEMENT CO LTD

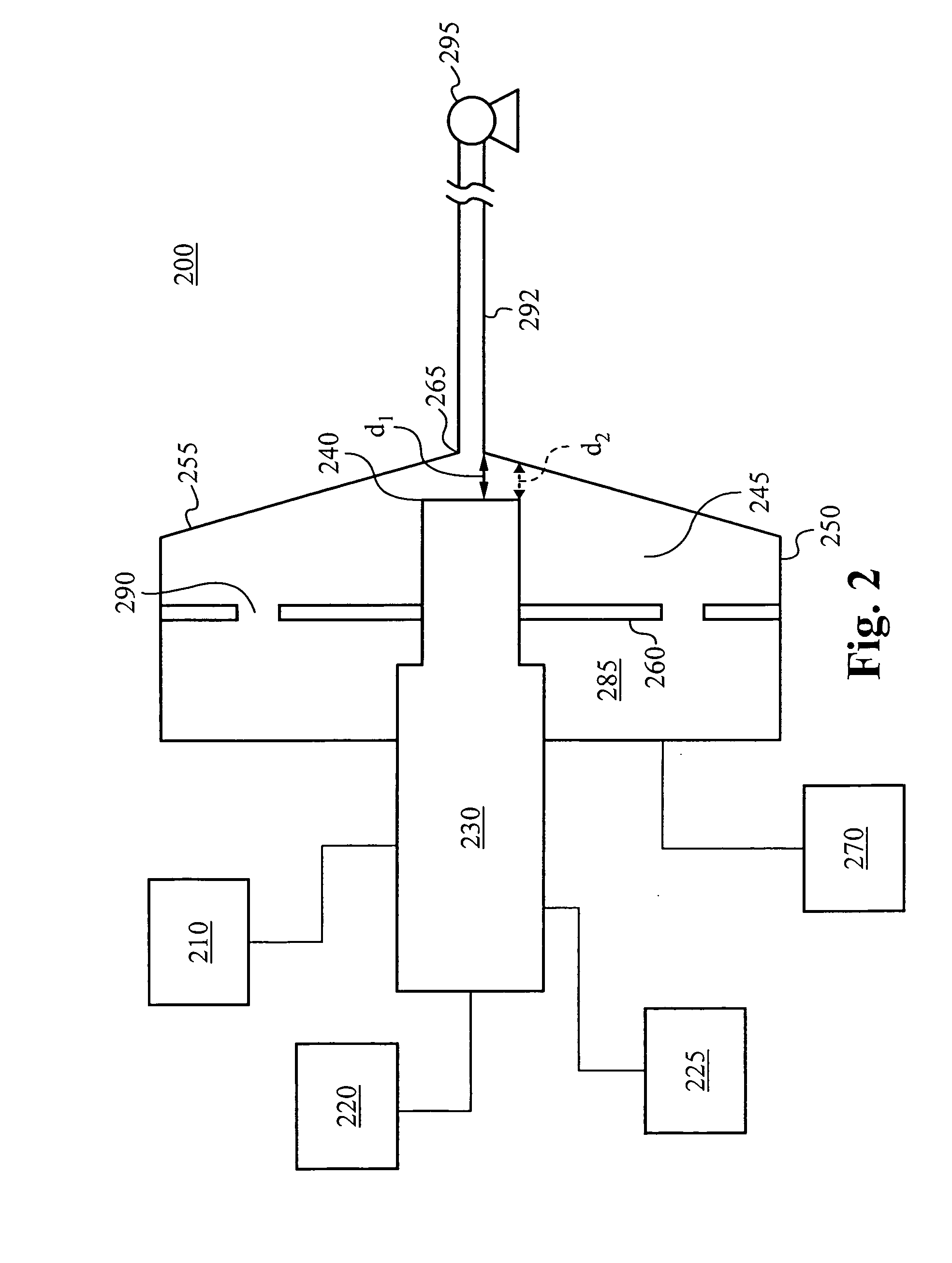

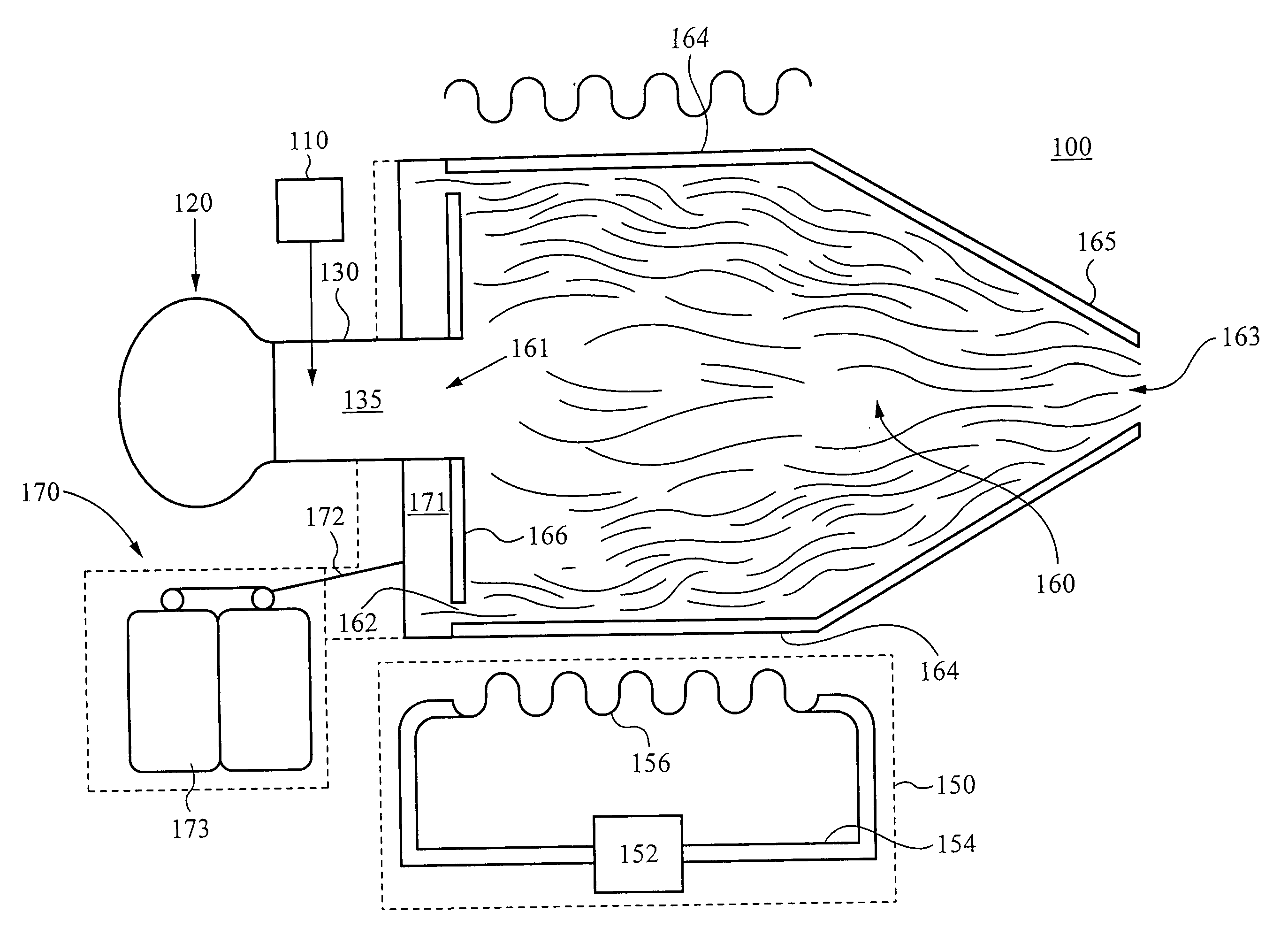

Shape of cone and air input annulus

InactiveUS20080277266A1Minimize occurrenceHigh molecular weightDirect contact heat exchangersStationary tubular conduit assembliesInterior spaceInjection port

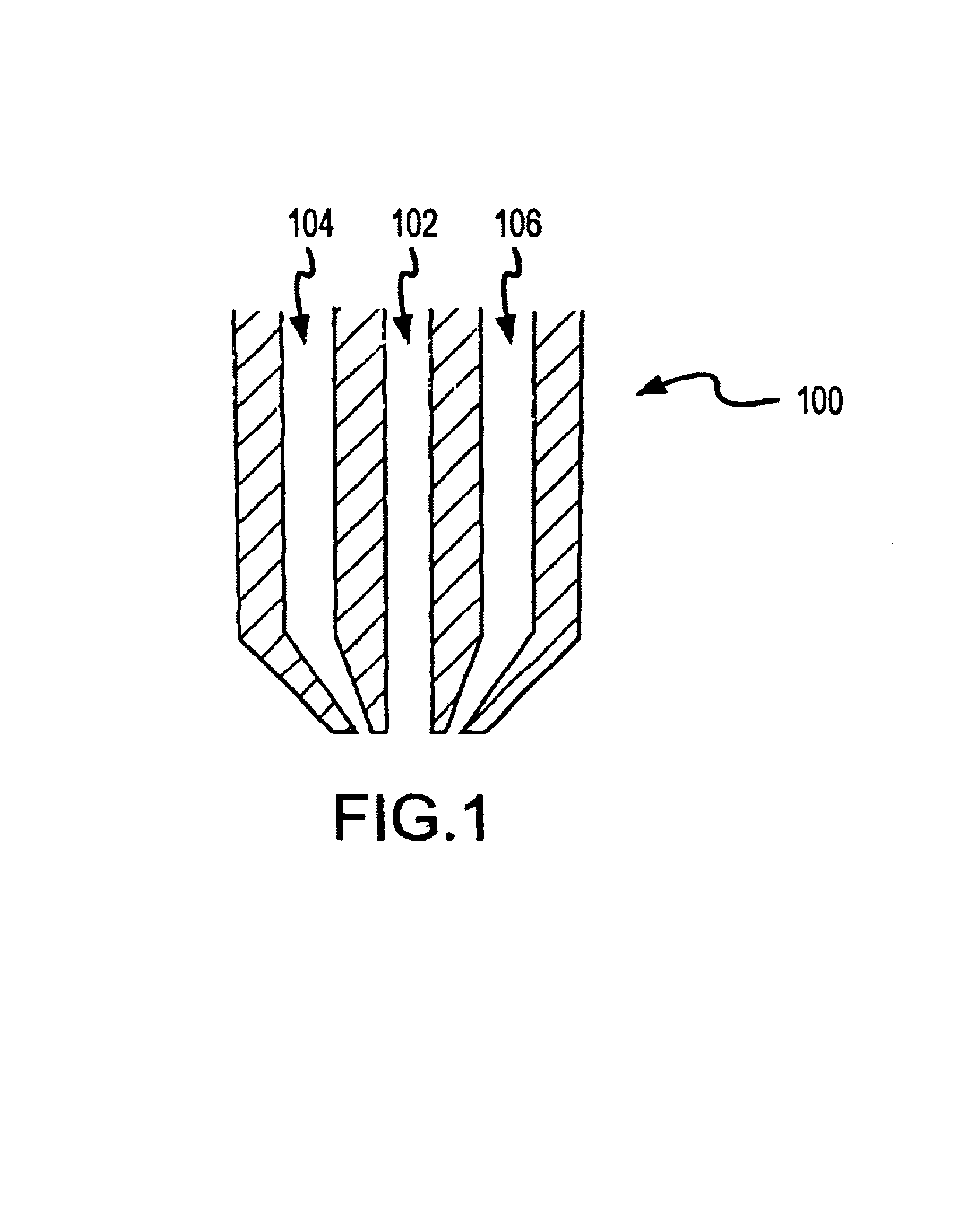

A constricting chamber having first and second ends, the chamber comprising: an interior surface formed between the first and second ends, disposed circumferentially around and defining an interior space and a longitudinal axis of the chamber; a frusto-conical surface disposed between the first and second ends and narrowing as it extends away from the first end and into the second end; an ejection port disposed at the second end and substantially aligned with the longitudinal axis; a cover disposed at the first end, substantially perpendicular to the longitudinal axis, and comprising a center substantially aligned with the longitudinal axis; an injection port disposed on the cover proximate the center, and configured to receive a reactive mixture into the chamber; and an annular supply portion disposed circumferentially around the longitudinal axis and comprising supply port(s) configured to supply conditioning fluid into the chamber in an annular formation along the interior surface.

Owner:SDC MATERIALS +1

Gas delivery system with constant overpressure relative to ambient to system with varying vacuum suction

ActiveUS20080277271A1Minimizes pressure differentialReduce pressureCatalyst activation/preparationDirect contact heat exchangersSuction stressAmbient pressure

A system operating in an environment having an ambient pressure, the system comprising: a reactor configured to combine a plasma stream, powder particles and conditioning fluid to alter the powder particles and form a mixture stream; a supply chamber coupled to the reactor; a suction generator configured to generate a suction force at the outlet of the reactor; a fluid supply module configured to supply the conditioning fluid at an original pressure; and a pressure regulation module configured to: receive the conditioning fluid from the fluid supply module, reduce the pressure of the conditioning fluid from the original pressure to a selected pressure relative to the ambient pressure regardless of any changes in the suction force at the outlet of the reactor, and supply the conditioning fluid at the selected pressure to the supply chamber.

Owner:UMICORE AG & CO KG +1

Formation of catalytic regions within porous structures using supercritical phase processing

InactiveUS20080280049A1Enable formationPretreated surfacesDirect contact heat exchangersMaterials scienceSupercritical fluid

A method of forming a catalytic region on a porous structure having an exterior surface and a plurality of pores, the method comprising: forming a supercritical dispersion, wherein the supercritical dispersion comprises a plurality of particles dispersed in a supercritical fluid; exposing the porous structure to the supercritical dispersion; and depositing the plurality of particles from the supercritical dispersion onto the porous structure, wherein each one of the deposited plurality of particles is catalytic, thereby forming one or more catalytic regions on the porous structure. The method is particularly well suited for creating catalytic regions within pre-formed microporous structures.

Owner:UMICORE AG & CO KG +1

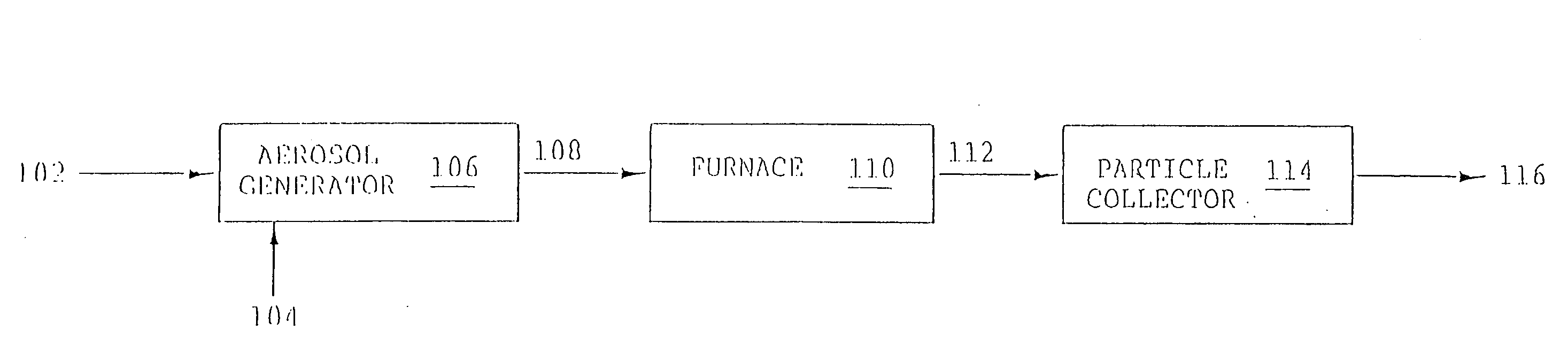

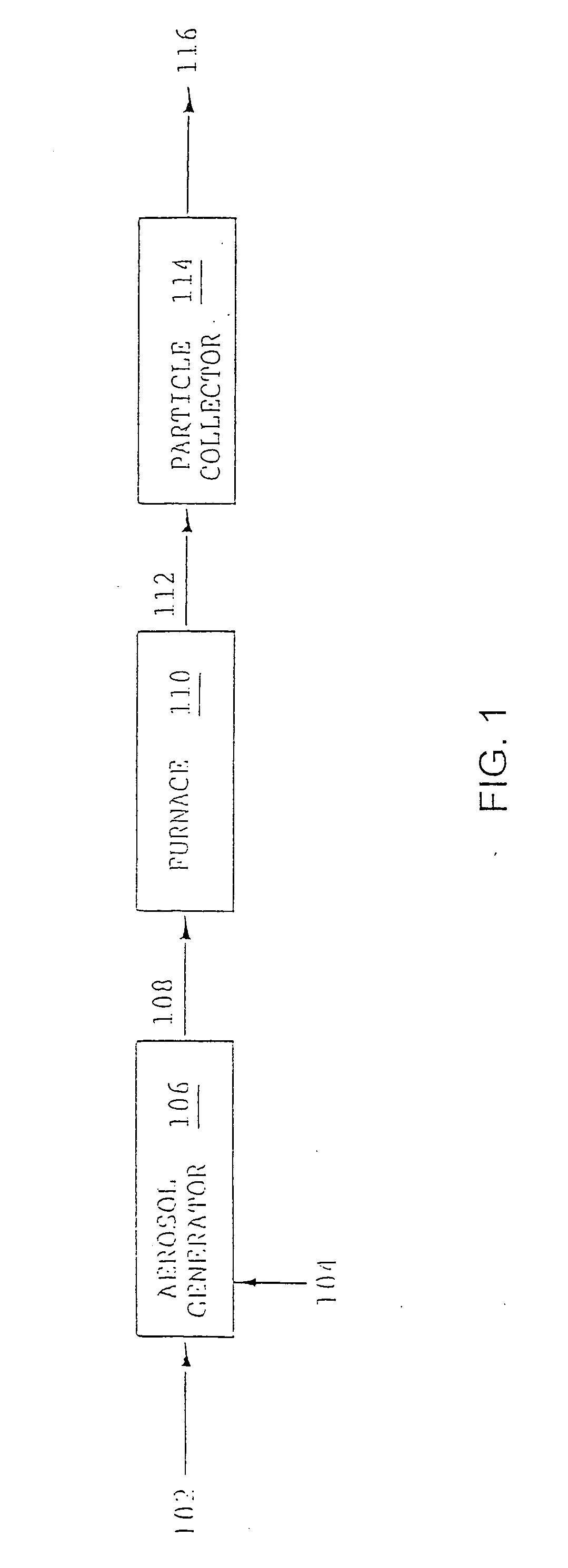

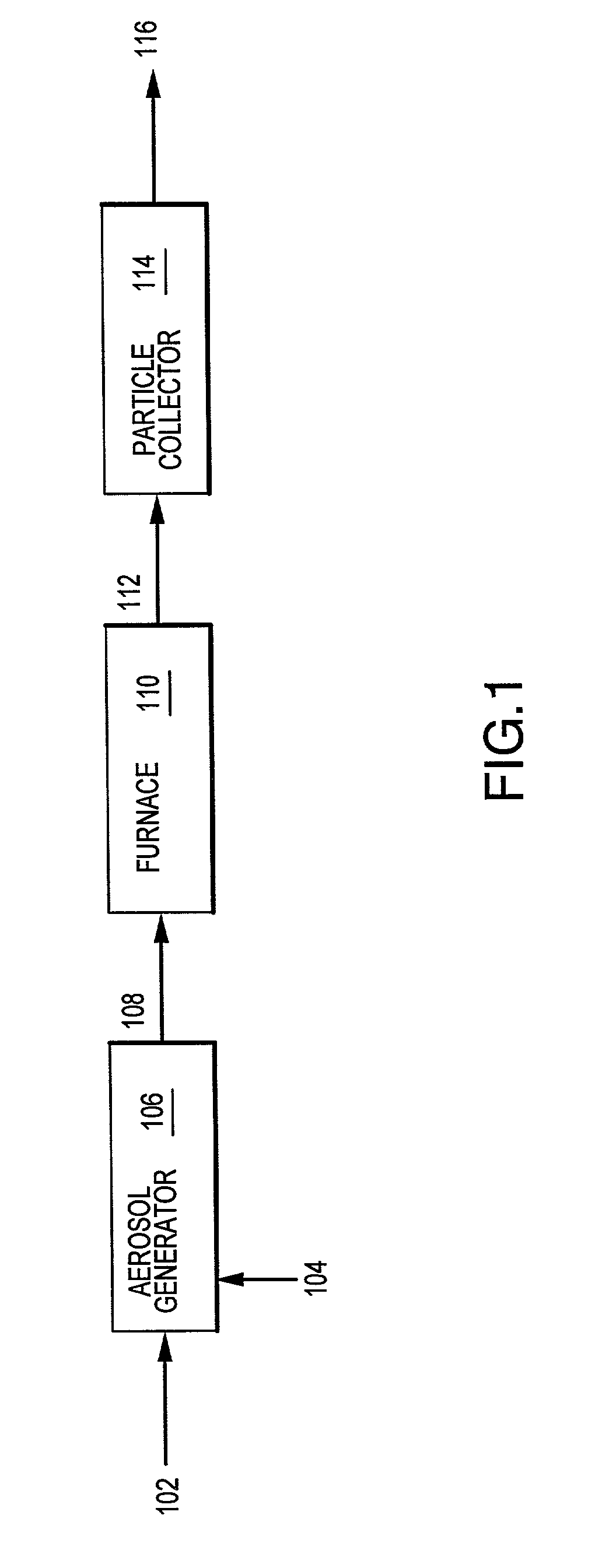

Aerosol method and apparatus, particulate products, and electronic devices made therefrom

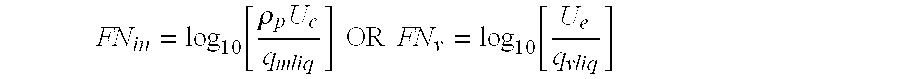

Metal-carbon composite powders and methods for producing metal-carbon composite powders. The powders have a well-controlled microstructure and morphology and preferably have a small average particle size. The method includes forming the particles from an aerosol of powder precursors. The invention also includes novel devices and products formed from the composite powders.

Owner:CABOT CORP

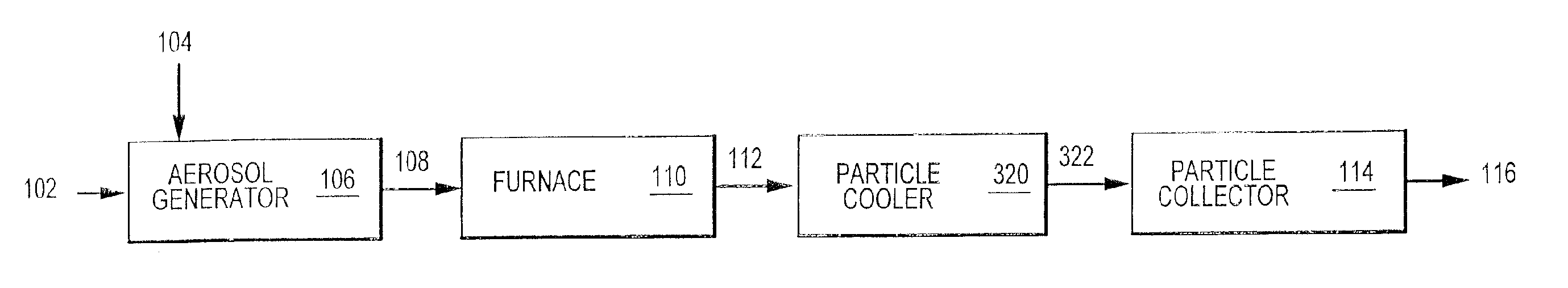

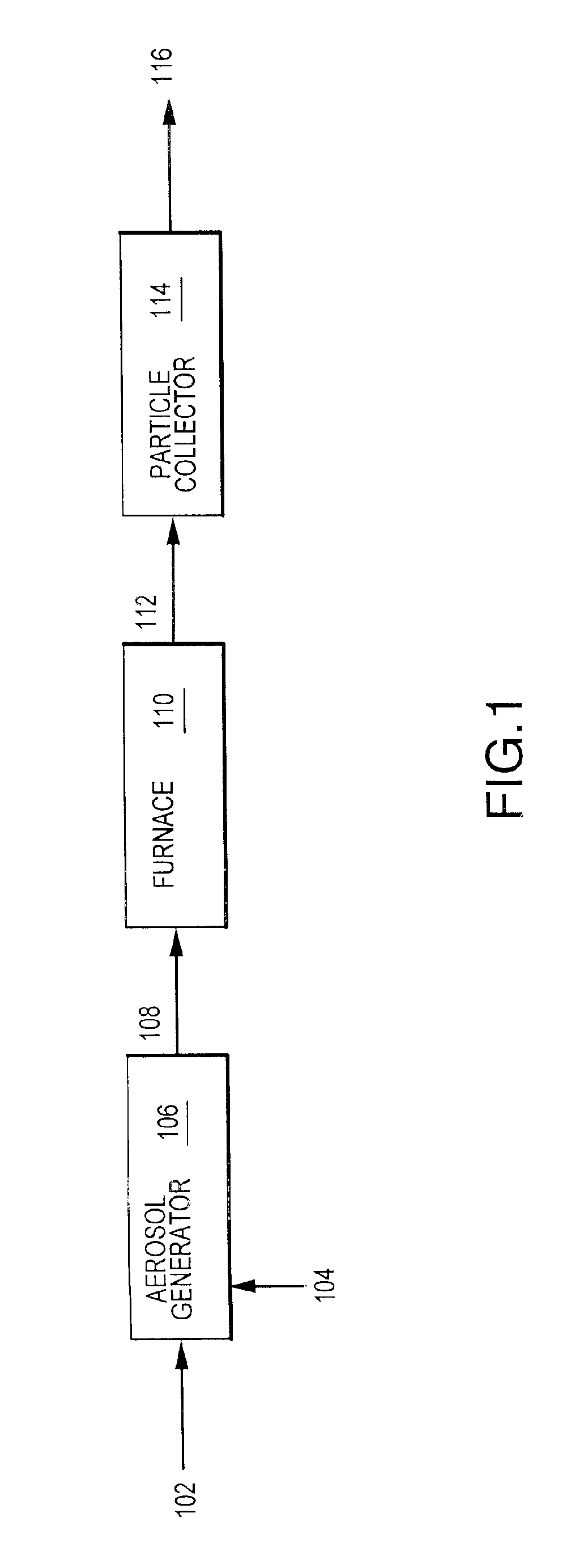

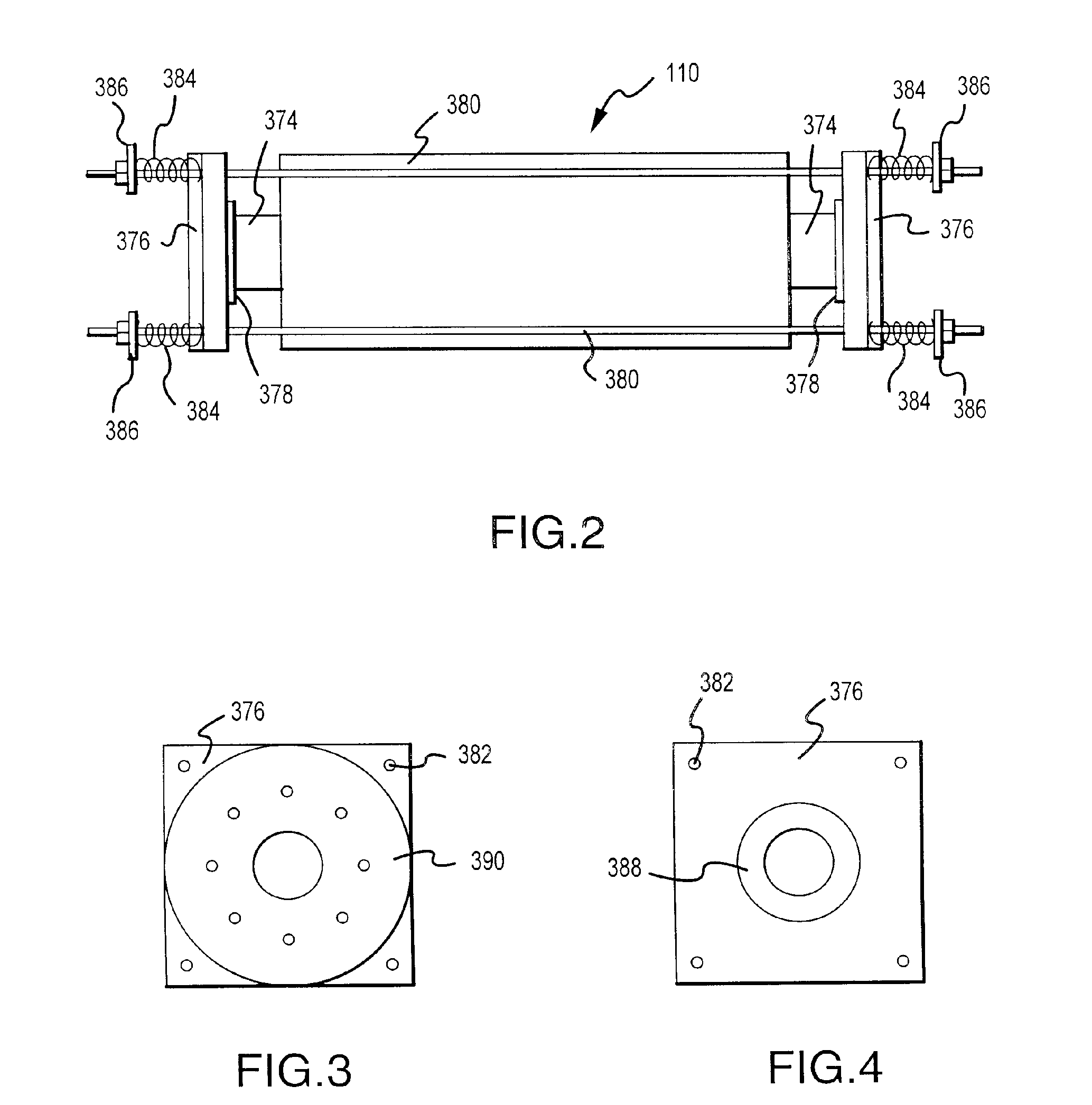

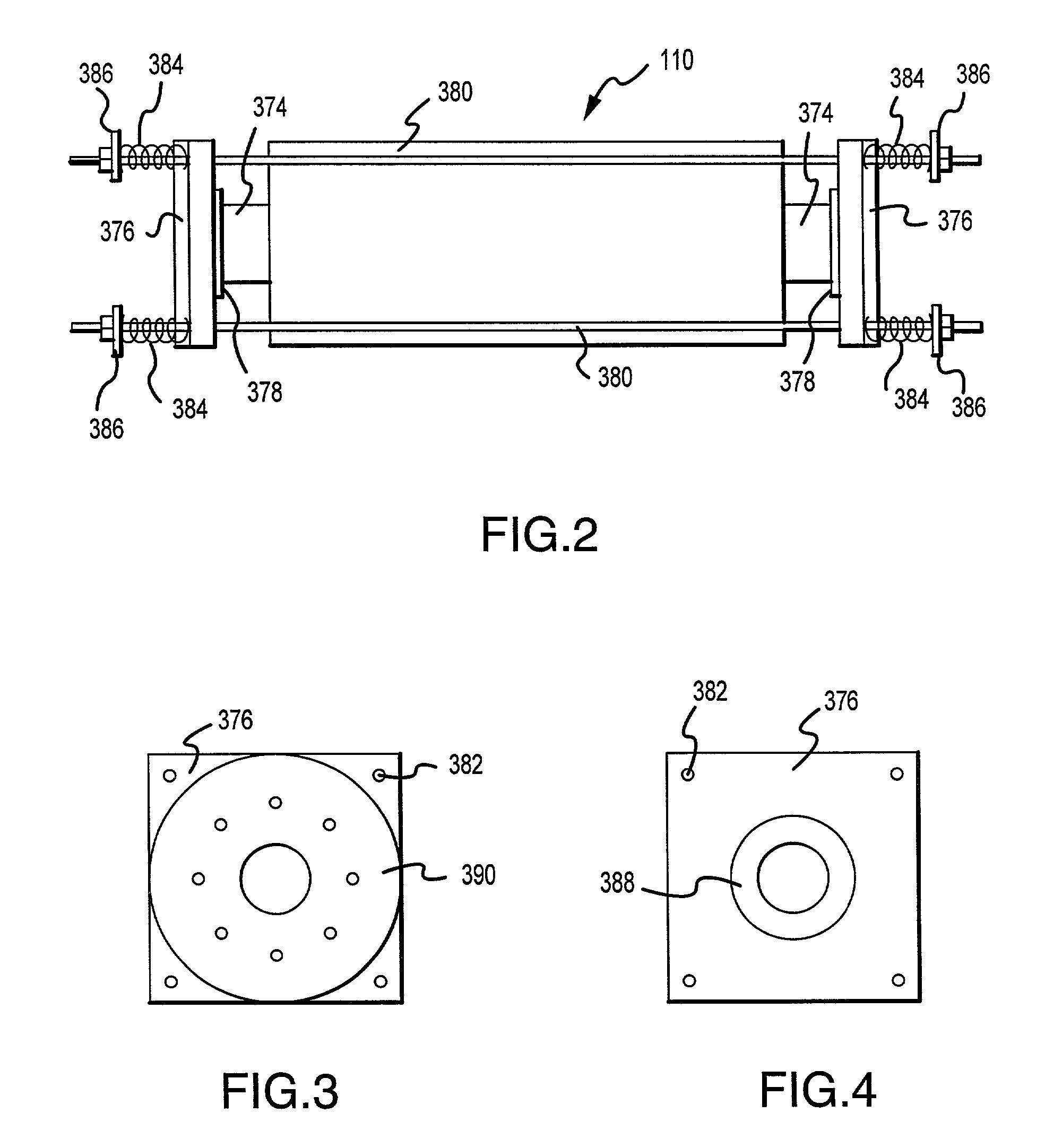

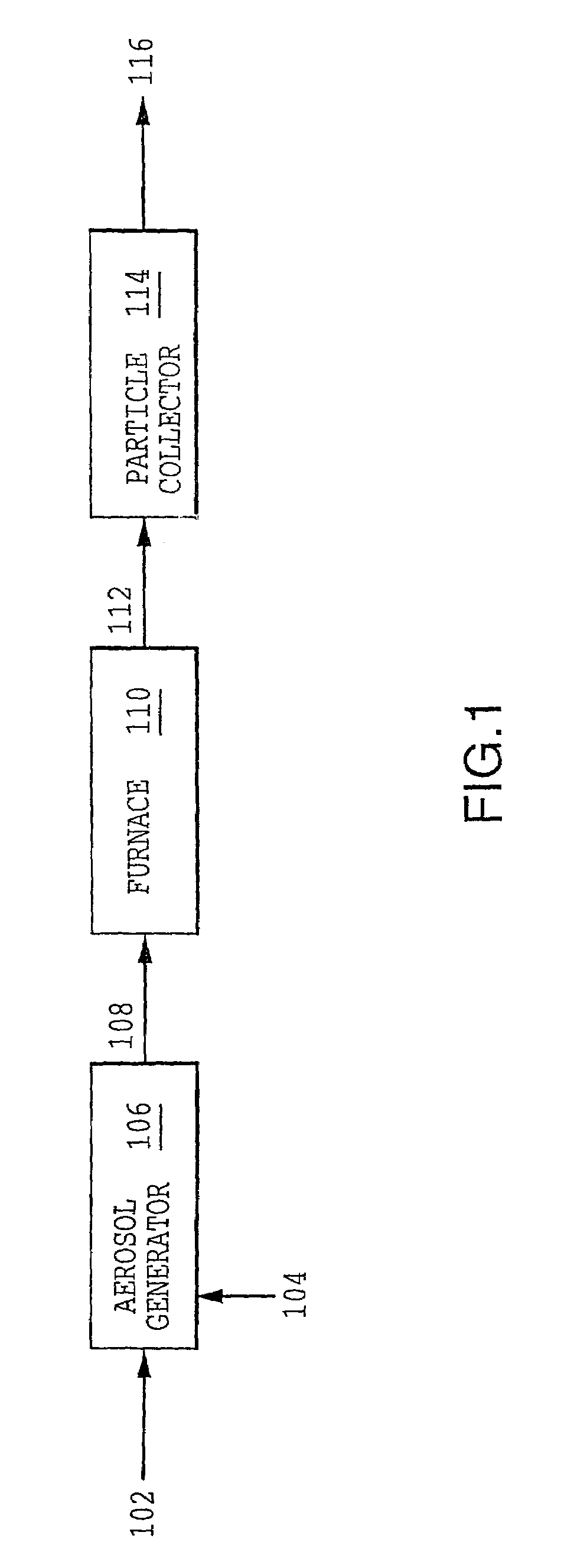

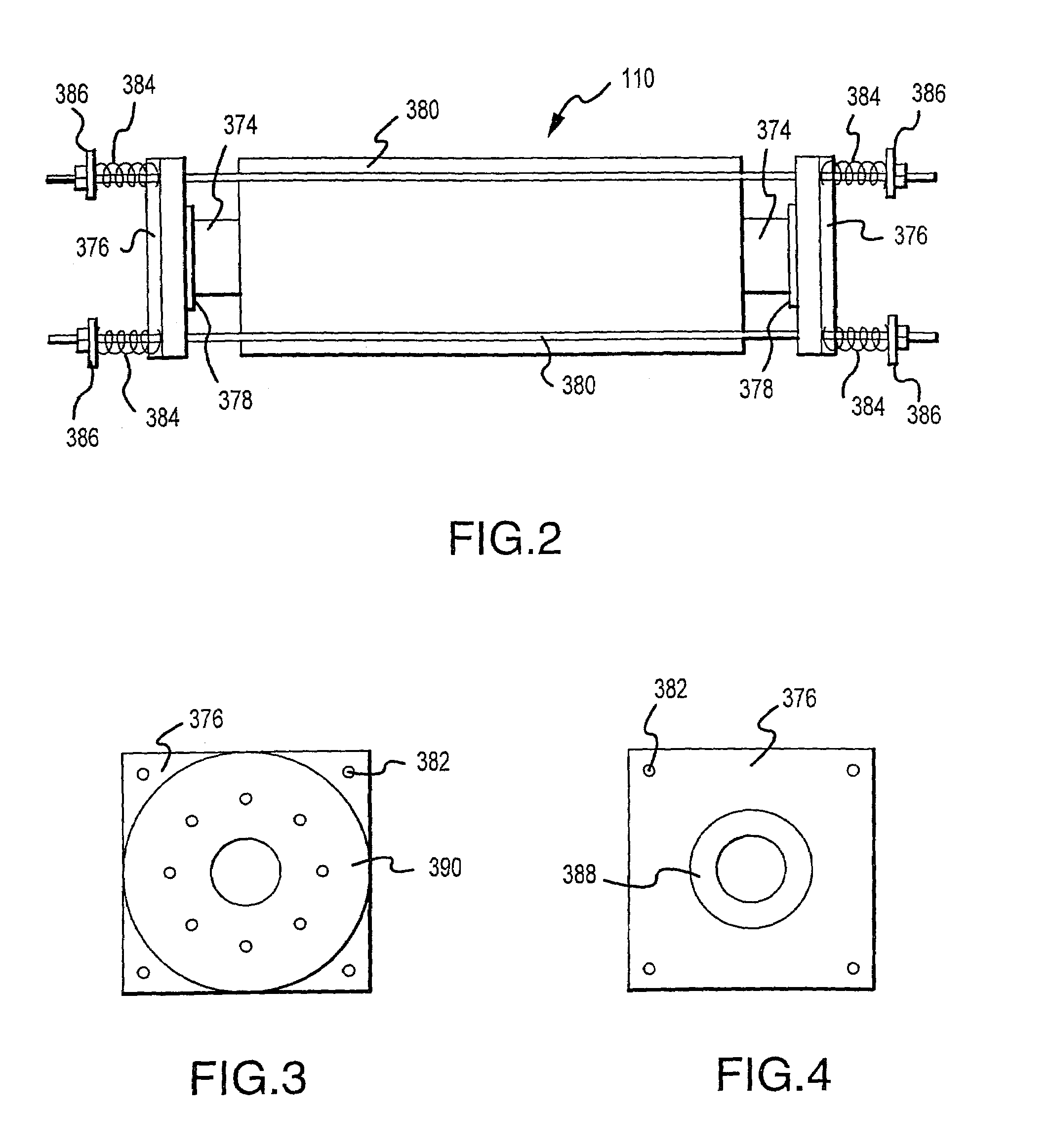

Coated silver-containing particles, method and apparatus of manufacture, and silver-containing devices made therefrom

InactiveUS20050061107A1Increase loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

Method for Covering Particles, Especially a Battery Electrode Material Particles, and Particles Obtained with Such Method and a Battery Comprising Such Particle

A method for covering particles having a diameter of maximally 60 μm by means of atomic layer deposition, whereby said method comprises the step of fluidizing said particles in a fluidized bed reactor using a first reactant gas comprising a first reactant for substantially completely covering said particles with a monolayer of said first reactant.

Owner:PNEUMATICOAT TECH LLC

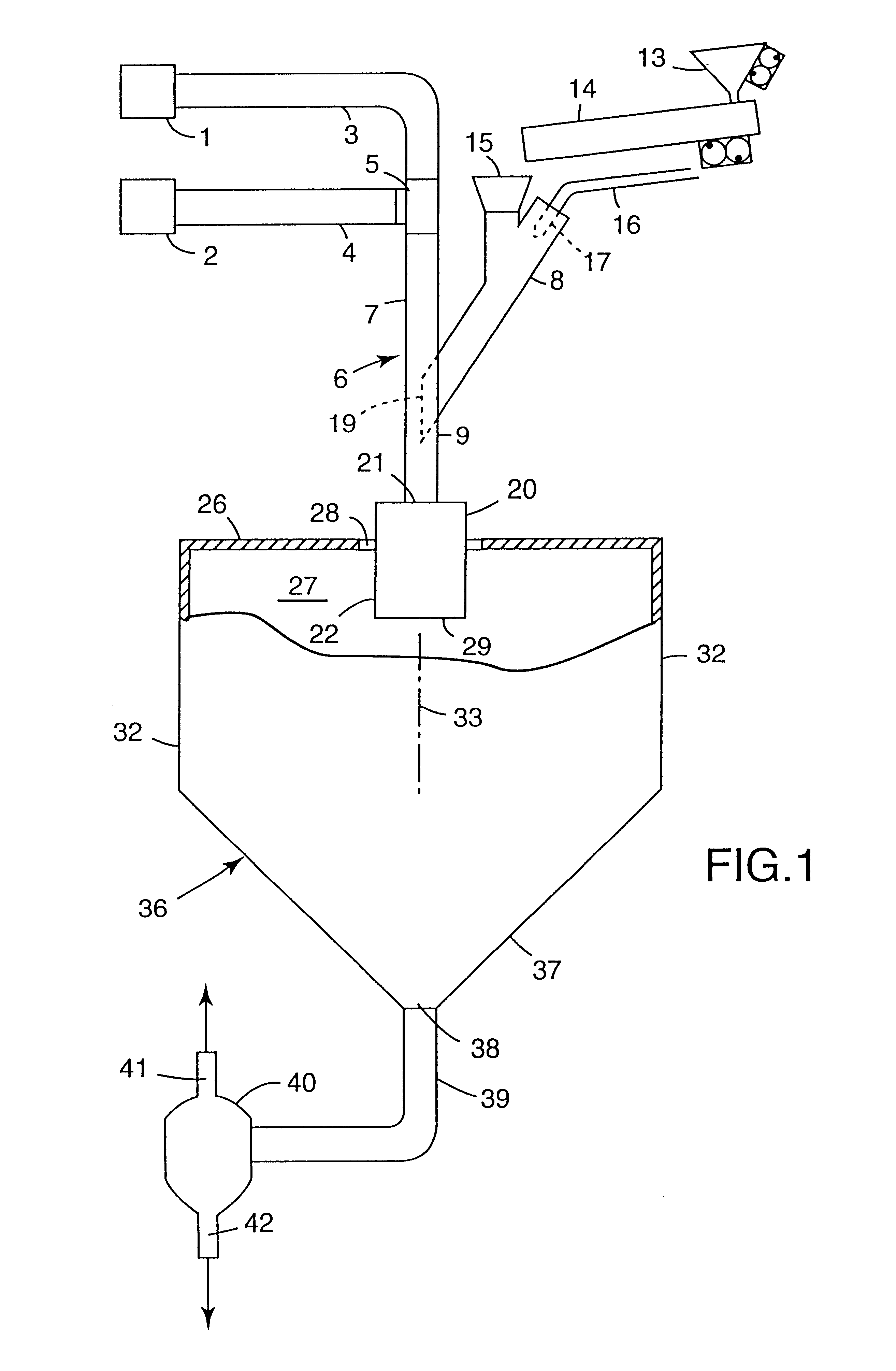

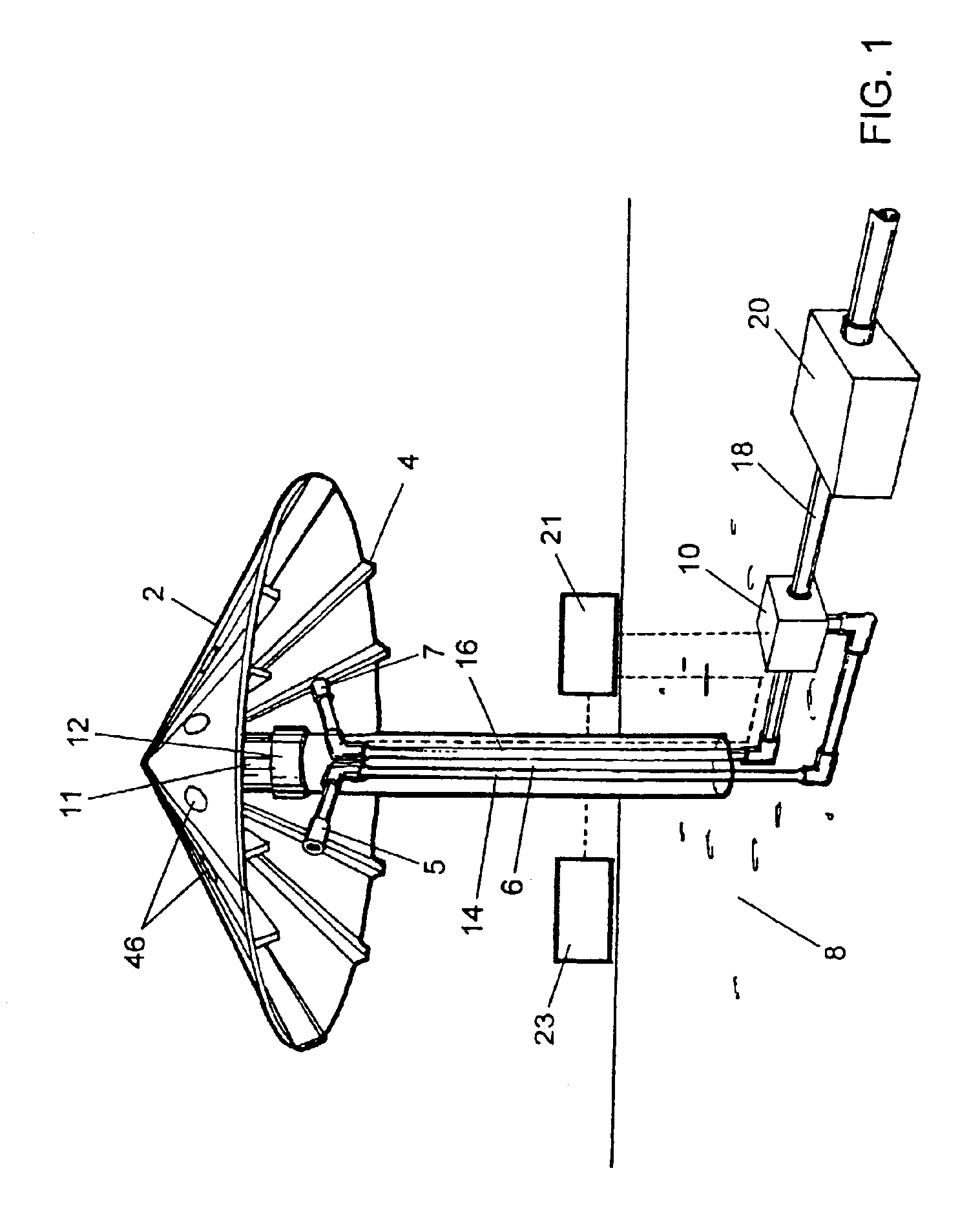

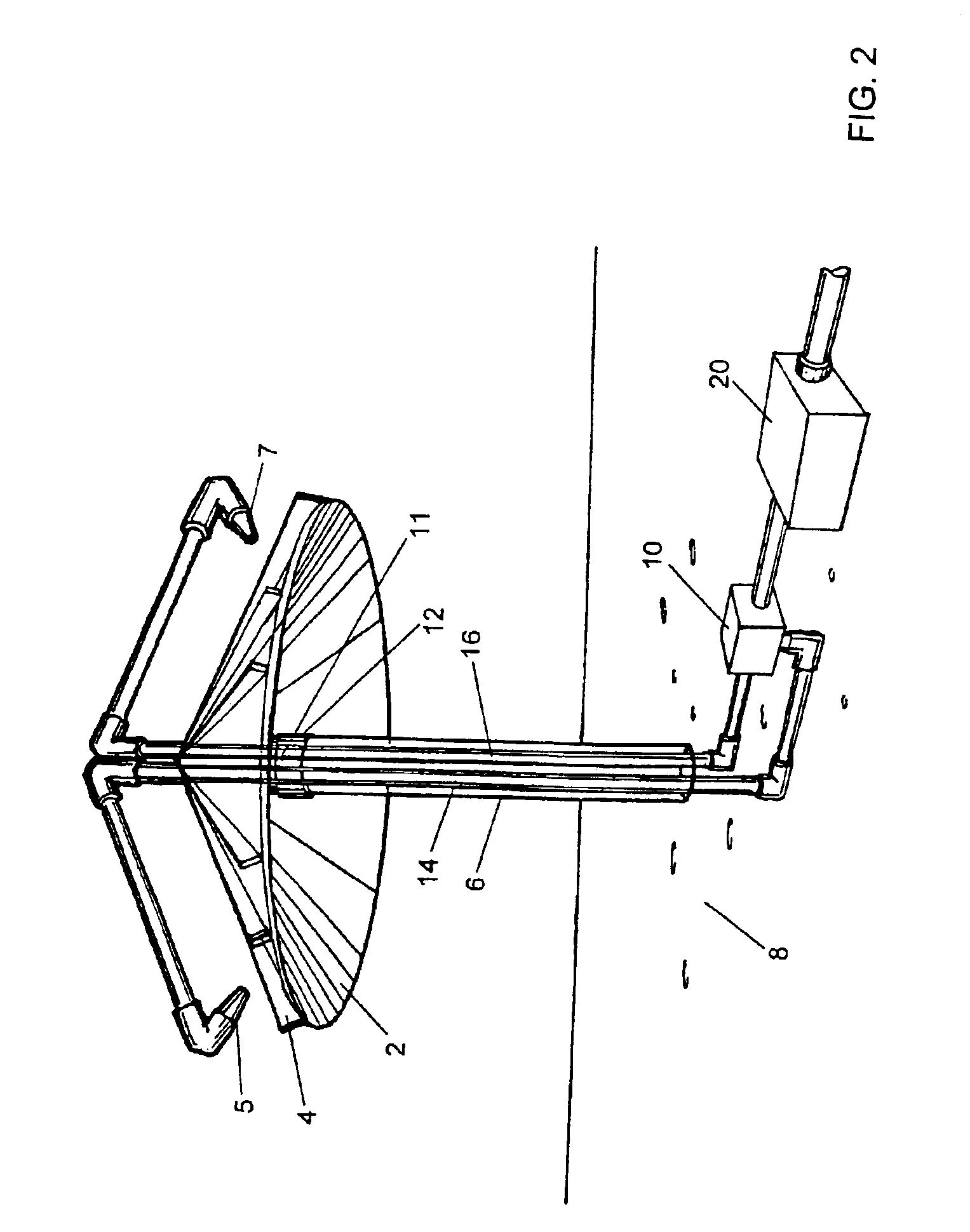

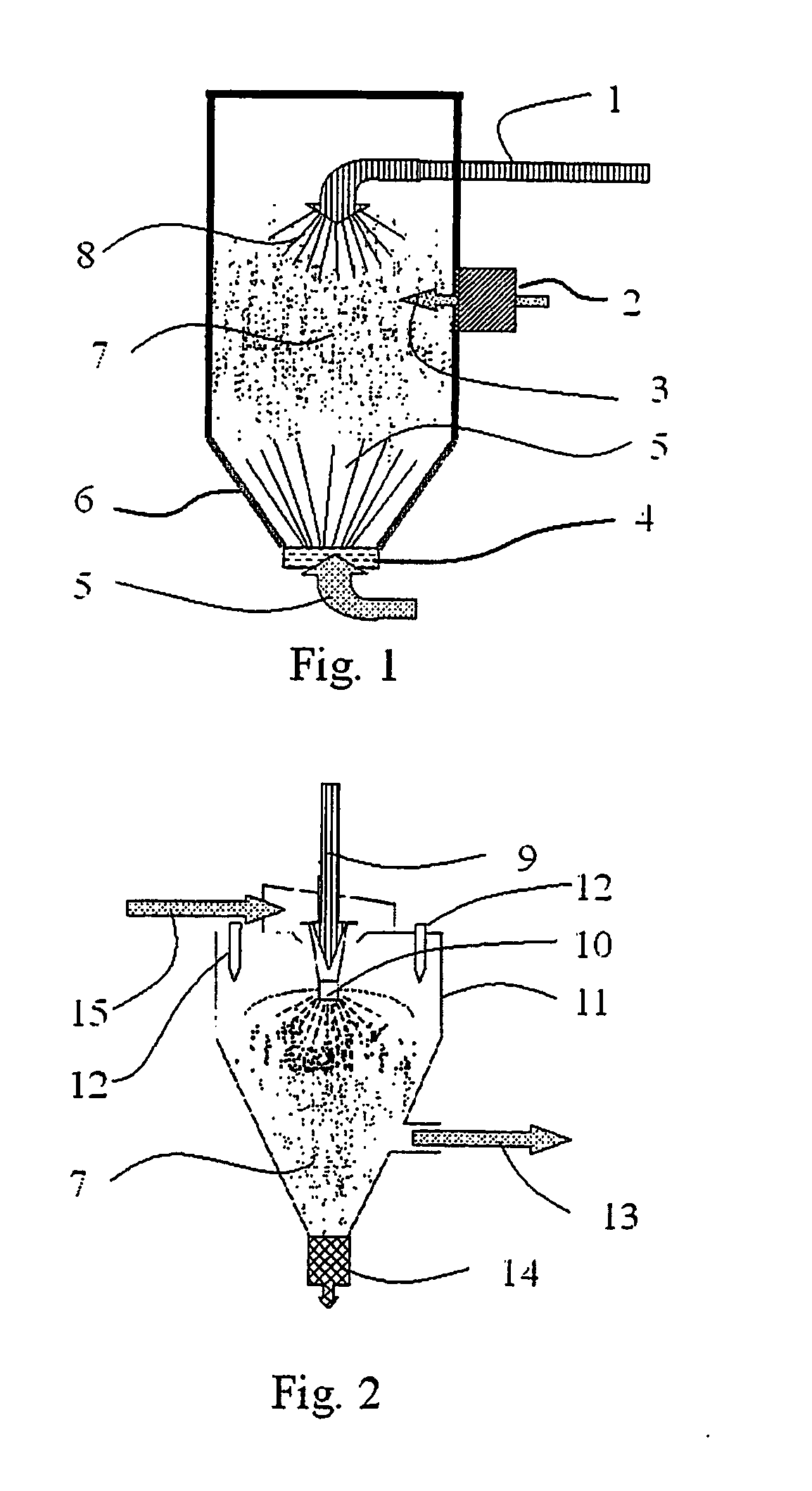

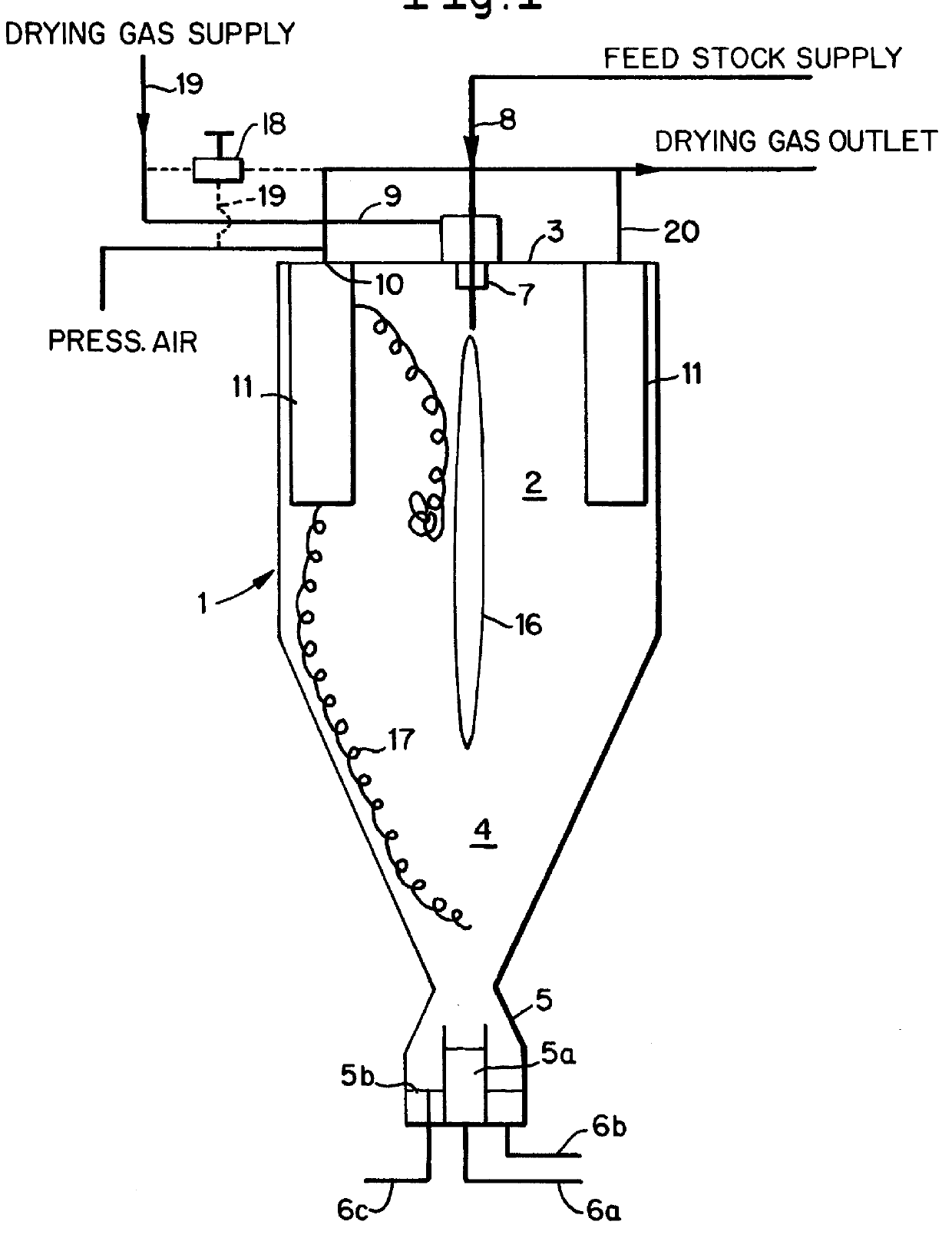

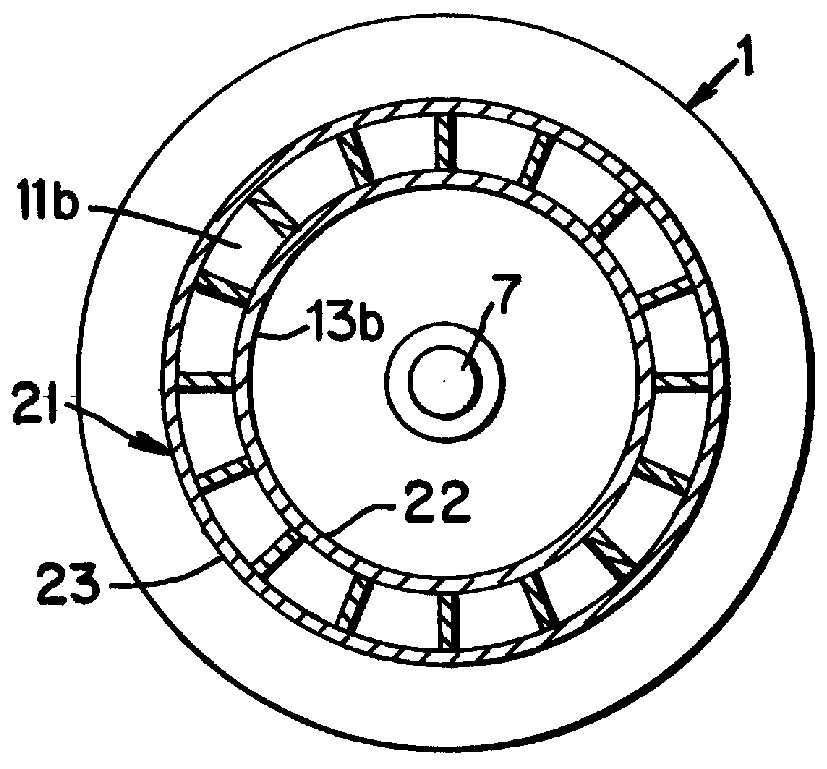

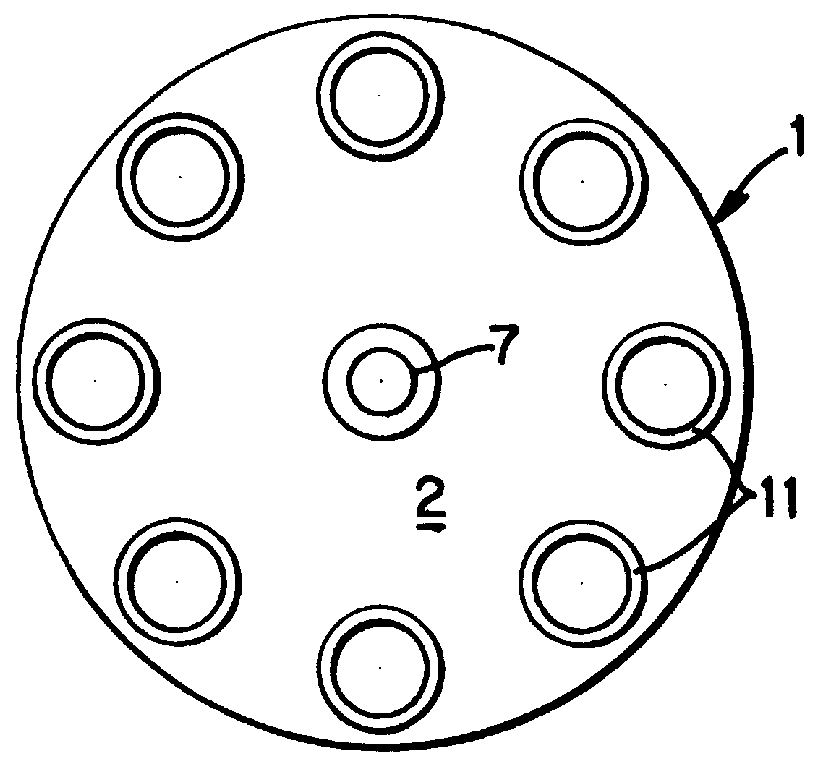

Spray drying method and apparatus and cleaning method for such an apparatus

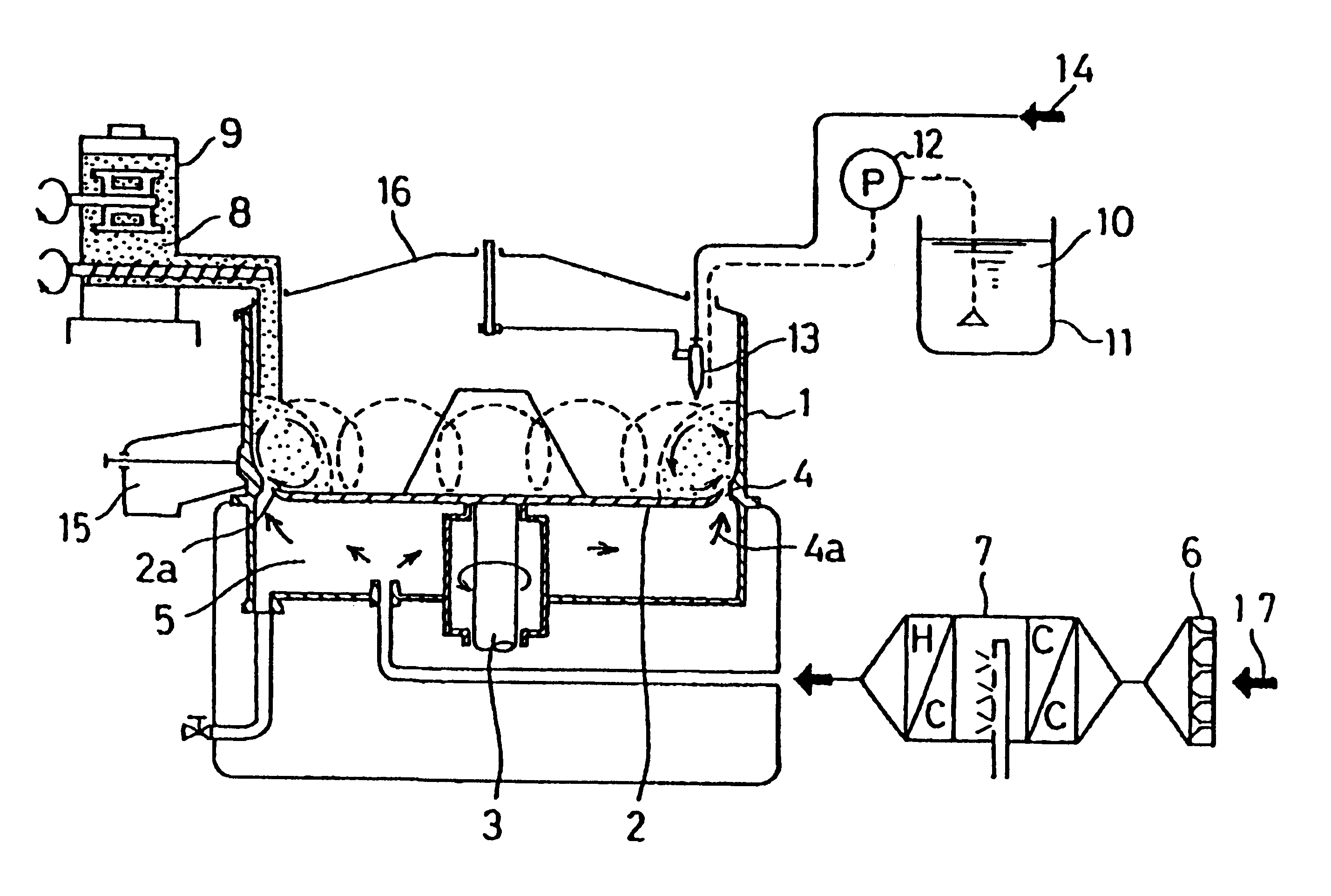

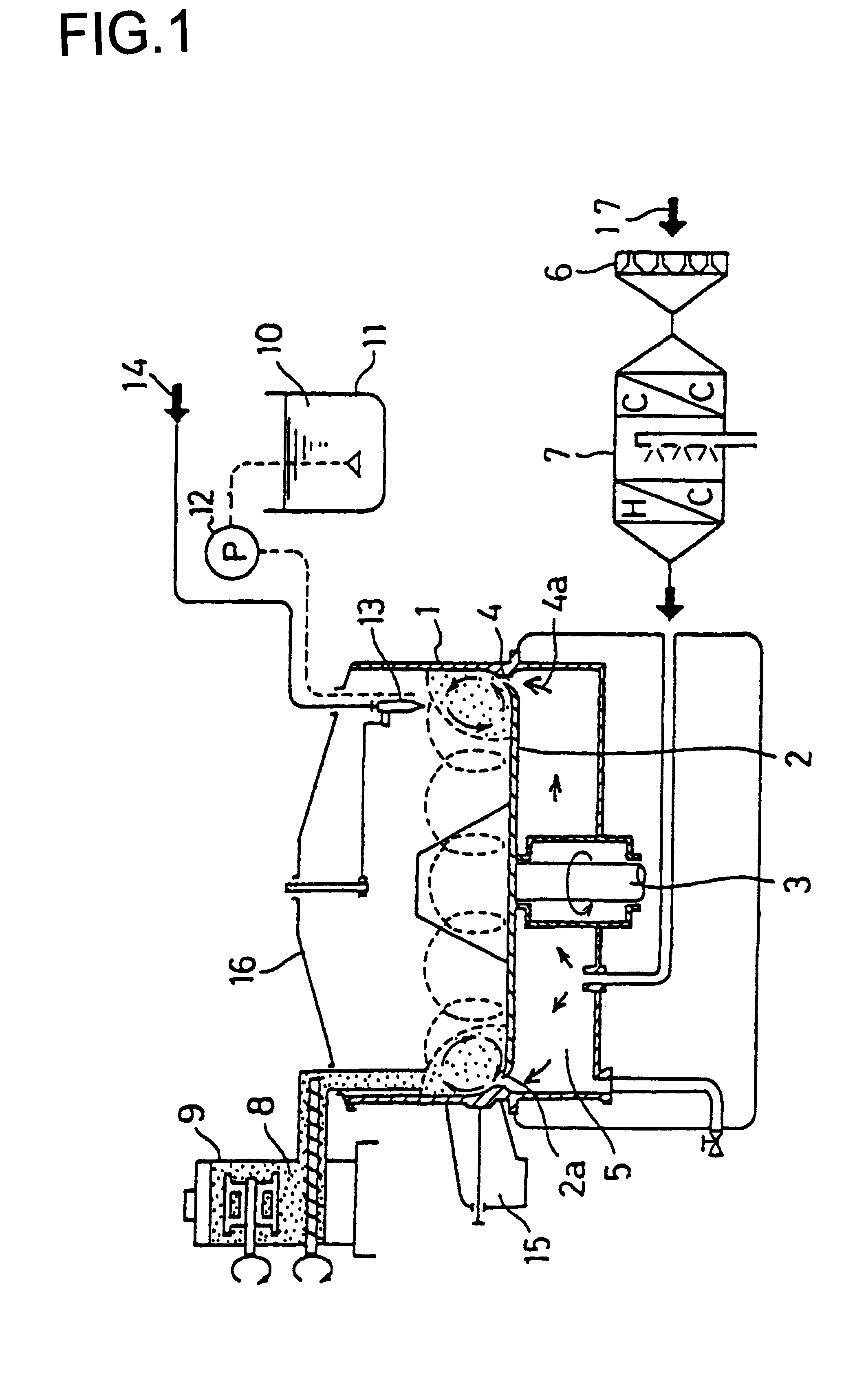

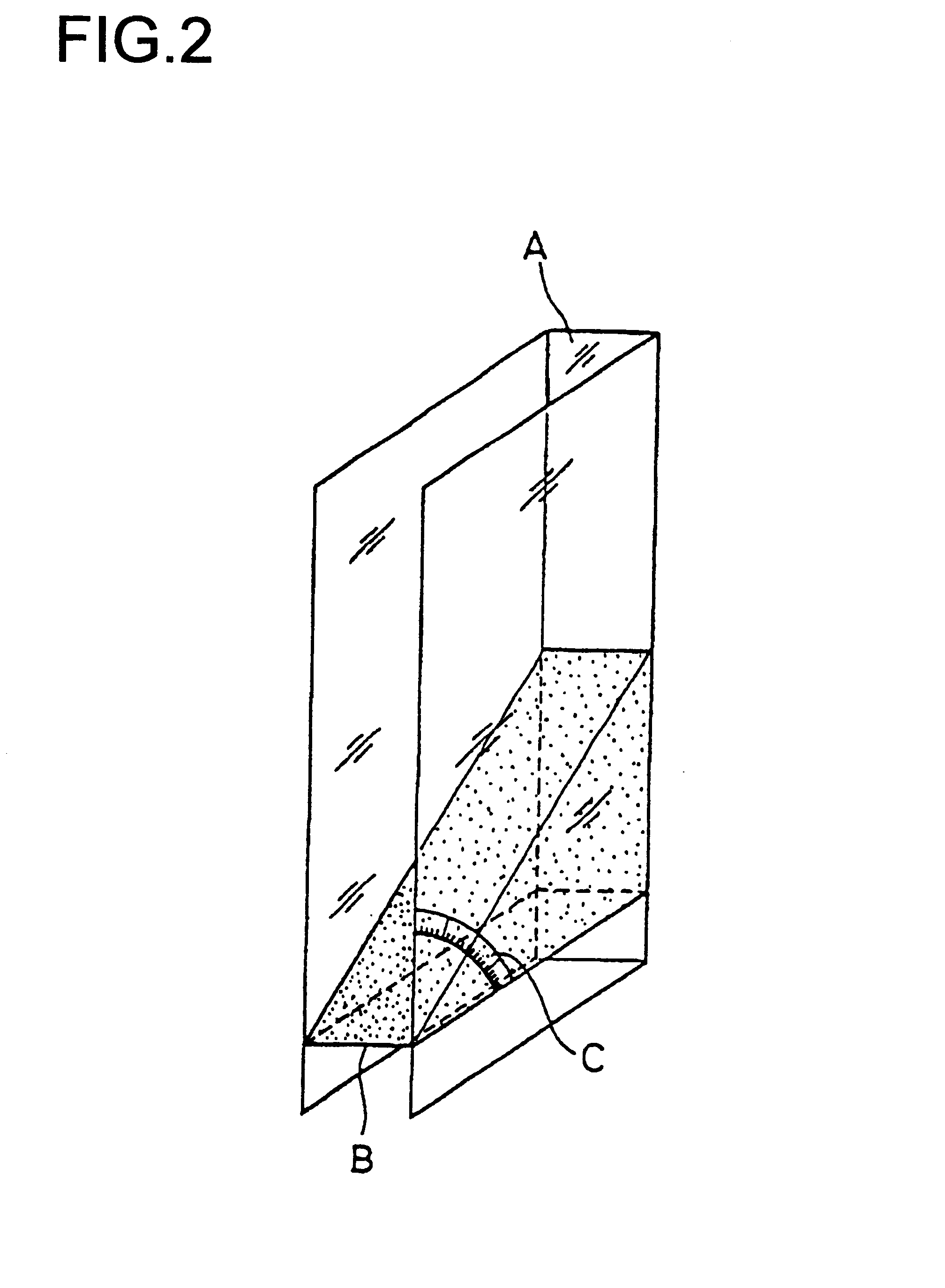

InactiveUS6058624ALess complicated and more compact overall structureEasy to cleanDrying using combination processesDrying solid materials with heatEngineeringCleaning methods

PCT No. PCT / DK97 / 00078 Sec. 371 Date Feb. 25, 1997 Sec. 102(e) Date Feb. 25, 1997 PCT Filed Feb. 20, 1997 PCT Pub. No. WO97 / 14288 PCT Pub. Date Apr. 24, 1997In fluidized spray drying of a feedstock to produce an agglomerate product by means of at least one spraying device (7) arranged in the upper part (2) of a vertically disposed drying chamber (1), in a lower part of which a fluid-bed is accommodated, a drying gas introduced into a processing zone (16) of the chamber (1) is exhausted through an integrated arrangement of filter elements (11) in the upper chamber part (2) to retain and allow agglomeration of the particles carried by the flow of drying gas on the filter elements (11). By intermittent supply of reverse flow gas pulses to the filter elements (11) the retained particles are released and returned to agglomeration zones (16, 17). The drying gas is introduced at a rate producing at the filter walls (13) a flow rate amounting to at least 150 cubic meters per hour per square meter of filter wall surface. In the non-operative condition of the spray drying apparatus the filter elements (11) may be cleaned-in-place by supplying a cleaning liquid to the interior of the elements.

Owner:NIRO

Process for the production of detergent granules

InactiveUS7053038B2Fine granularityPreventing aggregation and cakingInorganic/elemental detergent compounding agentsPigmenting treatmentCarbonationSURFACTANT BLEND

A low shear mechanical granulation process for the production of detergent granules, the process comprising contacting an acid precursor of an anionic surfactant, a non-surfactant acid and a solid carbonated neutralising agent wherein the solid carbonated neutralizing agent has a d3,2 average particle size no more than 90 μm, preferably no more than 80 μm, more preferably no more than 70 μm, still more preferably no more than 60 μm, yet more preferably no more than 50 μm and especially no more than 40 μm.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Nickel powders, methods for producing powders and devices fabricated from same

InactiveUS20050262966A1High crystallinityHigh rateGranule coatingCell electrodesSpherical morphologyMetal powder

Nickel powder batches and methods for producing nickel powder batches. The powder batches include particles having a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the nickel metal powders.

Owner:CABOT CORP

Process for the production of detergent granules

InactiveUS7018972B2Inorganic/elemental detergent compounding agentsPigmenting treatmentSolid componentOrganic chemistry

A process for the preparation of detergent granules, the process comprising:(i) a first step of admixing in a mechanical granulator, a solid component and a first liquid binder, to produce a powder; and(ii) a second step of admixing in a low shear granulator, the powder produced in step (i), and a second liquid binder, to produce the detergent granules;the second liquid binder having a different composition from the first liquid binder and the weight ratio of the first liquid binder to the second liquid binder being from 15:1 to 1:1, preferably from 10:1 to 1:1, more preferably from 5:1 to 1:1, most preferably from 3:1 to 2:1.

Owner:HENKEL IP & HOLDING GMBH

Method for making a film from silver-containing particles

InactiveUS7004994B2High rateIncrease loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

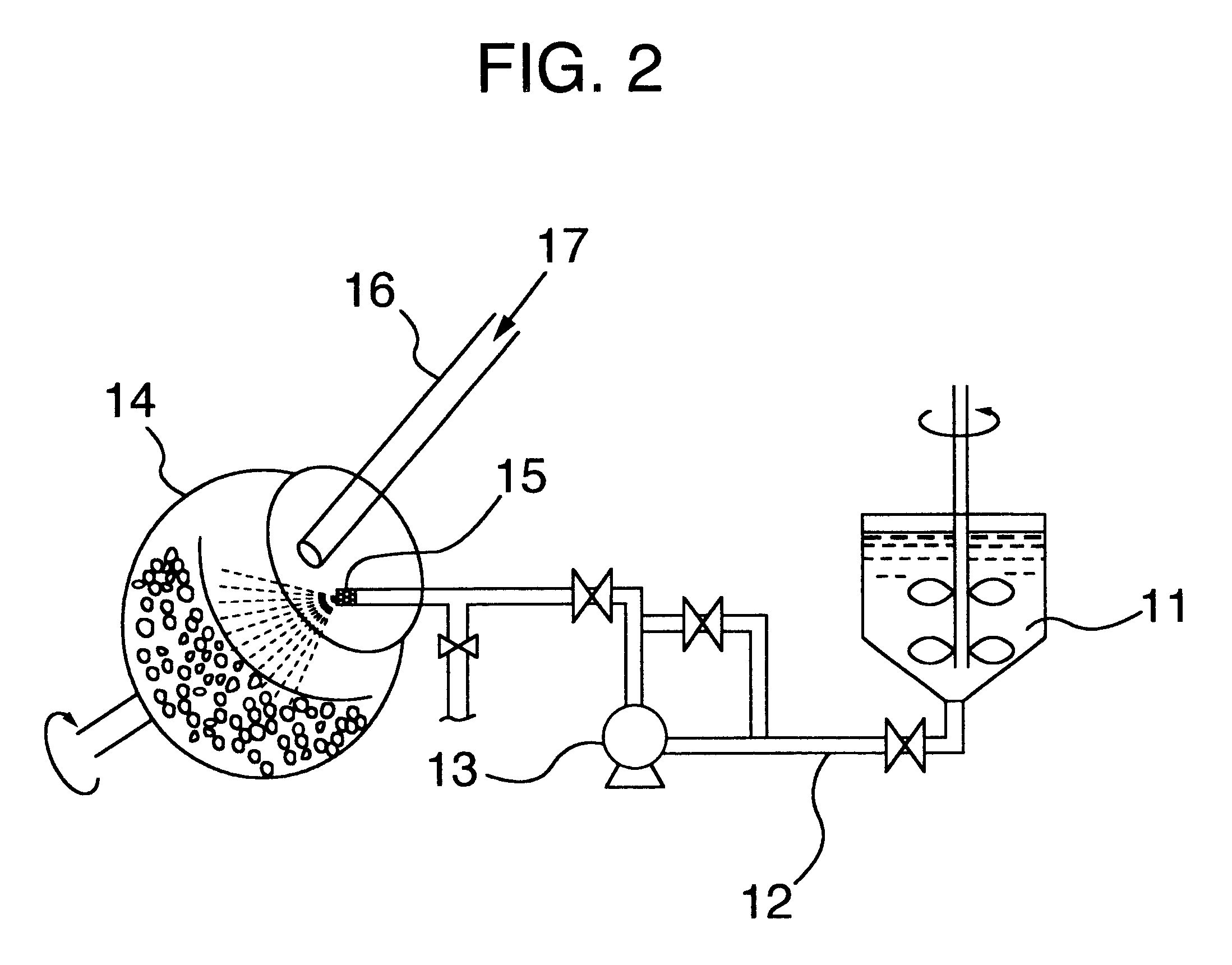

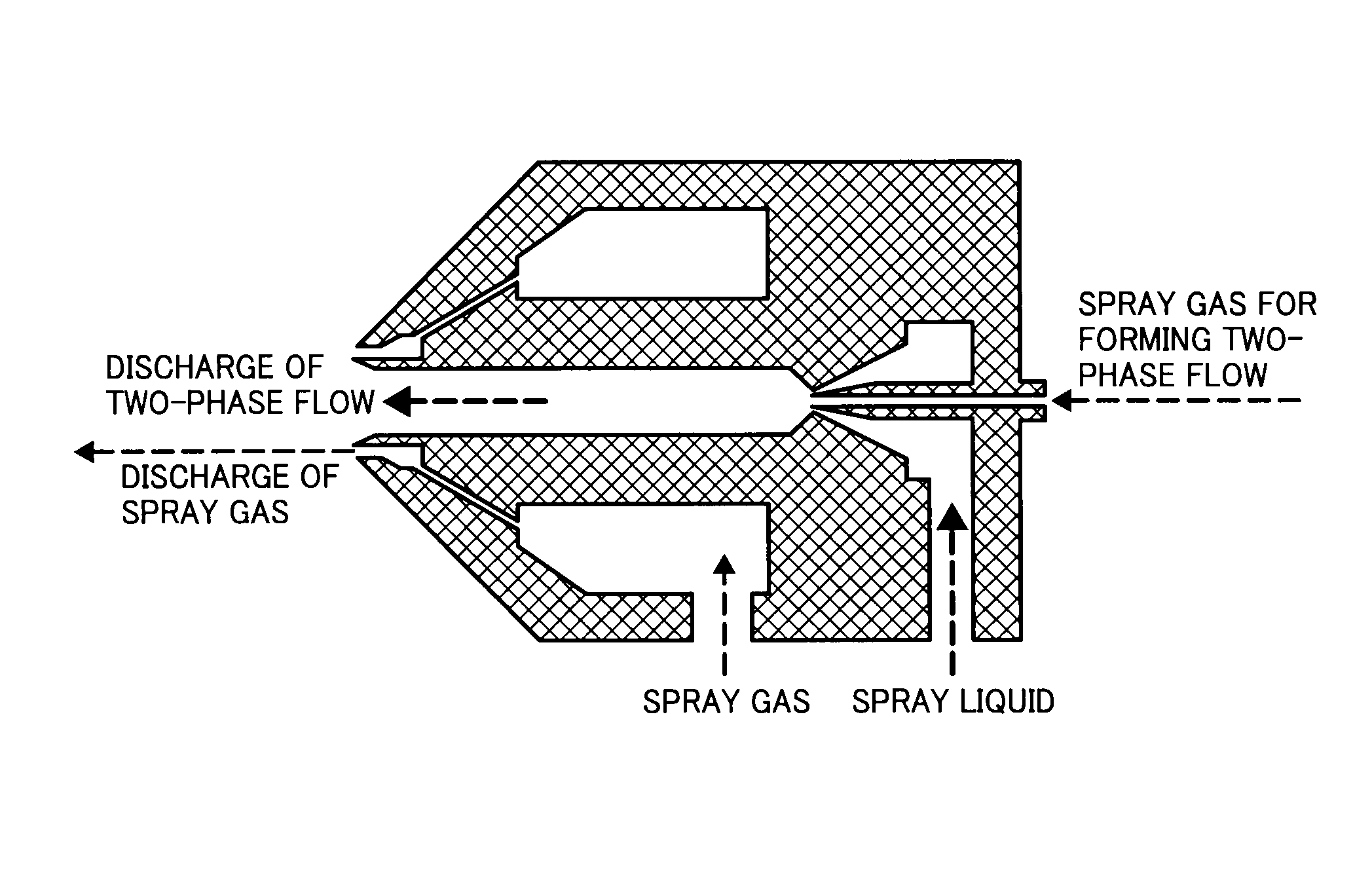

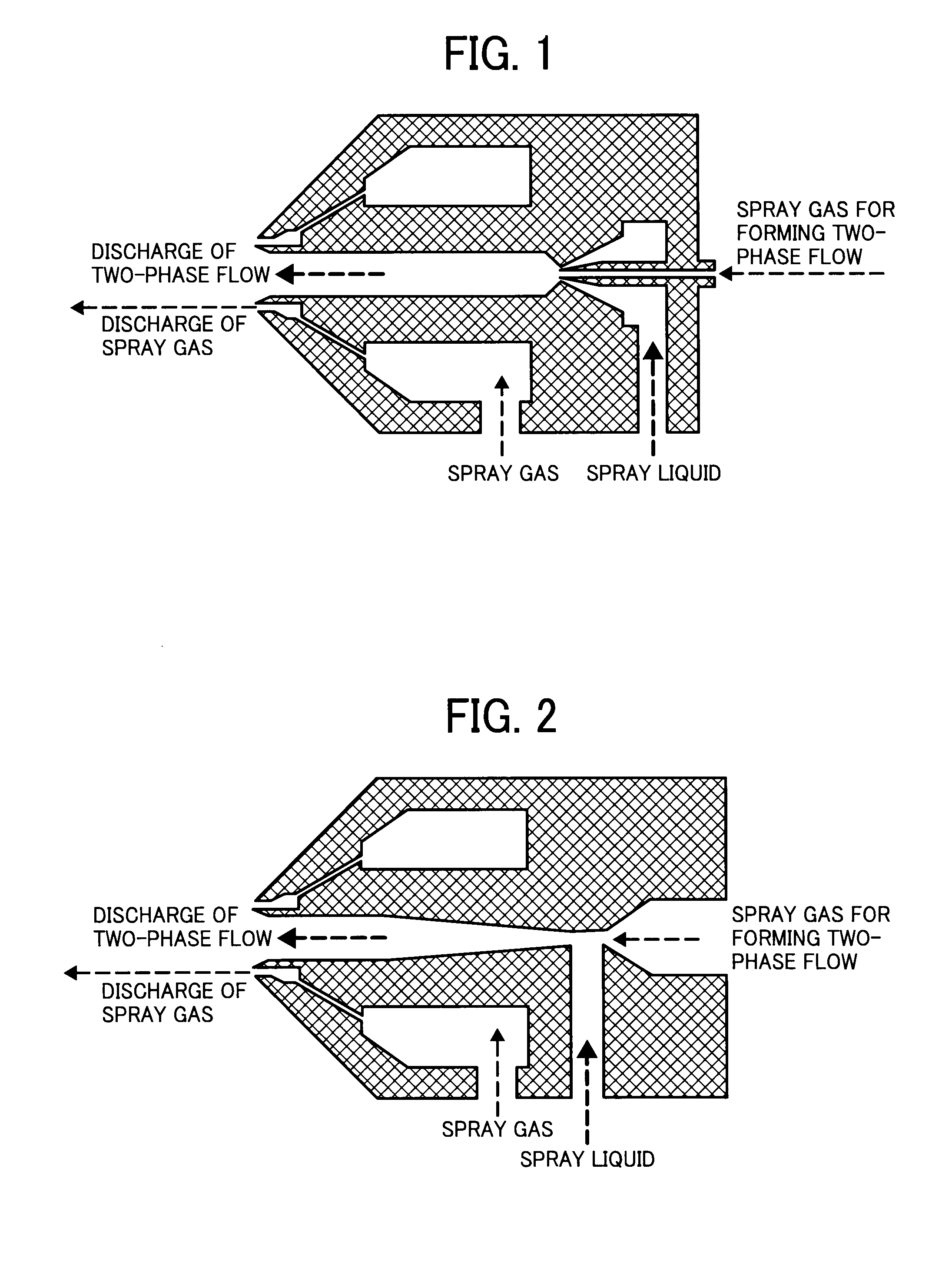

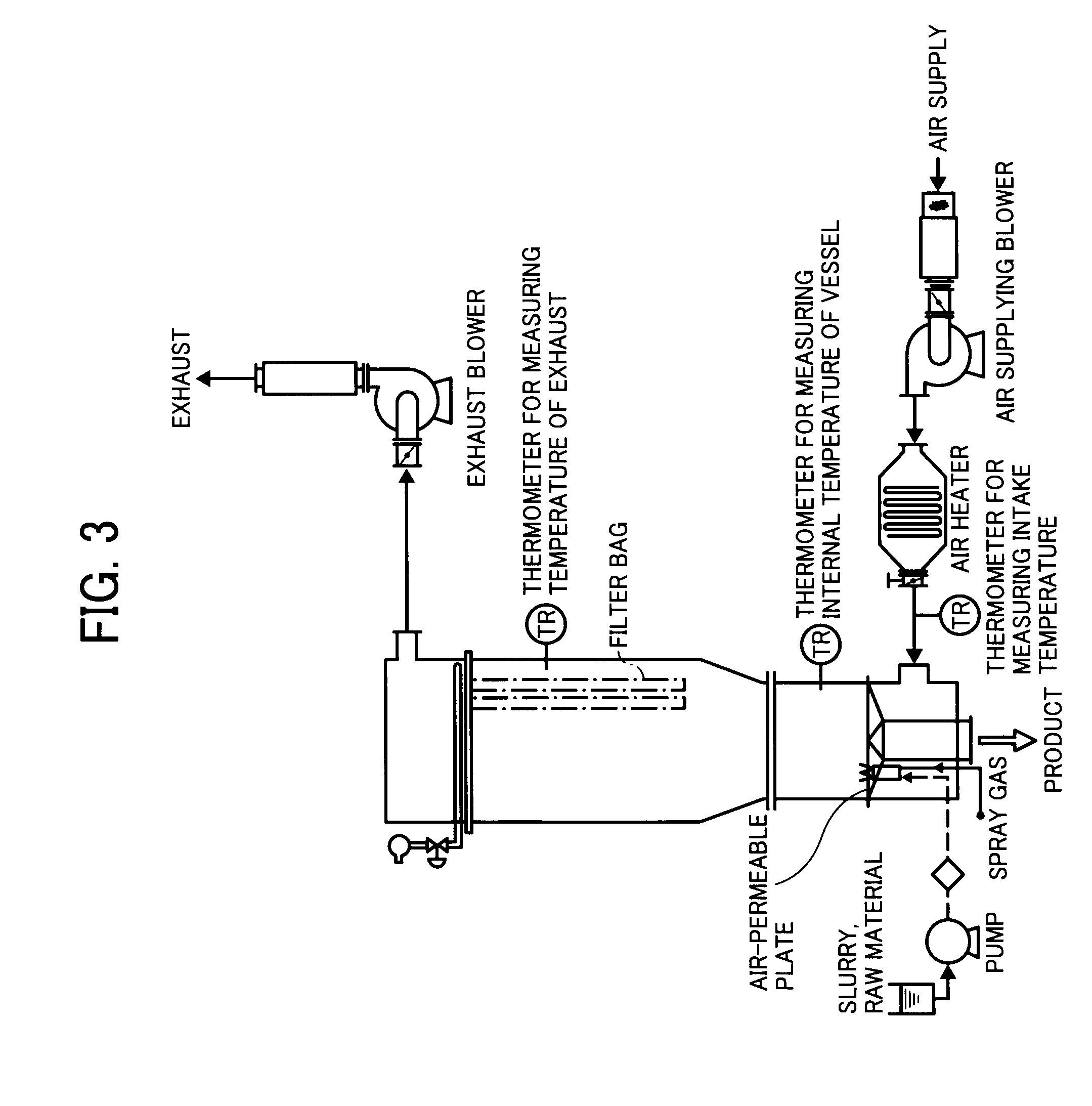

Method and device for coating particles, and carrier for use in developer

A method for coating particles with a coating liquid including supplying airflow to fluidize the particles; mixing the coating liquid with a spray gas in a two-fluid spray nozzle to form a two-phase flow; and atomizing the two-phase flow with the spray gas to spray a mist of the coating liquid upon the particles. A coating device including a vessel; a fluidizing device configured to supply airflow to fluidize a powder in the vessel; and a spray nozzle configured to mix the coating liquid with a spray gas to form a two-phase flow, and to atomize the two-phase flow with the spray gas to spray a mist of the coating liquid. A particulate carrier for use in electrophotographic developer including particles of a core material and a cover layer thereon and prepared by the coating method mentioned above.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com