Water cyclone with improved base pipe and overflows structure

A technology for hydrocyclones and overflow pipes, which is applied in the direction of swirl devices and devices in which the axial direction of the swirl can be reversed, etc., which can solve the problem of reducing the space under the cone of the cyclone and increasing the energy consumption of the cyclone , Reduce the separation efficiency of the cyclone, etc., to achieve the effects of reducing energy consumption, increasing the effective working space, and improving separation efficiency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention can be further understood through the following examples, but the content of the present invention cannot be limited.

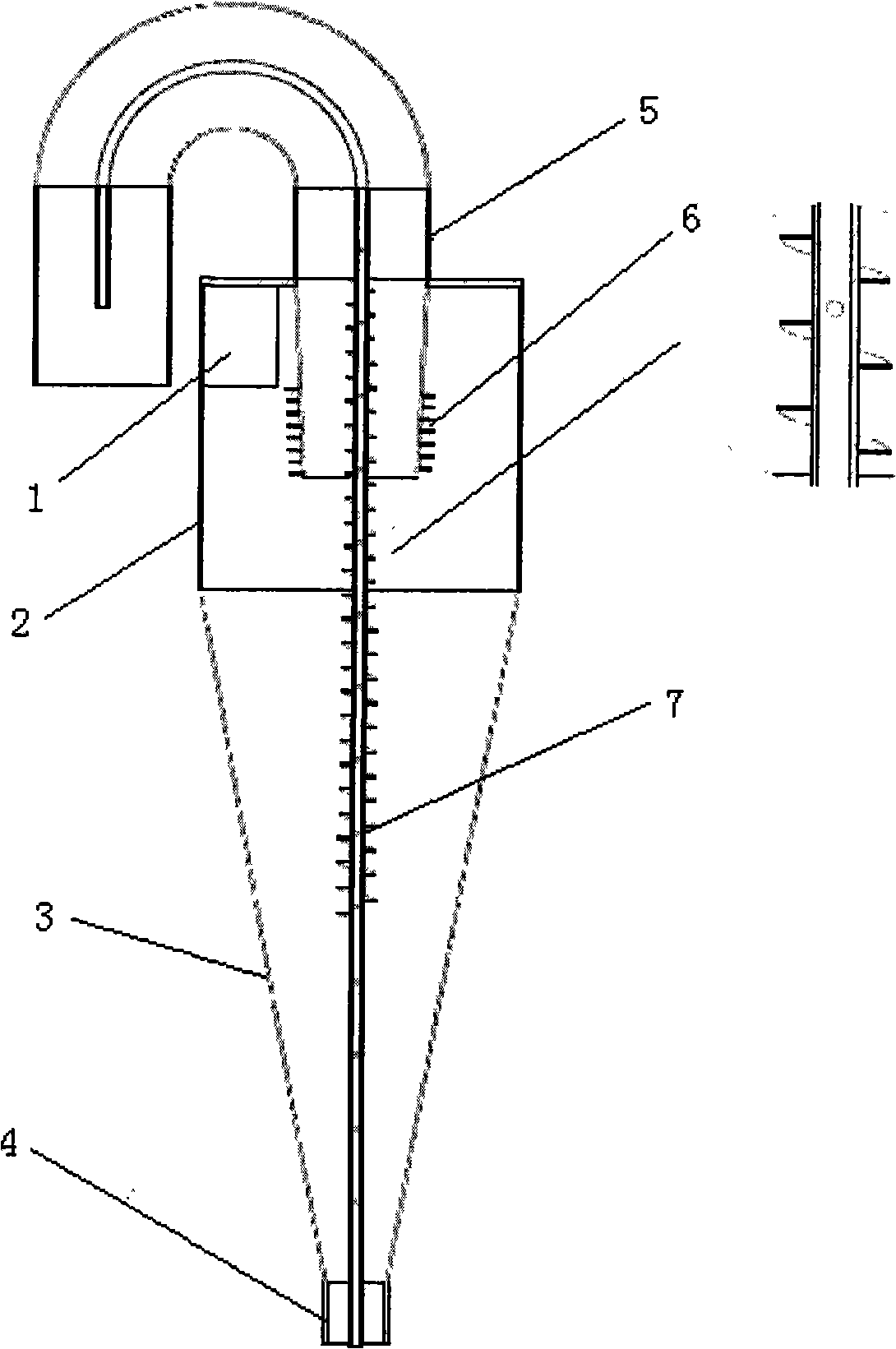

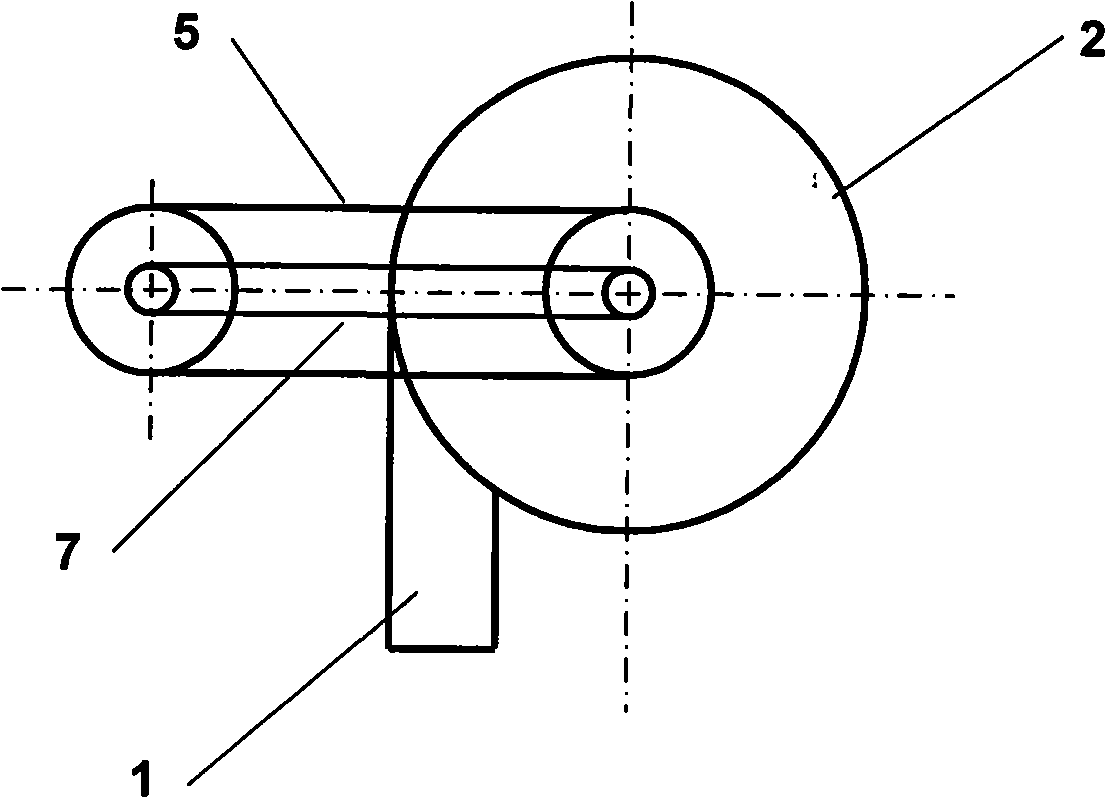

[0031] as attached figure 1 and 2 As shown, the utility cyclone consists of a feed pipe 1, a cylindrical section 2 of the cyclone, a conical section 3 of the cyclone, an underflow pipe 4, an overflow pipe 5, a spiral fin 6 at the lower part of the overflow pipe, The central column with the helical guide vanes is composed of 7. The central column is a hollow pipe with several small exhaust holes on it. The diameter of the exhaust holes can be 3 to 5 mm for small cyclones and about 5 to 20 in number. The diameter of exhaust holes for large cyclones , can be 5~10mm, and the number can be about 10~50. So that the air column precipitated during the swirl operation can enter the center pipe and be taken away by the negative pressure generated by the flow rate of the overflow liquid discharged from the overflow pipe. Too many vent h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com