Numerically-controlled machine tool lubricant and preparation method thereof

A CNC machine tool and lubricant technology, applied in the field of lubricating oil, can solve the problems that the effect of lubricating oil cannot be achieved as expected, the price of diamond nanoparticles is expensive, and the cost of lubricating oil preparation is increased, so as to achieve good anti-oxidation effect and reduce friction performance , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

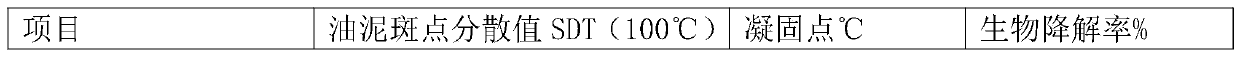

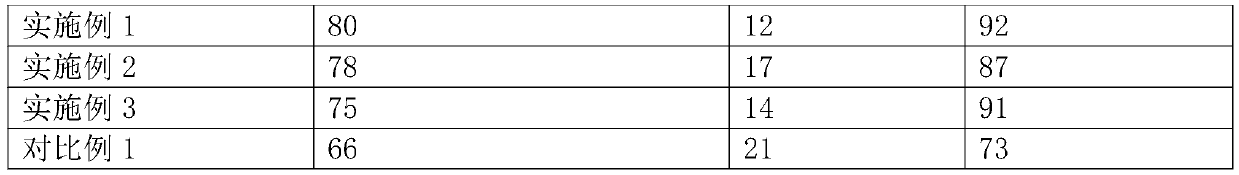

Examples

Embodiment 1

[0021] A lubricant for CNC machine tools, mainly composed of the following raw materials in weight percentage: 10% oxygen-containing organic compound, 5% oxidized polyethylene, 5% acrylic acid, 2% vulcanized lard, 3% extruded anti-wear agent, rust inhibitor 2%, dispersant 4%, nano particle composition 0.002%, and the rest is base oil for lubricating oil.

[0022] Wherein, the nanoparticle composition is compounded by nanoscale cobalt powder and nanoscale rhodium powder according to a weight ratio of 4:0.1; the extrusion antiwear agent is vulcanized whale oil; the rust inhibitor is petroleum sulfonic acid Sodium; the dispersant is compounded from polyoxyethylene alkyl ether, polyoxyethylene alkyl ether phosphate, sorbitan trioleate and paraffin wax in a weight ratio of 2:2:1:5.

[0023] The preparation method of the numerical control machine tool lubricant of the present embodiment comprises following preparation steps:

[0024] (1) Weigh nano-scale cobalt powder and nano-scal...

Embodiment 2

[0030] A lubricant for numerically controlled machine tools, mainly composed of the following raw materials in weight percent: 5% oxygen-containing organic compound, 2% oxidized polyethylene, 2% acrylic acid, 1% vulcanized lard, 1% extruded anti-wear agent, antirust agent 1%, dispersant 2%, nano particle composition 0.001%, and the rest is base oil for lubricating oil.

[0031] Wherein, the nanoparticle composition is compounded by nanoscale cobalt powder and nanoscale rhodium powder according to a weight ratio of 3:0.1; the extrusion antiwear agent is chlorotrifluoroethylene telomer; the rust inhibitor It is benzotriazole; the dispersant is compounded by polyoxyethylene alkyl ether, polyoxyethylene alkyl ether phosphate, sorbitan trioleate and paraffin wax in a weight ratio of 1:3:3:5 made.

[0032] The preparation method of the numerical control machine tool lubricant of the present embodiment comprises following preparation steps:

[0033] (1) Weigh nano-scale cobalt powd...

Embodiment 3

[0039] A lubricant for CNC machine tools, mainly composed of the following raw materials in weight percentage: 15% oxygen-containing organic compound, 8% oxidized polyethylene, 8% acrylic acid, 3% vulcanized lard, 5% extruded anti-wear agent, antirust agent 5%, dispersant 6%, nano particle composition 0.005%, and the balance is base oil for lubricating oil.

[0040] Wherein, the nanoparticle composition is compounded by nanoscale cobalt powder and nanoscale rhodium powder according to a weight ratio of 5:0.1; the extrusion antiwear agent is tricresyl phosphate; the rust inhibitor is polyethylene Diol dioleate; the dispersant is compounded by polyoxyethylene alkyl ether, polyoxyethylene alkyl ether phosphate, sorbitan trioleate and paraffin in a weight ratio of 2:1:1:5 Matched.

[0041] The preparation method of the numerical control machine tool lubricant of the present embodiment comprises following preparation steps:

[0042] (1) Weigh nano-scale cobalt powder and nano-sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com