Process for preparing nano polymer chelating agent contg. thioureido

A polymer chelating agent, technology containing thiourea group, applied in the field of preparation of nanometer polymer chelating agent containing thiourea group, to achieve high adsorption capacity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

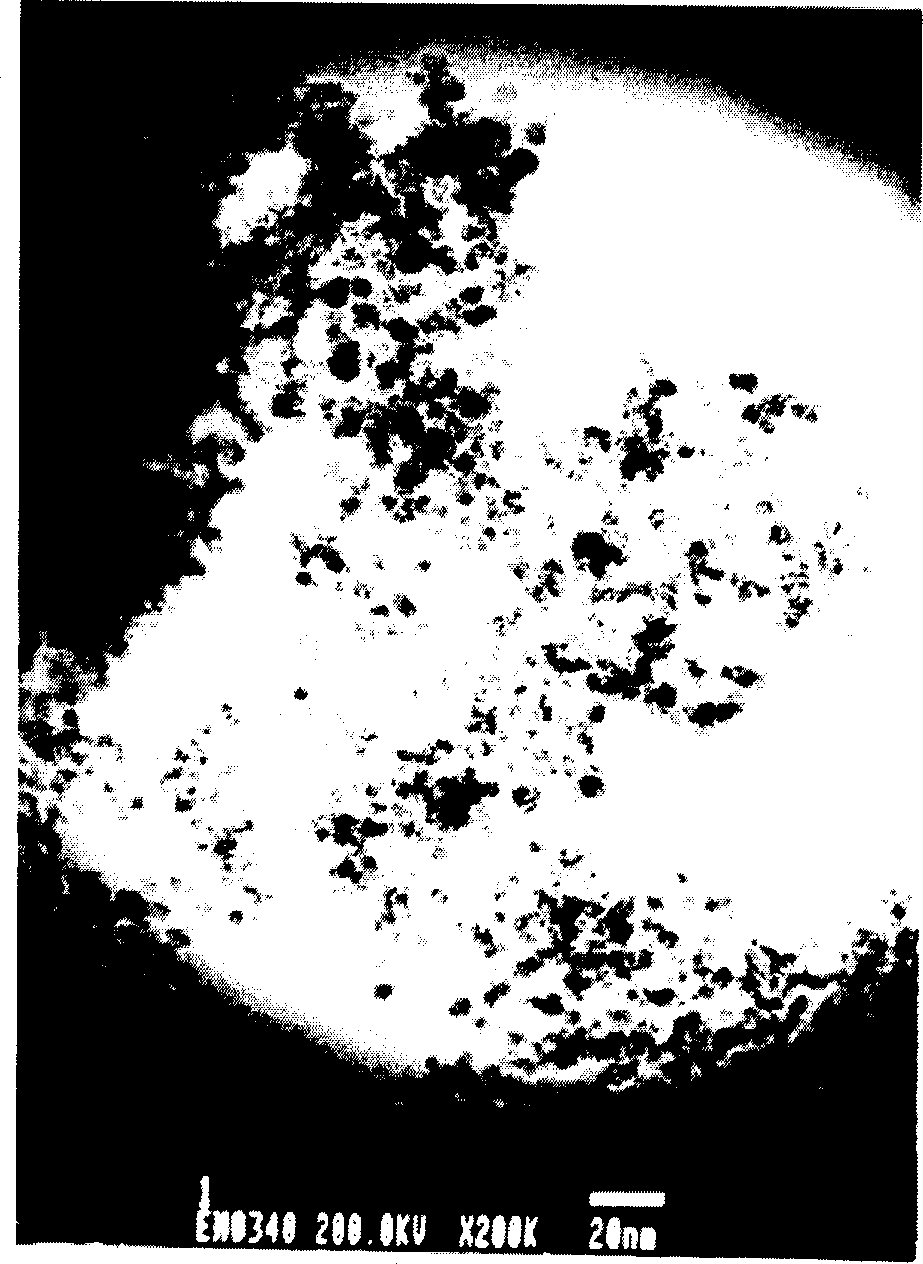

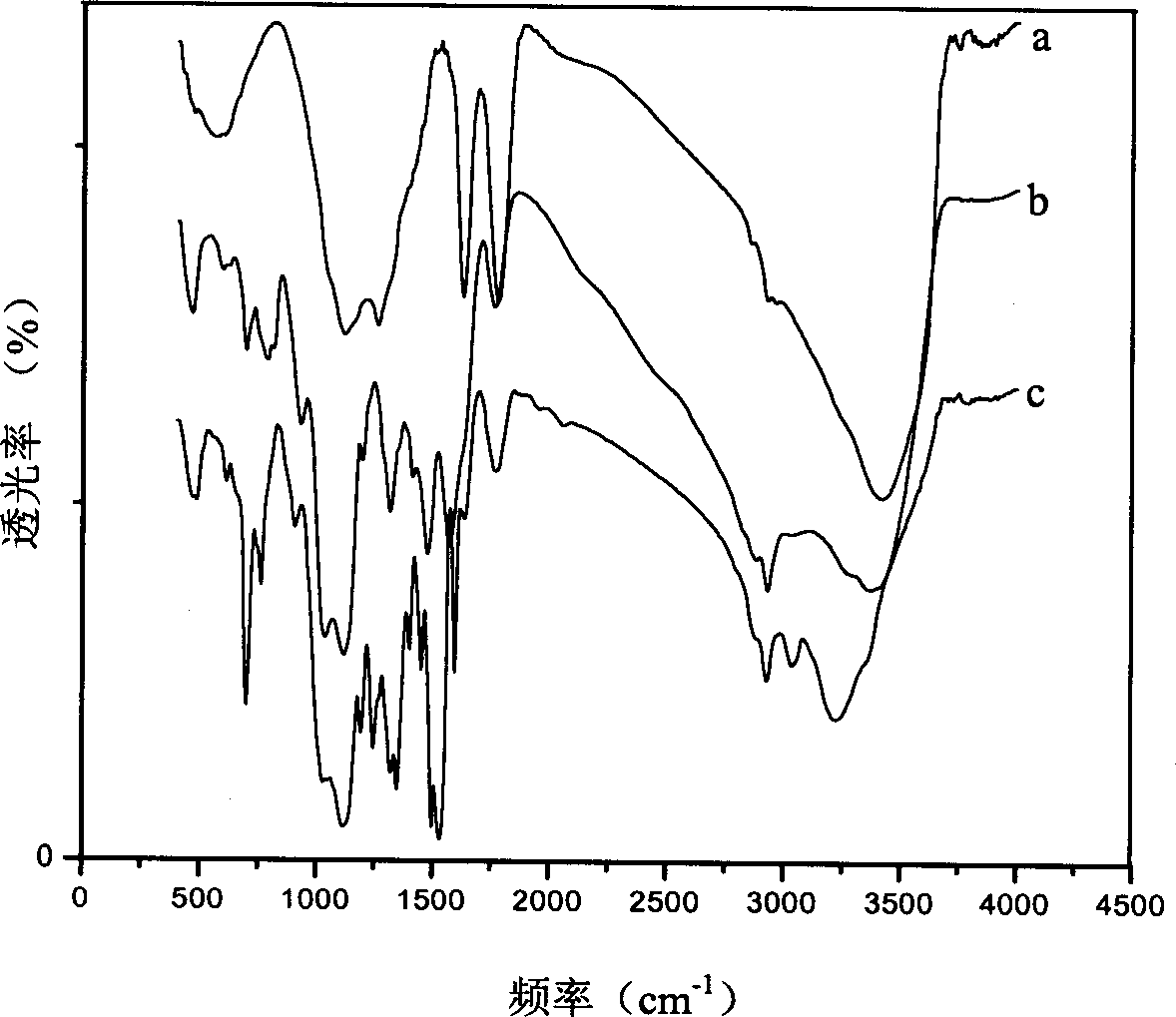

[0015] Ultrasonic dispersion of 0.1g of nano-diamond particles in 5 mL of toluene solution of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane with a concentration of 99.0%wt, stirred for 24 hours, and centrifugal separation of nano-diamonds The particles were washed successively with toluene and deionized water, and vacuum-dried at a constant temperature of 50° C. for 24 hours to obtain nano-diamond particles with ethylenediamino functional groups on the surface.

[0016] Ultrasonically disperse 0.1 g of the above-prepared nano-diamond particles containing ethylenediamino functional groups on the surface in 5 mL of benzene solution containing 15% phenylisothiocyanate, stir and react at 104-106 °C for 2 hours, and centrifuge to separate the nano-diamond particles. The particles are washed successively with benzene and deionized water, and vacuum-dried at a constant temperature of 50° C. for 48 hours to obtain the desired nanometer thiourea-containing polymer chelating agent.

[...

Embodiment 2

[0019] Ultrasonic dispersion of 0.1g of nano-diamond particles in 50mL of 0.5%wt N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane in acetone solution, stirred for 24 hours, and centrifugal separation of nano-diamonds The particles were washed sequentially with acetone and deionized water, and vacuum-dried at a constant temperature of 50° C. for 36 hours to obtain nano-diamond particles with ethylenediamino functional groups on the surface.

[0020] Ultrasonic disperse 0.1 g of the nano-diamond particles containing ethylenediamino functional groups on the surface prepared above in 20 mL of toluene solution containing 5% phenyl isothiocyanate, stir and react at 104-106 °C for 4 hours, and centrifuge to separate the nano-diamond particles. The particles are washed successively with toluene and deionized water, and vacuum-dried at a constant temperature of 50° C. for 24 hours to obtain the required nanometer thiourea group-containing polymer chelating agent.

[0021] The functional ...

Embodiment 3

[0023] Ultrasonic dispersion of 0.1g of nano-diamond particles in 50 mL of acetone solution of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane with a concentration of 25%wt, stirred for 24 hours, and centrifugal separation of nano-diamonds The particles were washed successively with acetone and deionized water, and vacuum-dried at a constant temperature of 55° C. for 36 hours to obtain nano-diamond particles with ethylenediamino functional groups on the surface.

[0024] Ultrasonic disperse 0.1 g of the nano-diamond particles containing ethylenediamino functional groups on the surface prepared above in 10 mL of toluene solution containing 5% phenylisothiocyanate, stir and react at 104-106 °C for 8 hours, and centrifuge to separate the nanoparticles , washed with toluene and deionized water in sequence, and vacuum-dried at a constant temperature of 60° C. for 24 hours to obtain the desired nanometer thiourea-containing polymer chelating agent.

[0025] The functional groups on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com