Secondary epitaxy method for preparing high-quality diamond single crystal by adopting nanostructure

A diamond single crystal and nanostructure technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high quality and performance requirements of substrate materials, reduce defects, eliminate impurities, eliminate defects, reduce The effect of defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The secondary epitaxial method for preparing high-quality diamond single crystals using nanostructures, the steps include:

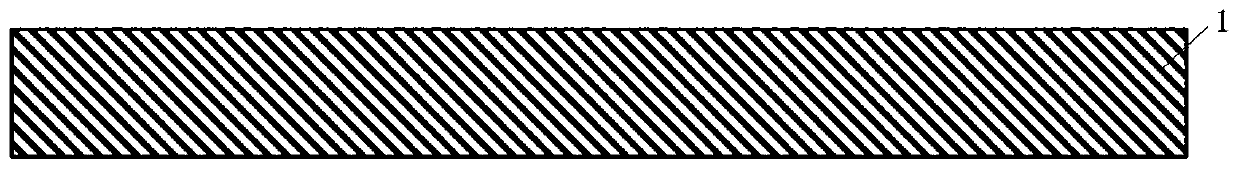

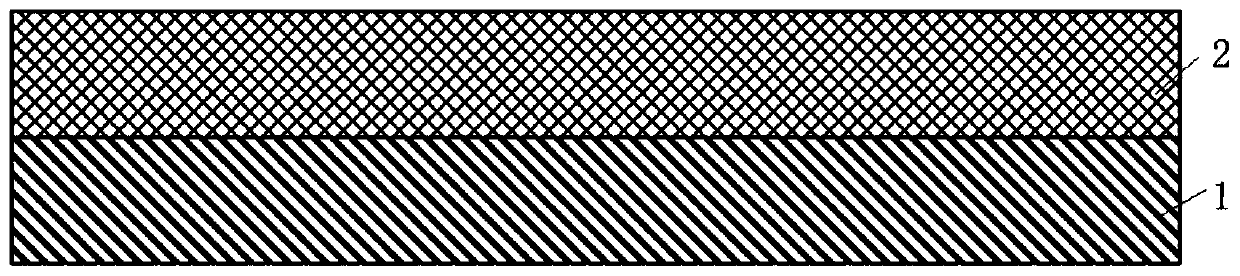

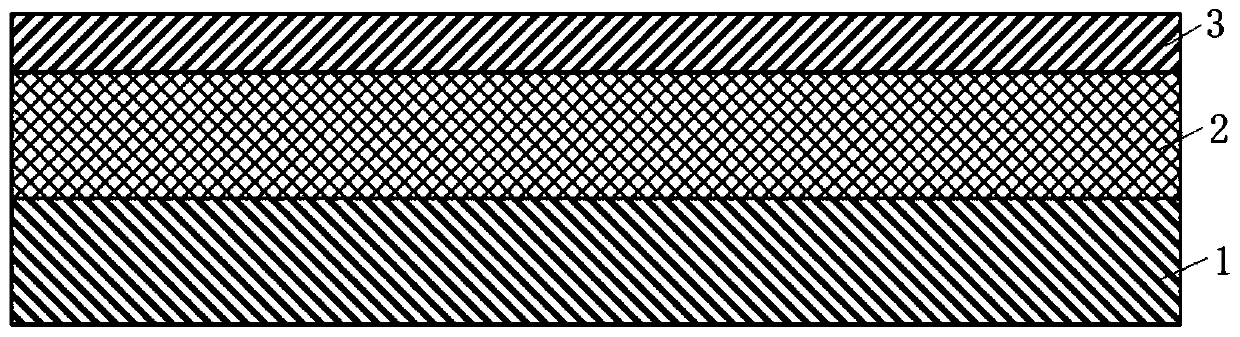

[0043] Step 1, select the octagonal diamond seed crystal 1 prepared by the high temperature and high pressure method as the substrate, such as figure 1 shown.

[0044] Step 2, cleaning the diamond seed crystal: place the single crystal diamond seed crystal in acetone, absolute ethanol, and water in sequence, and ultrasonically clean it for 20 minutes with an ultrasonic power of about 600W to remove organic impurities on the crystal surface, and finally dry it in a vacuum oven to obtain Clean seed crystals.

[0045] Step 3, pretreating the diamond substrate.

[0046] Place the cleaned seed crystal on the molybdenum tray in the MPCVD reaction chamber, and pump the vacuum of the reaction chamber to less than 10 - 6 mbar, the pressure of the reaction chamber is 200mbar, the temperature is 900°C, the microwave power is 3000W, and the flow rate of 2...

Embodiment 2

[0061] The secondary epitaxial method for preparing high-quality diamond single crystals using nanostructures, the steps include:

[0062] In step 1, an octagonal diamond seed crystal prepared by a high temperature and high pressure method is selected as a substrate.

[0063] Step 2, cleaning the diamond seed crystal: place the single crystal diamond seed crystal in acetone, absolute ethanol, and water in sequence, and ultrasonically clean it for 30 minutes with an ultrasonic power of about 500W to remove organic impurities on the crystal surface, and finally dry it in a vacuum oven to obtain Clean seed crystals.

[0064] Step 3, pretreating the diamond substrate.

[0065] Place the cleaned seed crystal on the molybdenum tray in the MPCVD reaction chamber, and pump the vacuum of the reaction chamber to less than 10 - 6 mbar, the pressure of the reaction chamber is 300mbar, the temperature is 1100°C, the microwave power is 3500W, and the flow rate of 350sccm hydrogen gas is ...

Embodiment 3

[0078] The secondary epitaxial method for preparing high-quality diamond single crystals using nanostructures, the steps include:

[0079] In step 1, an octagonal diamond seed crystal prepared by a high temperature and high pressure method is selected as a substrate.

[0080] Step 2, cleaning the diamond seed crystal: place the single crystal diamond seed crystal in acetone, absolute ethanol, and water in sequence, and ultrasonically clean it for 10 minutes with an ultrasonic power of about 100W to remove organic impurities on the crystal surface, and finally dry it in a vacuum oven to obtain Clean seed crystals.

[0081] Step 3, pretreating the diamond substrate.

[0082] Place the cleaned seed crystal on the molybdenum tray in the MPCVD reaction chamber, and pump the vacuum of the reaction chamber to less than 10 - 6 mbar, the pressure of the reaction chamber is 50mbar, the temperature is 600°C, the microwave power is 2400W, and the flow rate of hydrogen gas is 40sccm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com