Method for preparing single-wall carbon nano-tube by employing diamond nano particles

A single-walled carbon nanotube and nanoparticle technology, which is applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as unfavorable single-walled carbon nanotube application and inability to completely remove catalyst particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

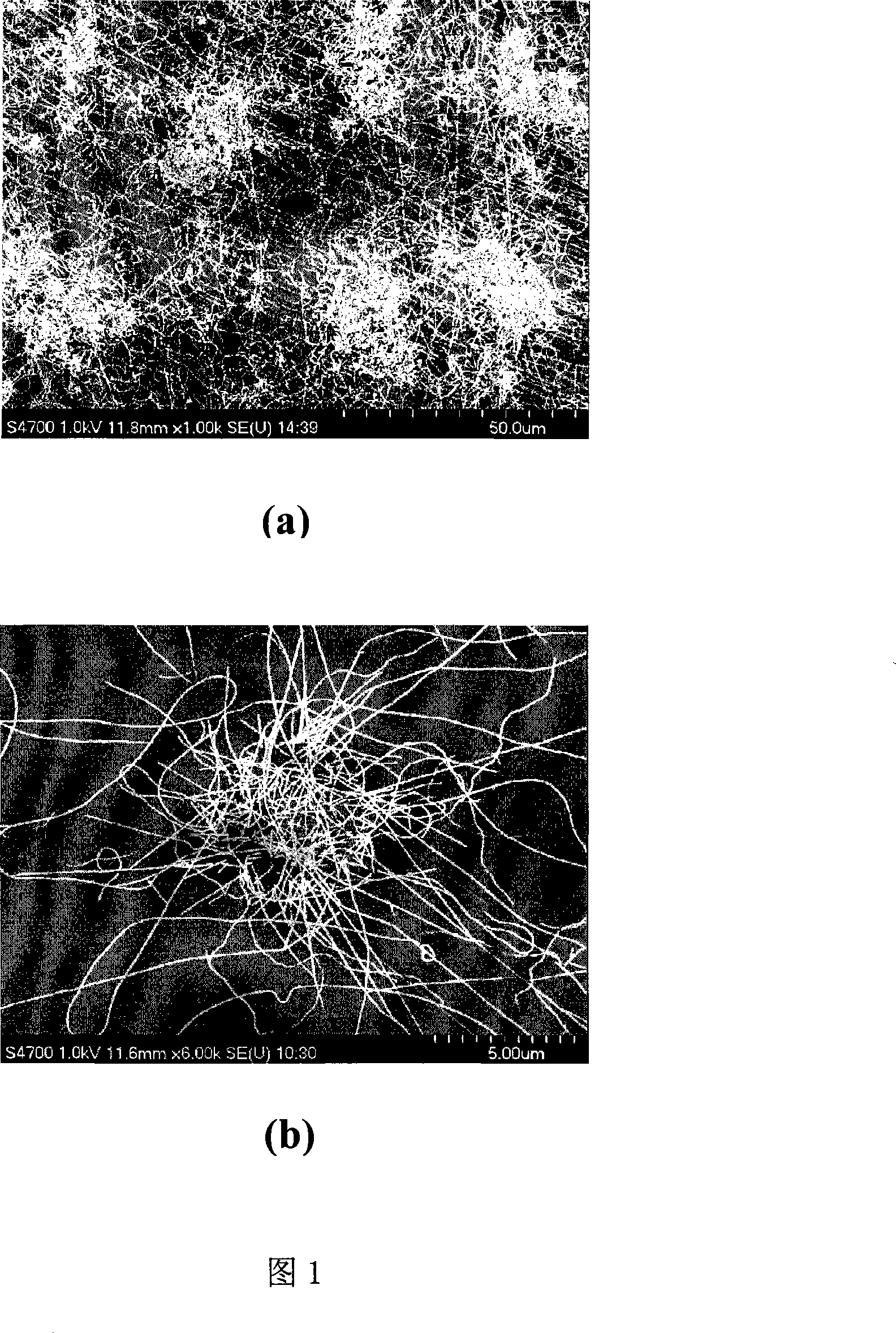

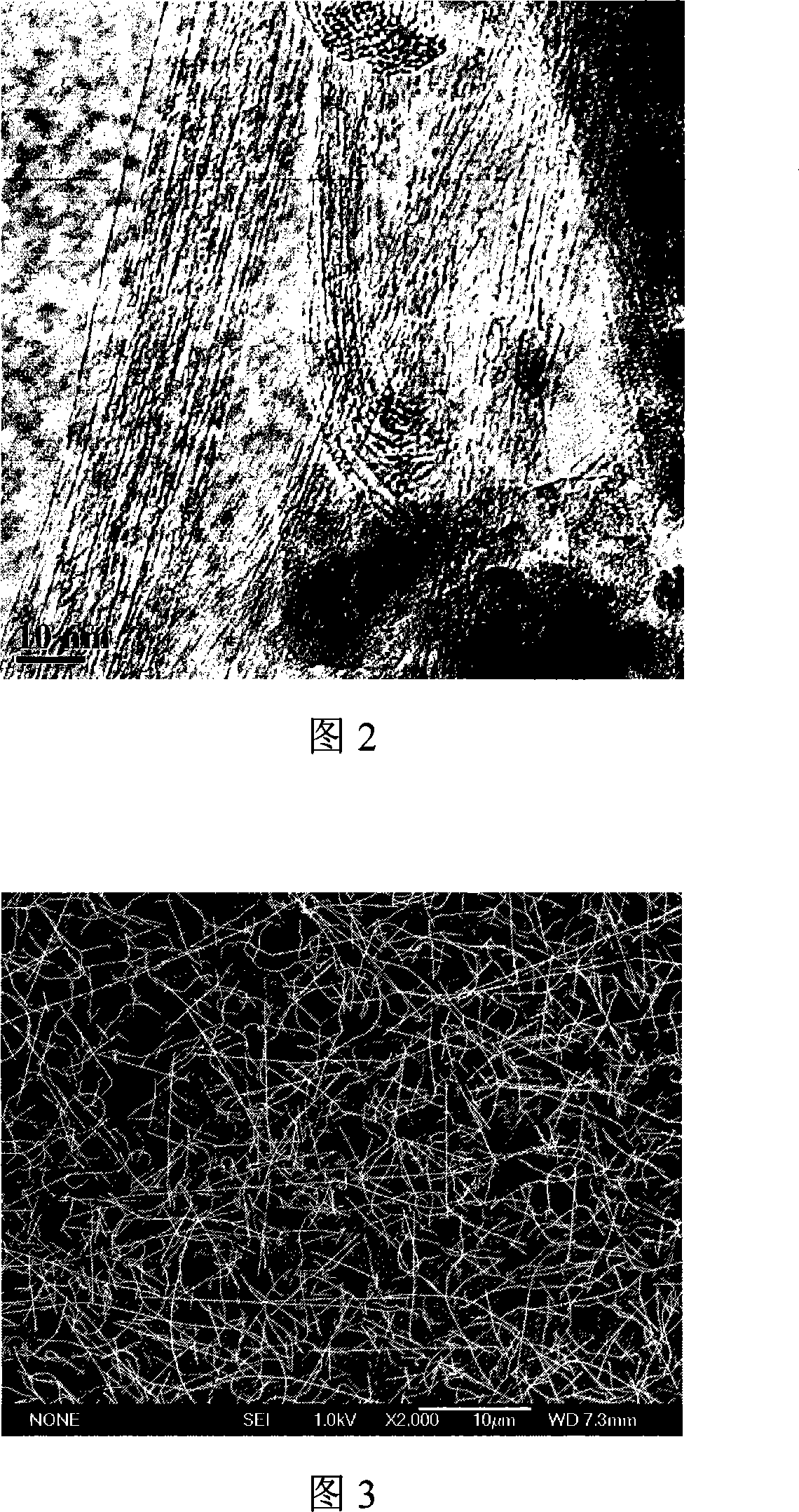

[0017] First disperse 0.05 g of 5-10nm diamond nanoparticles in 200 ml of absolute ethanol, 2 SiO with a thickness of 50nm 2 The / Si substrate is placed in the diamond suspension and soaked for 10-30 minutes, and after the substrate is dried, the substrate is placed in a quartz tube in a horizontal resistance furnace experimental device. The substrate was heated to 900°C under an argon atmosphere, and 1000 ml / min of methane and 100 ml / min of hydrogen were introduced. After 60 minutes of reaction, the methane and hydrogen were turned off, and the electric furnace was cooled to room temperature under an argon atmosphere. In SiO 2 / Si substrate can be obtained by the single-walled carbon nanotubes prepared by diamond nanoparticles (as shown in Figure 1 and Figure 2). Through scanning electron microscopy, transmission electron microscopy and other equipment detection, it is found that the diameter of single-walled carbon nanotubes is 1-6 nm, and most of them are directly about 5...

Embodiment 2

[0019] This embodiment follows the following process: about 0.05 g of 15 nm diamond nanoparticles are dispersed in 200 ml of absolute ethanol to form a diamond-ethanol solution. Take a small amount of the diamond-ethanol solution with a medical syringe, and drop 2-3 drops on the Si substrate. After the substrate is dry, place the substrate in a quartz tube in a horizontal resistance furnace experimental device. The substrate was heated to 1100°C under an argon atmosphere, 50 ml / min of methane and 100 ml / min of hydrogen were introduced, the methane and hydrogen were turned off after 60 minutes of reaction, and the electric furnace was cooled to room temperature under an argon atmosphere. Single-walled carbon nanotubes prepared from diamond nanoparticles can be obtained on the Si substrate (as shown in FIG. 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com