Composite coatings for groundwall insulation, method of manufacture thereof and articles derived therefrom

A technology of insulating layer and electrical insulating layer, applied in magnetic circuits characterized by insulating materials, nanotechnology for materials and surface science, coatings, etc., can solve the problem of large components, multi-layer structures, time-consuming and expensive, Insulation thickness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] It is worth noting that the terms "first", "second", etc. as used herein do not denote any order, number or importance, but are used to distinguish one element from another. The term "a" does not denote a limitation of quantity, but rather that there is at least one of said item. The modifier "about" used in relation to a quantity is inclusive of the stated value and has a meaning determined by the context (eg, includes the degree of error associated with measurement of the particular quantity). It should be noted that all ranges disclosed in the specification are inclusive and independently combinable.

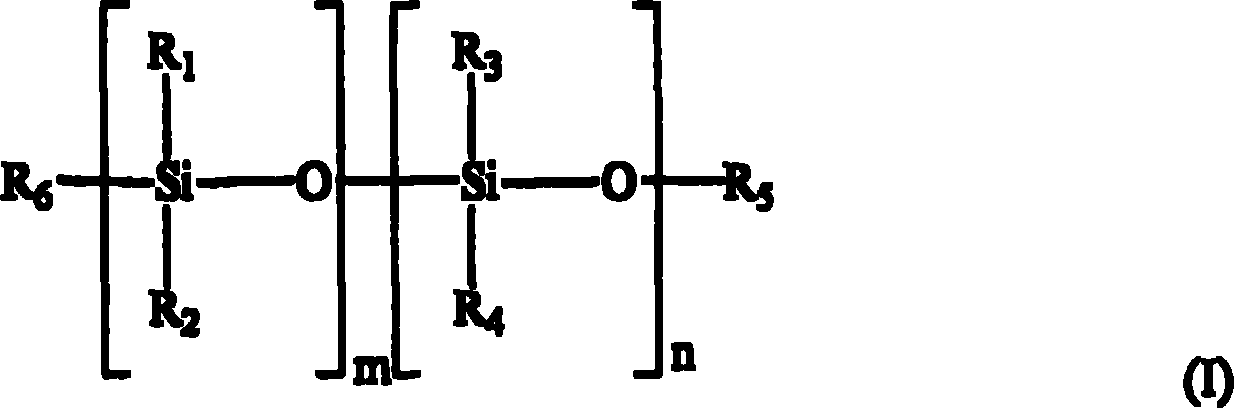

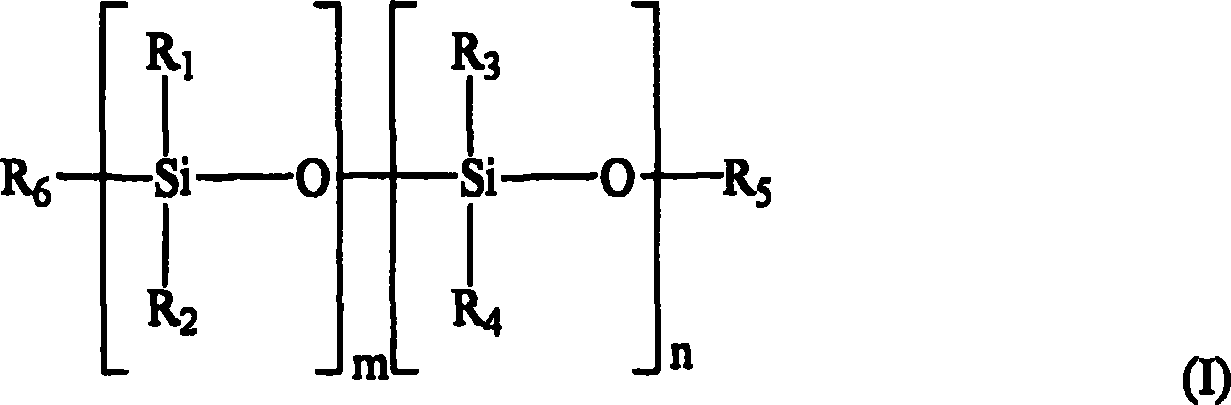

[0009] The present invention discloses an insulating layer which can be used to protect and isolate electrical components of electrical devices such as motors, generators and the like. The invention also discloses a method of applying the insulating layer on an electrical component for an electrical device. Suitable examples of such electrical components include cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com