Method for dispersing detonation method nano-diamond in liquid phase

A nano-diamond and detonation technology, which is applied in the field of nano-diamond preparation, can solve the problems of nano-diamond pollution and nano-diamond agglomeration by detonation method, and achieve the effect of simple process and overcoming product pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. Add 50 mg of detonation nano-diamond powder into 100 mL of deionized water, where the average particle size of the nano-diamond powder is 5 nm, and ultrasonically treat it with an ultrasonic generator to form a detonation nano-diamond suspension.

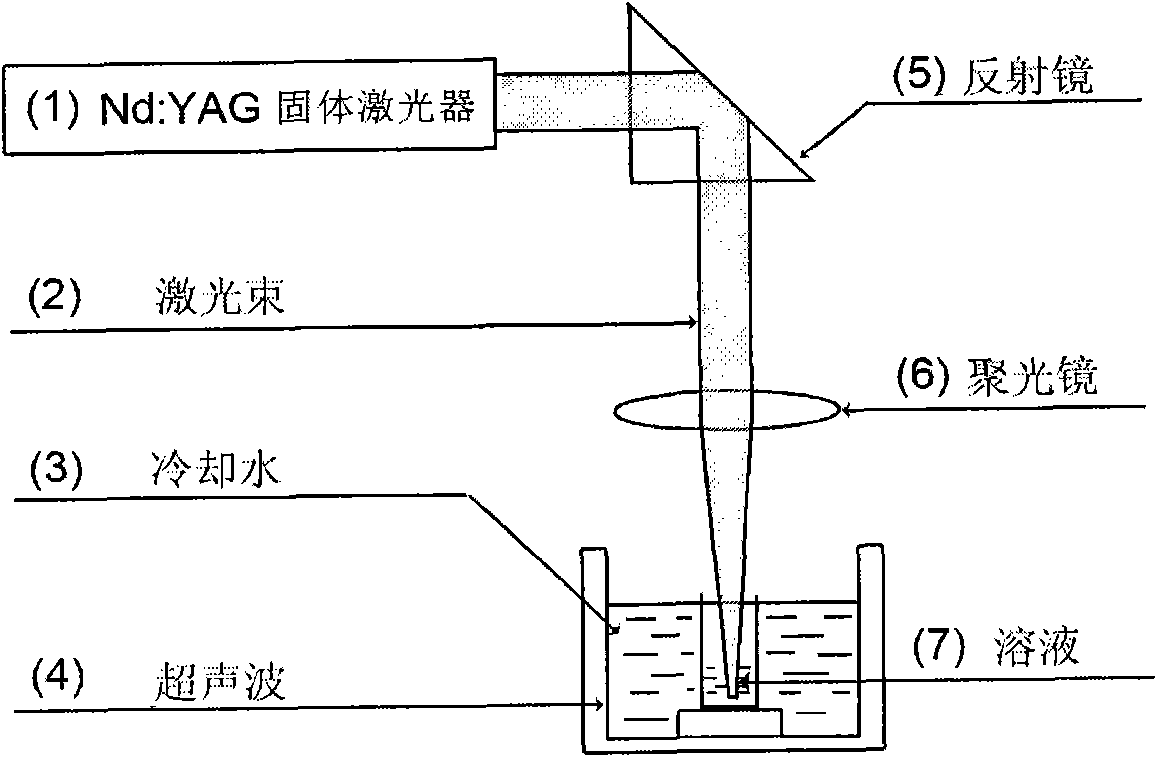

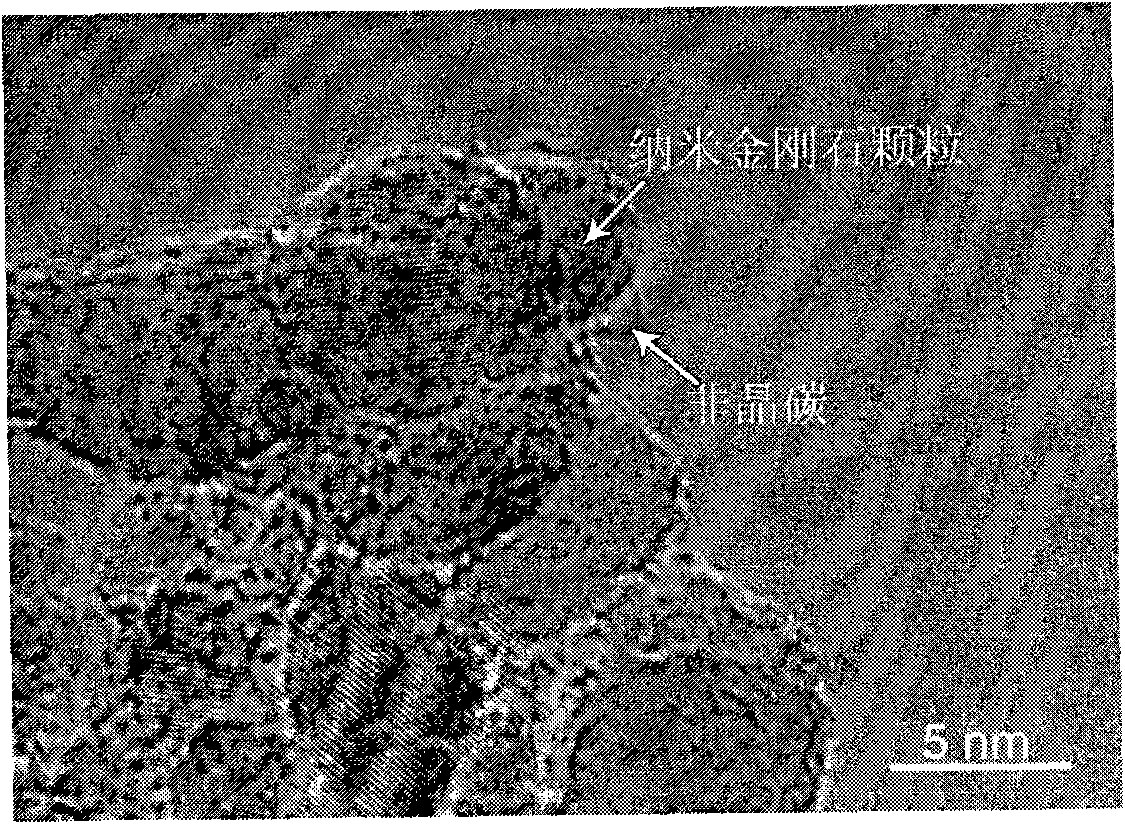

[0030] b. Use the pulsed laser to bombard the detonation method nano-diamond suspension in step a, the laser focus converges on the liquid surface, and in the micro-area of the liquid surface where the laser beam acts, the amorphous carbon in the nano-diamond aggregate will absorb the laser to generate High temperature and decomposition, the high temperature of amorphous carbon decomposition will break the covalent bonds between nano-diamond particles, so that the agglomerated detonation nano-diamonds will be deagglomerated to form monodisperse diamond nanoparticles. The laser power density in the active area is 10 6 W / cm 2 , the laser action time is 3h, the wavelength of the pulsed laser beam is 1.06μm, the pulse width...

Embodiment 2

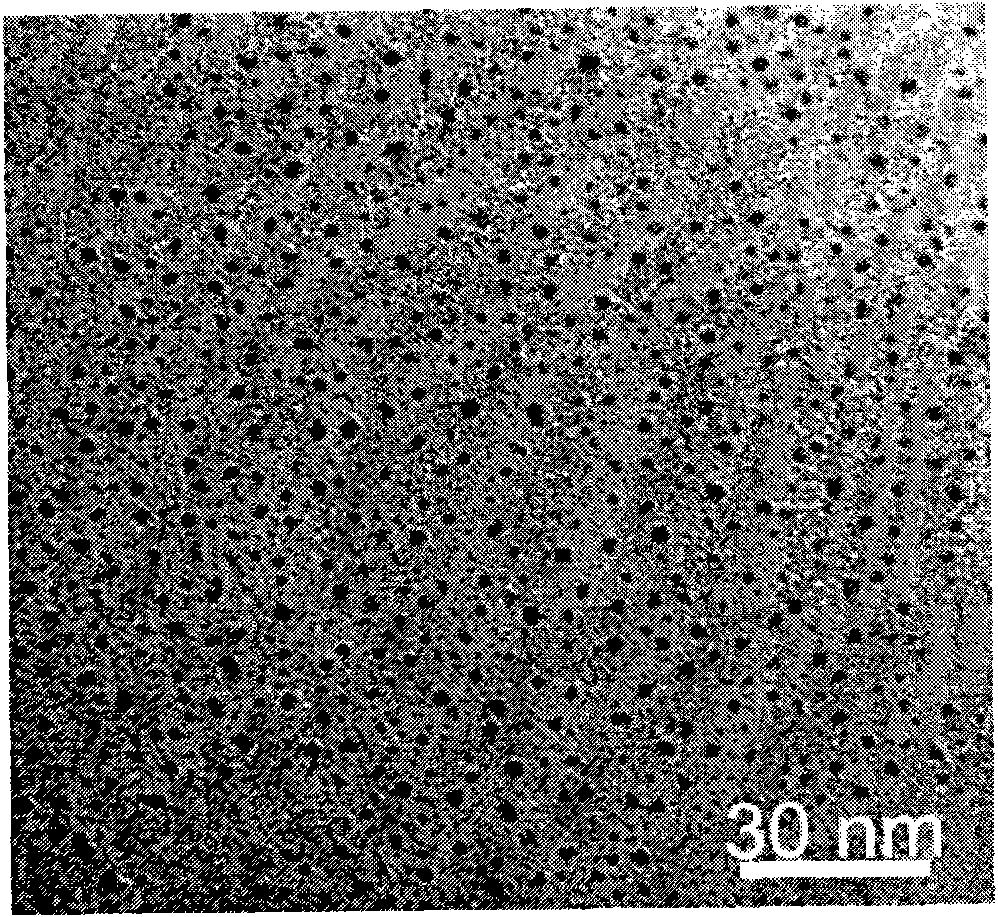

[0037]In the same reaction device, the processing conditions not described are all the same as in Example 1. The Nd-YAG solid-state laser outputs a pulsed laser beam with a wavelength of 1.06 μm (pulse width 1.0 ms, pulse frequency 20 Hz), which is focused on the surface of the detonation nano-diamond suspension after being converged by an optical lens. The liquid medium is deionized water, and the detonation method nano-diamond suspension is dispersed by ultrasonic waves to form a uniform detonation method nano-diamond suspension. The container containing the detonation nano-diamond suspension is cooled by an external circulating water bath. After continuous laser bombardment for 1 h, the reacted product was purified by acid washing to obtain gray diamond nanoparticles with an average particle size of 4 nm. see image 3 , is shown as a transmission electron micrograph of dispersed nano-diamond particles obtained by laser bombarding deionized nano-diamond suspension in deion...

Embodiment 3

[0039] In the same reaction device, the processing conditions not described are all the same as in Example 1. Change the pulse frequency of the pulsed laser beam to 10 Hz. The liquid medium is deionized water, and the detonation method nano-diamond suspension is dispersed by ultrasonic waves to form a uniform detonation method nano-diamond suspension. The container containing the detonation nano-diamond suspension is cooled by an external circulating water bath. After continuous laser bombardment for 1 h, the reacted product was purified by acid washing to obtain gray diamond nanoparticles with an average particle size of 4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com