Preparation method for fiber-reinforced superhigh temperature ceramic matrix composite

An ultra-high temperature ceramic and fiber reinforced technology is applied in the field of preparation of ceramic matrix composite materials to achieve the effects of good ablation resistance, high degree of densification and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

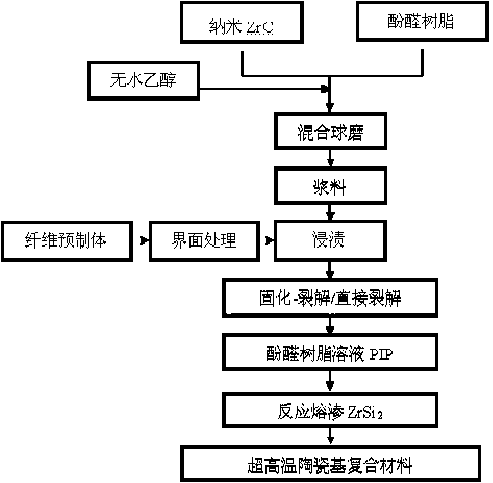

[0026] The invention provides a method for preparing a fiber-reinforced ultra-high temperature ceramic matrix composite material, the method comprising the following steps:

[0027] (1) preparing nanometer zirconium carbide, phenolic resin and solvent into a uniformly dispersed slurry by ball milling;

[0028] (2) Utilizing the slurry prepared in step (1) to impregnate a fiber preform without an interface or a prefabricated interface;

[0029] (3) Curing / cracking or directly cracking the impregnated fiber preform to obtain a ZrC-containing fiber preform, the cracking temperature is 900-1000° C., and the time is 0.5-1.0 hours;

[0030] (4) Treat the fiber preform obtained in step (3) by the organic precursor impregnation-cracking method to obtain a porous ZrC-C composite material intermediate; use the organic precursor impregnation-cracking method to treat the fiber preform , introducing carbon to obtain a ZrC-C porous intermediate, the cracking temperature is 900-1000°C, and ...

Embodiment 1

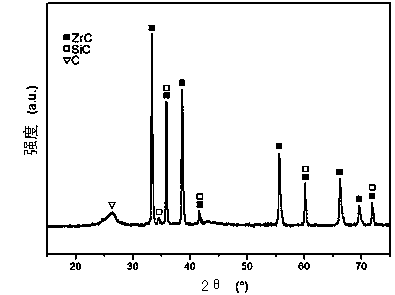

[0049] according to figure 1 The process shown was carried out. Firstly, using absolute ethanol as solvent, 200g ZrC nanopowder and 100g phenolic resin were milled for 24 hours to form a uniform slurry. A three-dimensional carbon fiber braid without interface (70mm×60mm×10mm) was used as a fiber preform, impregnated in the above slurry, then cured, and cracked at 900°C for 30min to obtain an ultra-high temperature ceramic matrix composite preform. The preform was impregnated with an anhydrous ethanol solution of phenolic resin, cracked after drying, and the number of impregnation-cracking cycles was 3 times, and C was obtained. f / ZrC-C porous intermediate with an open porosity of 28.2%. ZrSi 2 The alloy is the zirconium source, and the reaction infiltration is carried out in a vacuum environment at 1900 ° C for 60 minutes to obtain the final C f / ZrC-SiC ultra-high temperature ceramic matrix composites. Infiltration of ZrSi into Composite Materials 2 Alloy conversion to...

Embodiment 2

[0052] Similar to the steps in Example 1, the difference is that the impregnation-cracking cycle of the preform is 5 times using phenolic resin absolute ethanol solution, and the obtained C f The open porosity of the / ZrC-C porous intermediate is 20%. Prepared C f The content of ZrC in the / ZrC-SiC ultra-high temperature ceramic matrix composite material is 24vol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com