Carbon fiber-enhanced ZrB2-ZrN composite ceramic-based composite material and preparation method thereof

A technology of composite ceramics and composite materials, which is applied in the field of ultra-high temperature thermal protection structures, can solve the problems of uncontrollable material components and distribution, inability to shape components with complex shapes, and limit the application range of material engineering, so as to achieve high component content, The effect of high temperature resistance and high volume content of ceramic phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

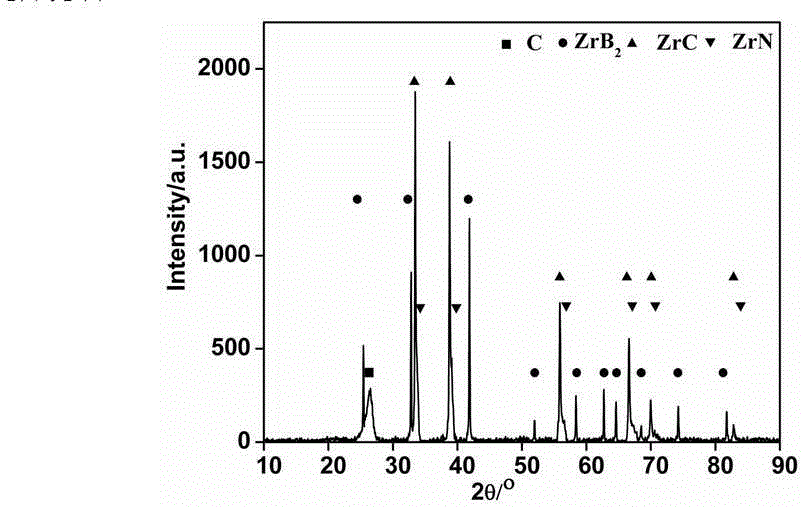

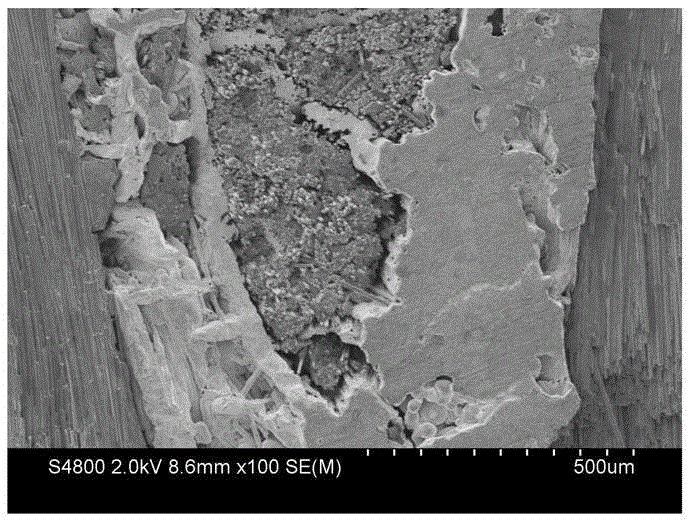

[0035] A carbon fiber reinforced ZrB 2 -ZrN multiphase ceramic matrix composites, with ZrB 2 -ZrN composite phase ceramics as the matrix, and carbon fiber braids as the reinforcing phase. Among them, carbon fiber reinforced ZrB 2 -The volume fraction of carbon fiber in the ZrN multiphase ceramic matrix composite is 51%, ZrB 2 -The volume fraction of ZrN composite ceramics is 28.5%, while ZrB 2 -ZrB in ZrN composite ceramics 2 The volume fraction of ZrN is 9.5%, and the volume fraction of ZrN is 19%.

[0036] The carbon fiber reinforced ZrB of the present embodiment 2 -The preparation method of ZrN composite material, comprises the following steps:

[0037] S1. Preforming of fiber reinforcement: 200g of carbon fiber is three-dimensionally braided by a three-dimensional braiding machine to form a braided piece to obtain a carbon fiber reinforcement.

[0038] S2. Preparation of fiber protective coating: using propylene as the precursor, the carbon fiber reinforced body obt...

Embodiment 2

[0046] A carbon fiber reinforced ZrB 2 -ZrN multiphase ceramic matrix composites, with ZrB 2 -ZrN composite phase ceramics as the matrix, and the three-dimensional needle-punched felt of carbon fiber as the reinforcing phase. Among them, the volume fraction of carbon fiber in the carbon fiber reinforced ZrB2-ZrN composite ceramic matrix composite is 20%, and the ZrB 2 The volume fraction of -ZrN composite ceramics is 57%. while ZrB 2 -ZrB in ZrN composite ceramics 2 The volume fraction of ZrN is 19%, and the volume fraction of ZrN is 38%.

[0047] The carbon fiber reinforced ZrB of the present embodiment 2 -The preparation method of ZrN composite material, comprises the following steps:

[0048] S1. Preforming of fiber reinforcement: 80g of non-weft cloth and 20g of mesh tire are laminated and then needle punched with a needle punching machine to form a three-dimensional needle-punched felt to obtain a three-dimensional needle-punched carbon fiber reinforcement.

[0049...

Embodiment 3

[0056] A carbon fiber reinforced ZrB 2 -ZrN multiphase ceramic matrix composites, with ZrB 2 -ZrN composite ceramics as the matrix, with carbon cloth laminated puncture as the reinforcement phase, in which carbon fiber reinforced ZrB 2 -The carbon fiber volume fraction in the ZrN multiphase ceramic matrix composite is 20%, and the ZrB 2 -The volume fraction of ZrN composite ceramics is 31%, while ZrB 2 -ZrB in ZrN composite ceramics 2 The volume fraction is 10%, and the volume fraction of ZrN is 21%.

[0057] The carbon fiber reinforced ZrB of the present embodiment 2 -The preparation method of ZrN composite material, comprises the following steps:

[0058] S1. Preforming of fiber reinforcement: use two-dimensional carbon cloth as the carbon fiber reinforcement phase, laminate 30 layers of two-dimensional carbon cloth and perform Z-direction puncture to make carbon cloth laminated puncture to obtain carbon fiber reinforcement.

[0059] S2. Preparation of fiber protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com