Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

361results about How to "Eliminate resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

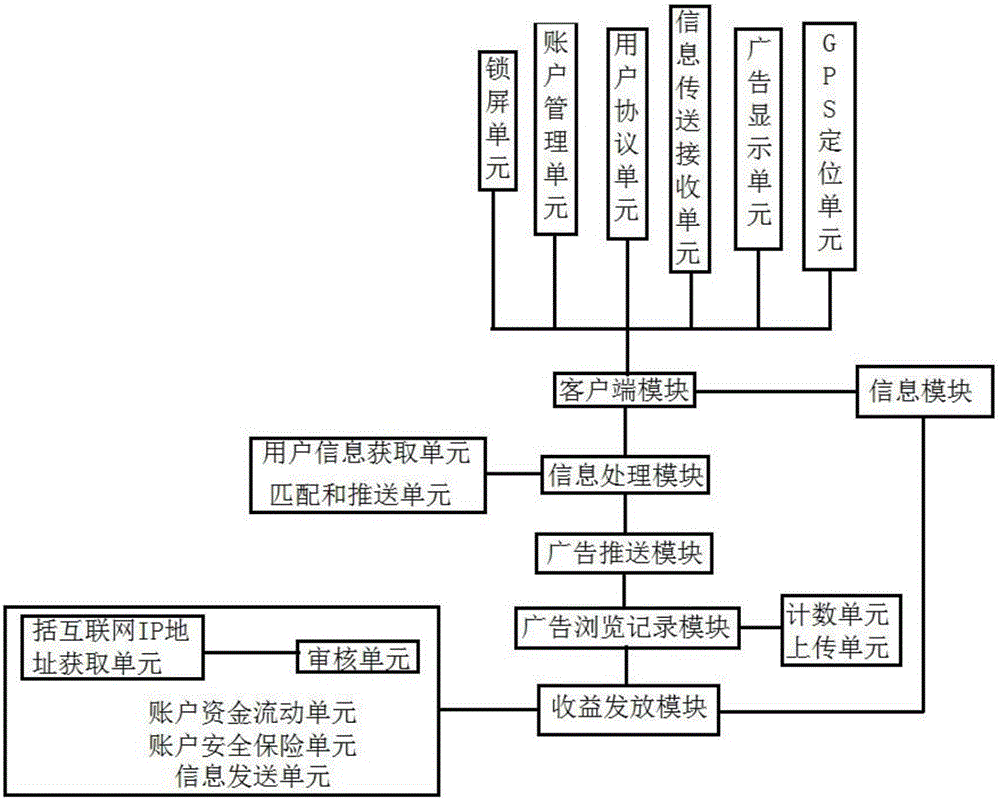

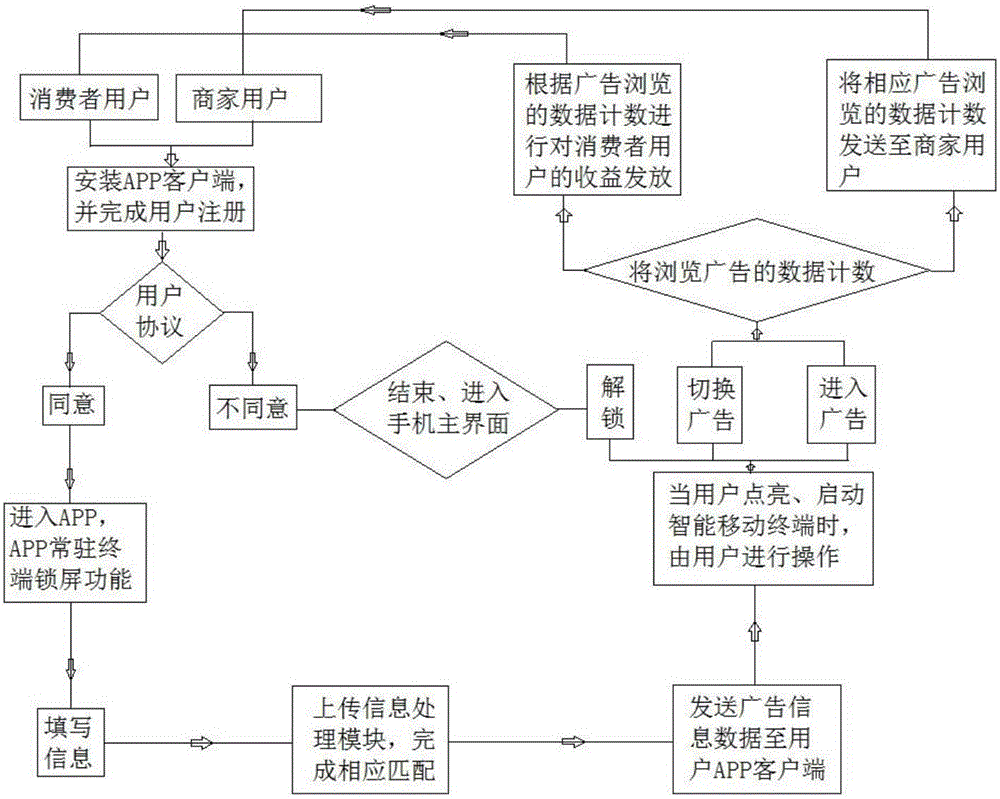

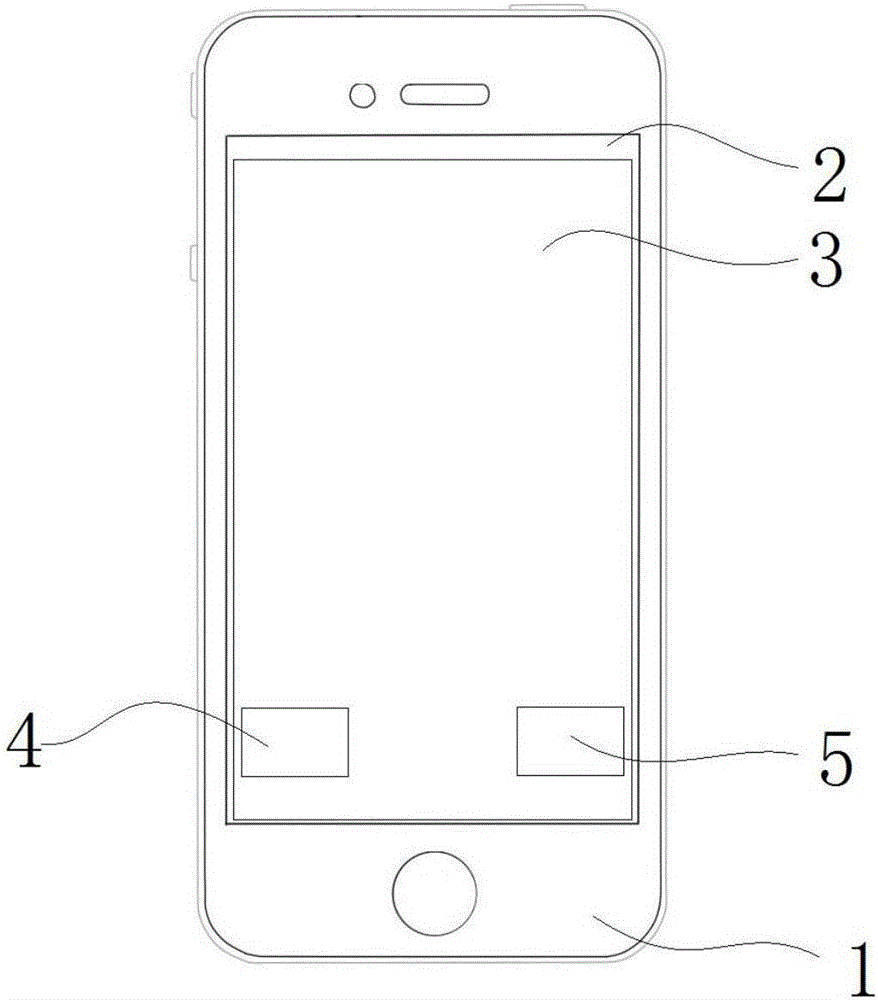

High-precision advertisement push system and method of mobile terminal based on mutual selection

InactiveCN105761101ATo achieve a win-win effectImprove efficiencyMarketingSpecial data processing applicationsComputer terminalWorld Wide Web

The invention provides a high-precision advertisement push system and method of a mobile terminal based on mutual selection between consumers and sellers, relates to the technical field of smart phones, especially to the field of using smart phones to display advertisements. According to the system and method of the invention, a paid manner is used to attract more users who would like to watch and browse advertisement information in a targeted manner, sellers are helped to obtain users rapidly, and ineffective advertising cost of the sellers is reduced; and the advertisement investing cost of the sellers corresponds to the users who browses advertisement directly; the sellers and the consumers make mutual selection directly, every cost of an advertiser directly corresponds to the consumers who actively receivers the advertisements, and the users read the content of advertisements initiatively and obtain benefits. Thus, the system and method can achieve a win-win effect for both the sellers and the consumers.

Owner:云南今日游情科技有限公司

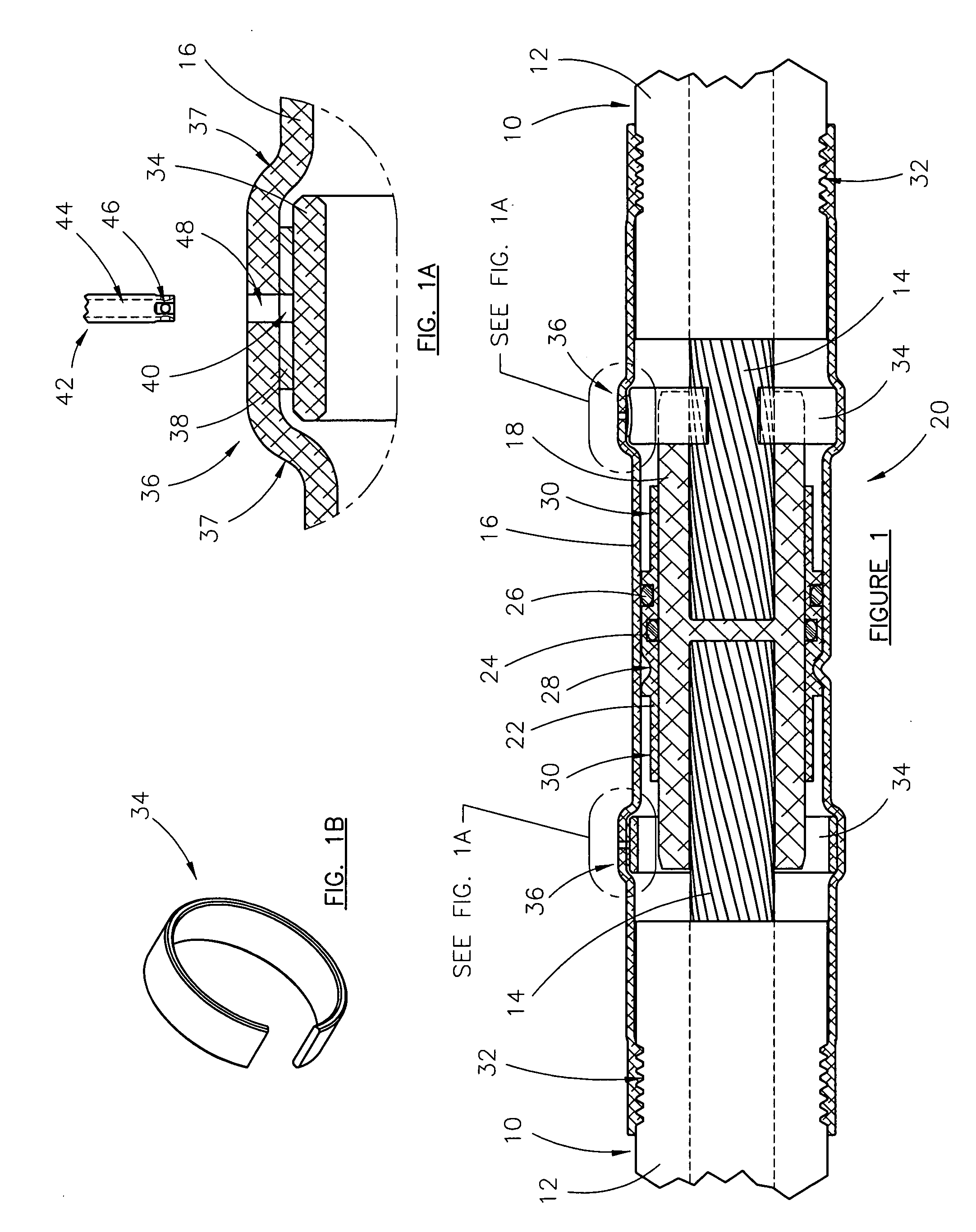

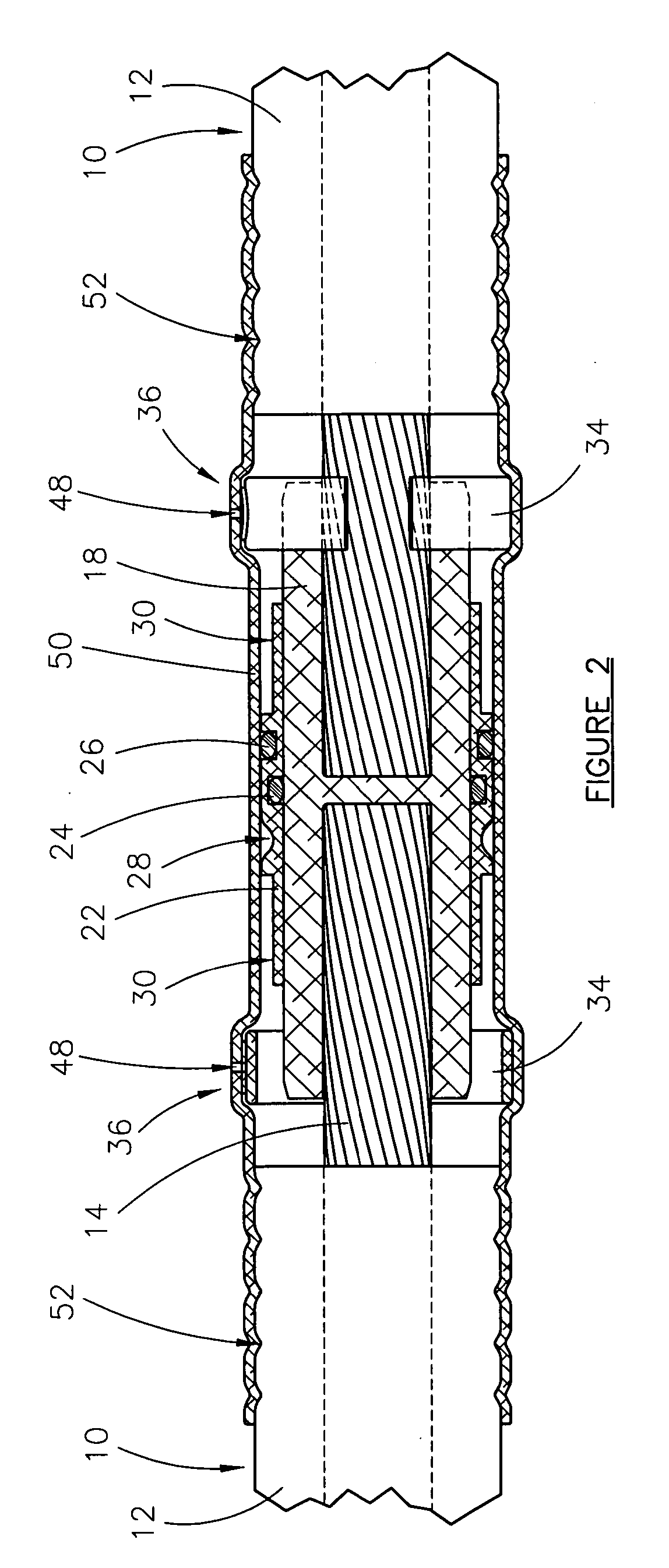

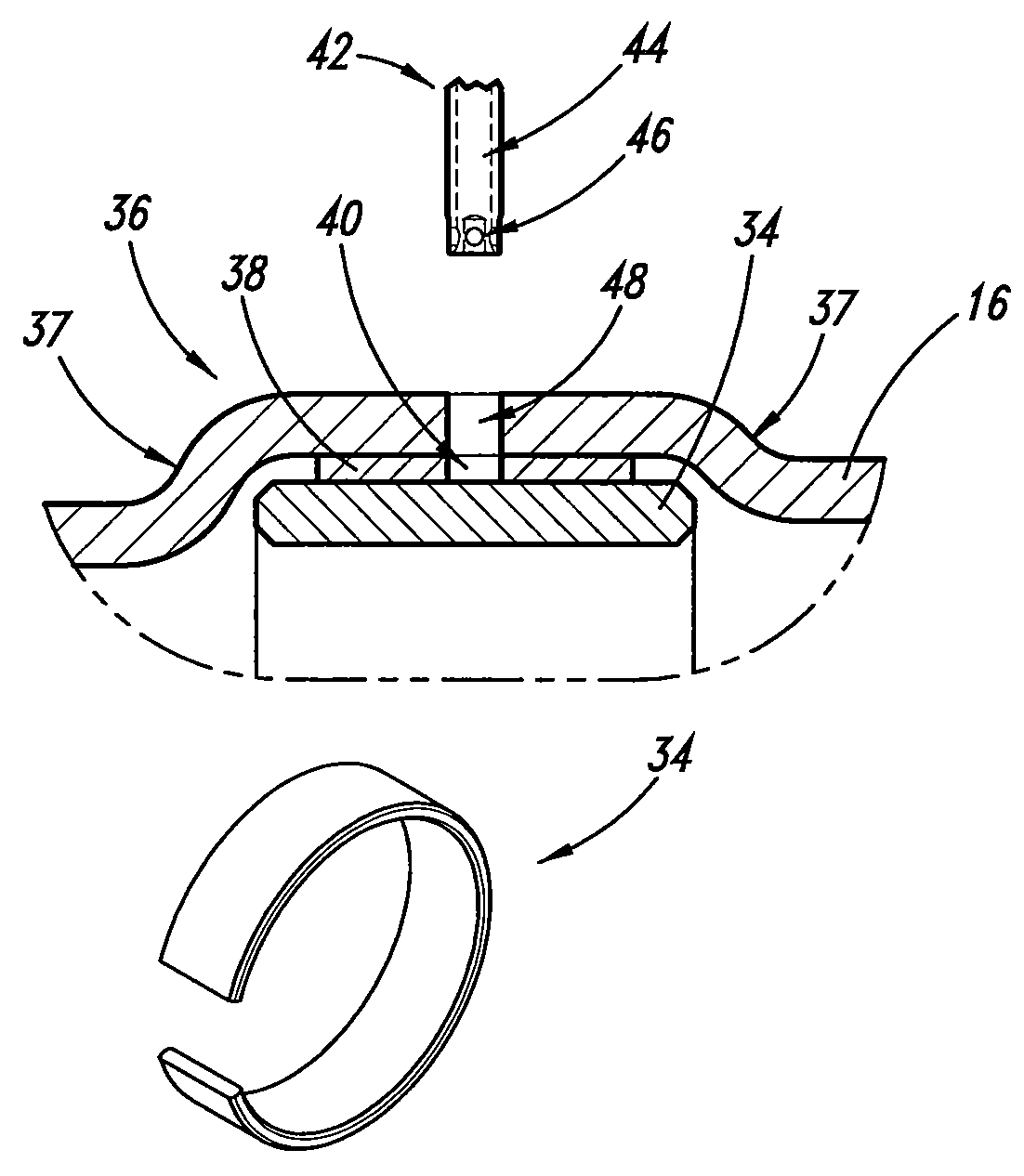

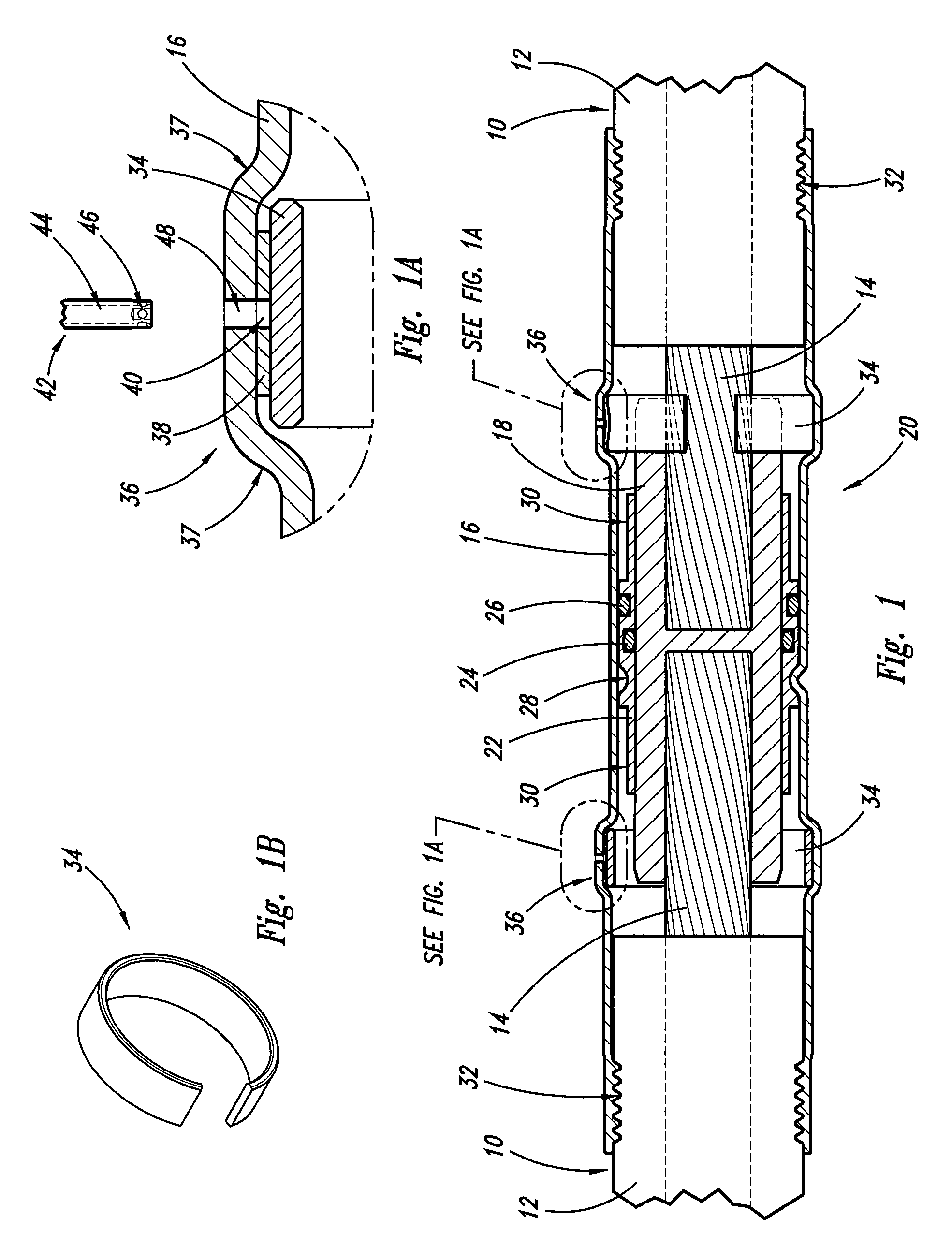

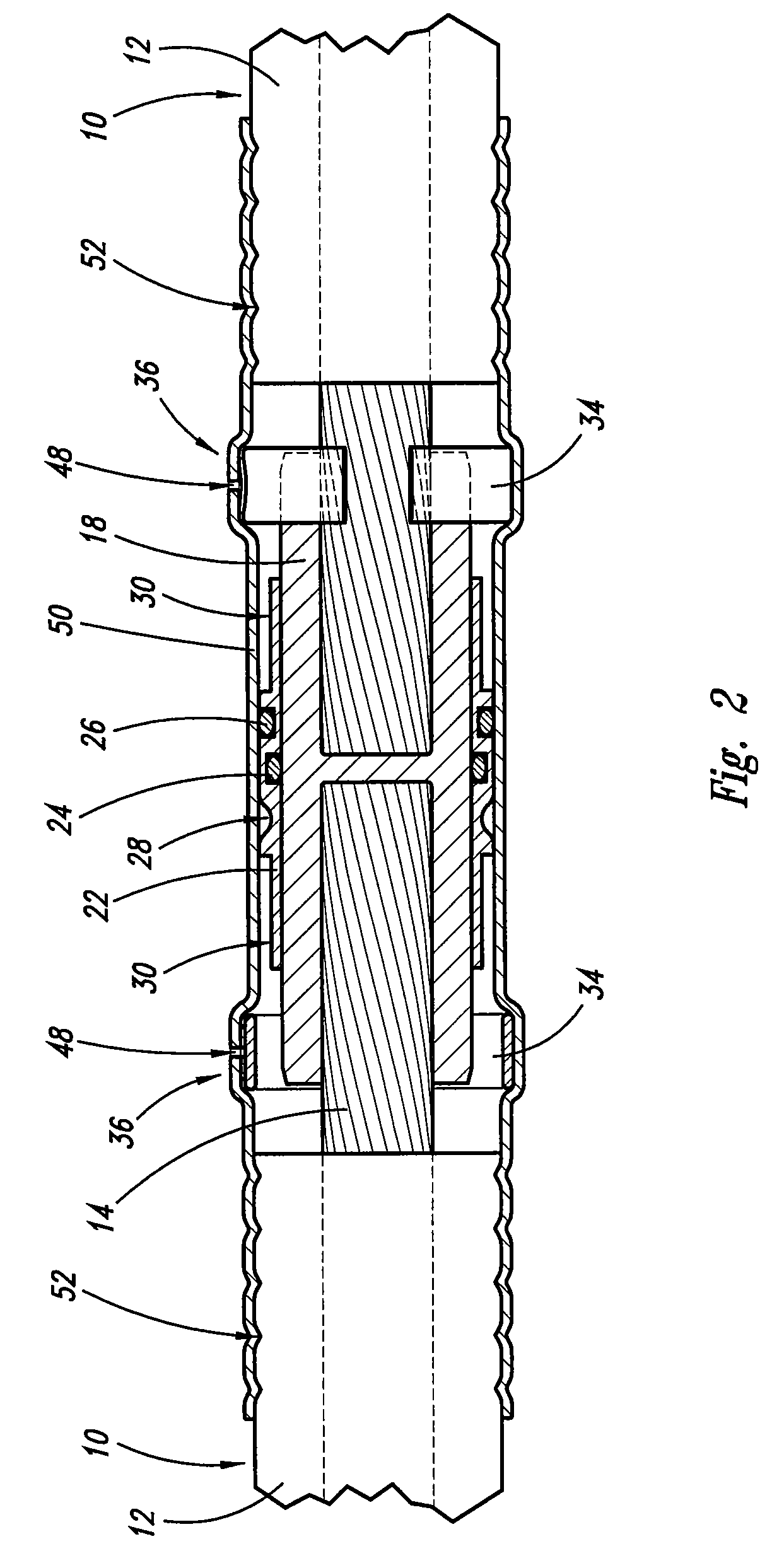

High-pressure power cable connector

ActiveUS20050191910A1Eliminate resistanceMaintaining fluid pressureCoupling device detailsTwo-part coupling devicesElectric forcePower cable

A high-pressure connector for an electrical power cable segment having a central stranded conductor encased in a polymeric insulation jacket with an interstitial void volume in the region of the conductor. The connector confines a fluid within the interstitial void volume at a residual pressure above atmospheric, but below the elastic limit of the insulation jacket. A housing interior chamber receives the conductor in fluid communication with the interstitial void volume. Some embodiments have the chamber sized to receive and overlap a portion of the insulation jacket with a housing end portion swaged thereto. A seal seals the insulation jacket with respect to the housing and a retaining member secures the cable segment to the housing to prevent pushback of the insulation jacket at the residual pressure.

Owner:NOVINIUM LLC

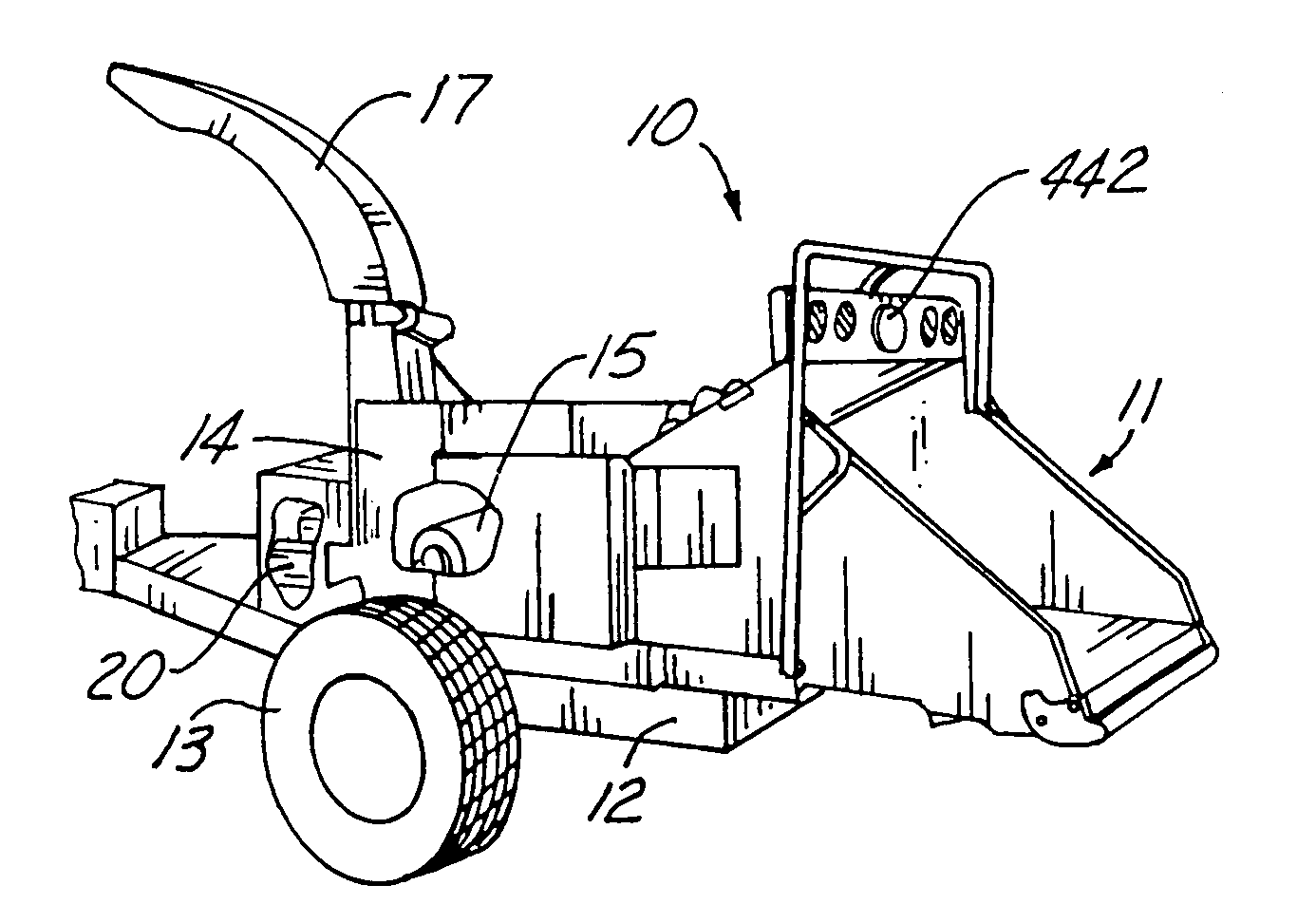

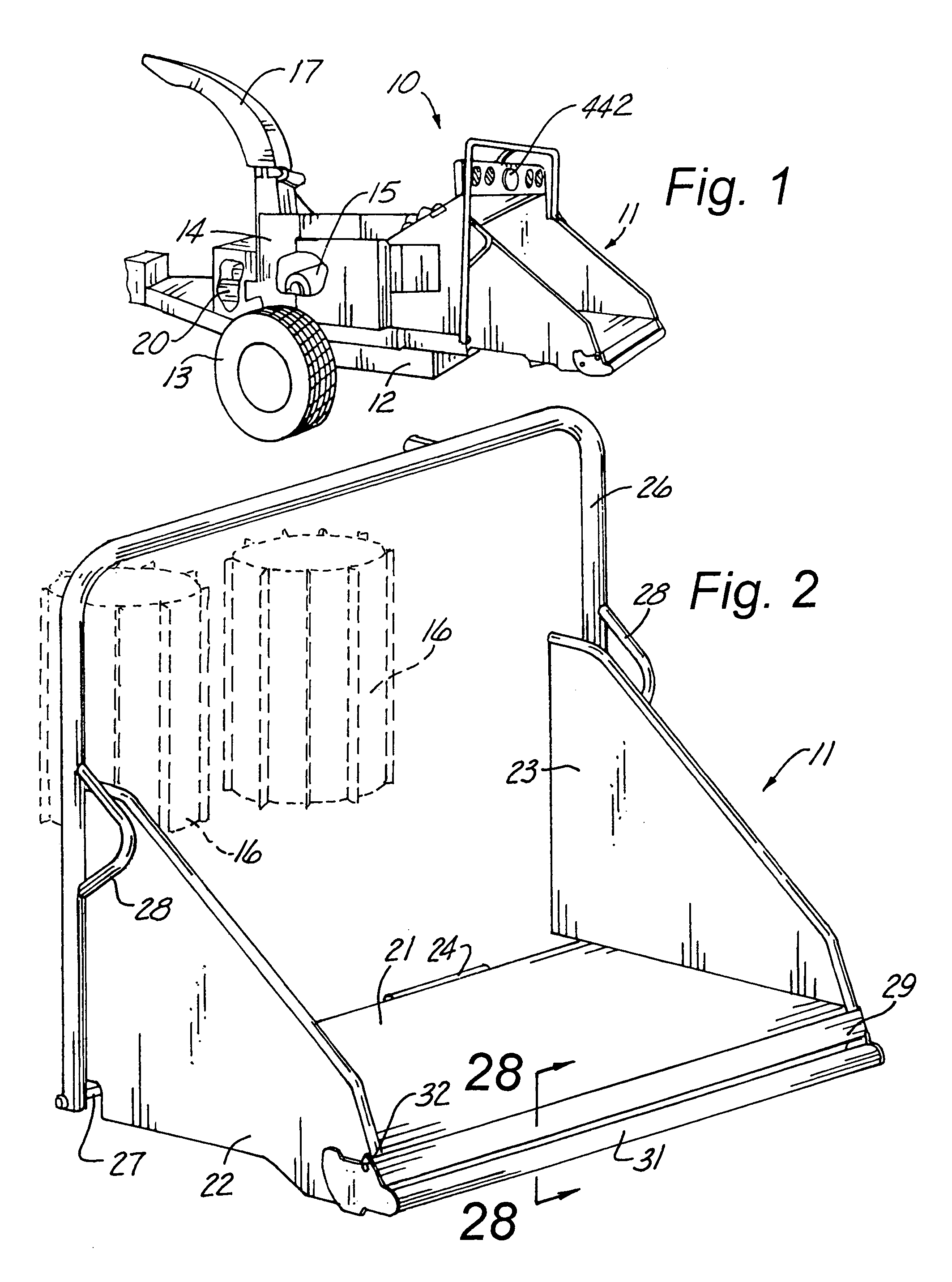

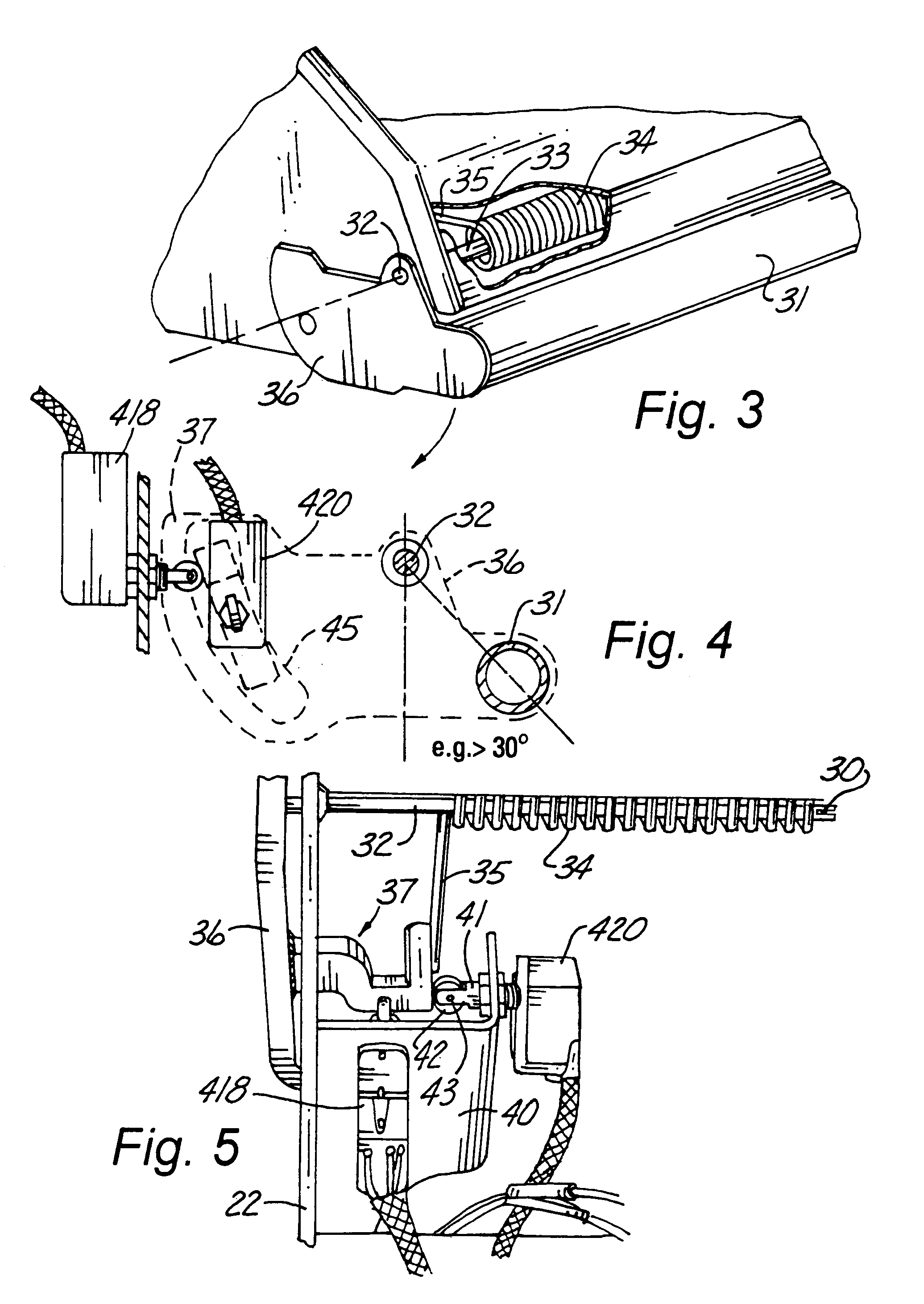

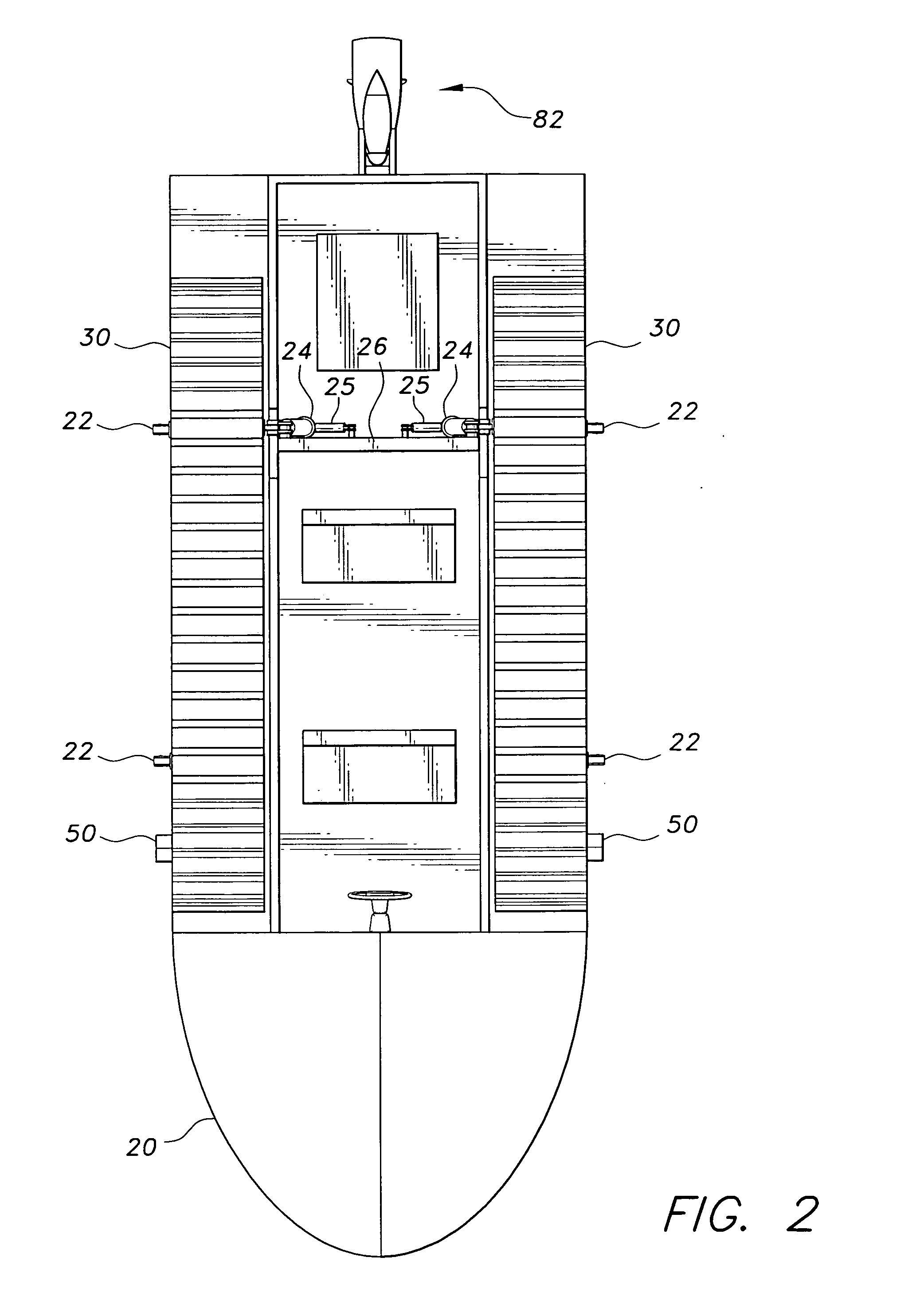

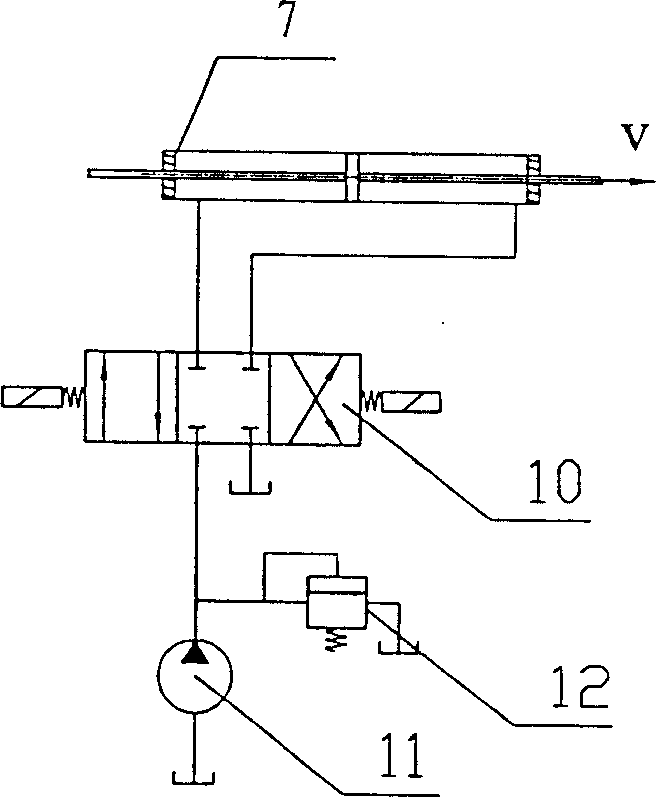

Brush chipper and methods of operating same

InactiveUS7011258B2Mechanism can be overcomeEliminate resistancePlant waste comminutingReed/straw treatmentHydraulic motorControl engineering

An improved brush cutter having an upper feed control member with stop, forward, neutral, and reverse positions also has a lower feed stop member with selectable sensitivity. Another aspect of the invention is to predict the feed roller shutoff point according to the rate of engine deceleration. According to another aspect, when the feed rollers stop feeding material into the cutters, to overcome drag on the cutters, a controller stops the feed rollers and then reverses them for a short time, and then reverses the rollers again if the problem is still present. To prevent jamming, a pressure switch senses when oil in a hydraulic motor system for rotating the feed rollers is too high and the controller momentarily reverses the feed rollers and then causes them to go forward, a cycle which can occur several times until the feed rollers are no longer stalled. By another aspect of the invention, the controller senses characteristics of the brush cutter and chooses an operating system based on the characteristics sensed. The controller can also sense if the brush chipper has not been used for a predetermined period of time and automatically reduce the idle speed of the engine until the brush chipper is used again, and then automatically return the engine to a normal idle speed before the feed rollers will pull brush into the brush chipper.

Owner:VERMEER MFG CO

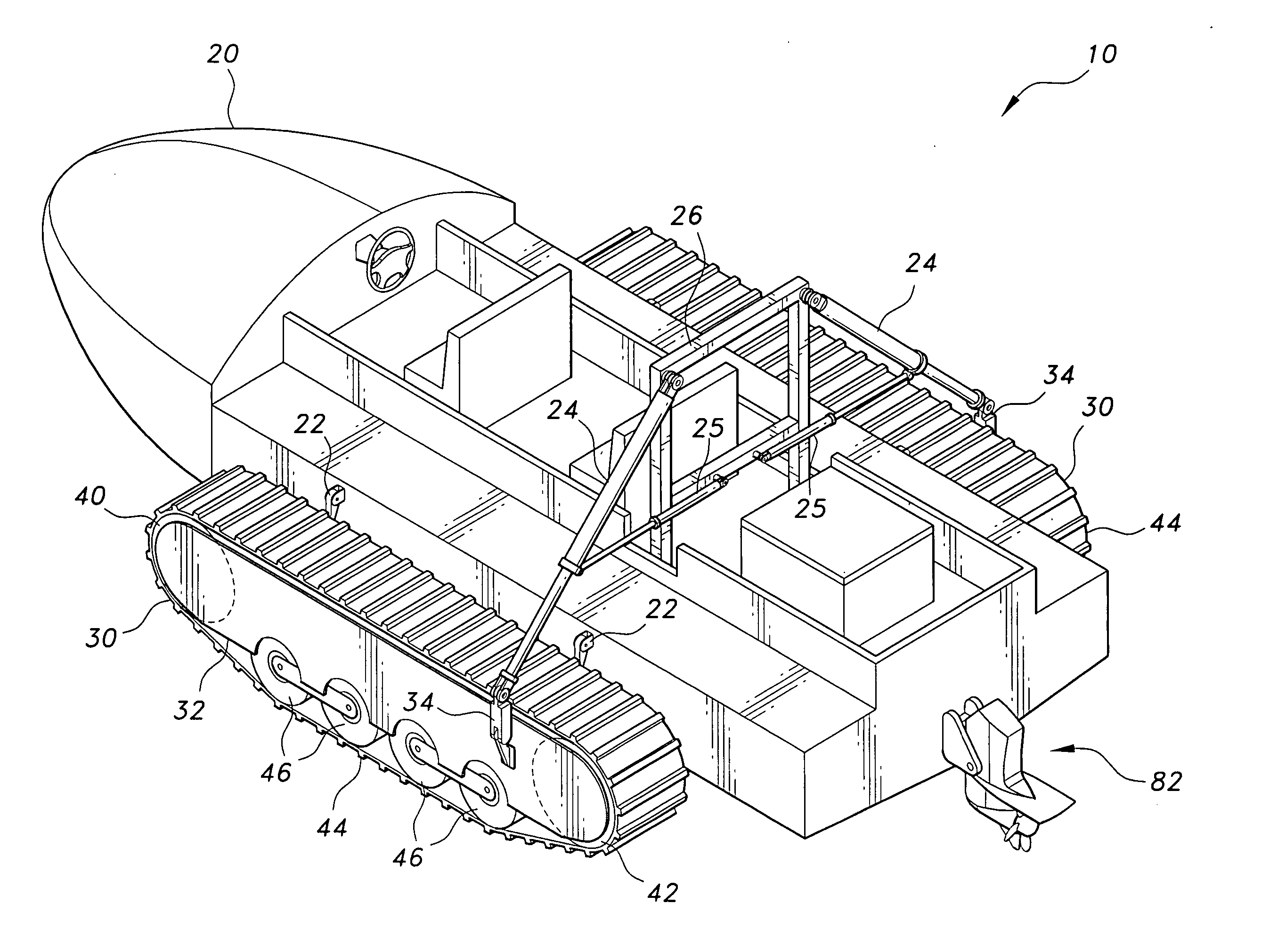

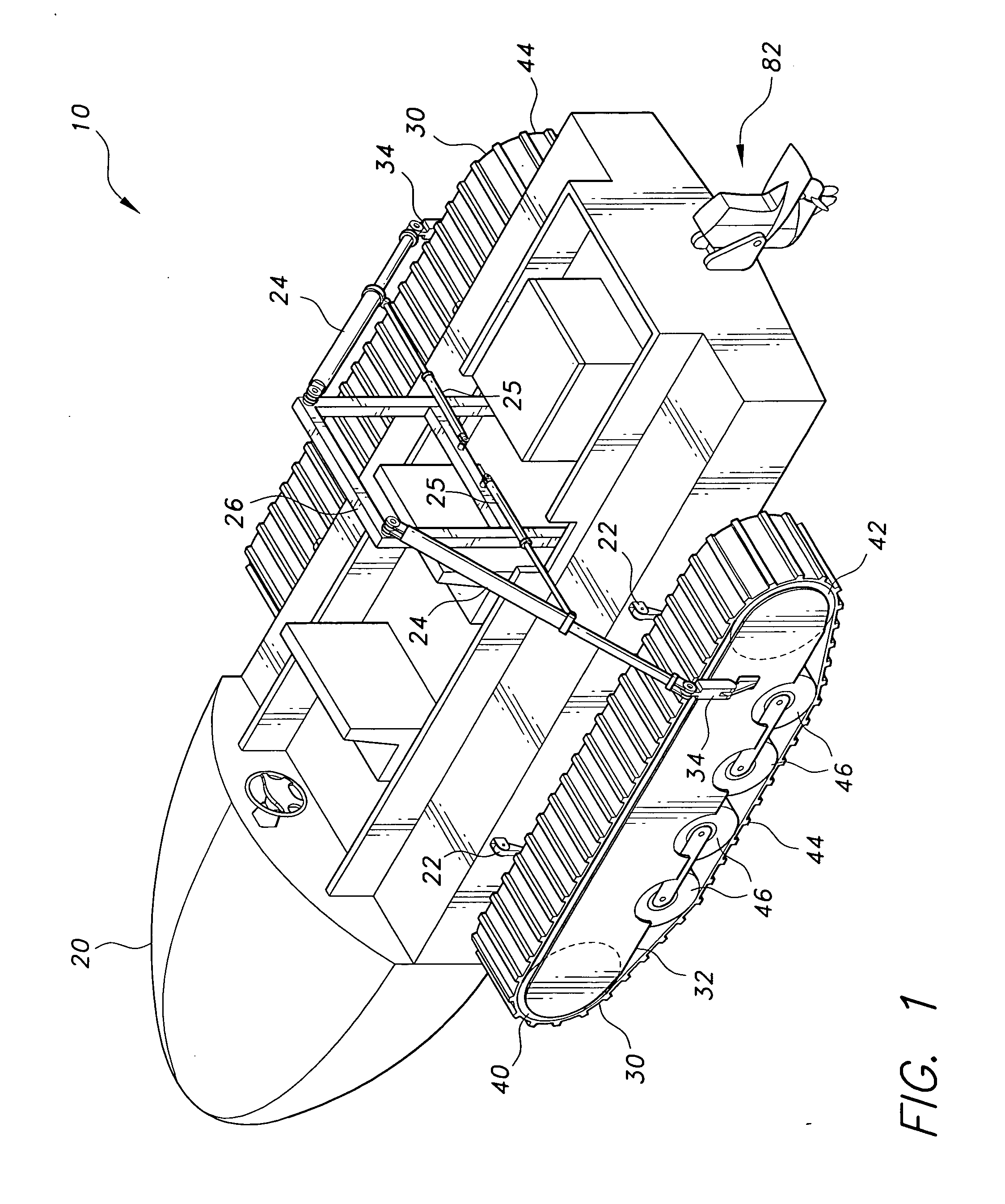

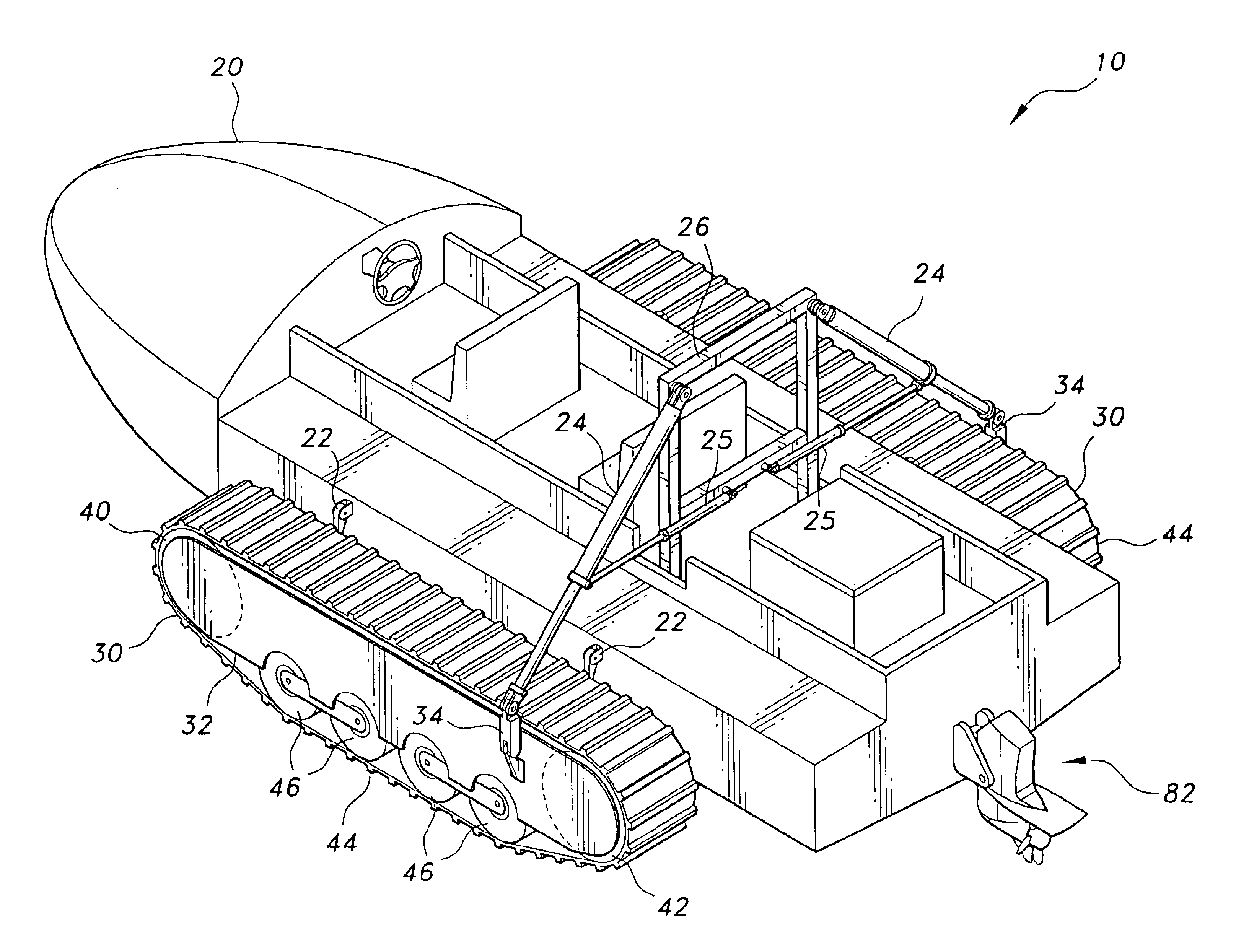

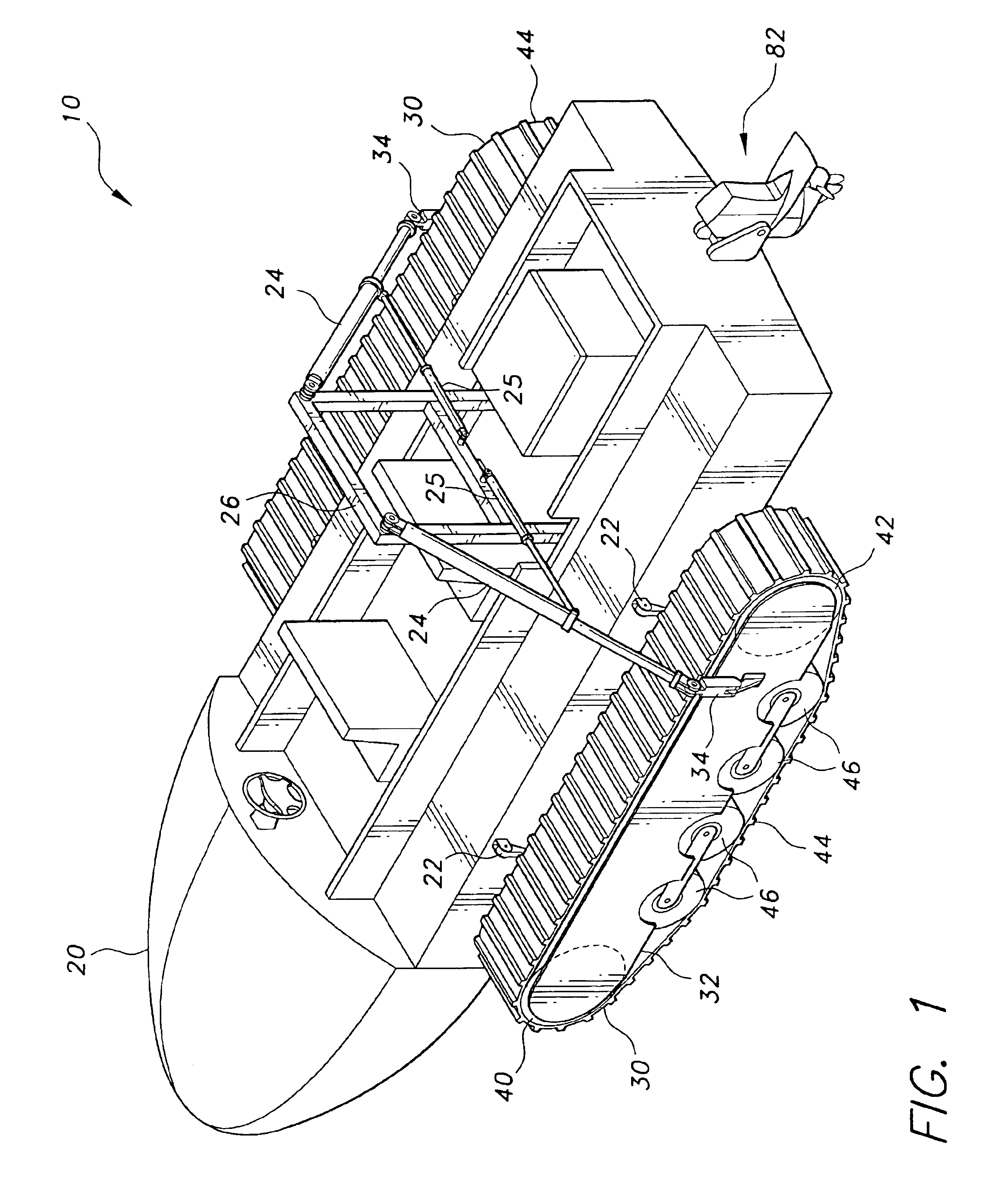

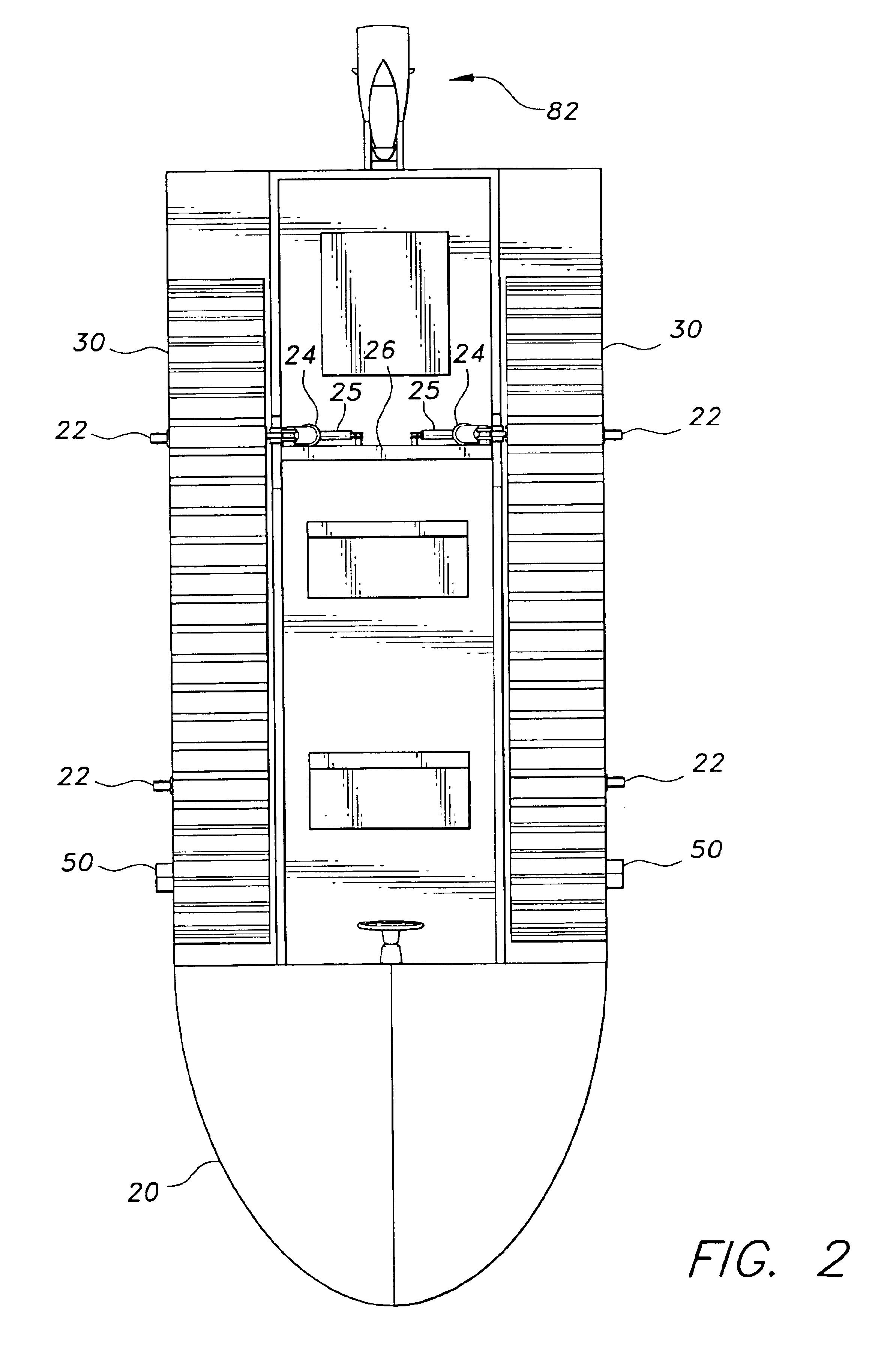

Amphibious vehicle

ActiveUS20050003715A1Narrow widthEasy to operateAmphibious vehiclesConveyorsHinge angleMarine engineering

The amphibious vehicle is a motorized vehicle capable of travel on land as well as in the water. The amphibious vehicle has a boat-like hull, and a caterpillar track assembly mounted along each side by hinges. The tracks are arranged so that they can be rotated between a lowered position, where they support the amphibious vehicle and provide traction and propulsion during land operation, and a raised position, where they rest vertically on or above the hull's deck during marine operation. With the caterpillar track assemblies in the raised position, stowed on the hull's deck, the caterpillar track assemblies are fully removed from the water to improve performance and maneuverability. Additionally, with the tracks in their upright position the overall width of the amphibious vehicle is narrowed to facilitate trailering. The tracks employ hydraulic motors in a direct drive configuration for propulsion, reducing weight and complexity of the tracks.

Owner:HEWITT STANLEY C

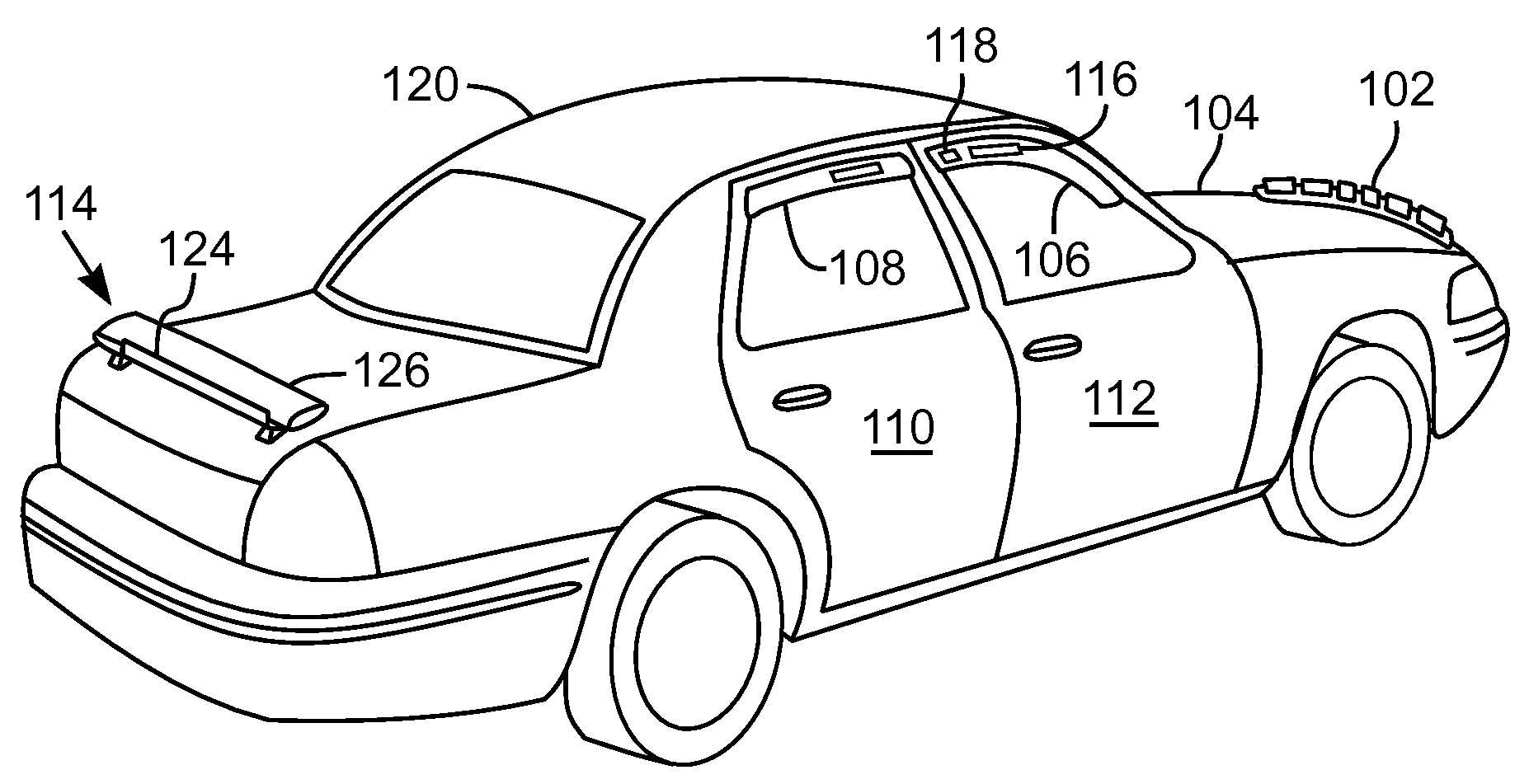

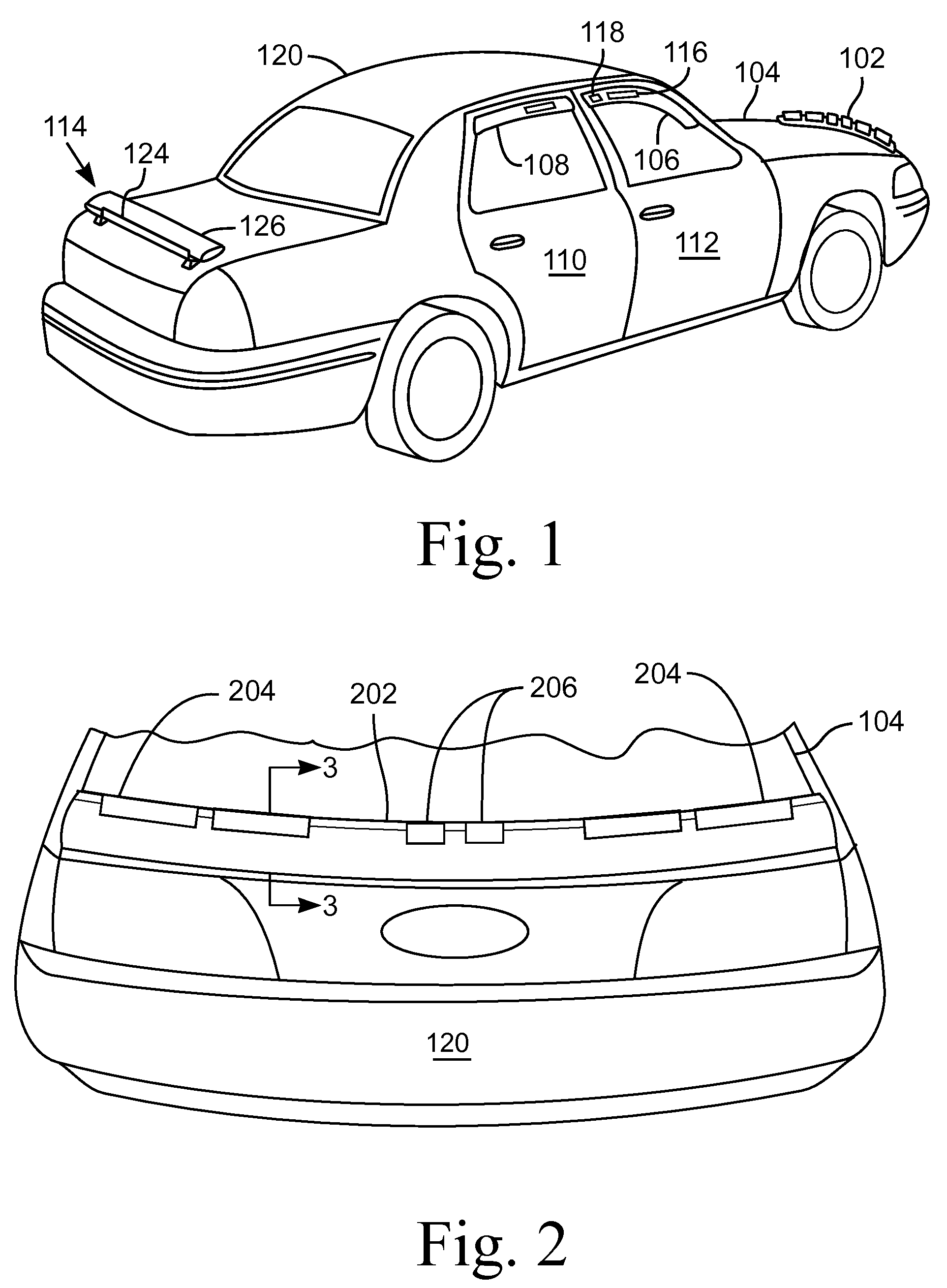

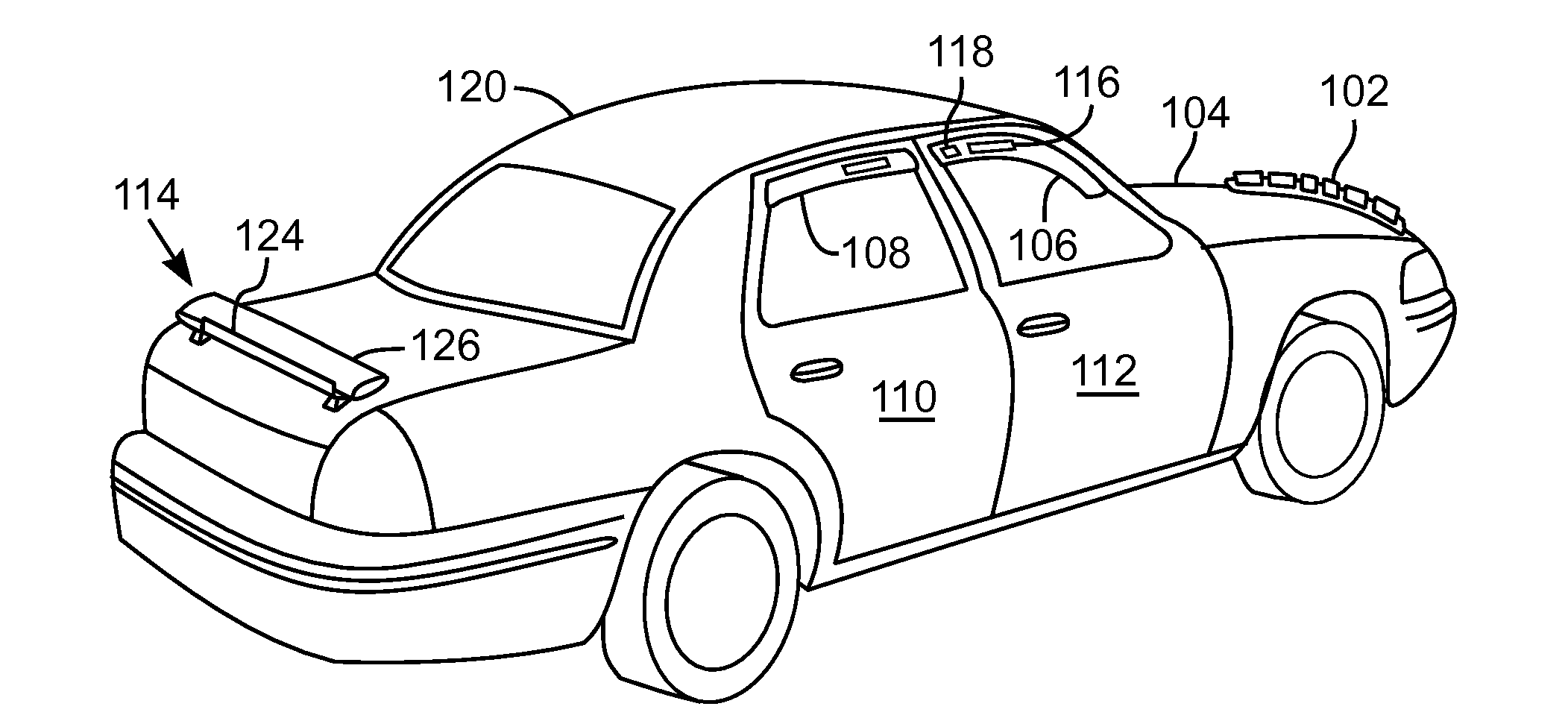

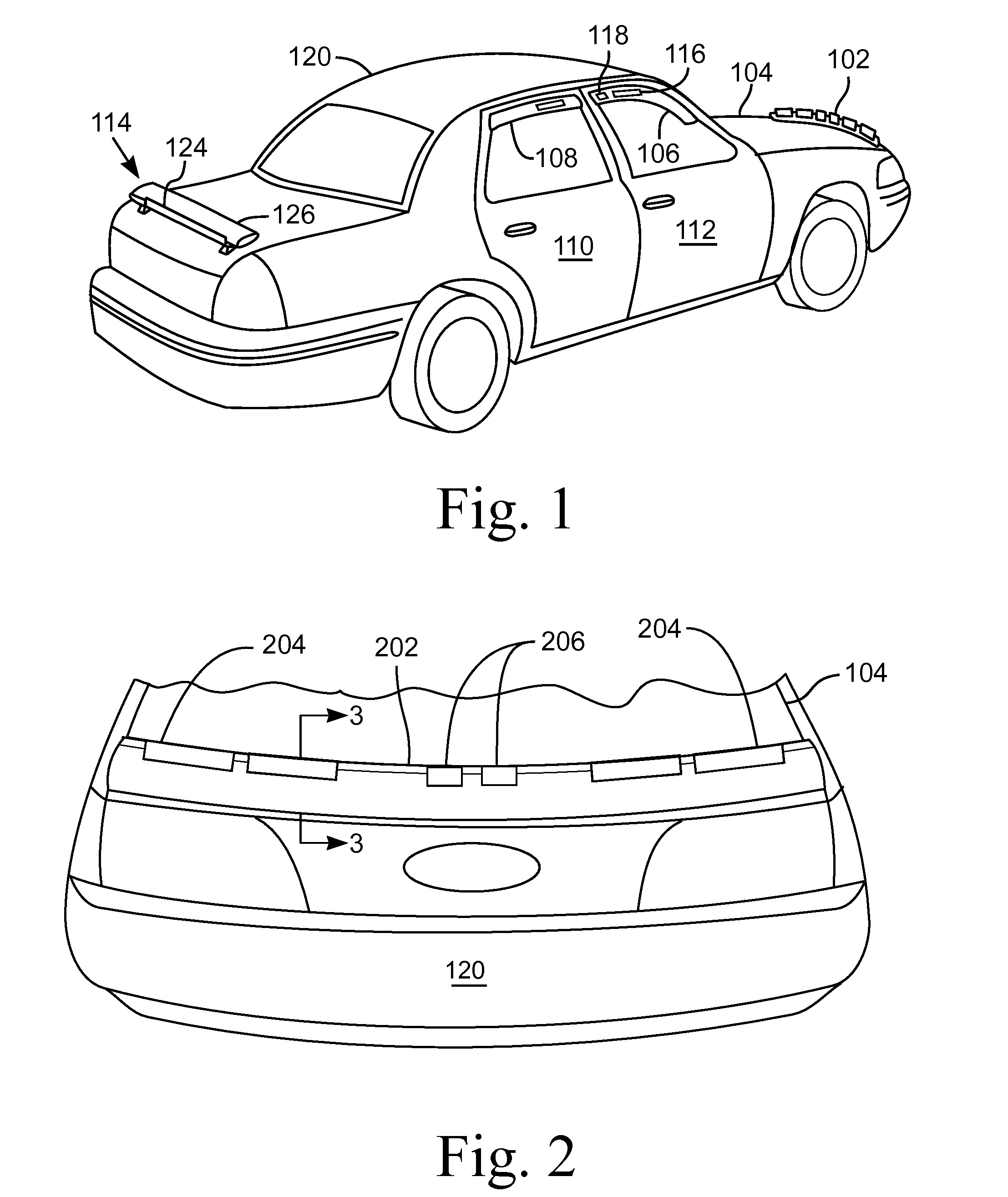

Emergency vehicle warning lights

InactiveUS7589622B2Remove noiseEliminate resistanceLighting support devicesVehicle interior lightingEngineeringVisor

Owner:FARLEYS CUSTOM AUTO SERVICES

High-pressure power cable connector

ActiveUS7195504B2Eliminate resistanceAvoid resistanceCoupling device detailsTwo-part coupling devicesPower cableElectrical conductor

A high-pressure connector for an electrical power cable segment having a central stranded conductor encased in a polymeric insulation jacket with an interstitial void volume in the region of the conductor. The connector confines a fluid within the interstitial void volume at a residual pressure above atmospheric, but below the elastic limit of the insulation jacket. A housing interior chamber receives the conductor in fluid communication with the interstitial void volume. Some embodiments have the chamber sized to receive and overlap a portion of the insulation jacket with a housing end portion swaged thereto. A seal seals the insulation jacket with respect to the housing and a retaining member secures the cable segment to the housing to prevent pushback of the insulation jacket at the residual pressure.

Owner:NOVINIUM LLC

Amphibious vehicle

InactiveUS6921304B2Easy to operateAchieve performanceAmphibious vehiclesConveyorsHydraulic motorMarine engineering

The amphibious vehicle is a motorized vehicle capable of travel on land as well as in the water. The amphibious vehicle has a boat-like hull, and a caterpillar track assembly mounted along each side by hinges. The tracks are arranged so that they can be rotated between a lowered position, where they support the amphibious vehicle and provide traction and propulsion during land operation, and a raised position, where they rest vertically on or above the hull's deck during marine operation. With the caterpillar track assemblies in the raised position, the caterpillar track assemblies are fully removed from the water to improve performance and maneuverability. Additionally, with the tracks in their upright position the overall width of the amphibious vehicle is narrowed to facilitate trailering. The tracks employ hydraulic motors in a direct drive configuration for propulsion, reducing weight and complexity of the tracks.

Owner:HEWITT STANLEY C

Therapy for neurological diseases

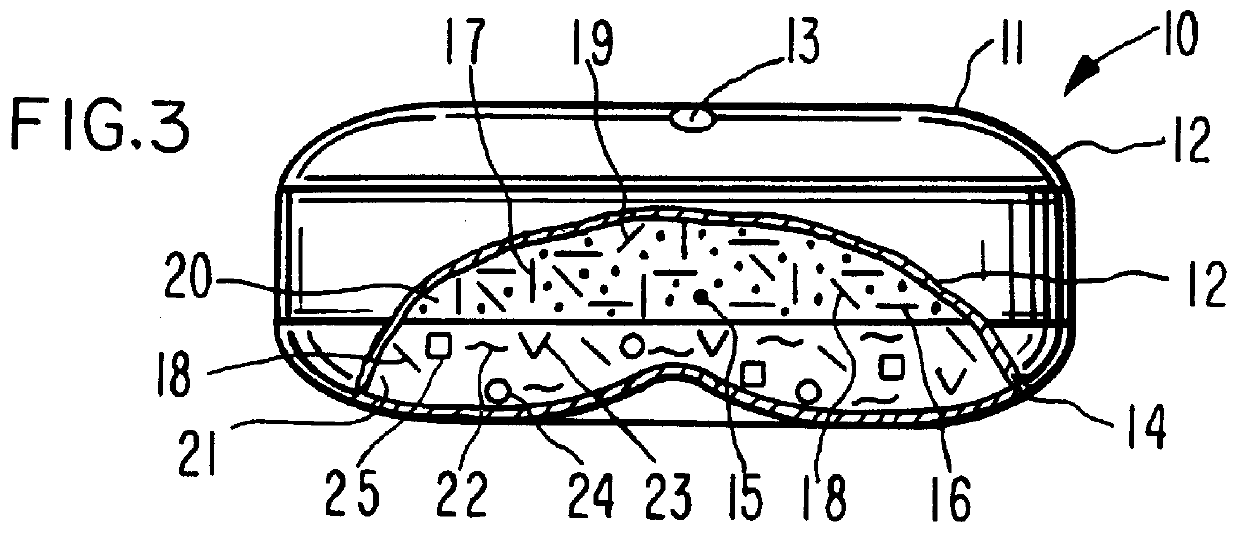

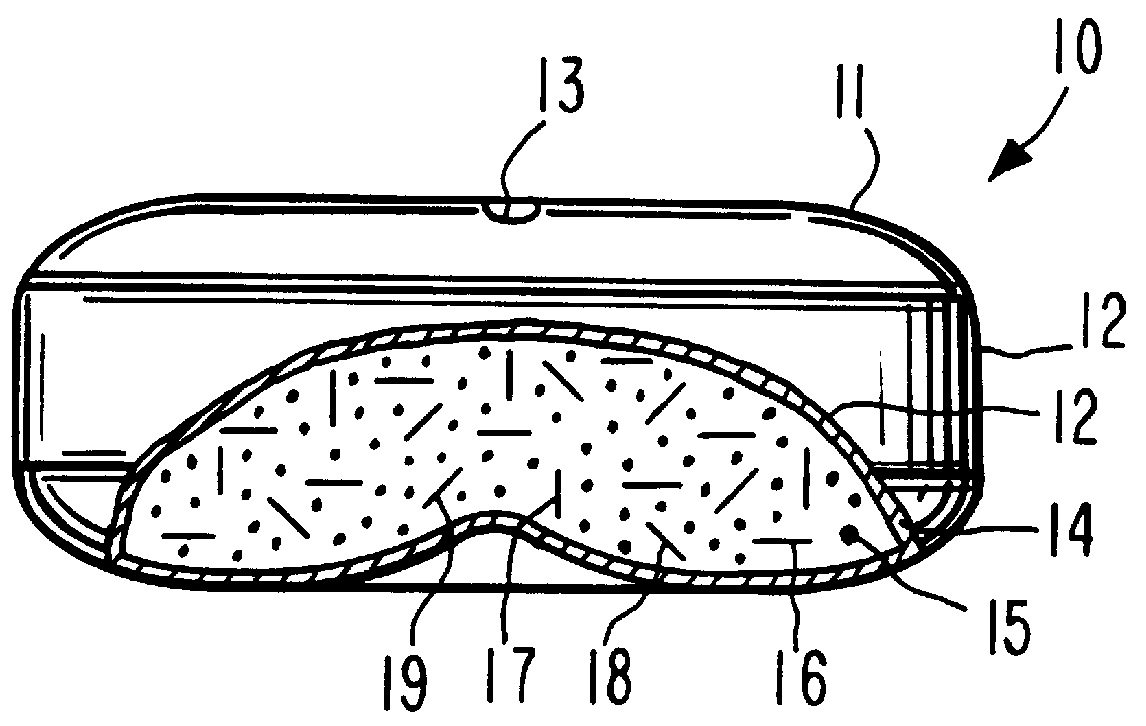

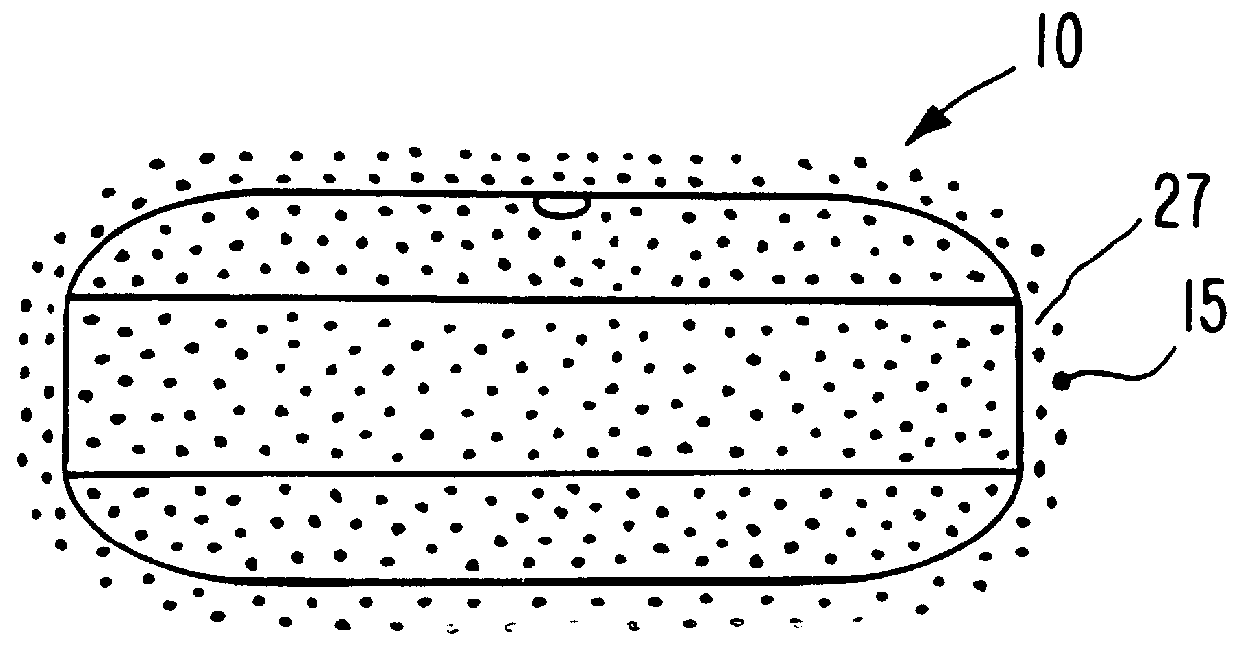

InactiveUS6036973AAvoiding toxic rangeShorten the progressPowder deliveryPill deliveryDiseaseNervous system

A dosage form is disclosed for administering 10 ng to 1200 mg tacrine to a patient in need of tacrine therapy.

Owner:ENCINAL PHARMA INVESTMENTS

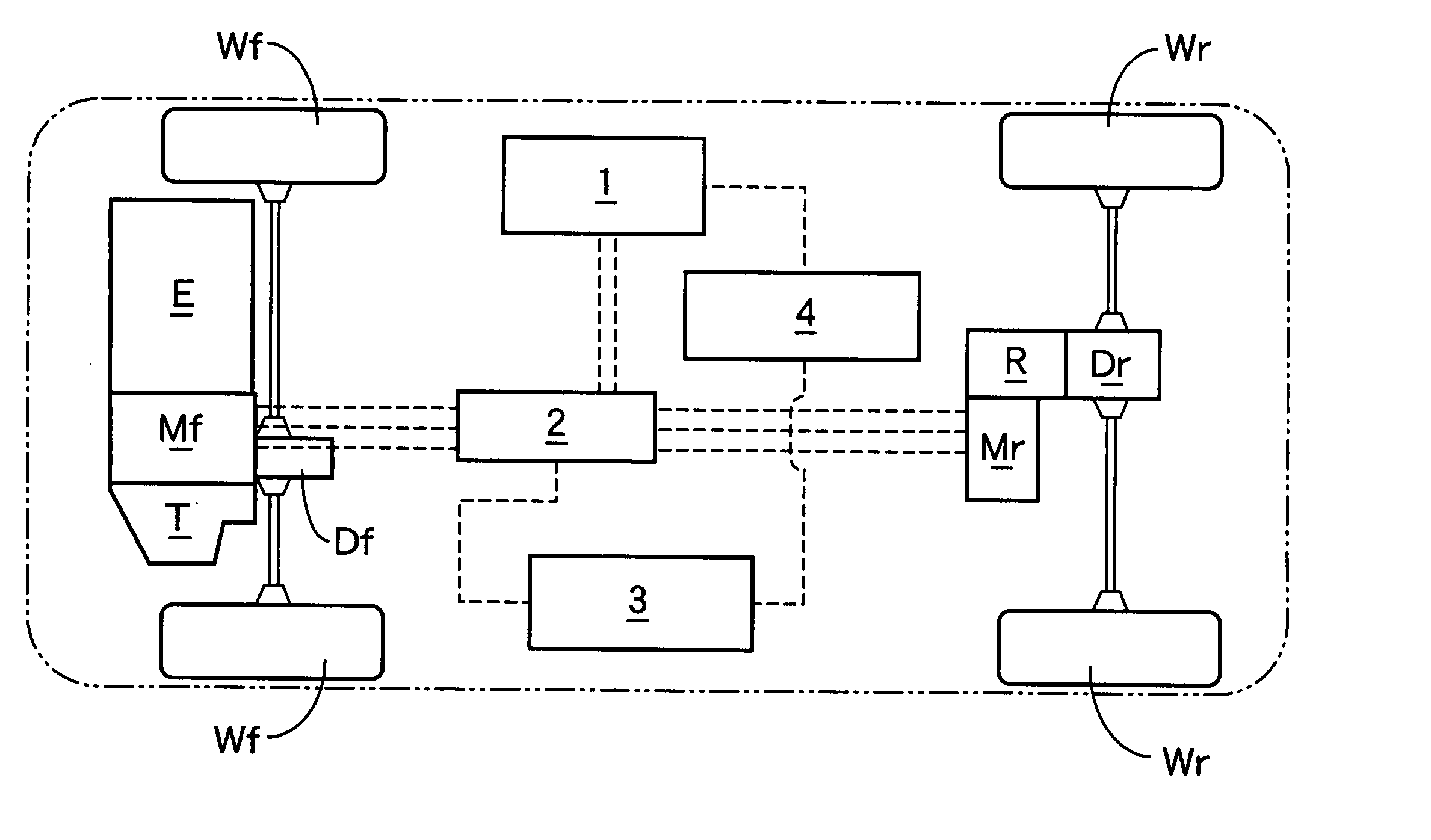

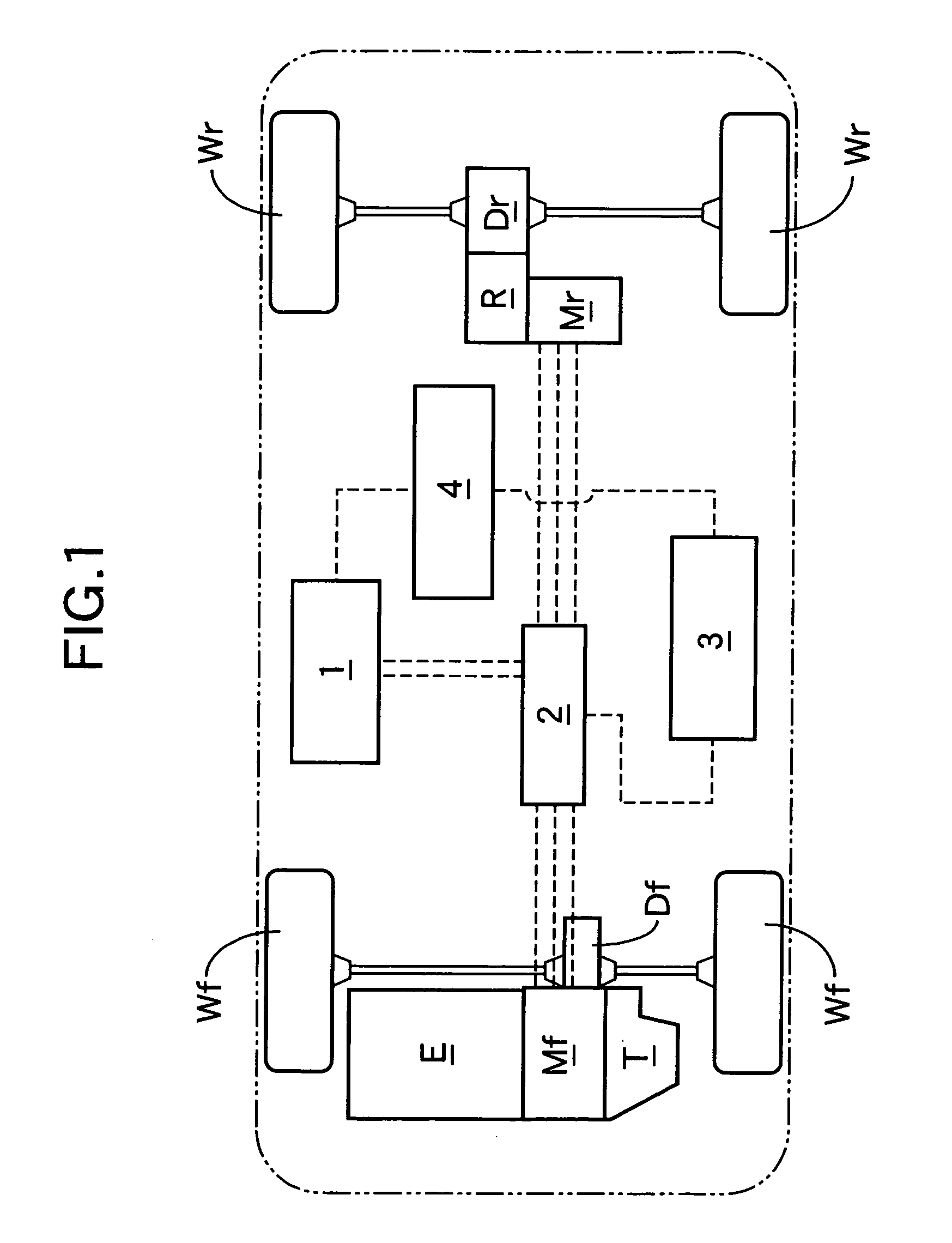

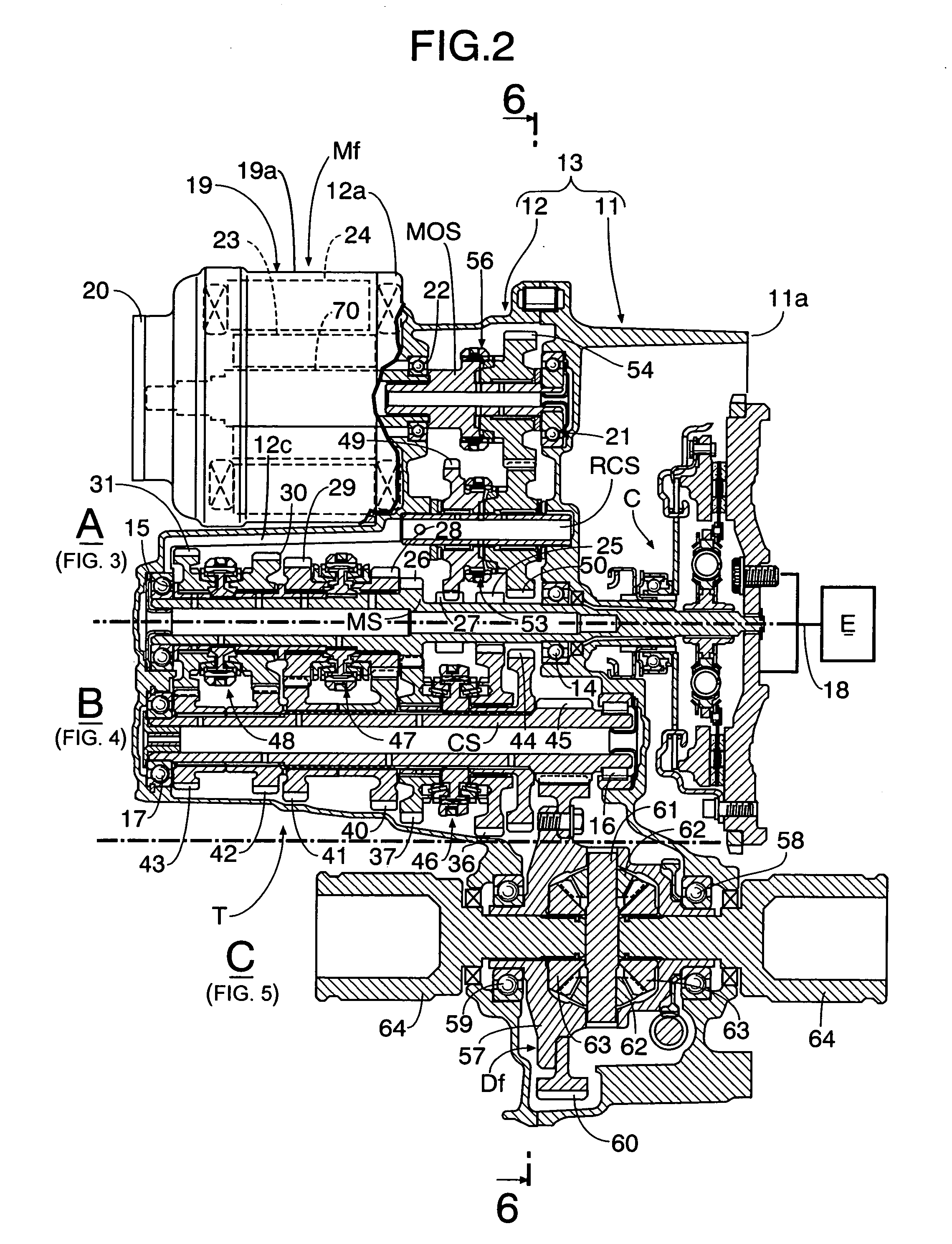

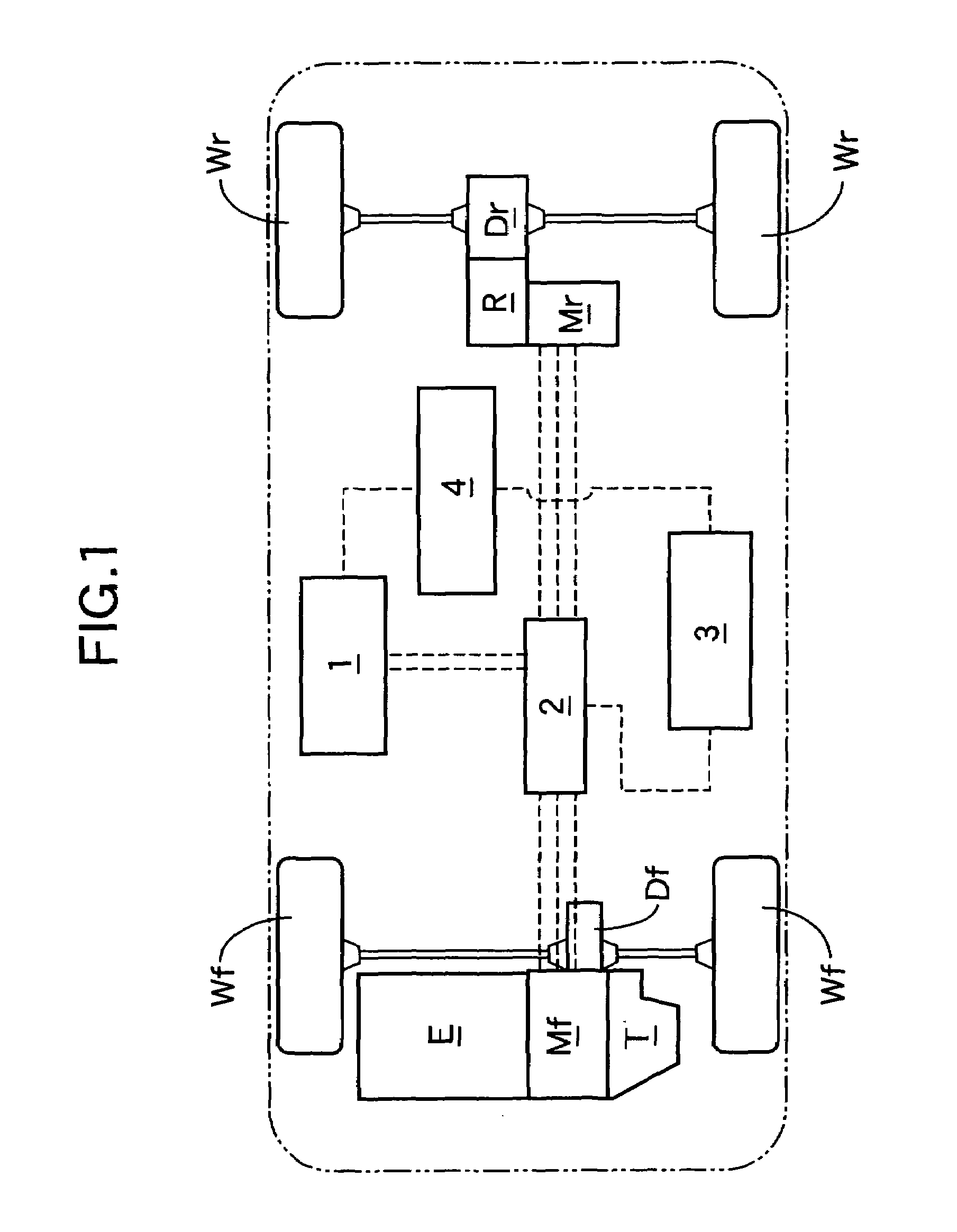

Vehicular drive system

ActiveUS20050139401A1Minimize loss in driving forceLoss of driving forceGearboxesMechanical actuated clutchesVariatorPower transmission

In a vehicular drive system for a hybrid vehicle, in which driving forces of an engine and a motor are transmitted through a power transmission mechanism to driven wheels, a common oil stored in a transmission case and a motor case is used for lubricating the power transmission mechanism and the motor. During travel by means of an engine, when a synchromesh mechanism operated by a shift fork isolates the motor from the power transmission mechanism, an oil return hole blocking rod, provided in the shift fork, blocks an oil return hole providing communication between the motor case and the transmission case, thereby preventing oil in the motor case from flowing into the transmission case, to lower oil level in the transmission case. Thus, during travel of the hybrid vehicle, driving force loss due to motor drag resistance and oil stirring resistance is minimized.

Owner:HONDA MOTOR CO LTD

Emergency vehicle warning lights

InactiveUS20080036582A1Eliminate wind wind noiseEliminate wind resistanceOptical signallingEngineeringVisor

A system for providing warning lights for emergency vehicles in which the warning lights are incorporated into standard appearing accessories of the vehicle. A hood mounted deflector includes warning lights and takedown lights. Side window vent visors include warning lights, alley lights, and a convenience light. A rear spoiler includes warning lights. The warning lights are connected to at least one controller that provides various patterns of warning lights involving at least one color. In one embodiment, the takedown lights are connected to a controller that provides for flashing the takedown lights in addition to operating them continuously. The convenience light is connected to the interior lights of the vehicle. An operator panel in the vehicle is connected to the controllers and the alley lights.

Owner:FARLEYS CUSTOM AUTO SERVICES

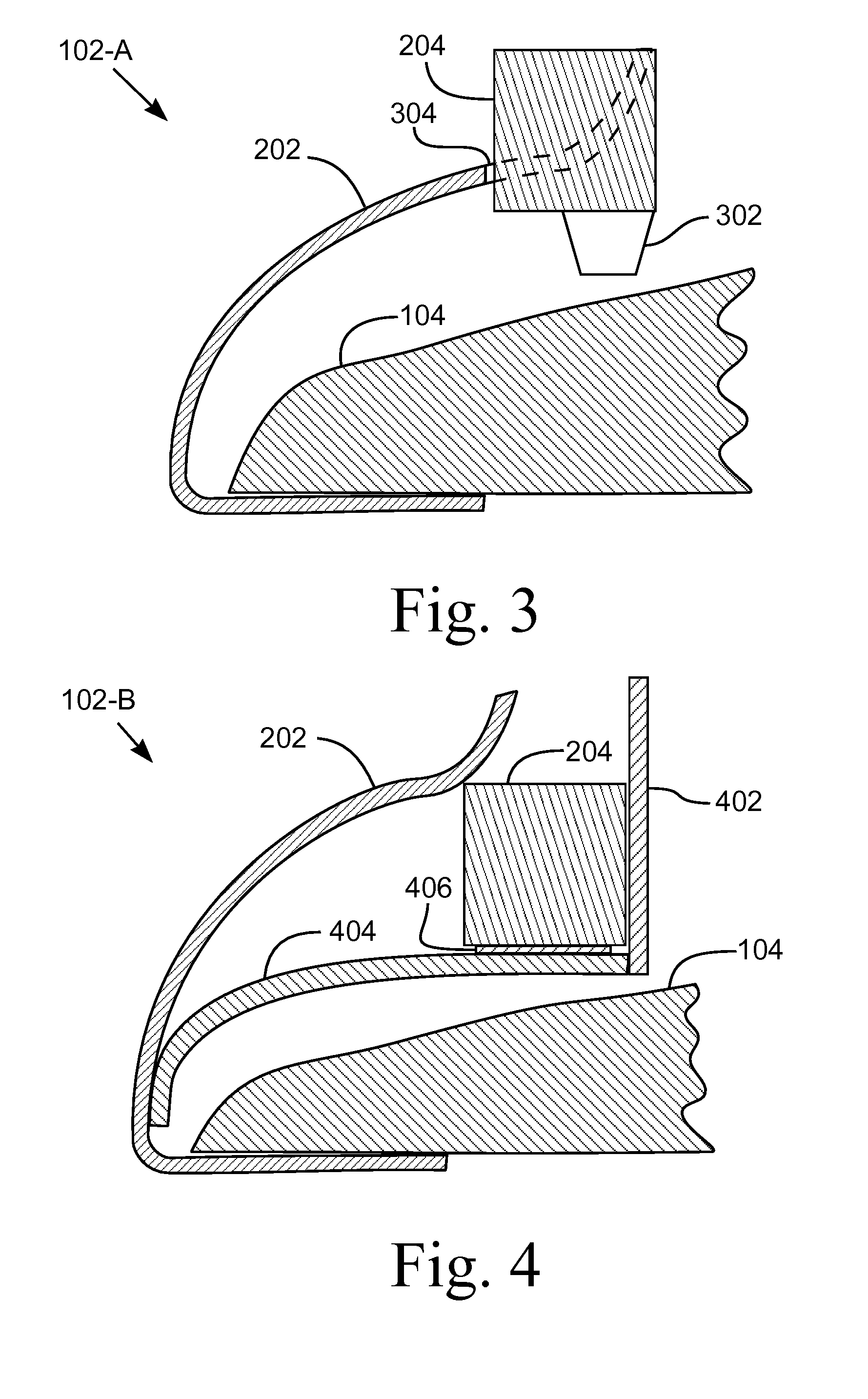

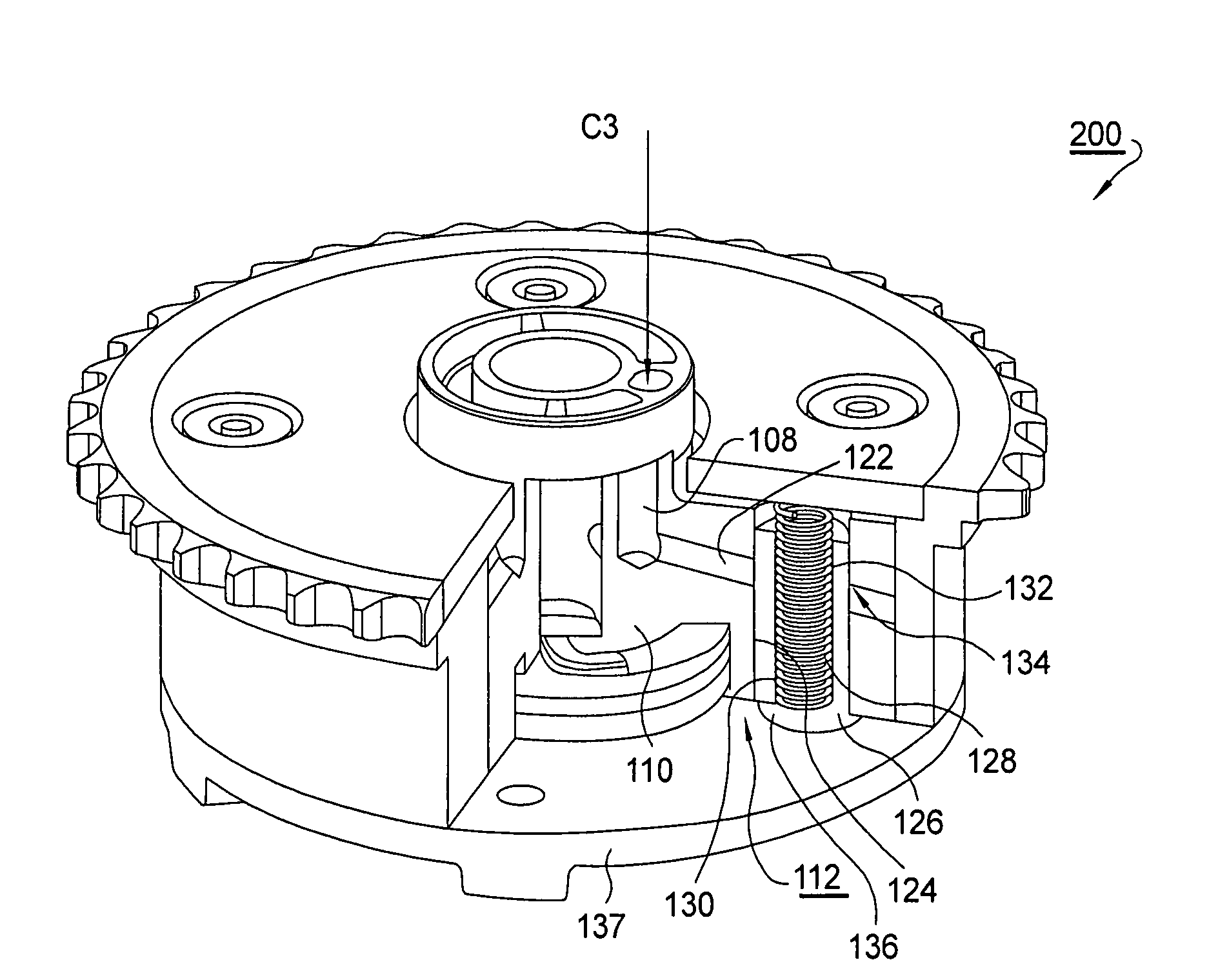

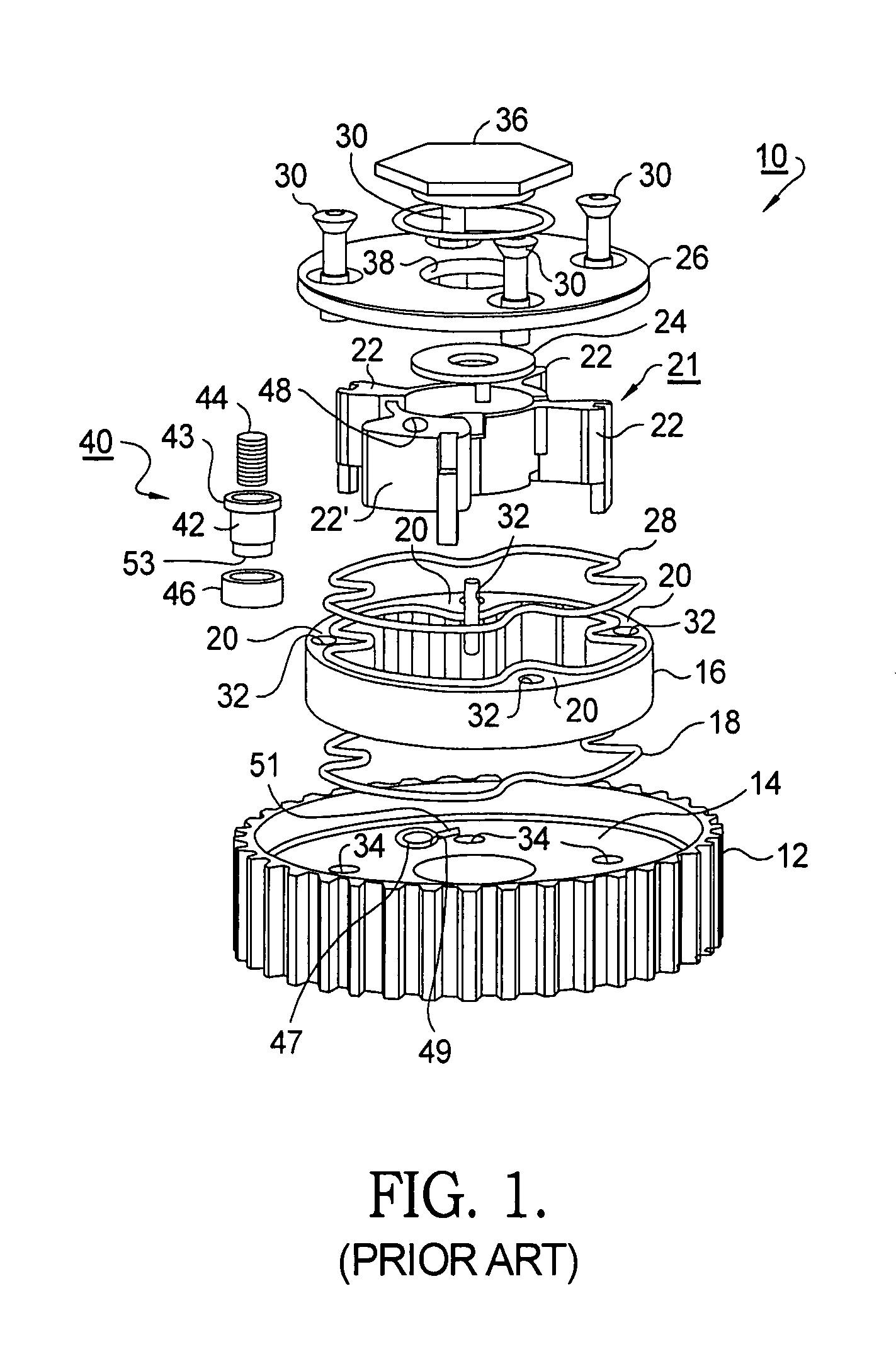

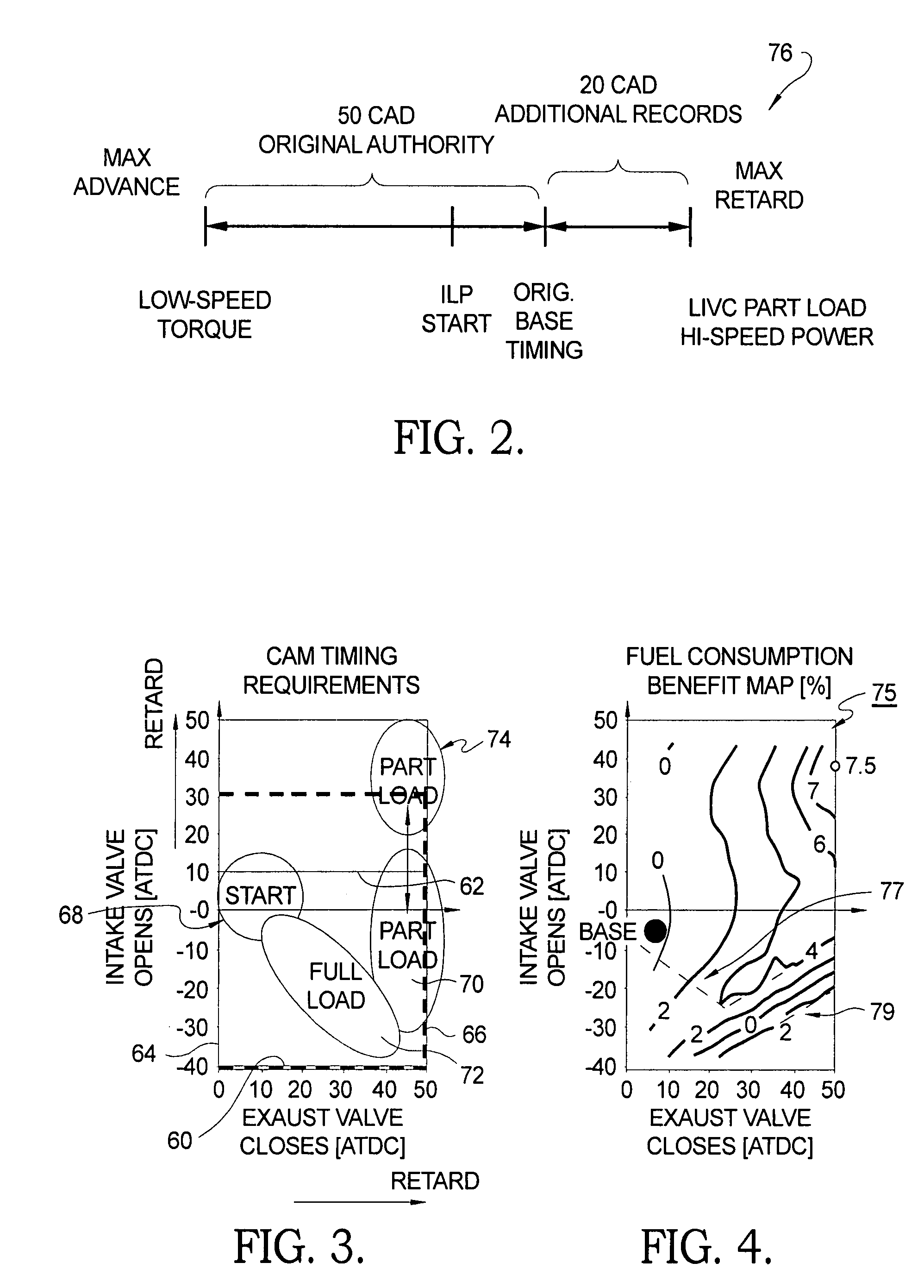

Vane-type cam phaser having increased rotational authority, intermediate position locking, and dedicated oil supply

ActiveUS7421989B2Eliminate resistancePrevent pressureOscillating piston enginesValve drivesEngineeringCam

A vane-type camshaft phaser having a rotational authority between 40 crank degrees before TDC and 30 crank degrees after TDC. The phaser includes a stator seat formed at a rotation position intermediate between full advance and full retard. A locking pin in a vane of the rotor engages the seat, locking the rotor at the intermediate position. The pin is disengaged by pressurized engine oil independent of oil flows for advance and retard of the rotor. The oil is controlled by a dedicated valve. Preferably, the seat and the ends of the locking pin are vented by passages in the rotor and stator which are aligned when the rotor is at the selected locking angle to remove oil resistance to entry of the pin into the seat. To position the locking pin over the seat, phasing rate is reduced to allow time for the locking pin to engage the seat.

Owner:DELPHI TECH IP LTD

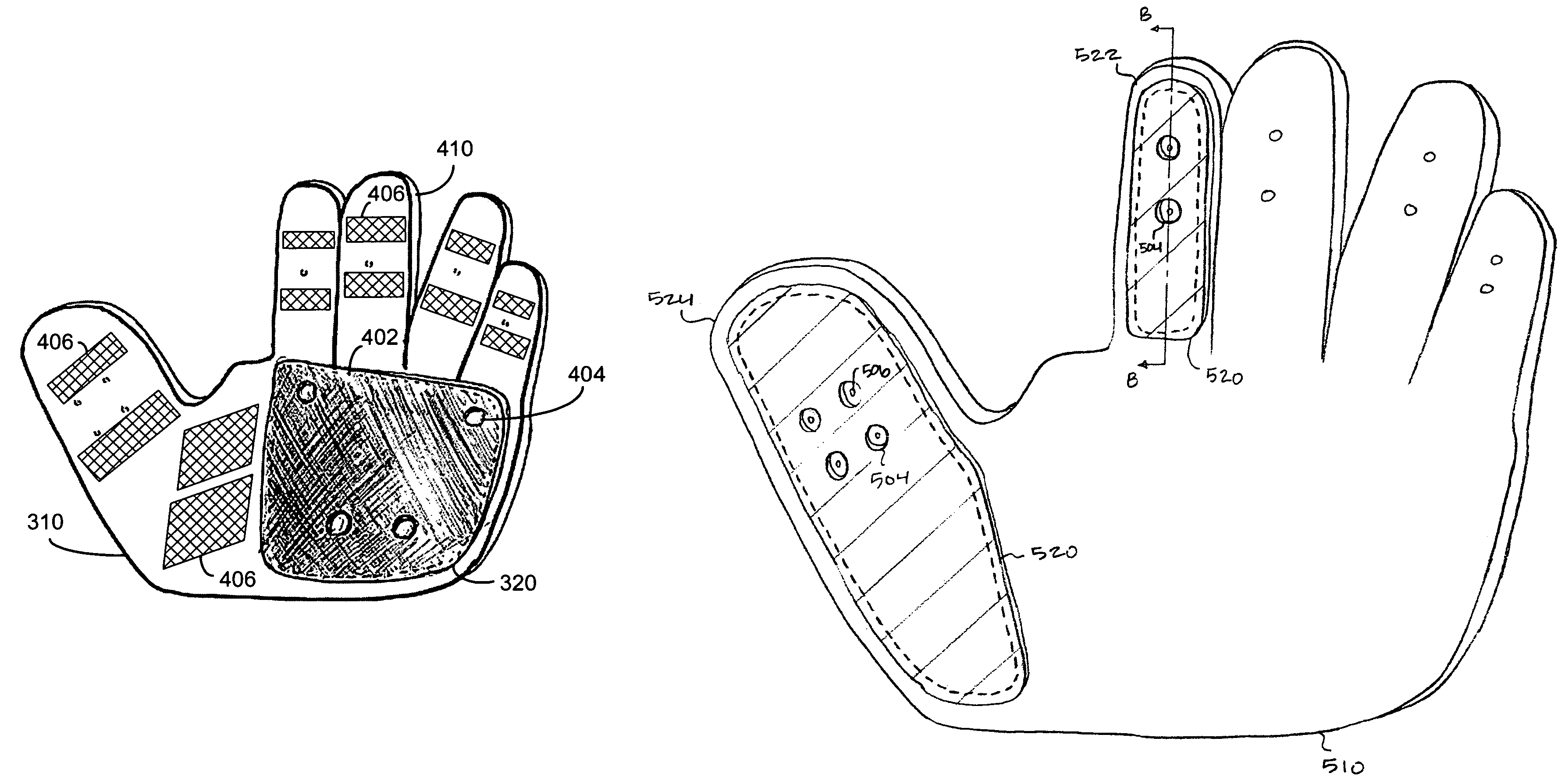

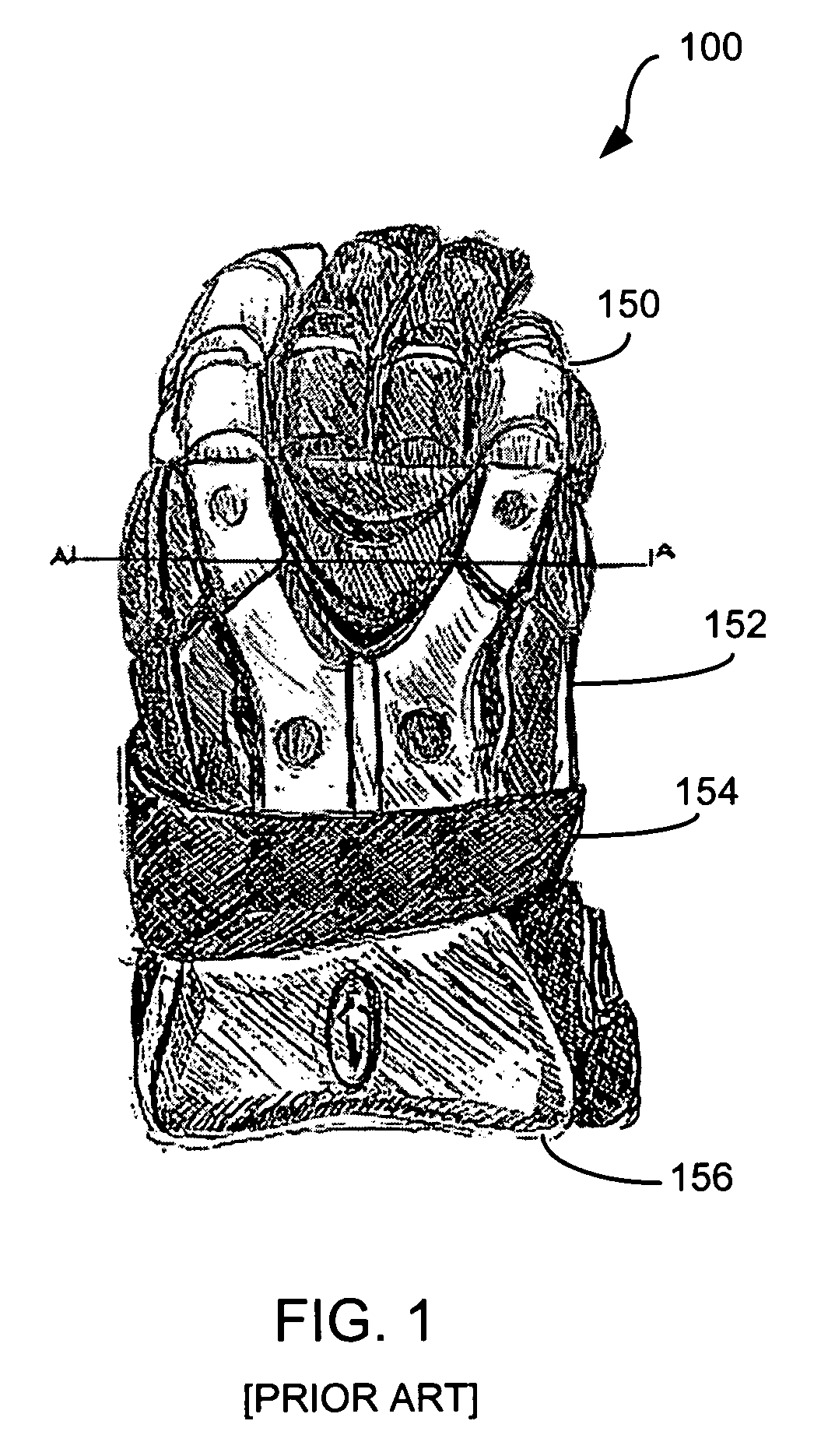

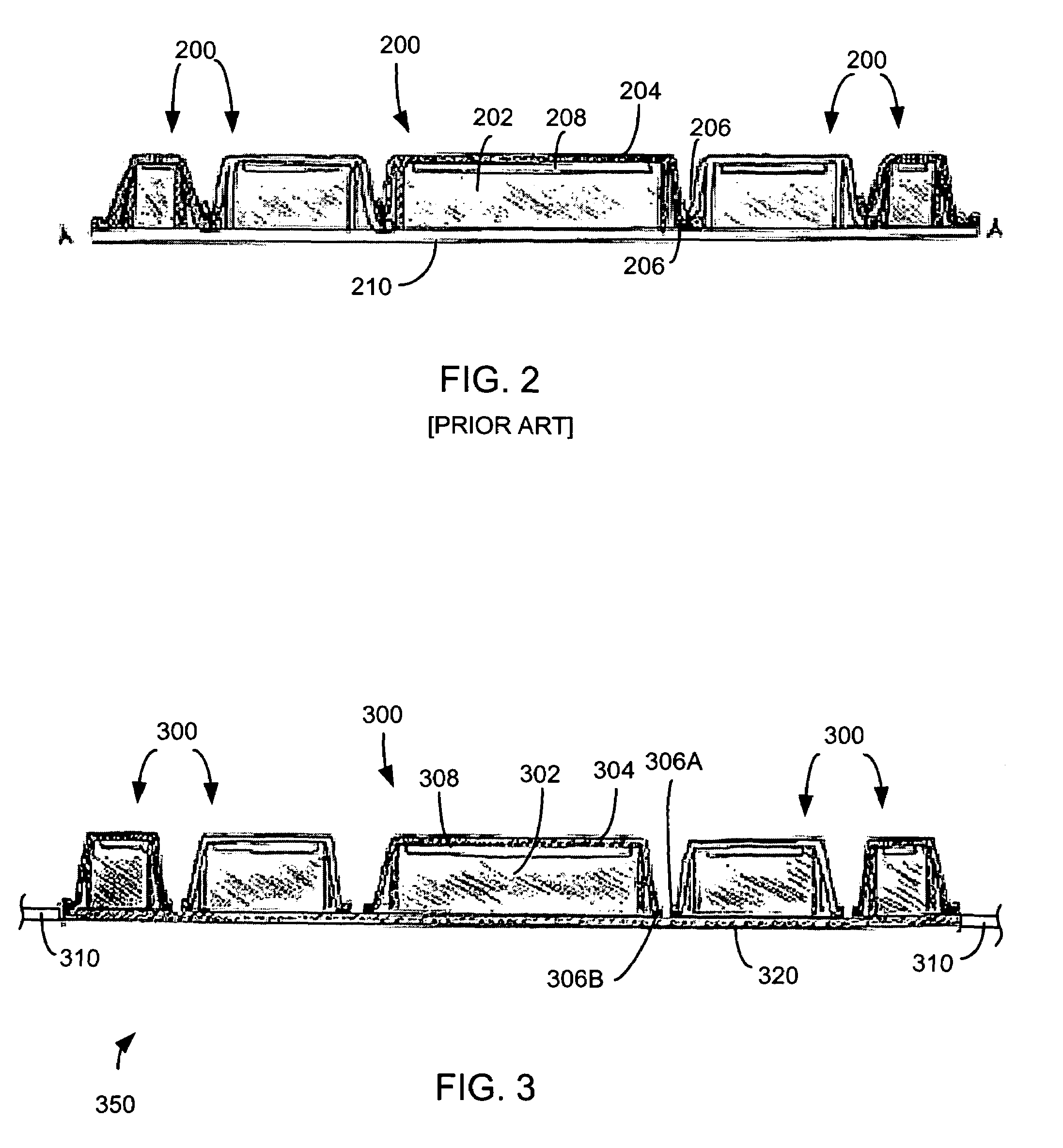

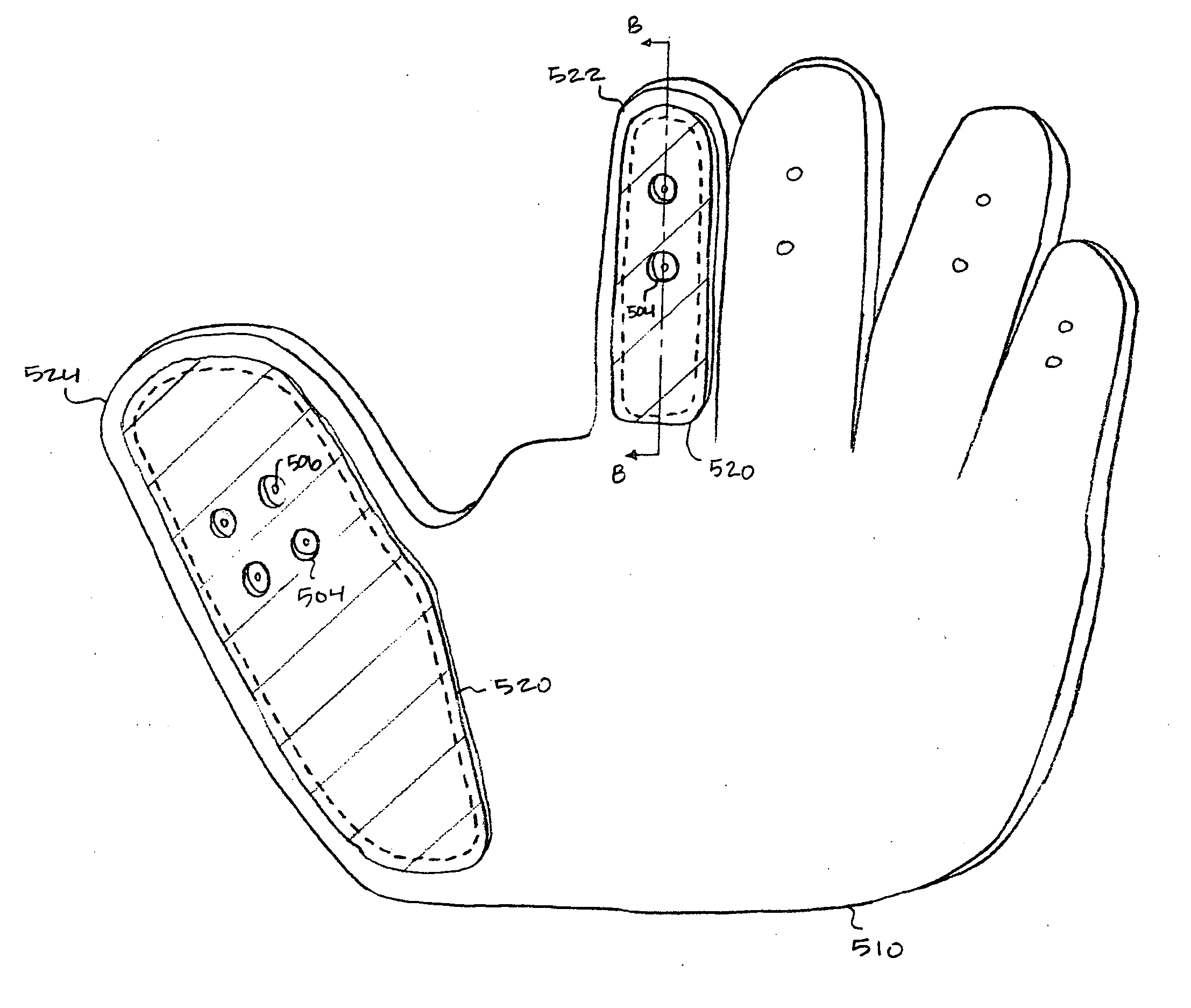

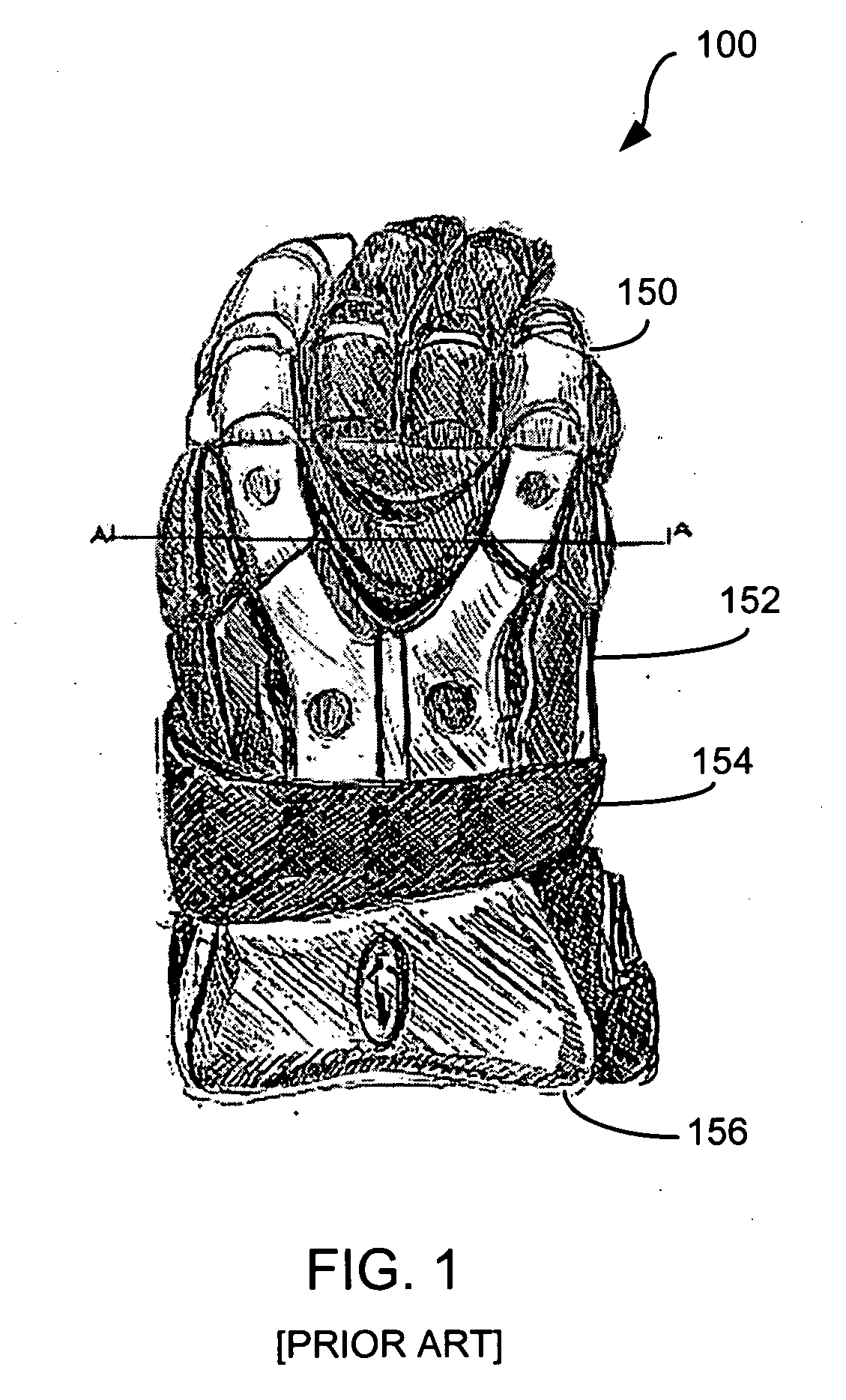

Protective glove with independent pads

ActiveUS7370373B2Flexible gloveEliminate resistanceGlovesSport apparatusElastic substrateBiomedical engineering

A protective glove having an elastic substrate, a first pad segment attached to the elastic substrate, and a second pad segment attached to the elastic substrate independently from the first pad segment. The elastic substrate can be disposed over an area intended to substantially cover a forearm, a wrist, a back of a hand, a finger, and / or a thumb of a user wearing the glove. The elastic substrate can be stretchable in different directions and to different degrees in the areas around each pad segment, thereby enabling independent movement of the individually attached pad segments to accommodate any number of contours and flex points. Other embodiments provide methods for manufacturing a protective glove having independent pads.

Owner:WM T BURNETT IP

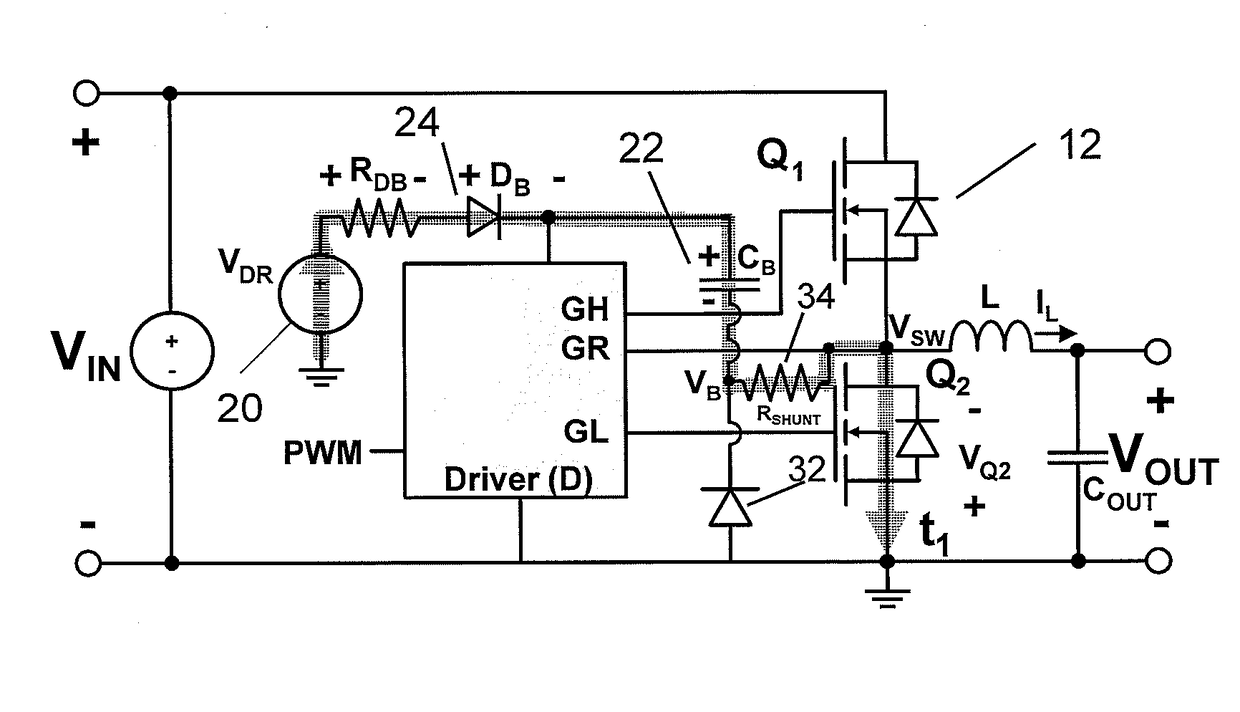

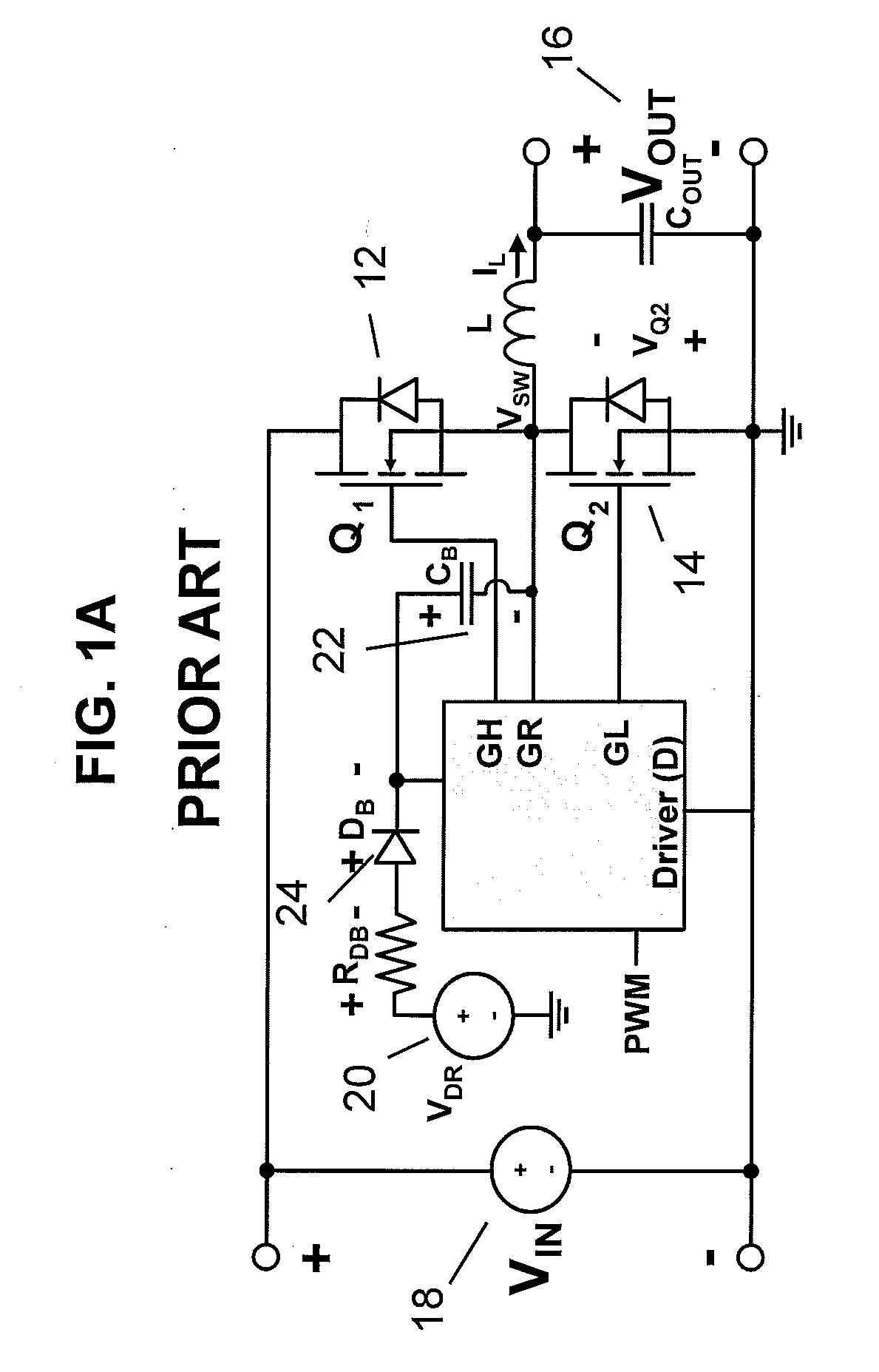

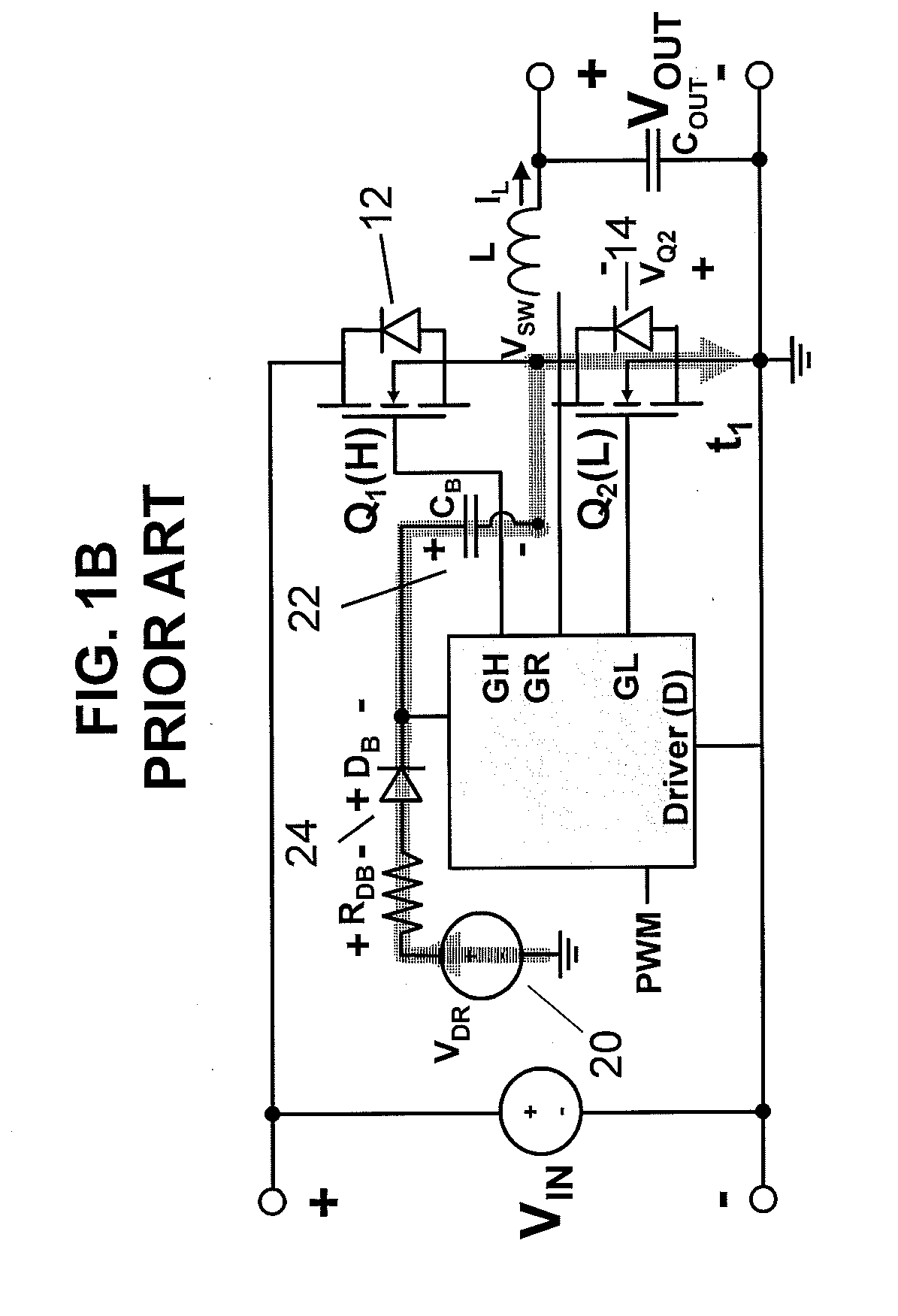

BOOTSTRAP CAPACITOR OVER-VOLTAGE MANAGEMENT CIRCUIT FOR GaN TRANSISTOR BASED POWER CONVERTERS

ActiveUS20180159529A1Lower overall pressure dropPreventing overvoltage conditionTransistorEfficient power electronics conversionCapacitanceLow voltage

A drive circuit for a half bridge transistor circuit formed of enhancement mode GaN transistors. A shunt diode is connected to the bootstrap capacitor at a node between the bootstrap capacitor and ground, the shunt diode being decoupled from the midpoint node of the half bridge by a shunt resistor. The shunt diode advantageously provides a low voltage drop path to charge the bootstrap capacitor during the dead-time charging period when both the high side and low side transistors of the half bridge are off.

Owner:EFFICIENT POWER CONVERSION CORP

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for quickening sousing of raw meat by adopting ultrasonic treatment

InactiveCN101999694AImprove tendernessImprove permeabilityFood preparationProcess engineeringRaw meat

The invention provides a method for quickening sousing of raw meat by adopting ultrasonic treatment, comprising the following steps of: treating raw fresh meat soaked in a sousing solution with a certain concentration (such as 0-26% salts) for a certain time (0-5h) by using the ultrasonic waves (the power range is 0-3000w) with a certain frequency range (20-100kHz) by utilizing the cavitation effect and the mechanical effect of ultrasonic waves to quicken the sousing of the raw meat, and installing a constant-temperature device on a ultrasonic treater to keep the temperatures of the sousing solution and the meat constant (the constant range is 0-25 DEG C). The method for quickening sousing of the raw meat by adopting ultrasonic treatment in the invention is applied to the large-scale quick-sousing production of the raw meat. The method for quickening the sousing of the raw meat by adopting the ultrasonic treatment in the invention has the characteristics of high speed, convenience, sanitation, energy saving and environmental protection, and benefits the quick sousing of most kinds of raw meat, and the time for standing sousing is 2-5 d in general while the time needed by the ultrasonic treatment is only 0-5 h.

Owner:QINGDAO AGRI UNIV +2

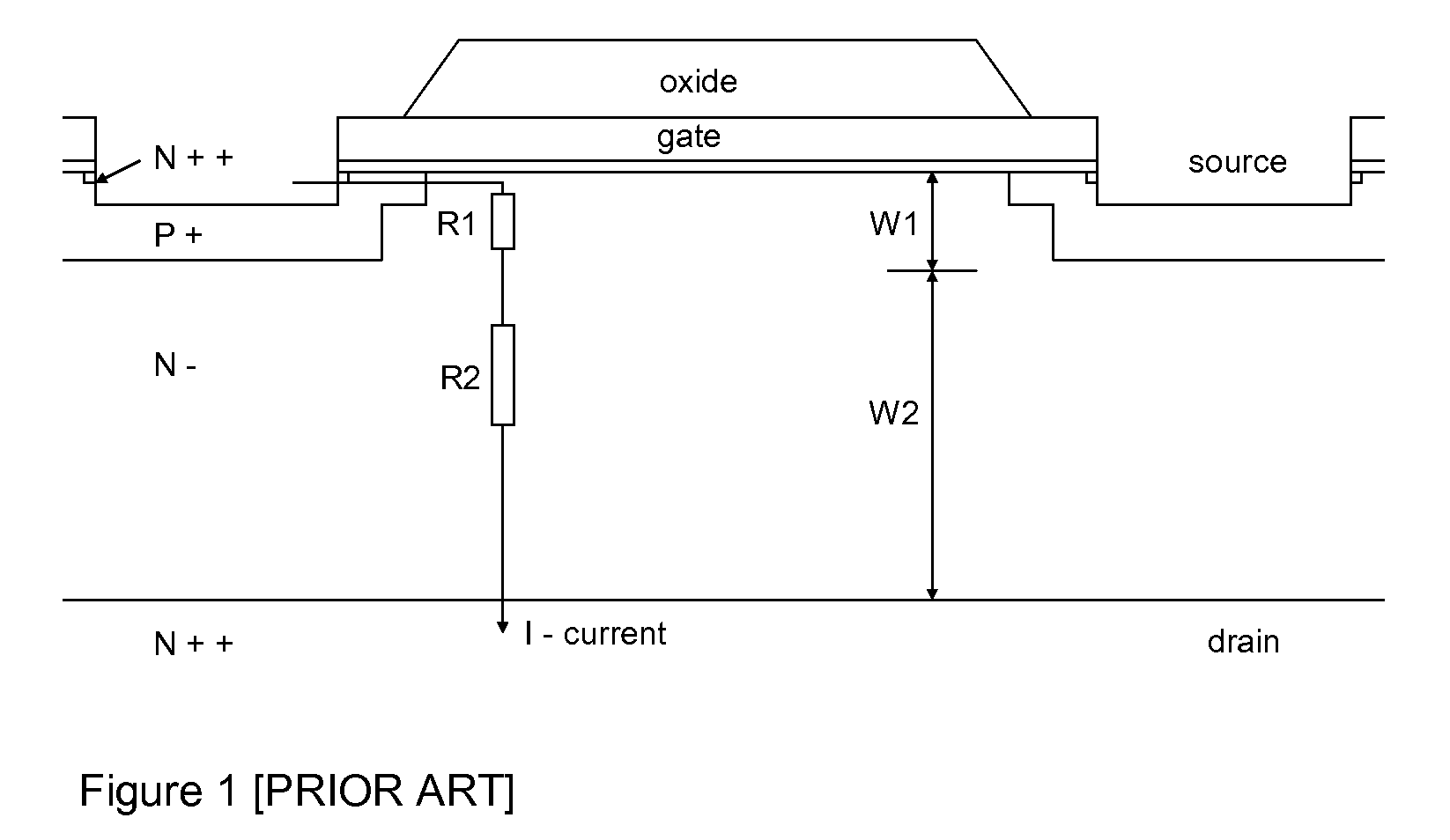

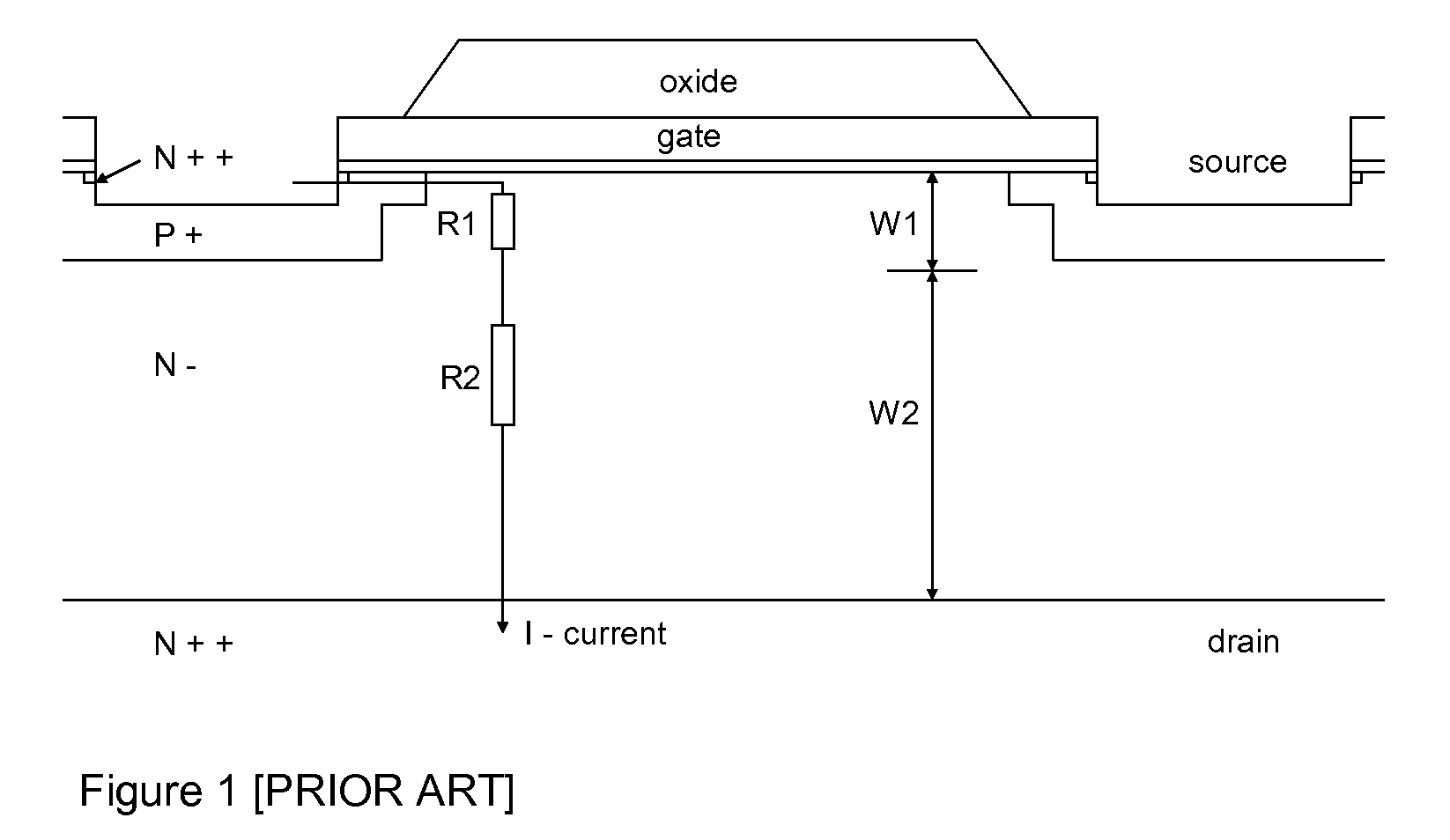

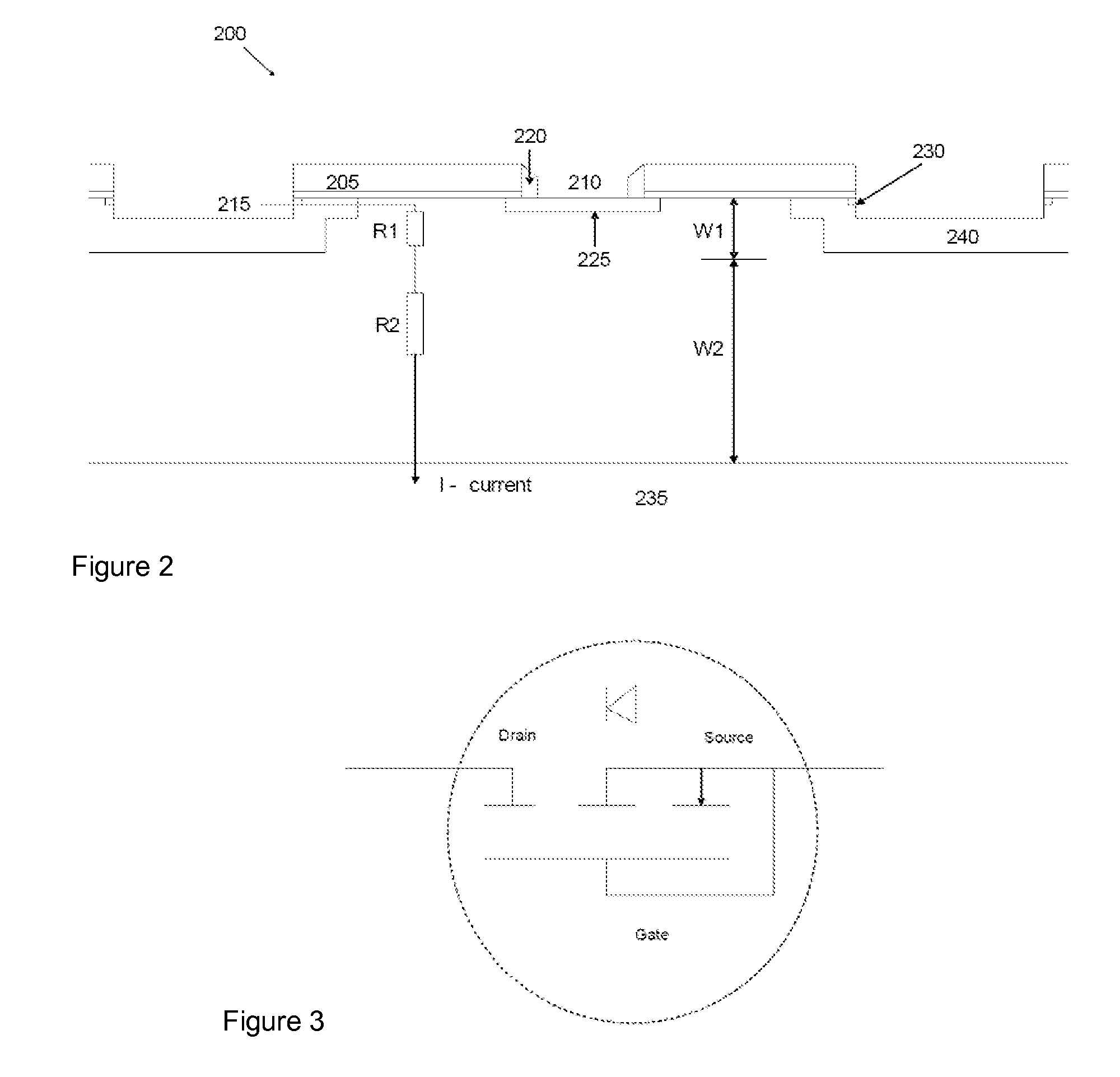

Adjustable Field Effect Rectifier

ActiveUS20090078962A1Function reliably and efficientlyFast recoveryThyristorMOSFETElectromagnetic interference

An Adjustable Field Effect Rectifier uses aspects of MOSFET structure together with an adjustment pocket or region to result in a device that functions reliably and efficiently at high voltages without significant negative resistance, while also permitting fast recovery and operation at high frequency without large electromagnetic interference.

Owner:STMICROELECTRONICS INT NV

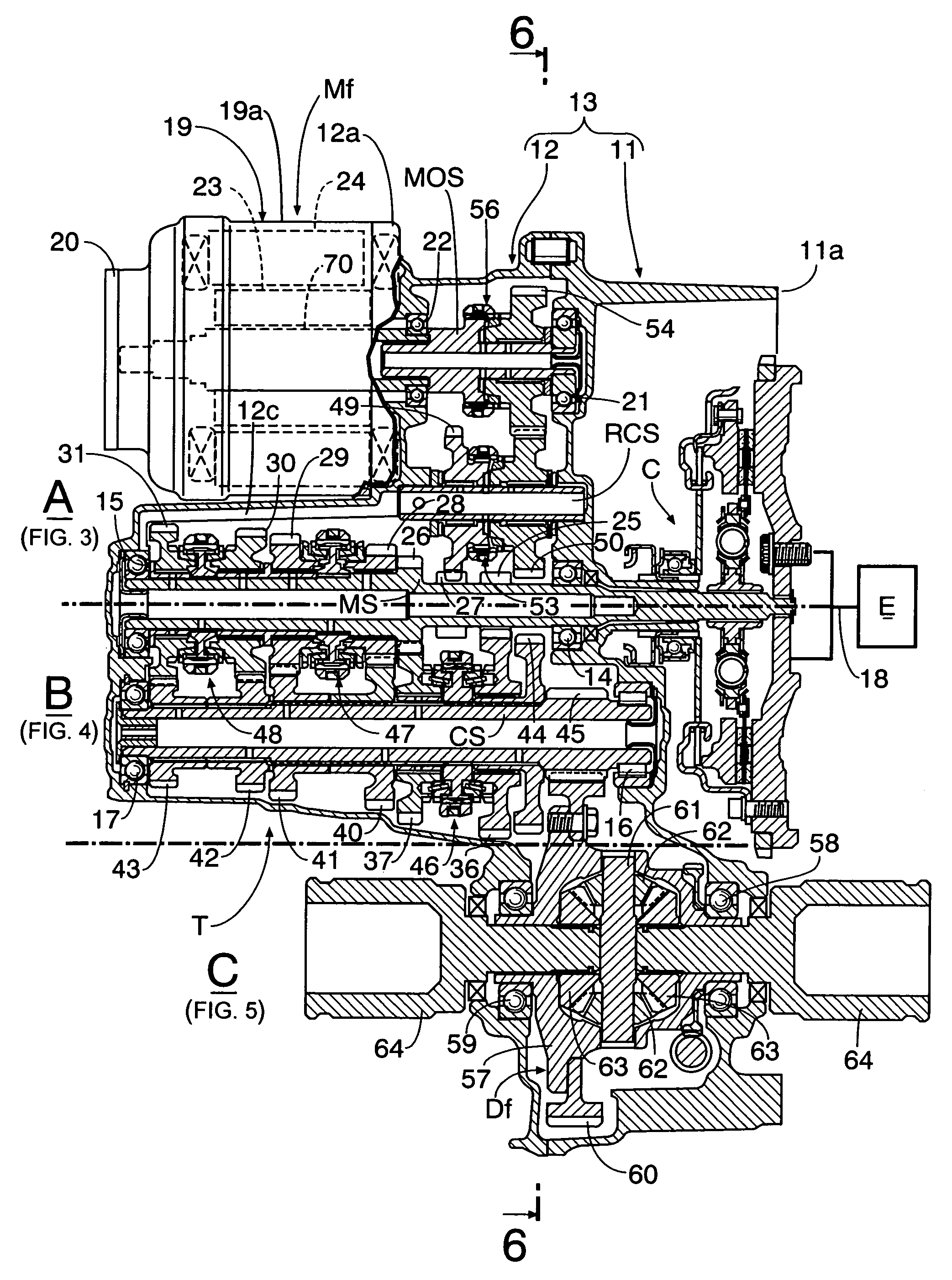

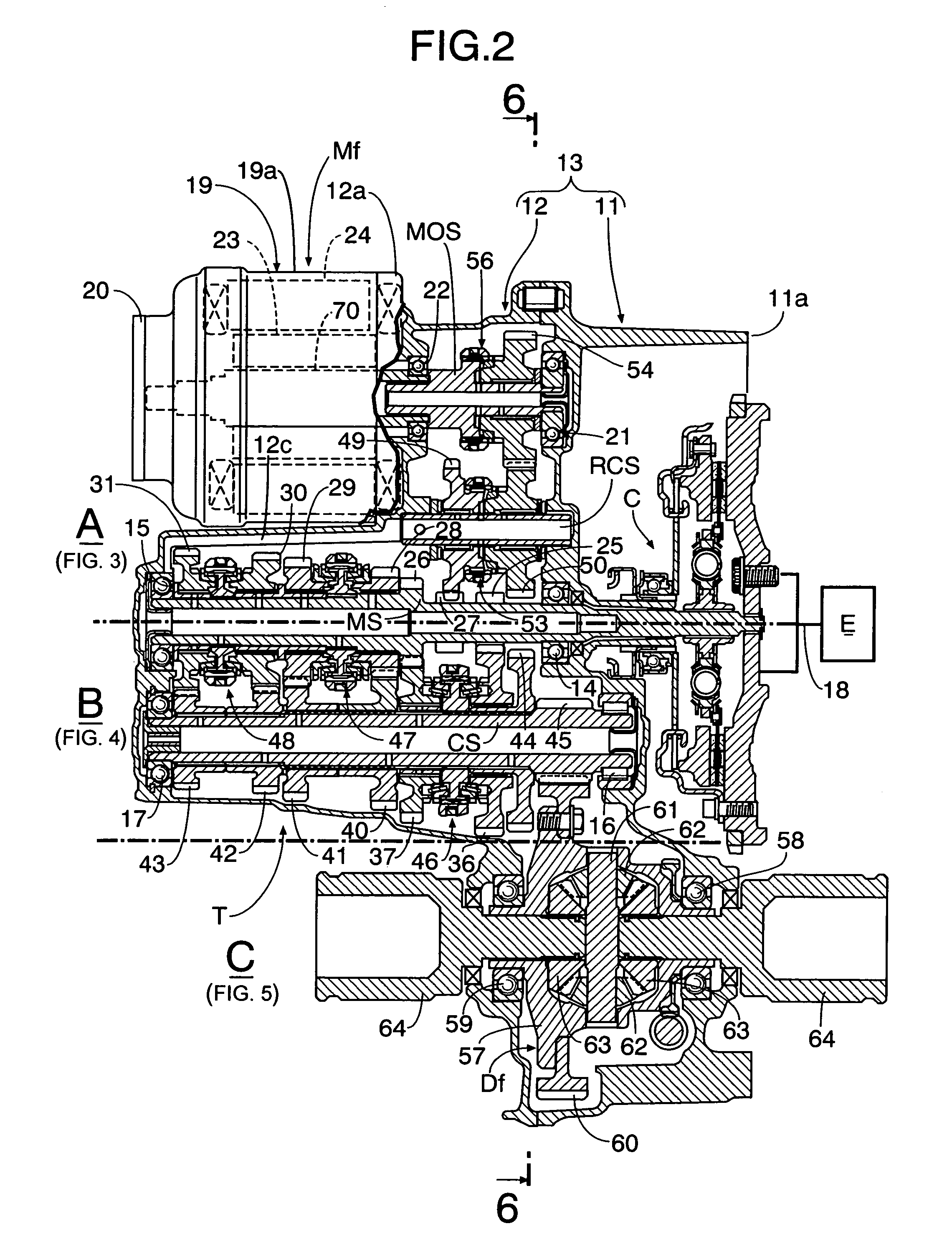

Vehicular drive system

ActiveUS7211025B2Loss of driving forceEliminate resistanceGearboxesMechanical actuated clutchesDrive wheelEngineering

In a vehicular drive system for a hybrid vehicle, in which driving forces of an engine and a motor are transmitted through a power transmission mechanism to driven wheels, a common oil stored in a transmission case and a motor case is used for lubricating the power transmission mechanism and the motor. During travel by using an engine, when a synchromesh mechanism operated by a shift fork isolates the motor from the power transmission mechanism, an oil return hole blocking rod, provided in the shift fork, blocks an oil return hole providing communication between the motor case and the transmission case, thereby preventing oil in the motor case from flowing into the transmission case, to lower oil level in the transmission case. Thus, during travel of the hybrid vehicle, driving force loss due to motor drag resistance and oil stirring resistance is minimized.

Owner:HONDA MOTOR CO LTD

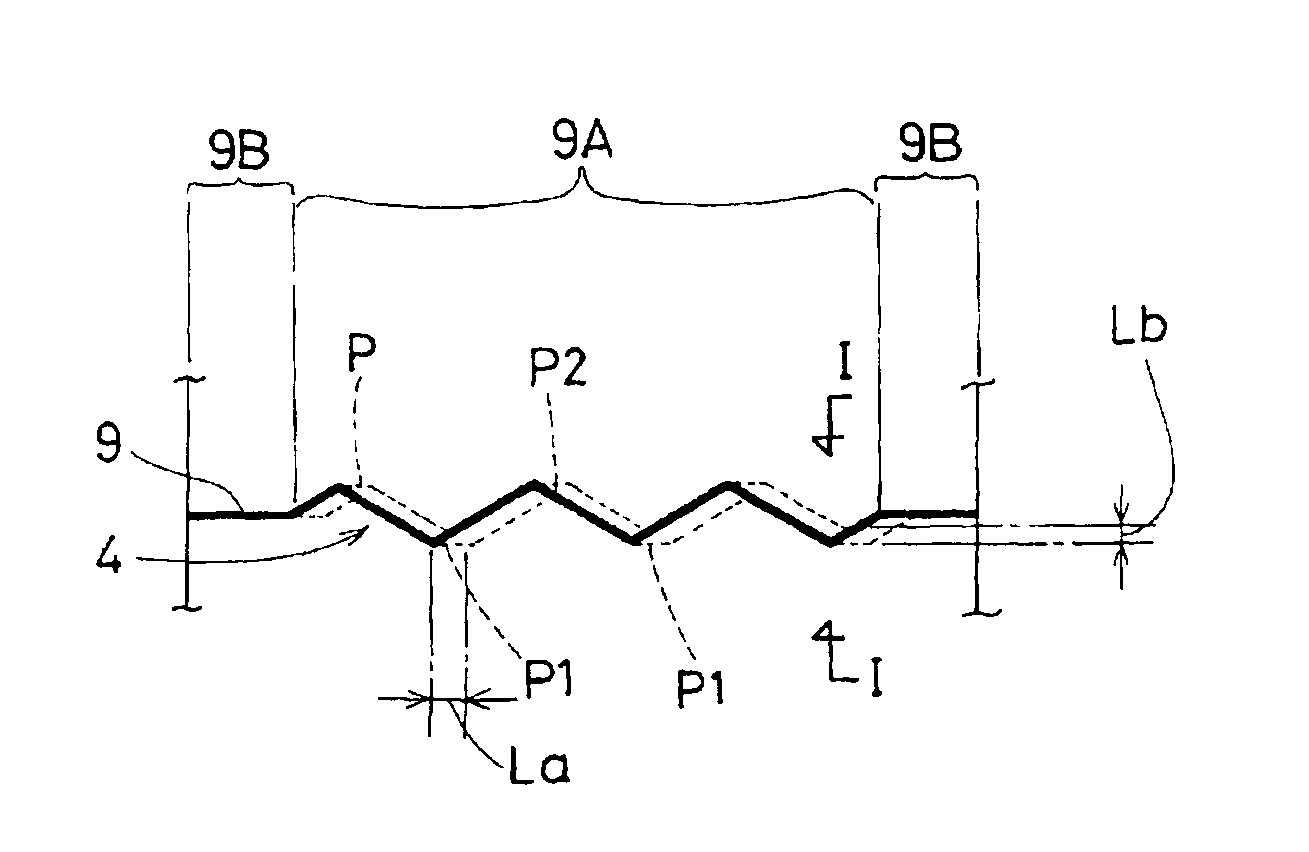

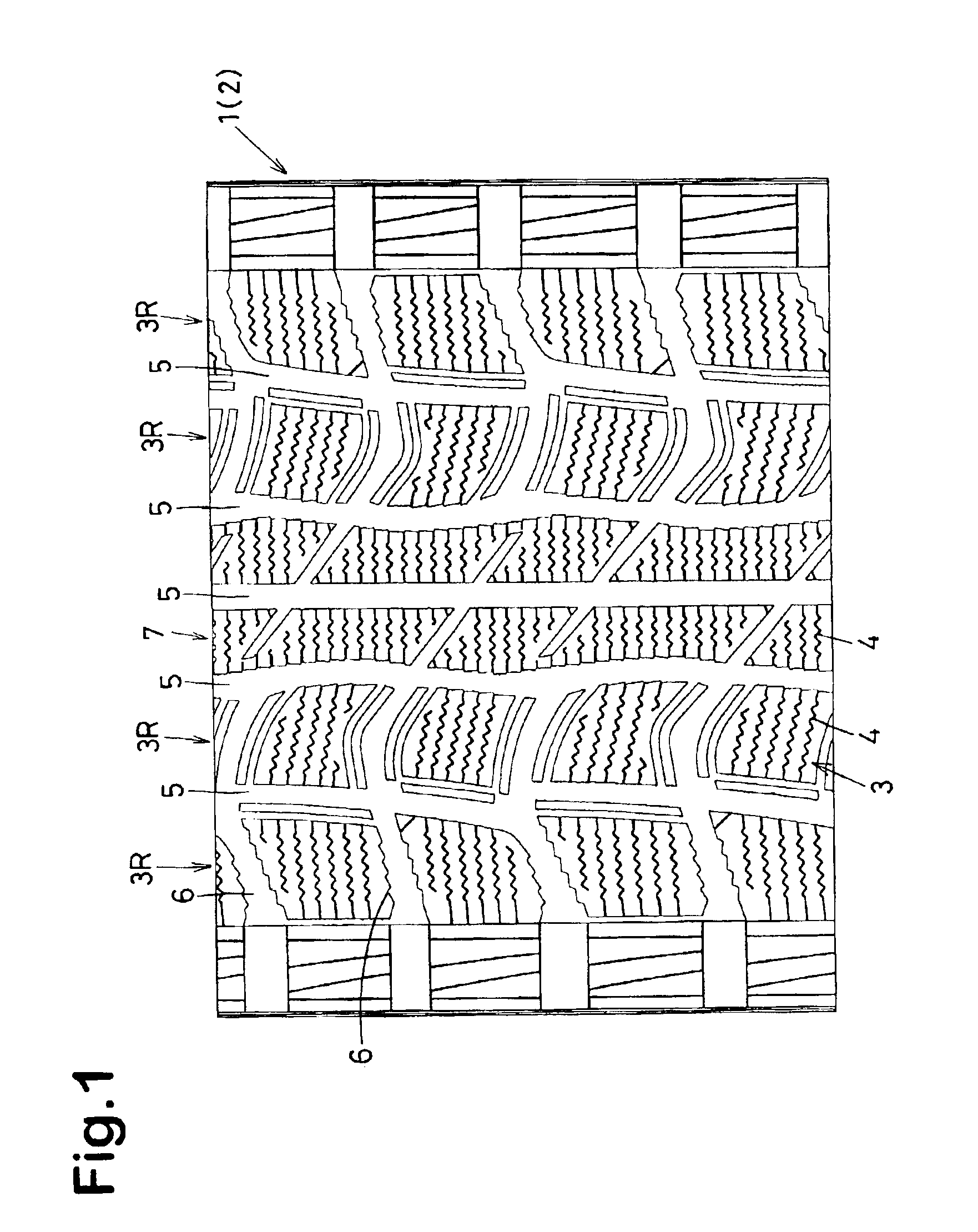

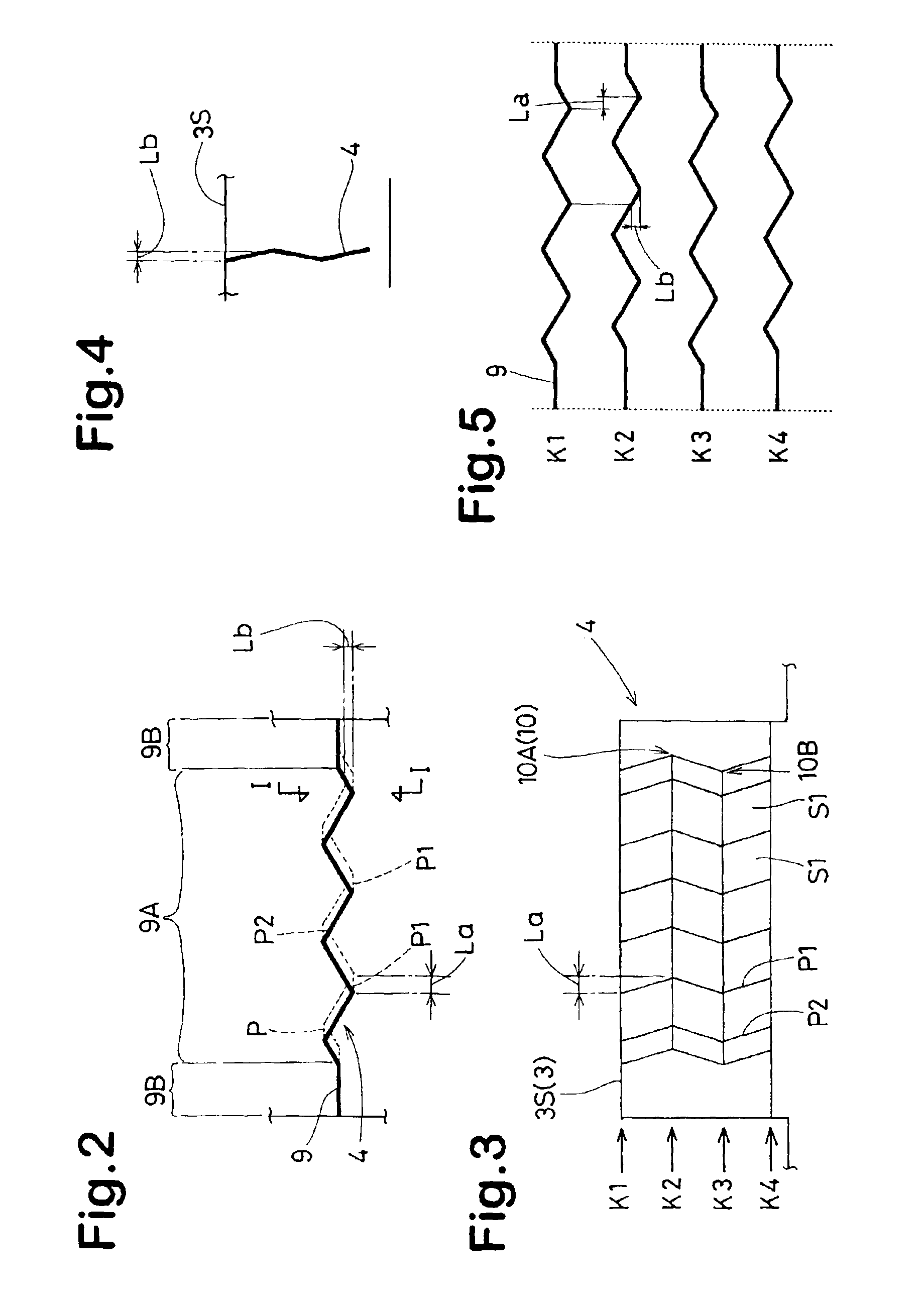

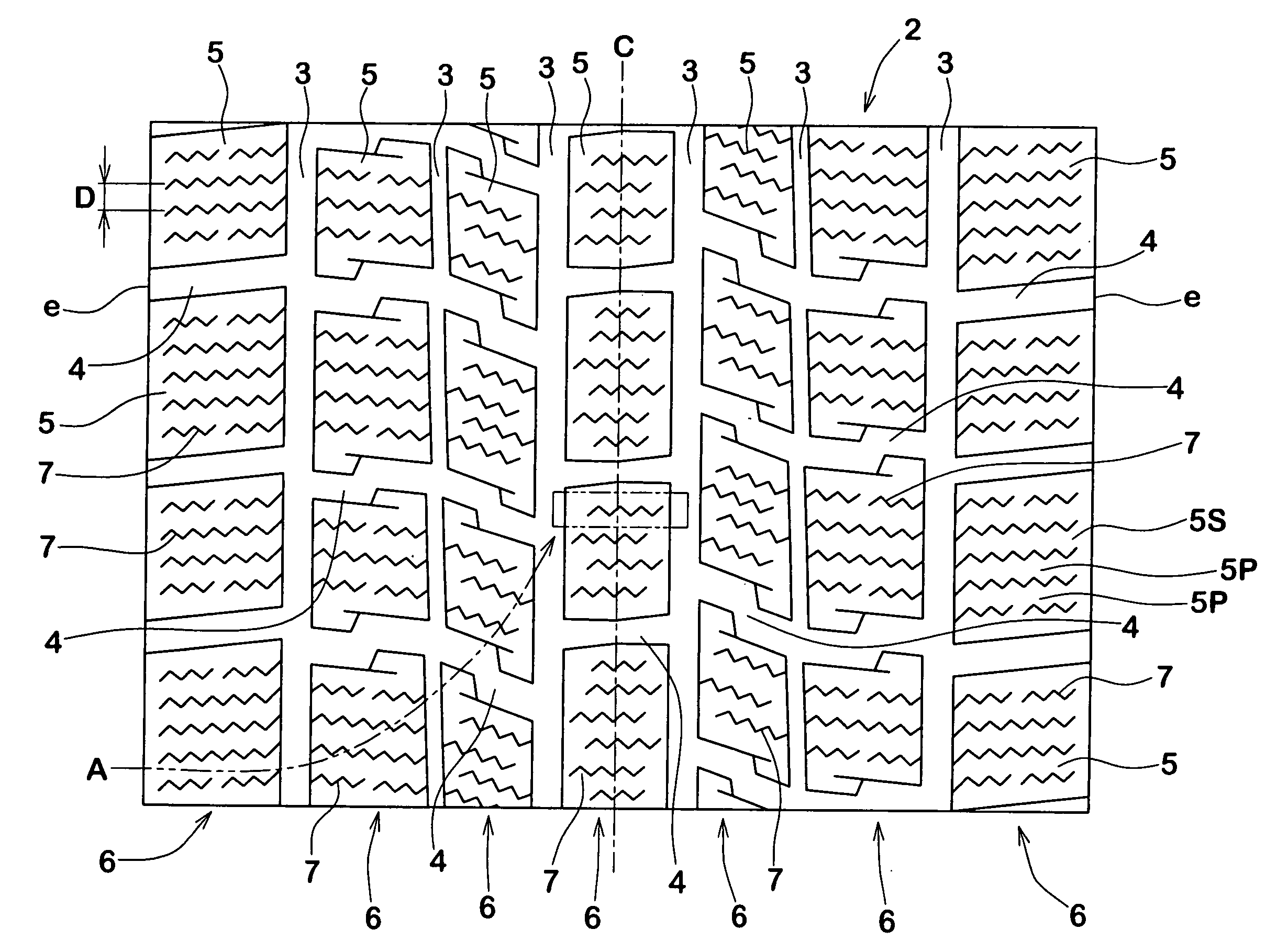

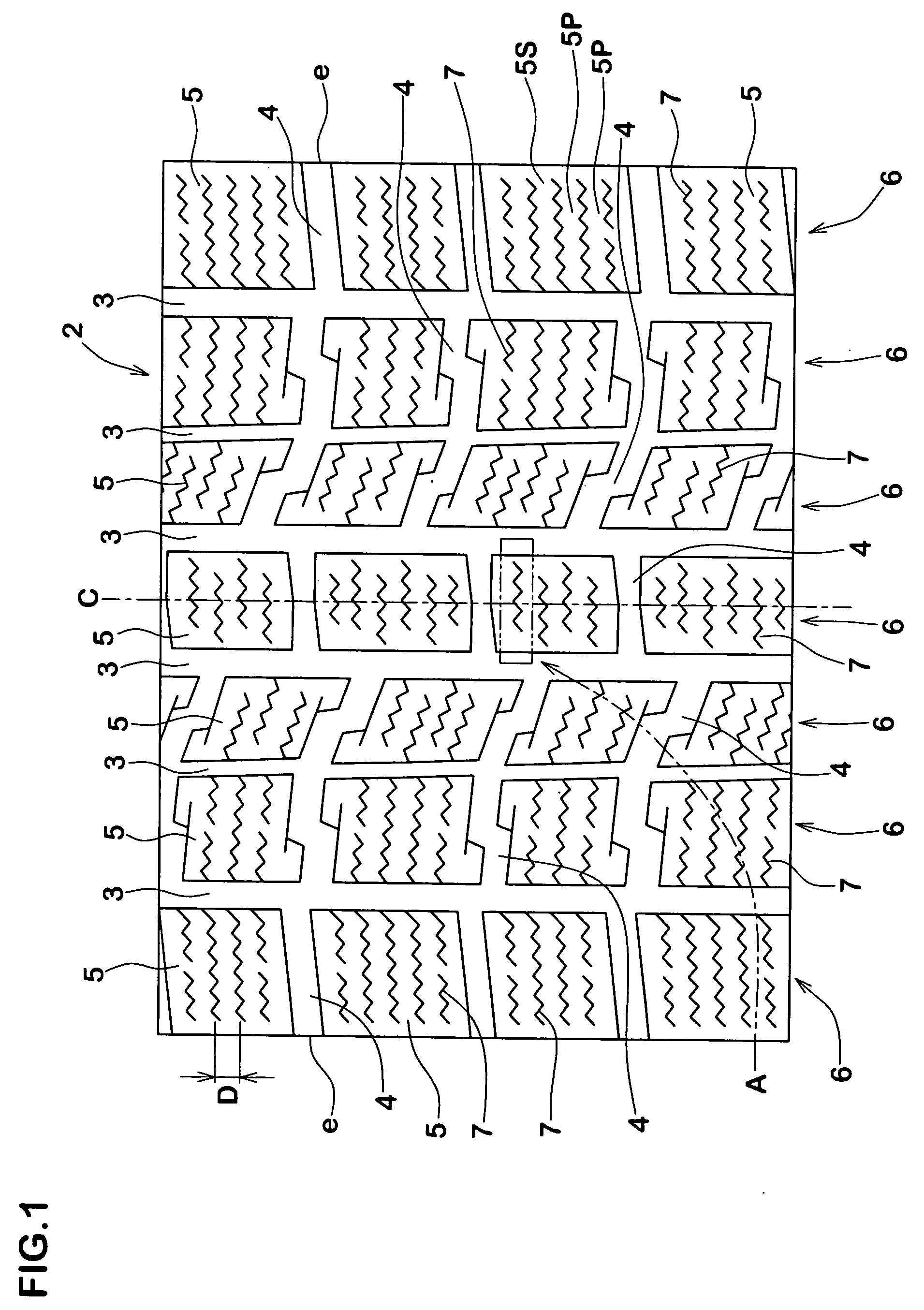

Pneumatic tire including sipes

InactiveUS6907910B2Reduce resistanceEliminate resistanceTyresTyre tread bands/patternsEngineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

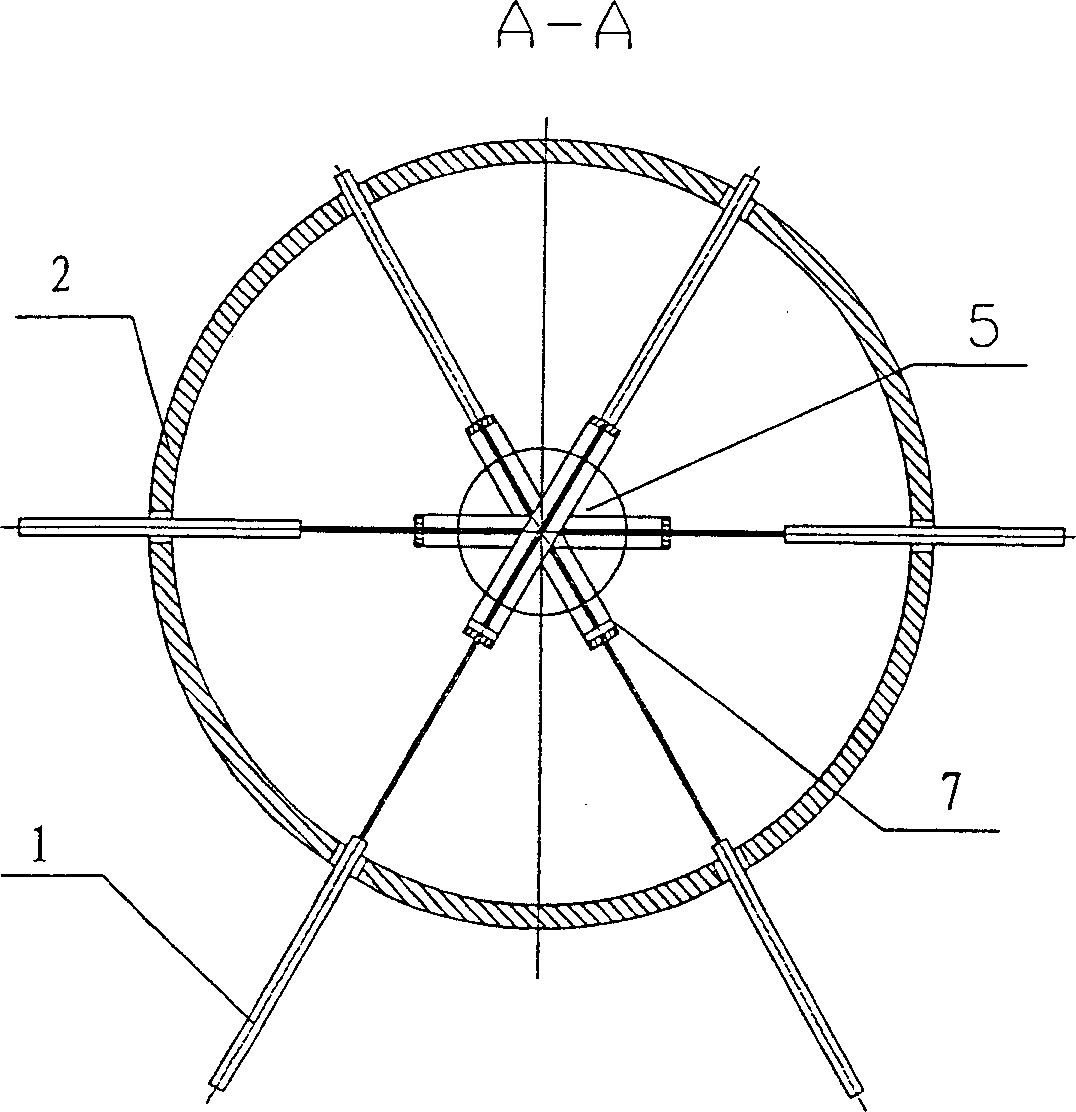

Collapsible paddle ocean current energy generator

InactiveCN1888420AUnaffected by tidal water level changesReduce resistanceHydro energy generationReaction enginesImpellerWork cycle

The present invention discloses telescopic paddle sea-current energy power generation equipment. It mainly includes the following several portions: cylindrical-type wheel hub, flat-plate straight blades, blade stretching and contracting mechanism, stainless steel band wheel, power generator and tower frame. Said invention also provides the working principle of said sea-current energy power generation equipment and its concrete operation method.

Owner:ZHEJIANG UNIV

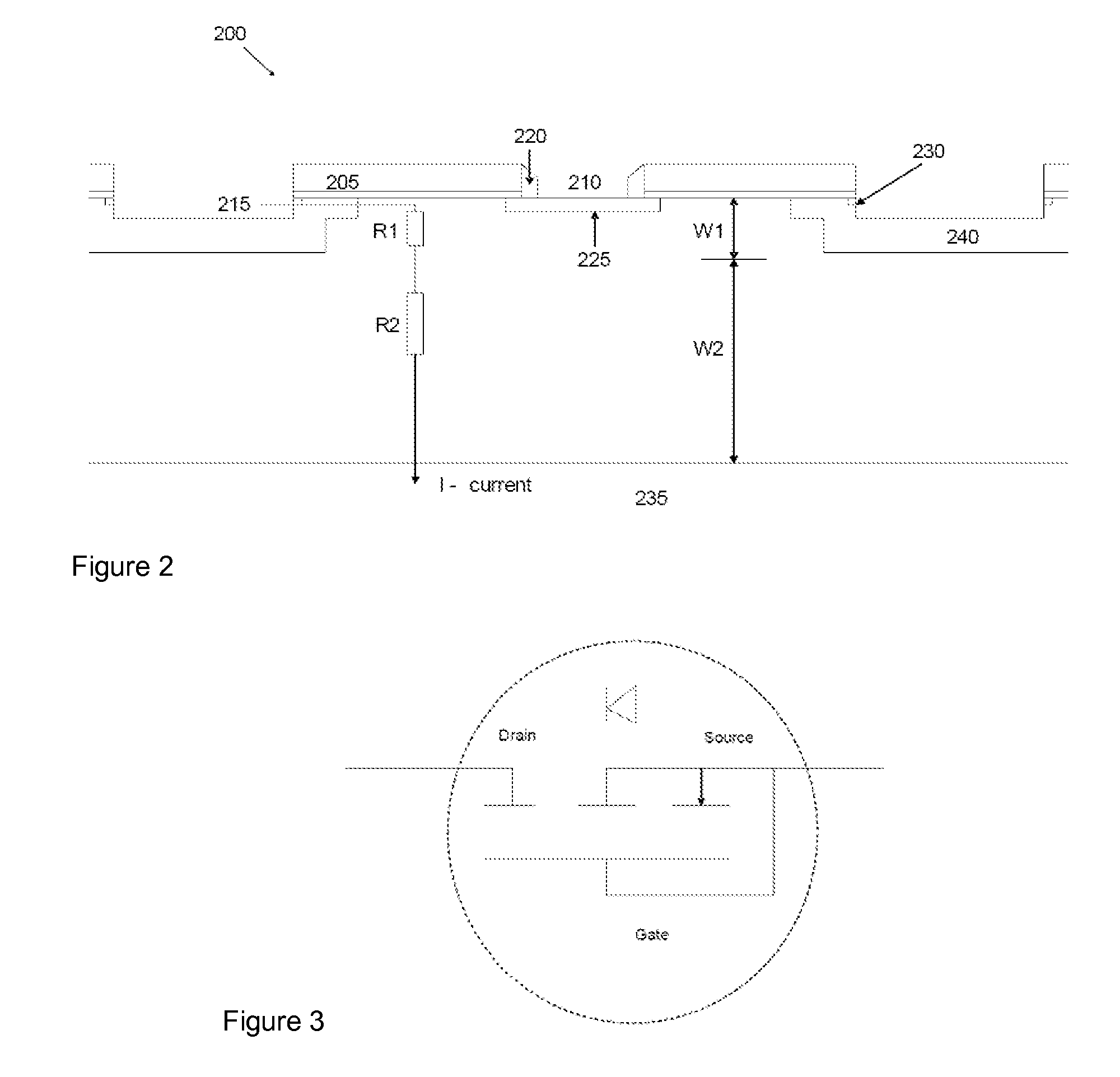

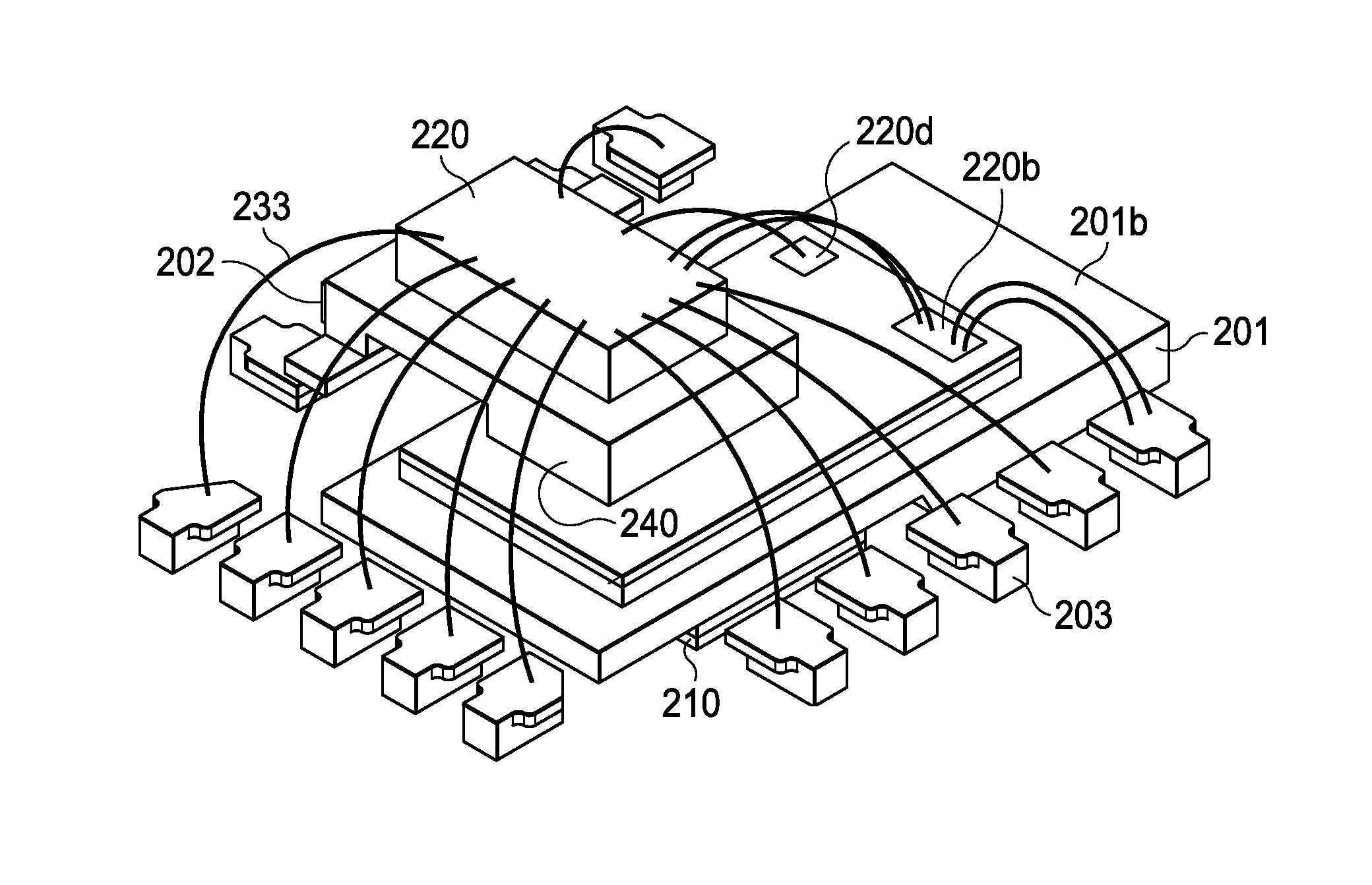

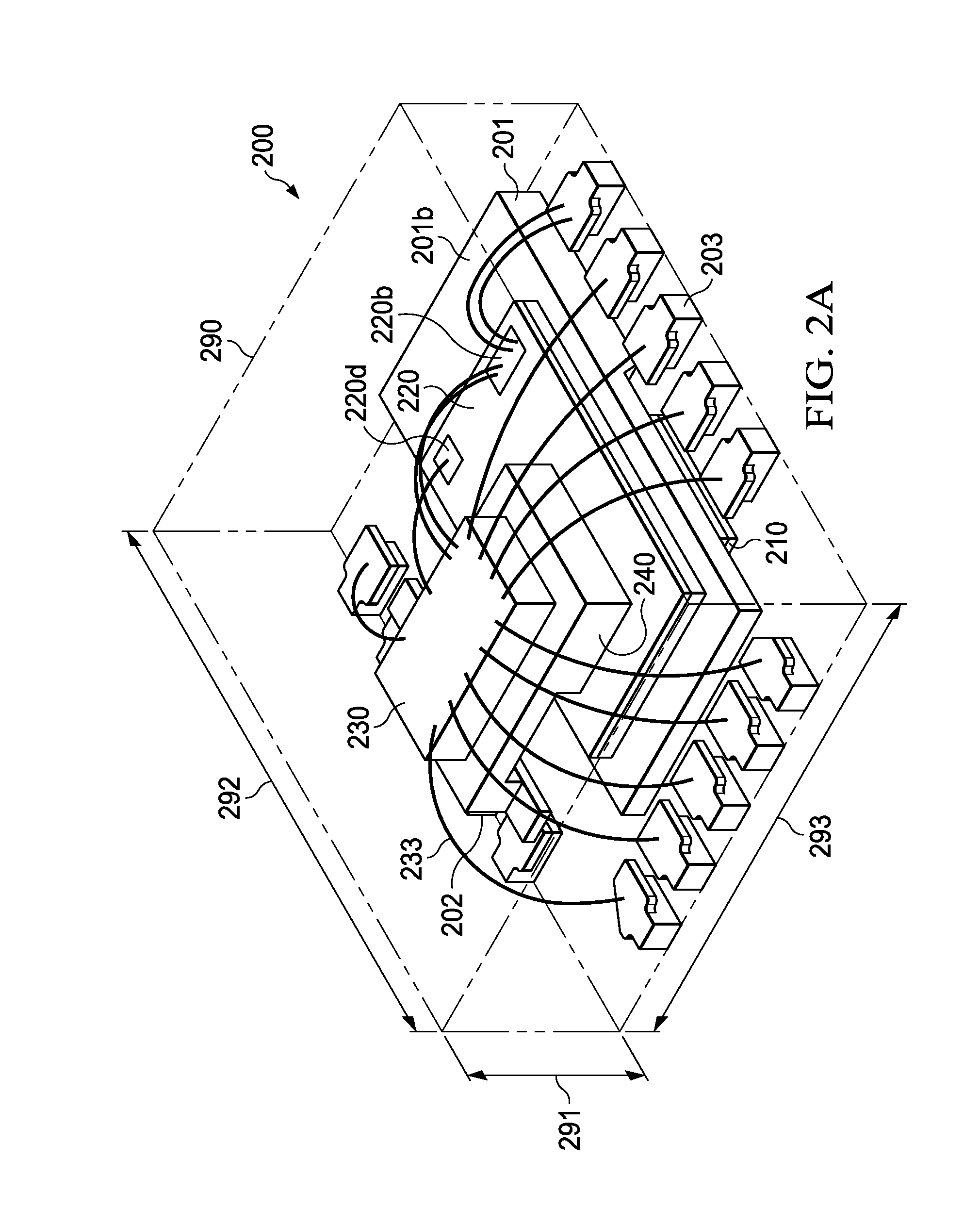

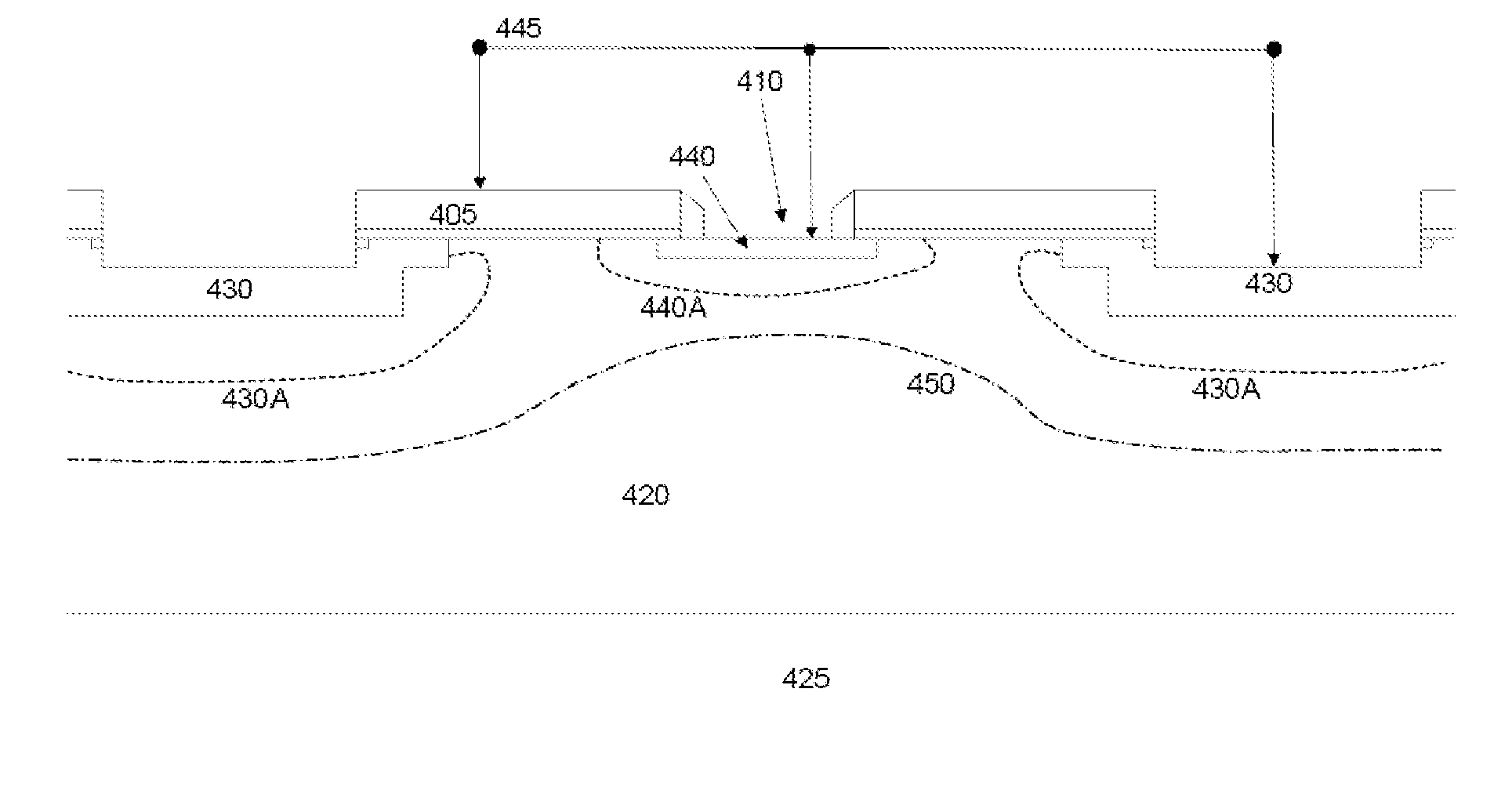

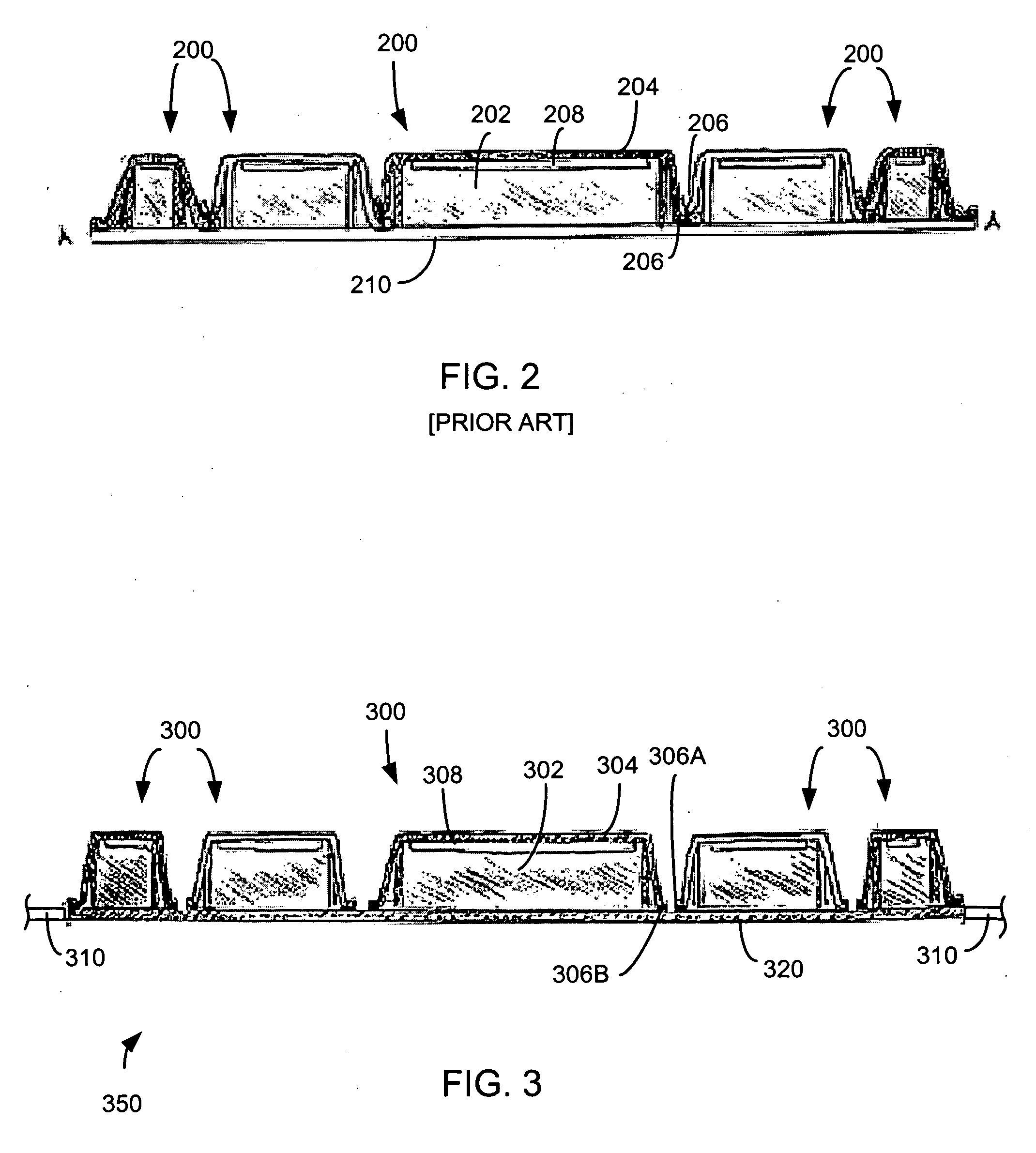

Stacked Synchronous Buck Converter Having Chip Embedded in Outside Recess of Leadframe

ActiveUS20150221584A1Reduce the overall heightLow powerSemiconductor/solid-state device detailsSolid-state devicesBuck converterSemiconductor chip

A power supply system (200) has a QFN leadframe with leads and a pad (201, switch node terminal); a pad surface having a portion recessed with a depth (270) and an outline suitable for attaching a semiconductor chip. A first FET chip (220) is vertically stacked to the opposite pad surface. A clip (240) is vertically stacked on the first FET chip and tied to a lead (202, grounded output terminal). A second FET chip (210) has its source terminal attached to the recessed portion and its drain (210a, input terminal) and gate (210b) terminals co-planar with the un-recessed portion. A driver-and-controller chip (230) is attached to the clip. Packaging compound (290) encapsulates the parts but leaves a pad surface and the drain and gate terminals of the second FET chip un-encapsulated.

Owner:TEXAS INSTR INC

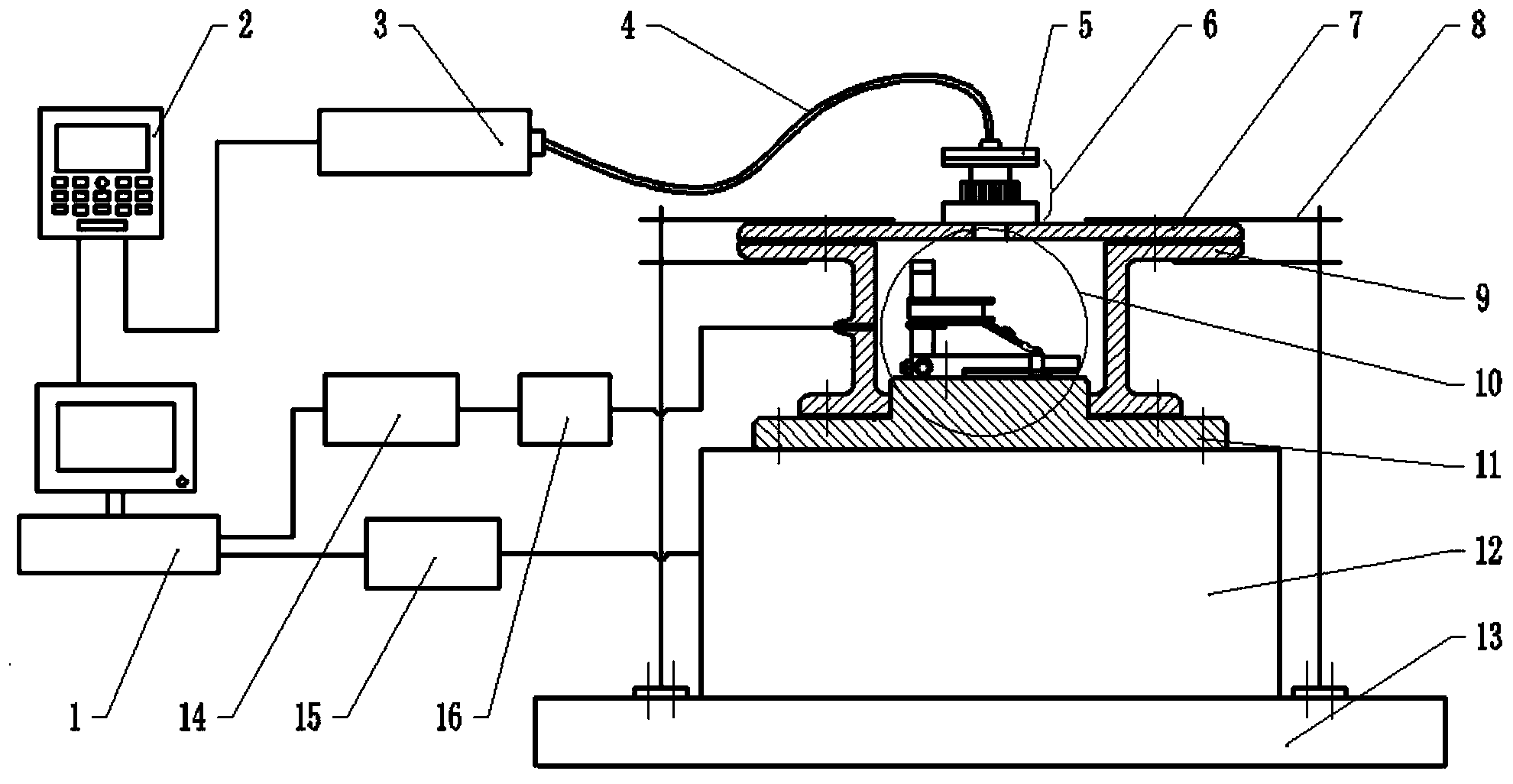

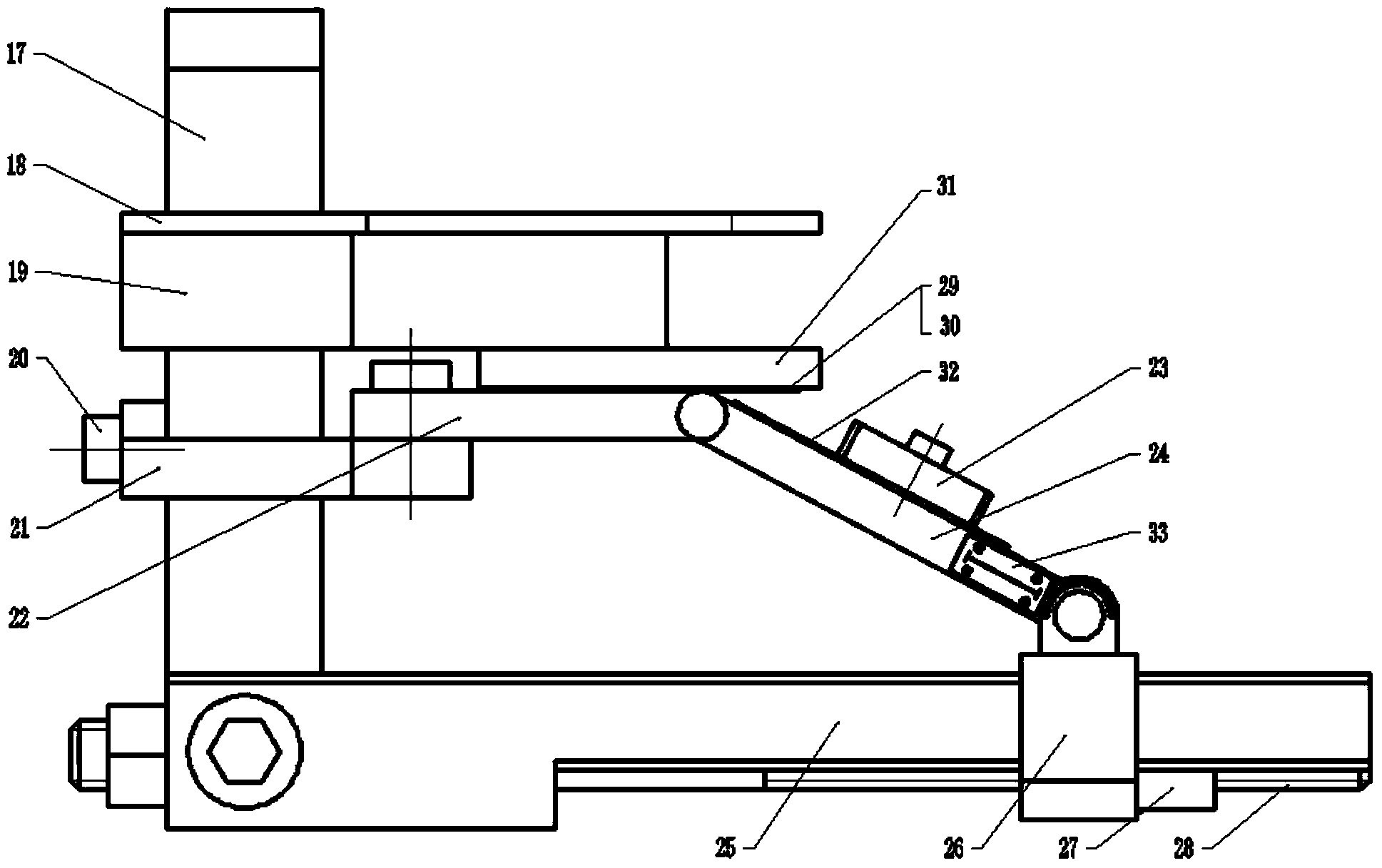

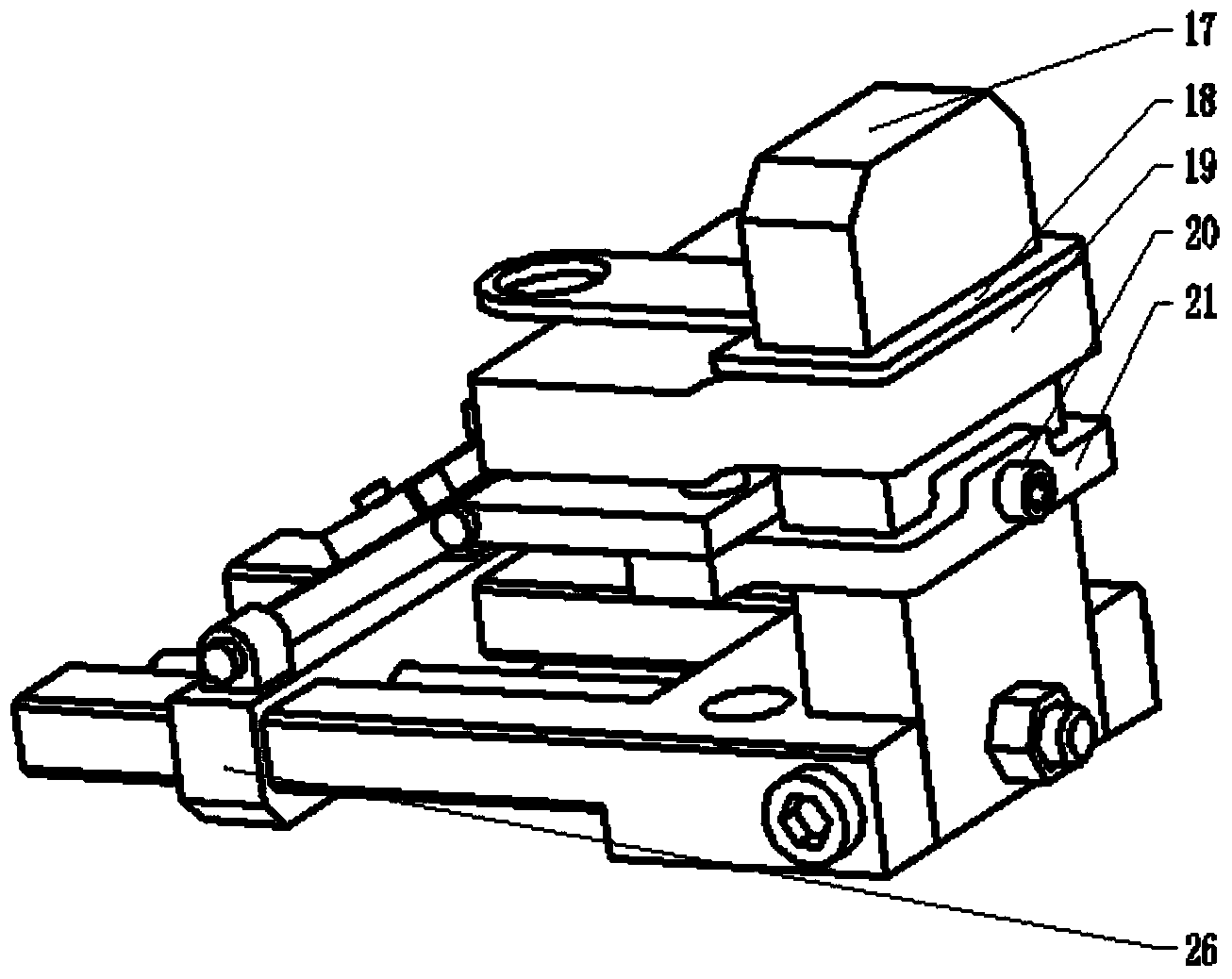

Laser shock welding device with shock angle continuously adjustable under vacuum environment

InactiveCN103722291AReduce productionFacilitates verification of the impact of laser shock welding on qualityWelding/cutting auxillary devicesAuxillary welding devicesComputer control systemEngineering

The invention provides a laser shock welding device with the shock angle continuously adjustable under a vacuum environment. The device comprises a computer control system, a laser generating system, a vacuum system and a clamp, wherein the clamp is located in a vacuum chamber and fixed on the bottom surface of the vacuum chamber, the clamp comprises a horizontal working platform with the vertical position adjustable and an inclined working platform with the inclining angle adjustable, the laser generating system is connected with the vacuum chamber through a light path, and the laser generating system and the vacuum system are both connected with the computer control system. According to the device, continuous adjustment of the shock angle is achieved during laser shock welding, resistance of the atmosphere to an ultra-thin composite plate material under the high-speed shock condition is eliminated, and welding performance is effectively improved.

Owner:JIANGSU UNIV

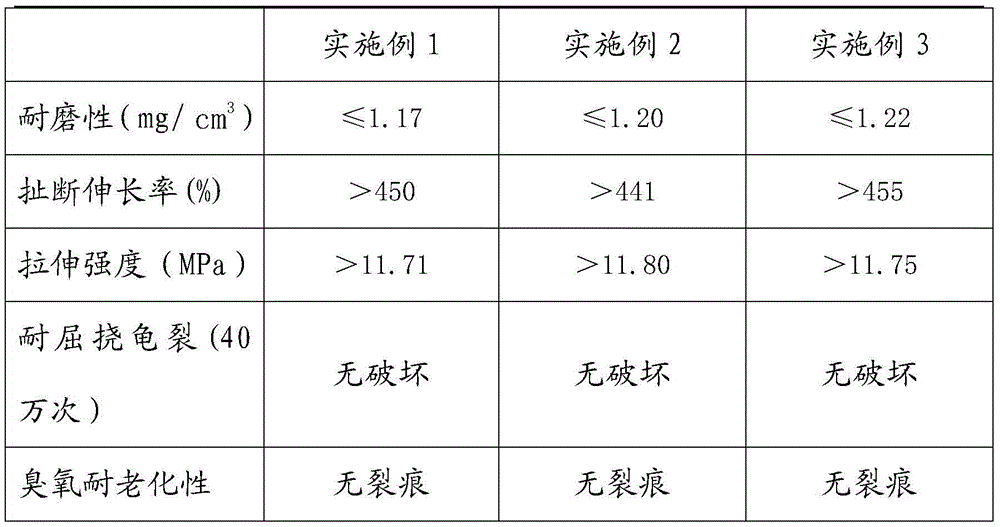

Pressure injection method for integral forming of non-pneumatic tire

The invention provides a pressure injection method for integral forming of a non-pneumatic tire. The method includes the following steps that firstly, configured raw materials for manufacturing the non-pneumatic tire are placed into a material storage box and are evenly stirred; secondly, the temperature of a pre-heating pressure injection machine is raised to 180-190 DEG C; thirdly, pressure of the pre-heating pressure injection machine is increased to 50-60 Pa; fourthly, the material inflow speed is adjusted to 10-20 m / s; fifthly, the pressure holding time is adjusted to 2-3 min; sixthly, the raw materials for manufacturing the non-pneumatic tire in the first step are injected into the pressure injection machine, and operation is started according to a preset mode; seventhly, after mold assembly, injection, hot melting, cooling and mold disassembly are sequentially performed, the non-pneumatic tire is obtained. The technology is simple, multi-time machining is not needed, one-time forming is achieved, operation is convenient, and cost is low; the obtained non-pneumatic tire is uniform and reasonable in structure and is not divided into an inner tire and an outer tire, friction force and resistance between the inner tire and the outer tire are eliminated, dynamic balance is good, and the non-pneumatic tire is resistant to abrasion and rolling and durable.

Owner:GUANGZHOU NEDONG INFORMATION TECH

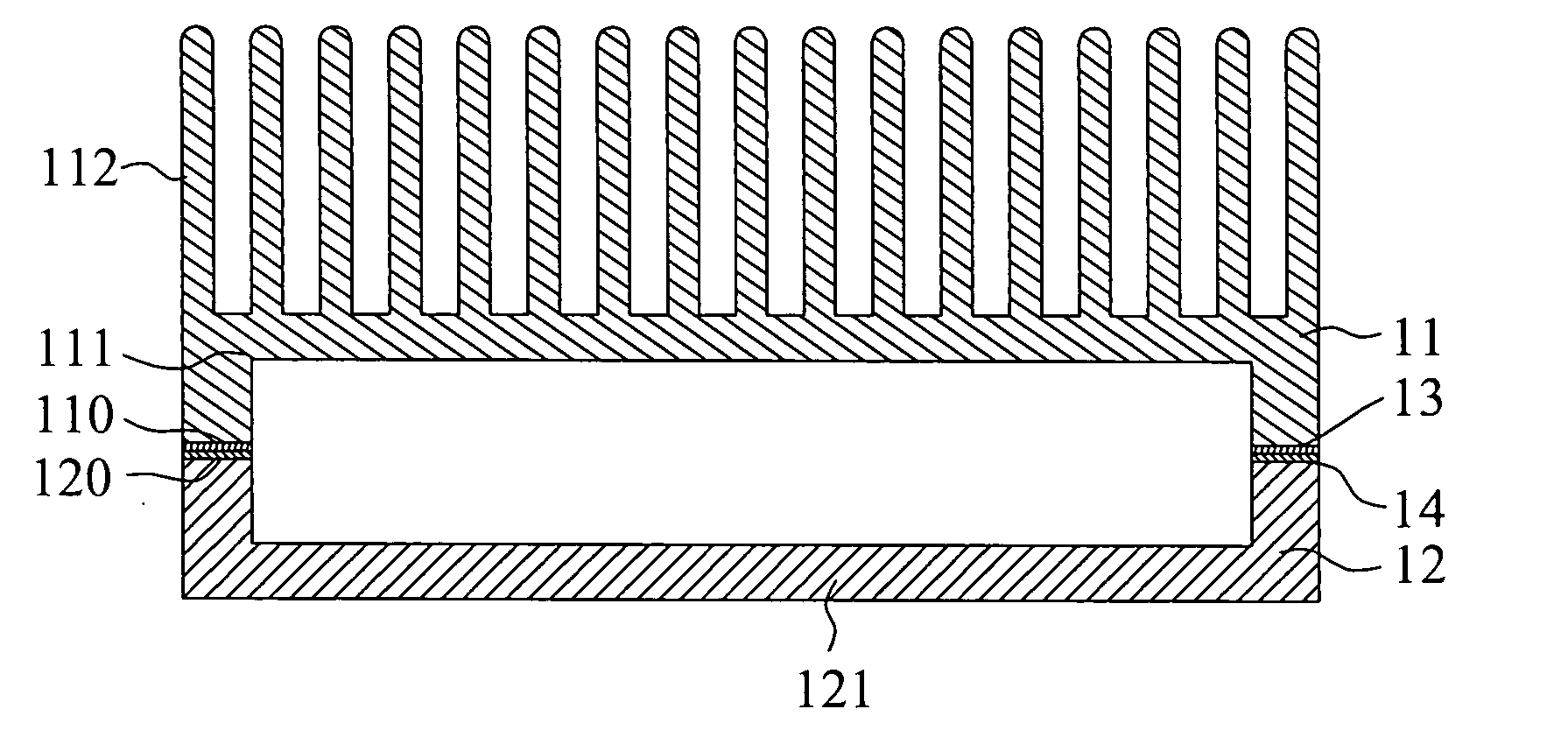

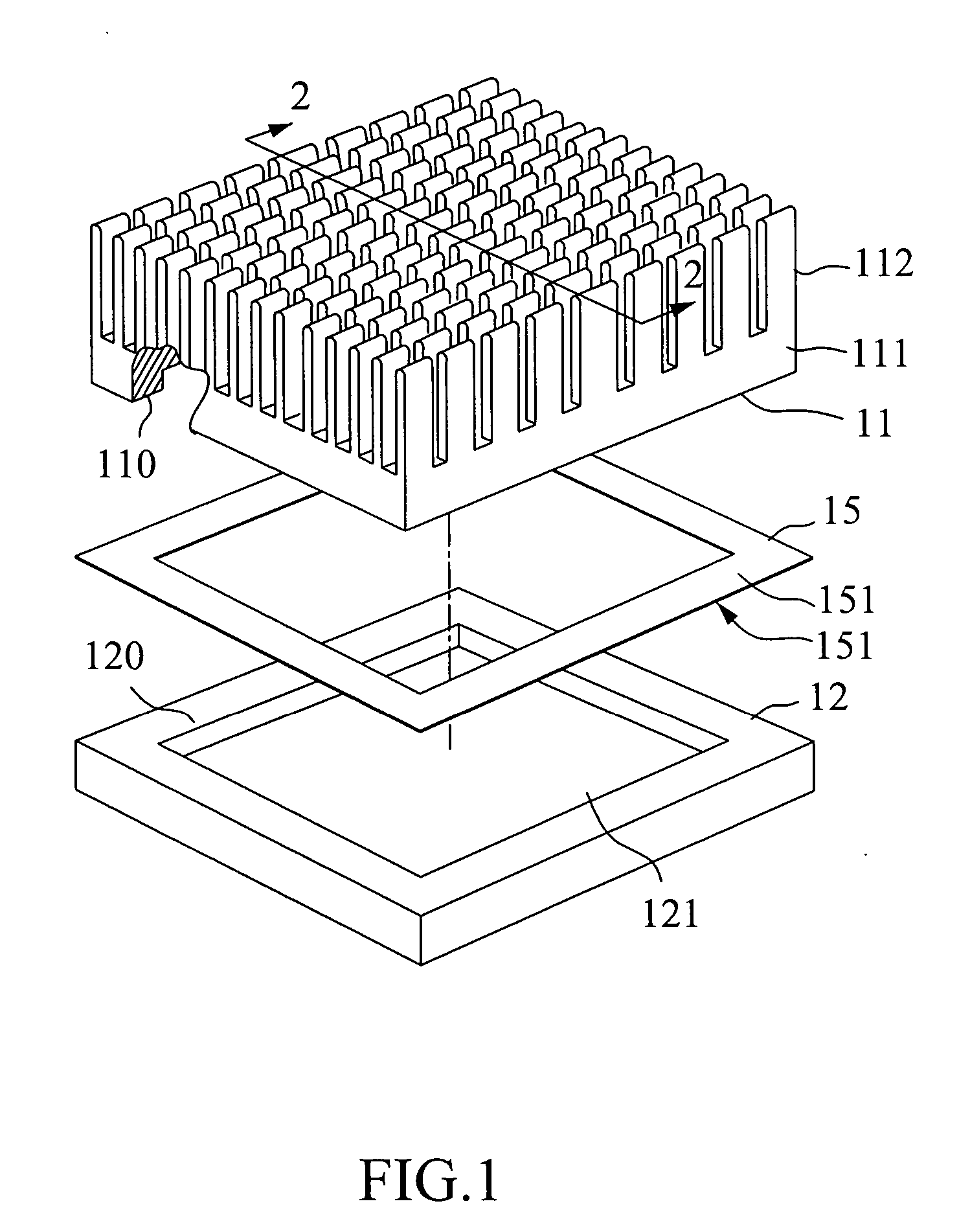

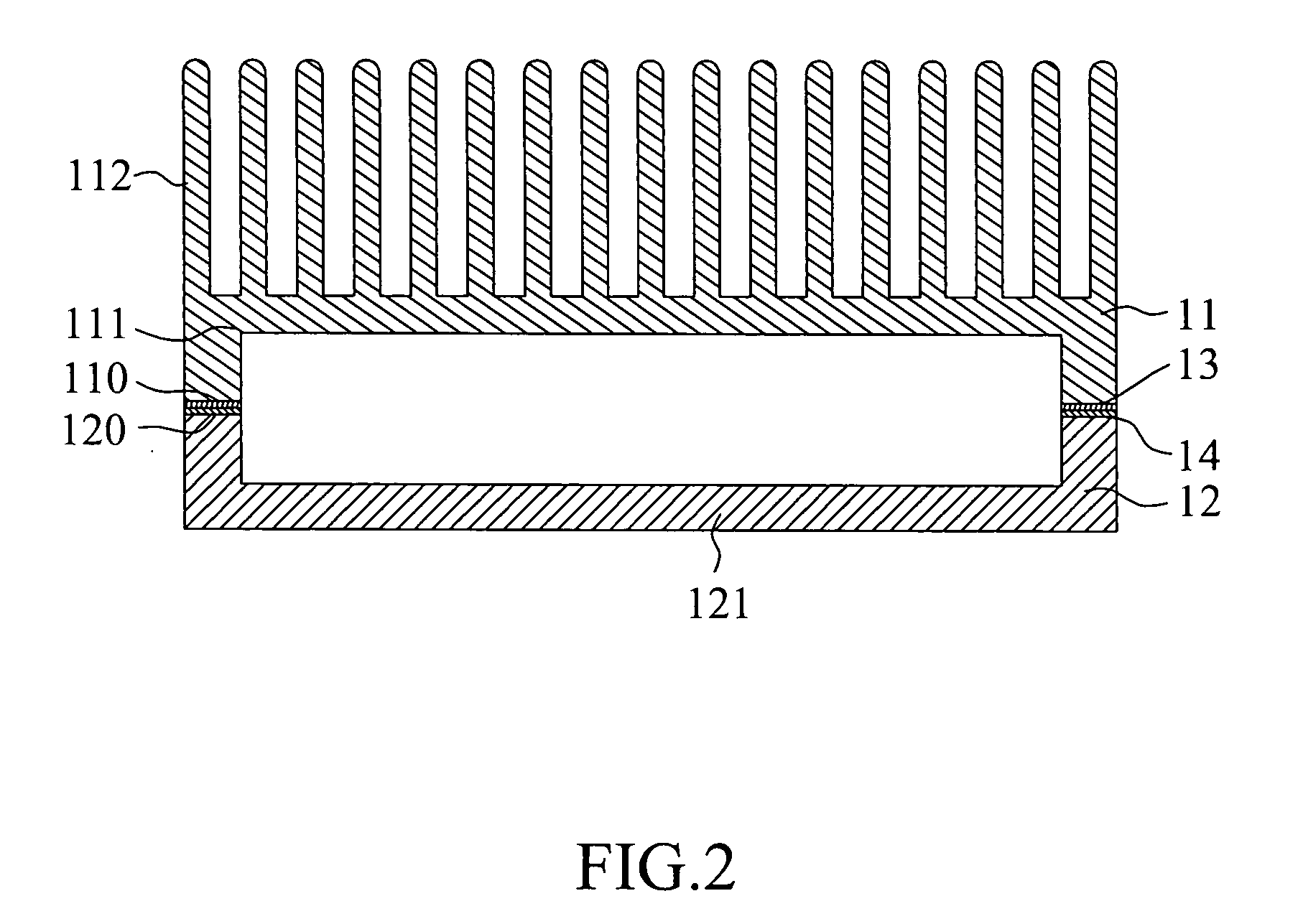

Heat sink and heat spreader bonding structure

InactiveUS20060021734A1Eliminate the problemEliminates formationDigital data processing detailsSemiconductor/solid-state device detailsHeat resistanceHeat transfer efficiency

A heat sink and heat spreader bonding structure includes a metal heat sink, a metal heat spreader, and an eutectic structure formed between the heat sink and the heat spreader by heating the heat sink and the heat spreader to a specific temperature of the eutectic temperature of the heat sink and the heat spreader but below the respective melting point of the heat sink and the heat spreader to cause the internal metal atoms of the heat sink and heat spreader to be rearranged. This bonding structure maintains the heat transfer efficiency of the bonding layer between the heat sink and the heat spreader, eliminates formation of crevice, heat resistance, and oxidation in the bonding layer.

Owner:IND TECH RES INST

Adjustable field effect rectifier

ActiveUS8148748B2Improve performanceImproving reverse recovery characteristicThyristorMOSFETHigh voltage igbt

An Adjustable Field Effect Rectifier uses aspects of MOSFET structure together with an adjustment pocket or region to result in a device that functions reliably and efficiently at high voltages without significant negative resistance, while also permitting fast recovery and operation at high frequency without large electromagnetic interference.

Owner:STMICROELECTRONICS INT NV

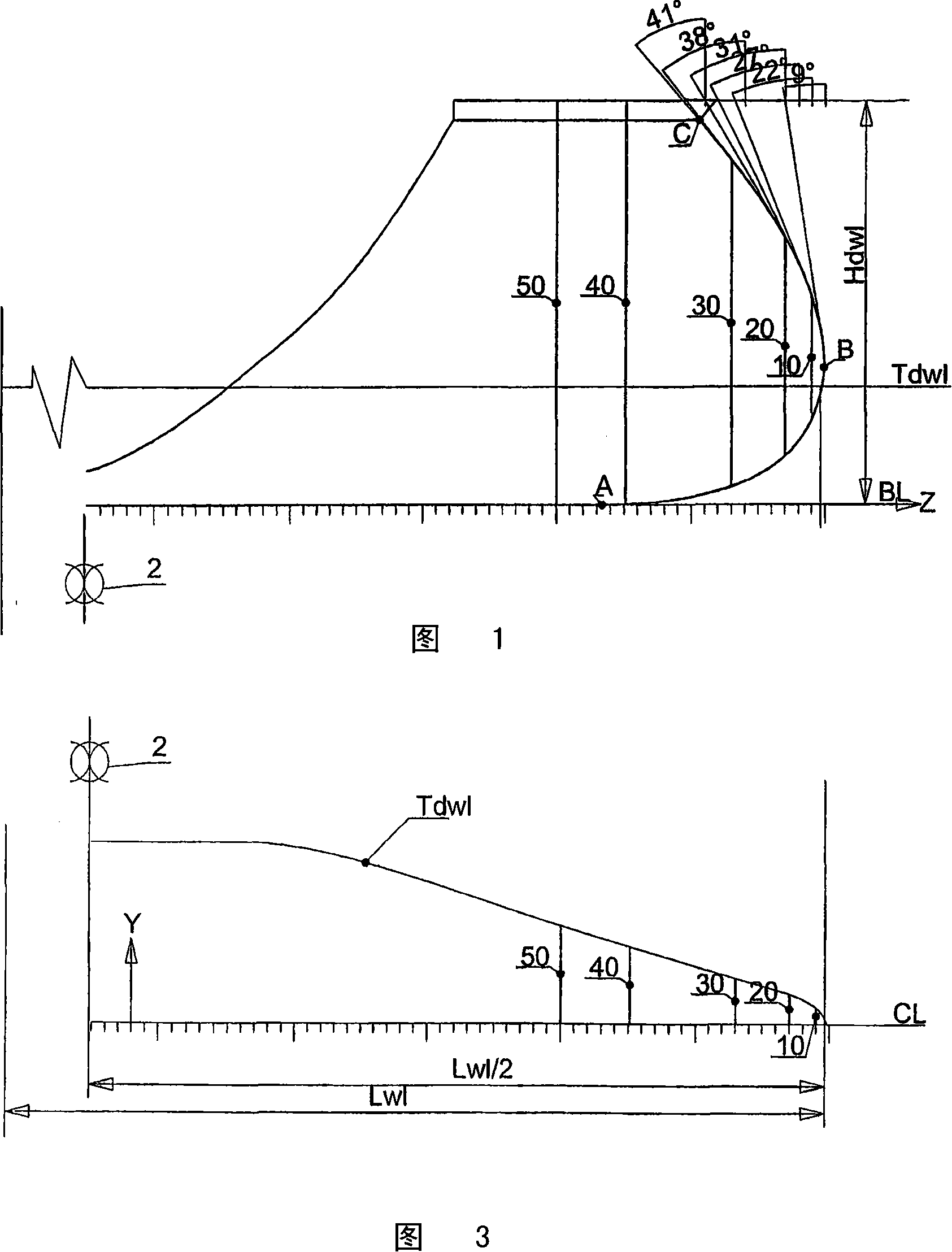

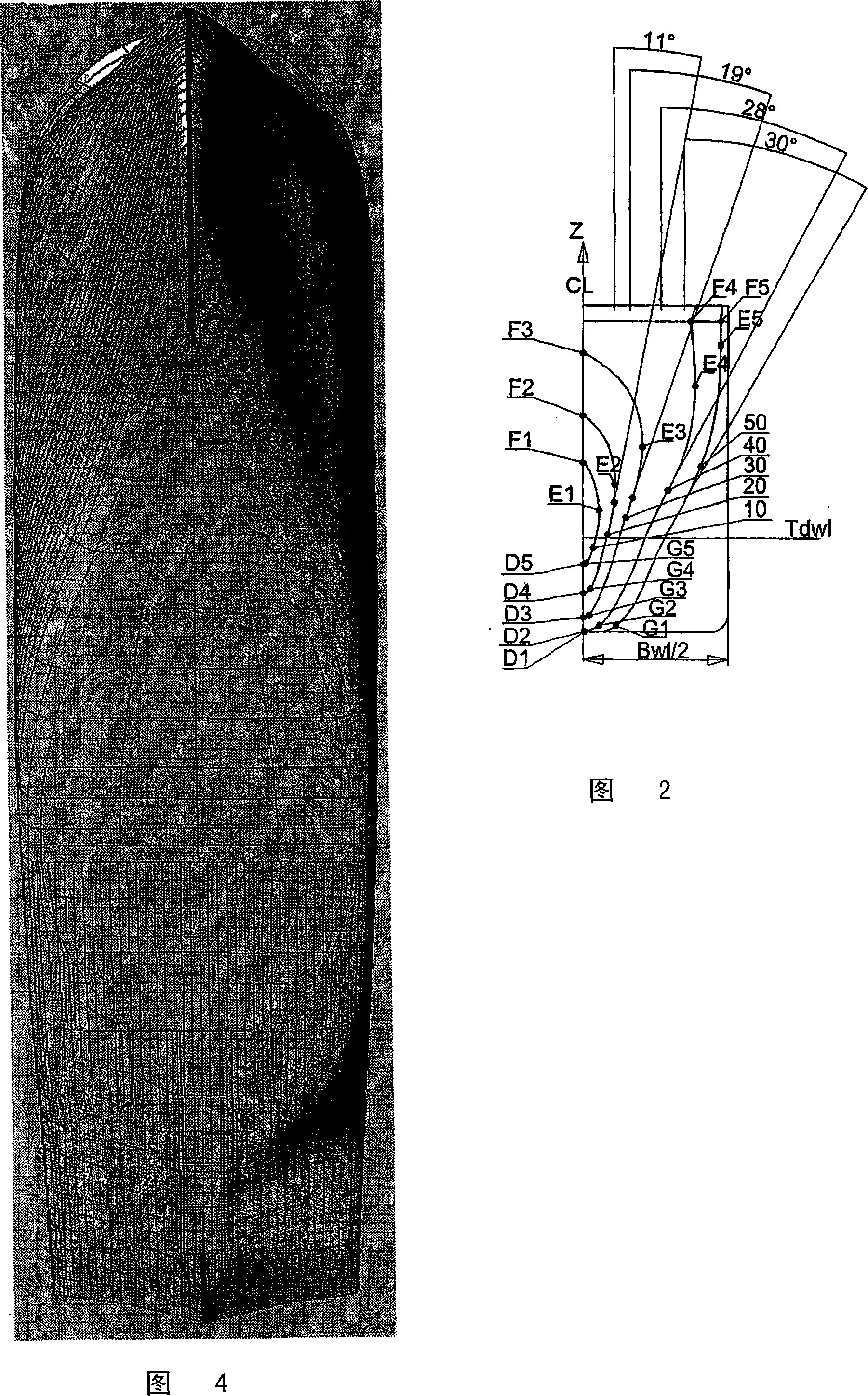

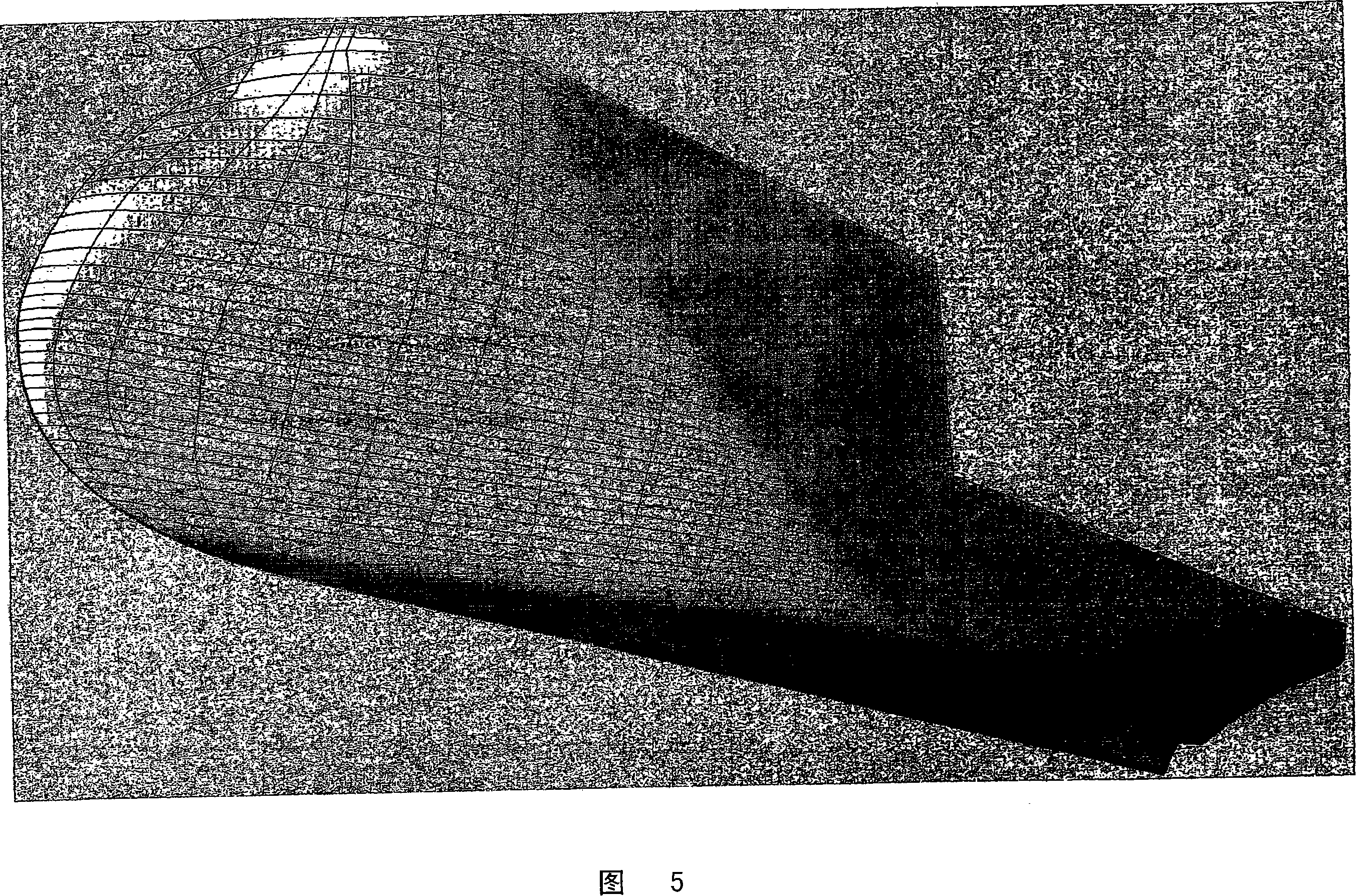

A foreship arrangement for a vessel of the deplacement type

ActiveCN101137536AReduce reflectionReduce slapWatercraft hull designVessel movement reduction by foilsMarine engineeringTransition point

A foreship arrangement for a vessel of the displacement type, which foreship consists of the part of the ship in front of the vessel's midship mark (2) and which vessel has a transversely symmetrical hull form about its centre line (CL) and a substantially conventional bow form below its design water line (Tdwl), characterised in that the stem line (1) of the vessel turns substantially backwards in relation to the length direction of the ship from a transition point (B) at or immediately above the design water line (Tdwl).

Owner:ULSTEIN DESIGN & SOLUTIONS AS

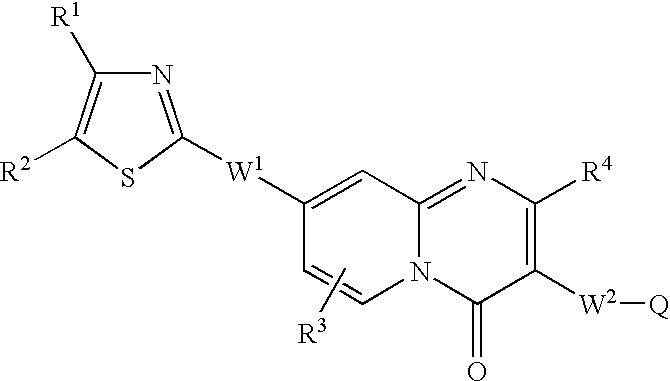

Drug efflux pump inhibitor

InactiveUS7056917B2Good curative effectEliminate resistanceBiocideOrganic chemistryArylHydrogen atom

A medicament for preventive and / or therapeutic treatment of a microbial infection which comprises as an active ingredient a compound represented by the following general formula (I): wherein, R1 and R2 represent hydrogen atom, a halogen atom, hydroxyl group or the like, W1 represents —CH═CH—, —CH2O—, —CH2CH2— or the like; R3 represents hydrogen atom, a halogen atom, hydroxyl group or an amino group; R4 represents hydrogen atom, a group of —OZ0-4R5 (Z0-4 represents an alkylene group, a fluorine-substituted alkylene group or a single bond, and R5 represents a cyclic alkyl group, an aryl group or the like); W2 represents a single bond or —C(R8)═C(R9)— (R8 and R9 represent hydrogen atom, a halogen atom, a lower alkyl group or the like, Q represents an acidic group, but W2 and Q may together form vinylidenethiazolidinedione or an equivalent heterocyclic ring; m and n represent an integer of 0 to 2, and q represents an integer of 0 to 3.

Owner:TRINE PHARMA +1

Pneumatic tire

InactiveUS20050150581A1Reduce resistanceEliminate resistanceTyresTyre tread bands/patternsEngineeringMechanical engineering

A pneumatic tire comprising a tread portion having tread elements each provided with a sipe, wherein the sipe is open to a upper surface of the tread element, and has an open top end including a zigzag part and a bottom, wherein the sipe comprises: a first portion in which the zigzag part of the open top end extends to a side of the bottom in a state of being inclined to one side of a longitudinal direction of the sipe; a second portion connected to an inner side in a radial direction of the first portion, and in which the zigzag part extends to the side of the bottom in a state of being inclined in an opposite direction to the first portion; and a third portion connected to an inner side in a radial direction of the second portion, and in which the zigzag part extends to the side of the bottom in a state of being inclined in an opposite direction to the second portion, and the sipe satisfies the following relation (1): α1>α2>α3 (1) [0001]where α1 is a ratio (a1 / h1) between a displacement length a1 of the first portion and a length h1 in a radial direction of the first portion, α2 is a ratio (a2 / h2) between a displacement length a2 of the second portion direction and a length h2 in a radial direction of the second portion, and α3 is a ratio (a3 / h3) between a displacement length a3 of the third portion and a length h3 in a radial direction of the third portion.

Owner:SUMITOMO RUBBER IND LTD

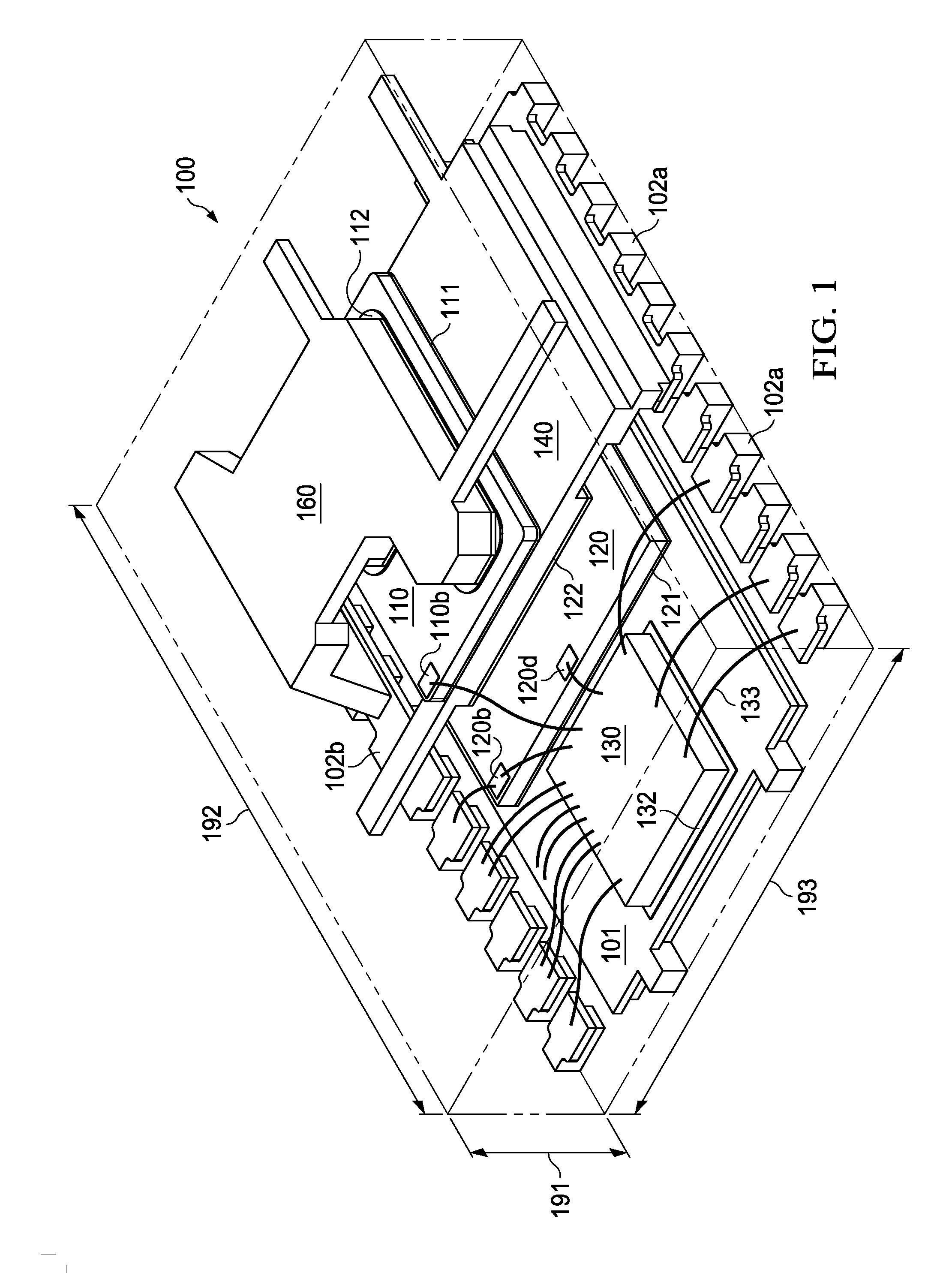

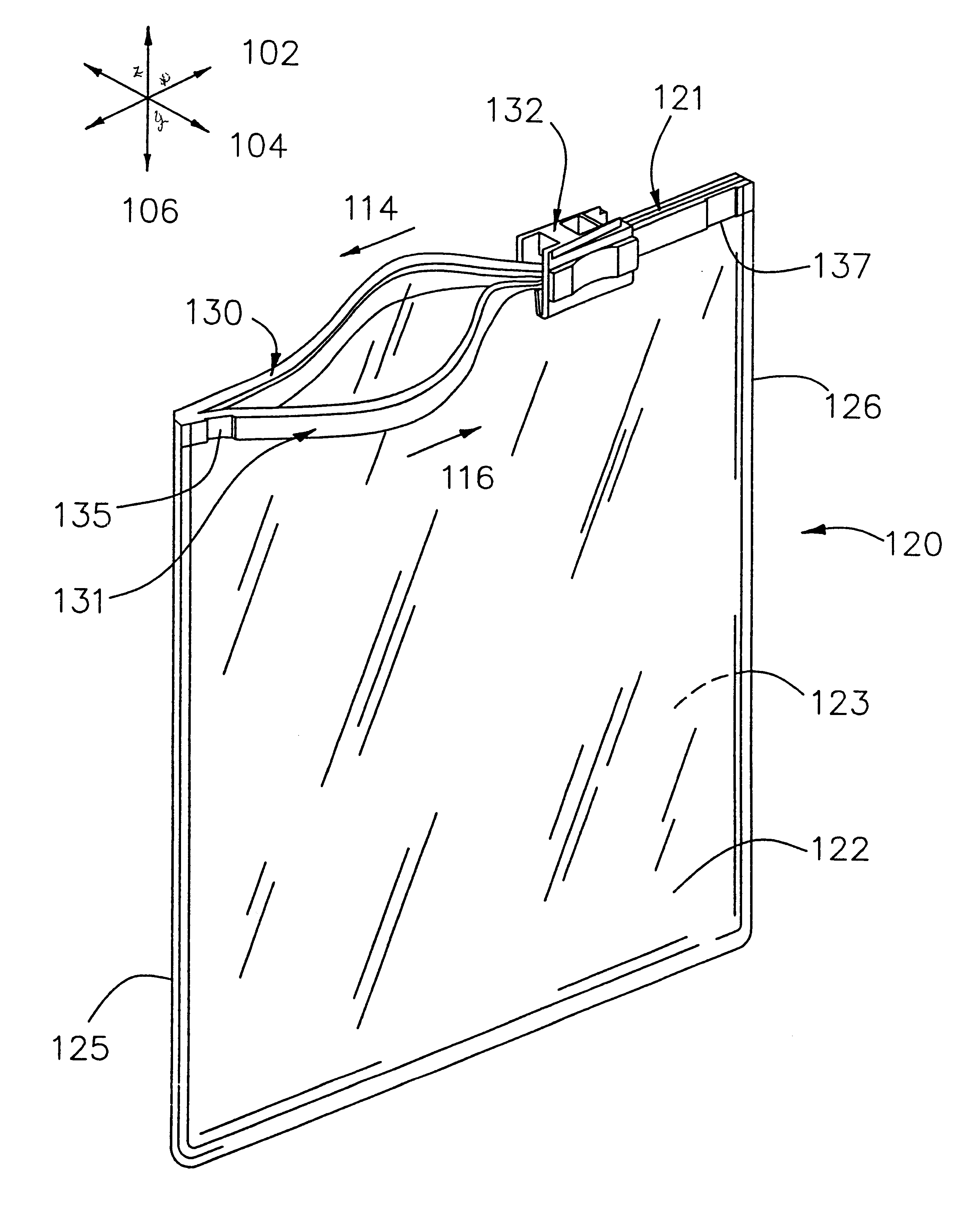

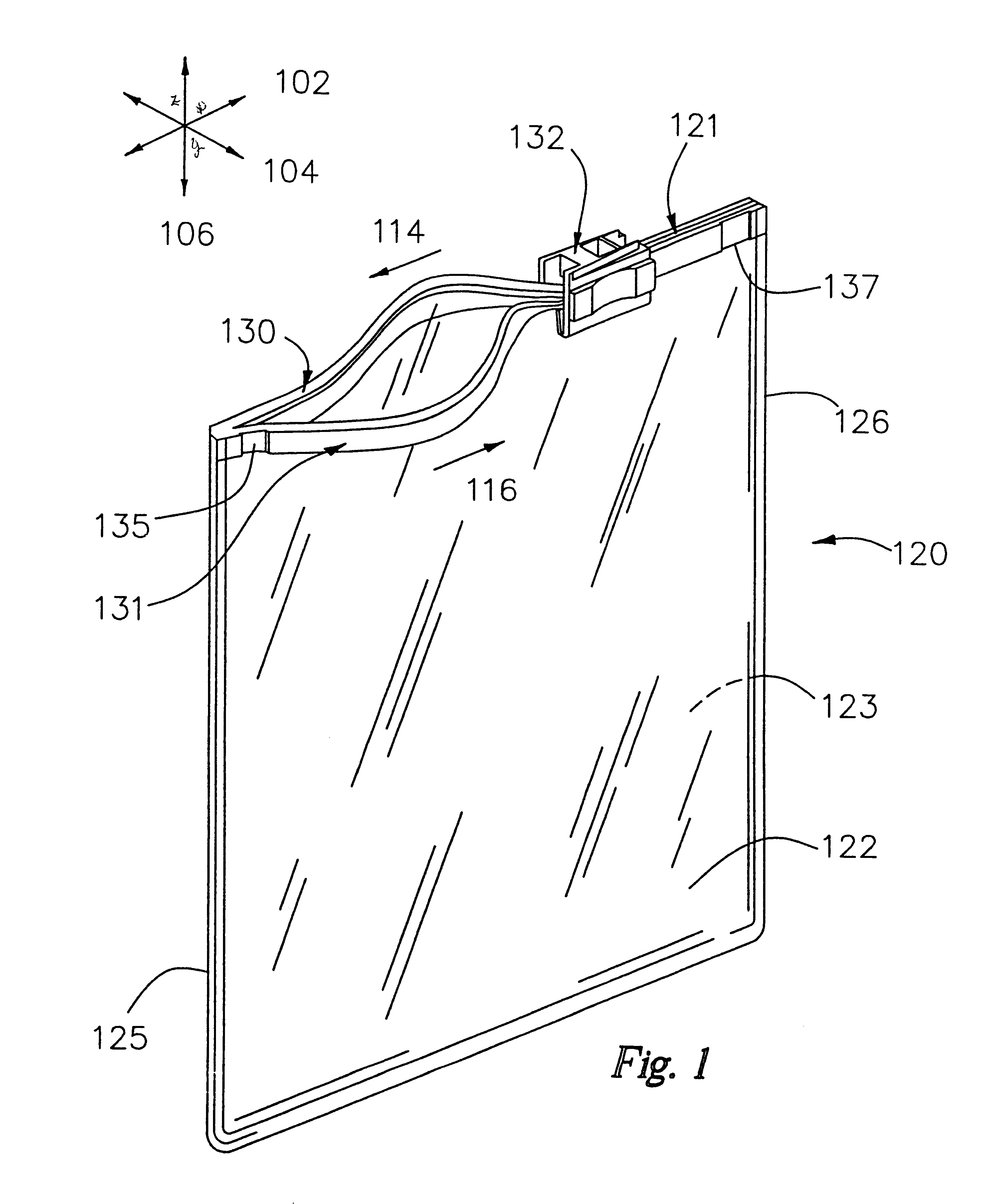

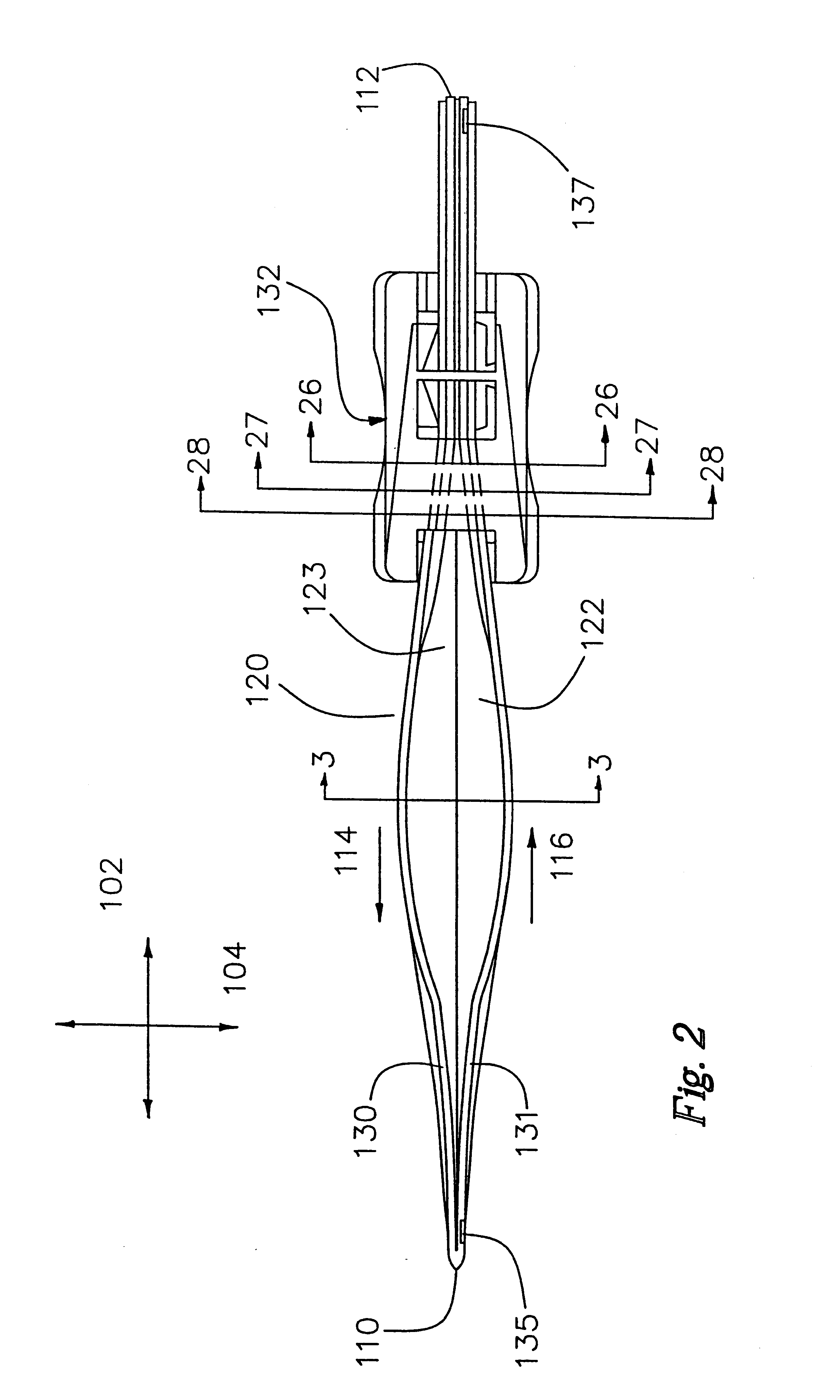

Closure device and method of assembly

InactiveUS6691375B1Facilitating occlusionFacilitating deocclusionSlide fastenersBagsEngineeringMechanical engineering

The closure device (121) includes interlocking fastening strips (130, 131) and a slider (132) slidably disposed on the fastening strips for facilitating the occlusion and deocclusion of the fastening strips when moved towards first and second ends thereof. A flexible slider (132) is provided for facilitating the attachment of the slider onto the fastening strips (130, 131) in the vertical Z axis (106). The slider (132) includes legs (240, 242) which provide resistance against the removal of the slider from the fastening strips (130, 131) in the vertical Z axis (106) thereafter. The closure device also provides resistance against the removal of the slider (132) from the fastening strips (130, 131) in the horizontal X axis (102).

Owner:THE GLAD PROD CO

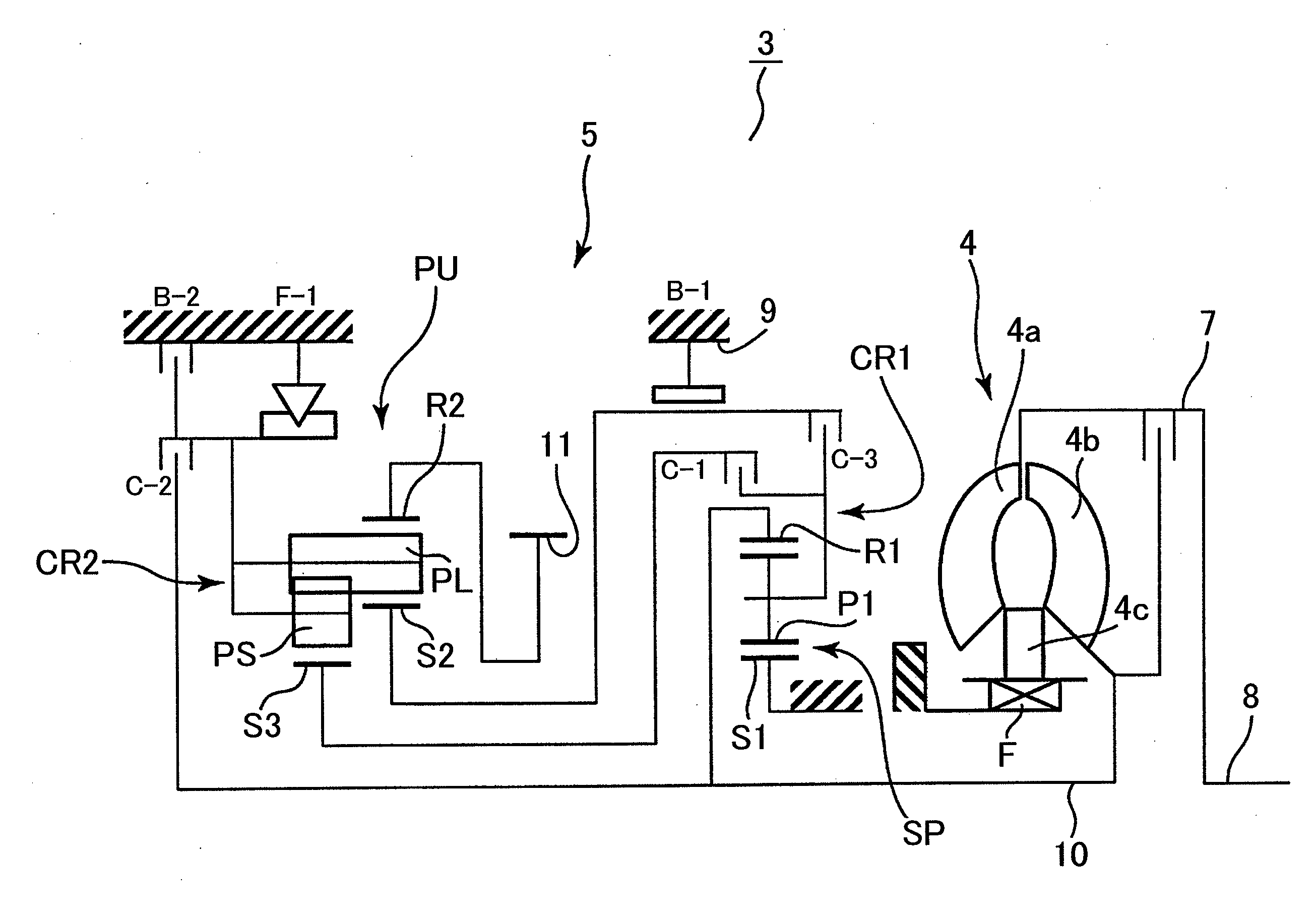

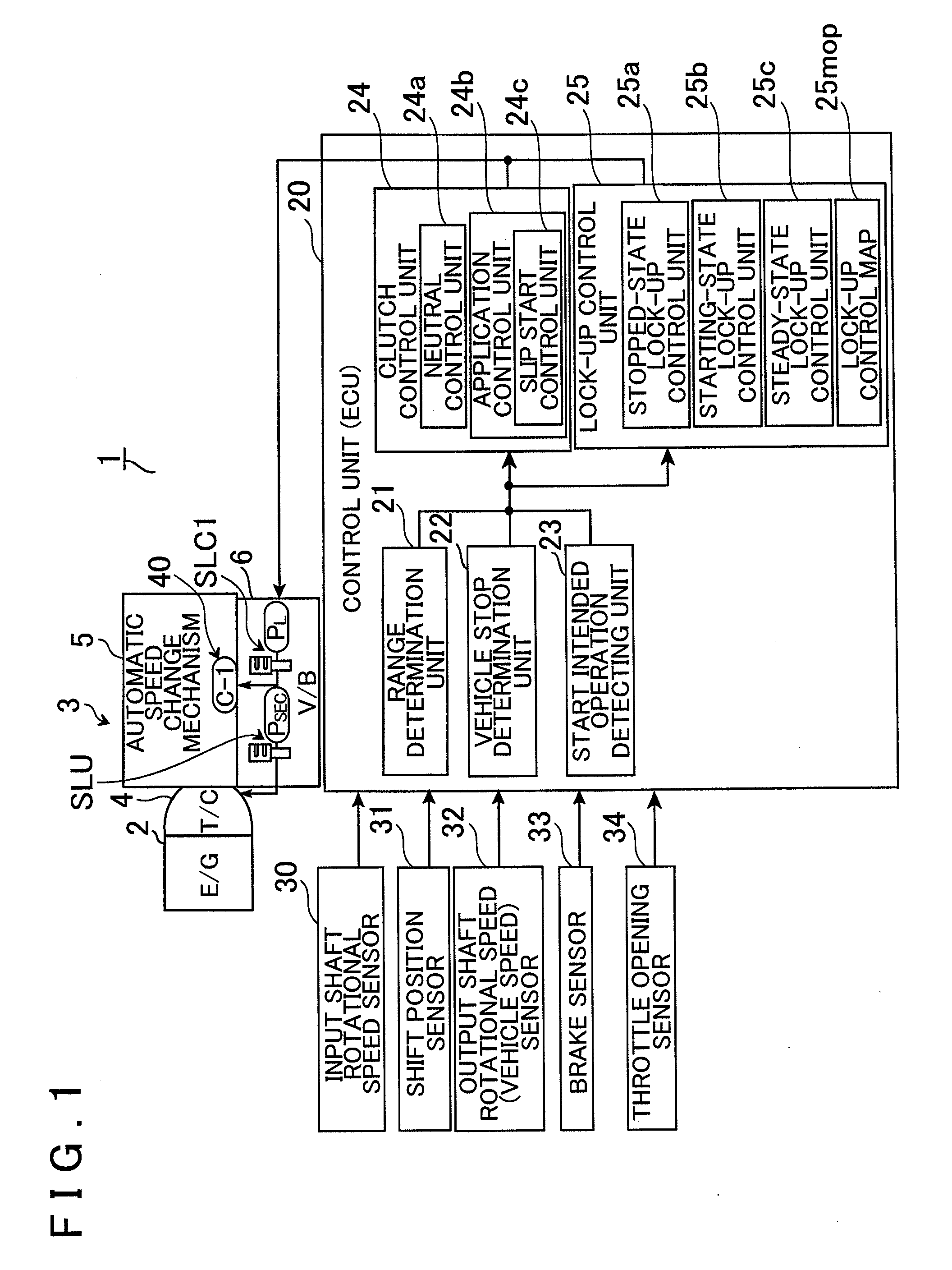

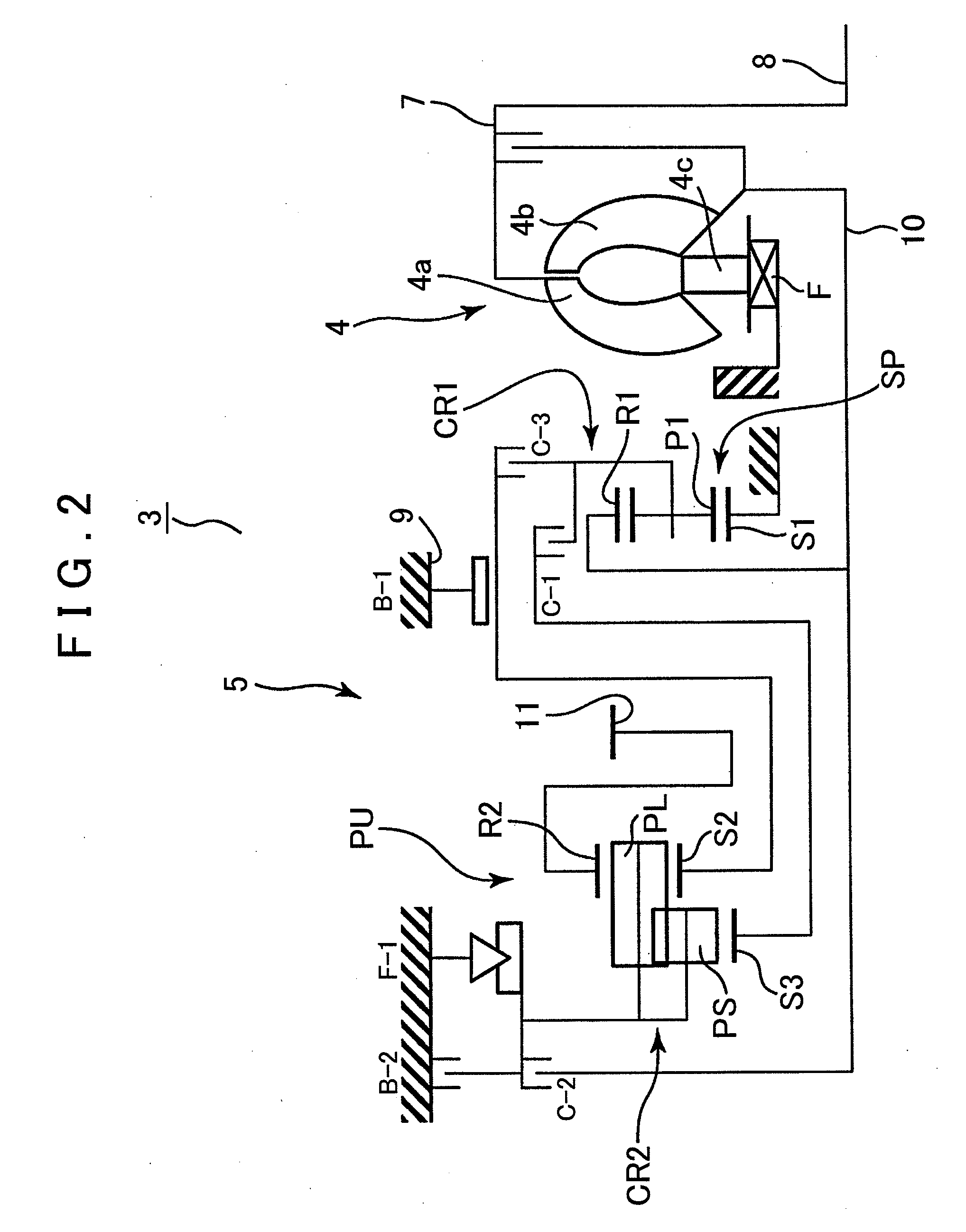

Control apparatus of automatic transmission

InactiveUS20110246036A1Improving fuel consumption and ride comfortAvoid delayClutchesDigital data processing detailsClutch controlAutomatic transmission

A control apparatus of an automatic transmission having an automatic speed change mechanism for changing a driving source speed of rotation and a clutch engaged at a start, a fluid transmission apparatus between the driving source and the automatic speed change mechanism, and a lock-up clutch for locking up the fluid transmission apparatus. The control apparatus includes a range unit that determines a shift range including a drive range, a vehicle stop unit that determines a stop of a vehicle, a start intended operation unit that detects an intended start vehicle operation, a clutch control unit that controls the clutch to be disengaged to place the automatic speed change mechanism in a neutral state while the shift range is determined to be the drive range and the vehicle is determined to be stopped, and performs engagement control of the clutch to control the start of the vehicle when the operation intended for starting the vehicle is detected, and a lock-up clutch control unit that controls the lock-up clutch to be engaged while the shift range is determined to be the drive range and the vehicle is determined to be stopped, and controls the lock-up clutch so that the lock-up clutch is at least engaged in a slip region in which a predetermined torque capacity is obtained, when the operation intended for starting the vehicle is detected.

Owner:AISIN AW CO LTD

Protective glove with independent pads

ActiveUS20060195967A1Flexible gloveEliminate resistanceGlovesSport apparatusElastic substrateEngineering

A protective glove having an elastic substrate, a first pad segment attached to the elastic substrate, and a second pad segment attached to the elastic substrate independently from the first pad segment. The elastic substrate can be disposed over an area intended to substantially cover a forearm, a wrist, a back of a hand, a finger, and / or a thumb of a user wearing the glove. The elastic substrate can be stretchable in different directions and to different degrees in the areas around each pad segment, thereby enabling independent movement of the individually attached pad segments to accommodate any number of contours and flex points. Other embodiments provide methods for manufacturing a protective glove having independent pads.

Owner:WM T BURNETT IP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com