Preparation method of low-cost boron carbide/aluminum composite board

A boron carbide and aluminum composite technology, applied in the field of materials, can solve the problems of high impurity content such as iron, complex process and high cost, and achieve the effects of low impurity content, simplified preparation process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

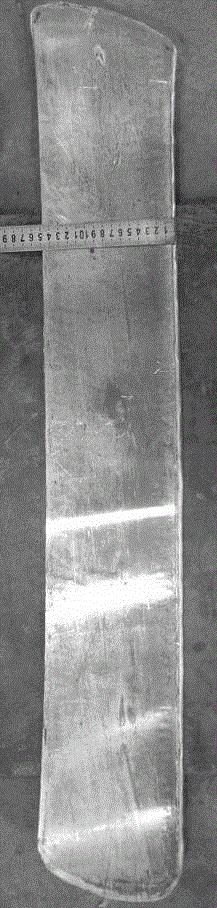

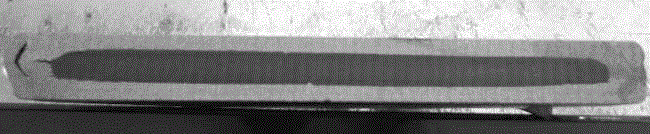

Image

Examples

Embodiment 1

[0038] (1) according to the following mass ratio B 4 C: aluminum alloy = 15:85 weigh B 4 C and aluminum alloy. B to be weighed 4 C and aluminum alloy are put into an aluminum ball mill pot for grinding, and the grinding balls are tungsten balls. After grinding, the slurry obtained by grinding is precipitated and dried to obtain mixed powder.

[0039] (2) Put the mixed powder prepared in step 1 into a mold, and mold it into a core blank with a pressure of 30 MPa.

[0040] (3) Aluminum alloy is used as the sheath material, and the core blank prepared in step 2 is loaded into the sheath; then the sheath is welded and packaged by argon arc welding, leak detection is carried out, and the heat degassing treatment is carried out after welding and packaging, and the temperature is 300°C, the time is 6h.

[0041] (4) Hot-rolling the core billet packaged by sheath welding and heat degassing treatment in step 3 to the designed size, the hot-rolling temperature is 350°C. After the h...

Embodiment 2

[0044] (1) according to the following mass ratio B 4 C: aluminum alloy = 5:95 weigh B 4 C and aluminum alloy. B to be weighed 4 C and aluminum alloy are put into an aluminum ball mill pot for grinding, and the grinding balls are tungsten balls. After grinding, the slurry obtained by grinding is precipitated and dried to obtain mixed powder.

[0045](2) Put the mixed powder prepared in step 1 into a mold, and mold it into a core blank with a pressure of 120 MPa.

[0046] (3) Aluminum is used as the sheath material, and the core blank prepared in step 2 is loaded into the sheath; the sheath is welded and packaged by argon arc welding, leak detection is carried out, and the heating and degassing treatment is carried out after welding and packaging, and the temperature is 500 ℃, the time is 3h.

[0047] (4) Hot-rolling the core billet packaged by sheath welding and heating and degassing in step 3 to the designed size, and the hot-rolling temperature is 450°C. After the hot r...

Embodiment 3

[0050] (1) according to the following mass ratio B 4 C: aluminum alloy = 50:50 weigh B 4 C and aluminum alloy. B to be weighed 4 C and aluminum alloy are put into an aluminum ball mill pot for grinding, and the grinding balls are tungsten balls. After grinding, the slurry obtained by grinding is precipitated and dried to obtain mixed powder.

[0051] (2) Put the mixed powder prepared in step 1 in a mold, and mold it into a core blank with a pressure of 200 MPa.

[0052] (3) Aluminum alloy is used as the sheath material, and the core blank prepared in step 2 is loaded into the sheath; then the sheath is welded and packaged by argon arc welding, leak detection is carried out, and the heat degassing treatment is carried out after welding and packaging, and the temperature is 600°C, the time is 2.5h.

[0053] (4) Hot-rolling the core billet packaged by sheath welding and heat-degassing treatment in step 3 to the designed size, and the hot-rolling temperature is 650°C. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com