Carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material and preparation method thereof

A composite material and carbon fiber technology, which is applied in the field of carbon fiber-reinforced carbon-silicon carbide-zirconium carbide composite materials and its preparation, can solve the problem of uneven distribution of metal and carbon matrix, inability to fully react metal and carbon matrix, and affecting ceramic matrix composites Material anti-oxidation, ablation resistance and other issues to achieve the effect of avoiding the accumulation of metal powder, improving the ablation resistance and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

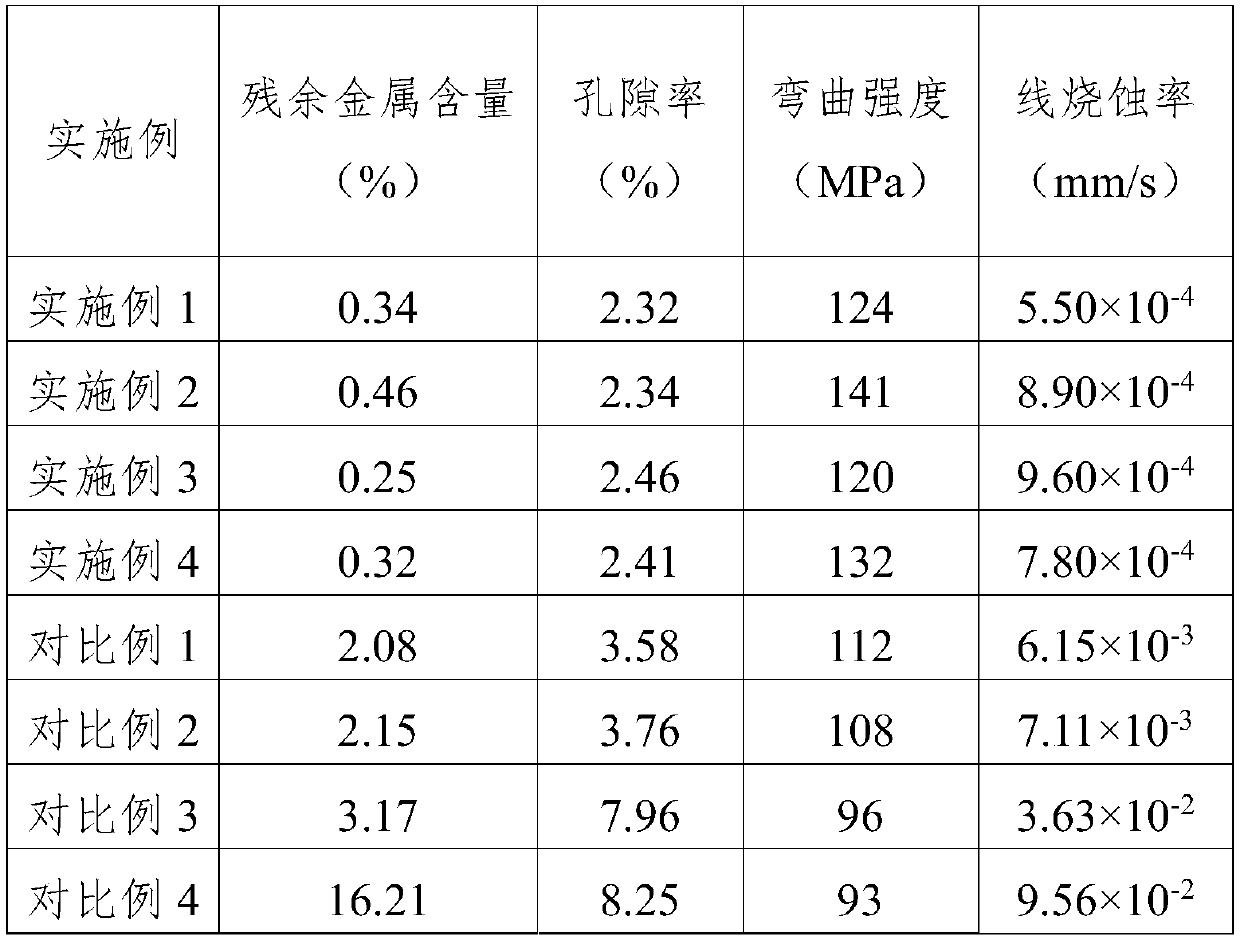

Examples

preparation example Construction

[0028] The present invention provides a kind of preparation method of carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material in the first aspect, described method comprises the following steps:

[0029] (1) Deposit pyrolytic carbon matrix on the carbon fiber surface that carbon fiber prefabricated body comprises, make modified carbon fiber prefabricated body (low density C / C green body); The PyC matrix (pyrolytic carbon matrix) is prepared inside the pure mesh needle-punched preform or carbon fiber carbon felt, so that the carbon fiber surface contained in the carbon fiber preform is deposited with a pyrolytic carbon matrix, and the obtained density is 0.8-1.2g / cm 3 low-density C / C body.

[0030] (2) Silicon powder, zirconium powder, graphite powder, phenolic resin and organic solvent are formulated into mixed resin solution; the mass ratio of silicon powder, zirconium powder, graphite powder and phenolic resin in the described mixed resin solution...

Embodiment 1

[0057] A kind of preparation method of C / C-SiC-ZrC composite material, its concrete steps are:

[0058] ①Put the carbon fiber pure mesh tire needle-punched prefabricated body into the CVI-C furnace, deposit it for 400 hours, and then undergo a high-temperature treatment at 1700°C to obtain a low-density C / C green body.

[0059] 2. Mix Si powder, Zr powder, graphite powder with a diameter not greater than 100nm and aminophenol formaldehyde resin and dilute with an alcoholic organic solvent to obtain a mixed resin solution; Si powder, Zr powder, graphite powder and ammonia in the mixed resin solution The mass ratio of phenolic resin is 1:6:5:100.

[0060] ③Using the mixed resin prepared in step ② with a mass ratio of silicon powder, zirconium powder, graphite powder and aminophenol-formaldehyde resin of 1:6:5:100 as the impregnating agent to vacuum impregnate the low-density C / C green body obtained in step ①, Then the impregnated low-density C / C green body is subjected to pressur...

Embodiment 2

[0064] A kind of preparation method of C / C-SiC-ZrC composite material, its concrete steps are:

[0065] ①Put the carbon fiber pure mesh tire needle-punched prefabricated body into the CVI-C furnace, deposit it for 400 hours, and then undergo a high-temperature treatment at 1700°C to obtain a low-density C / C green body.

[0066] 2. Mix Si powder, Zr powder, graphite powder with a diameter not greater than 100nm and aminophenol formaldehyde resin and dilute with an alcoholic organic solvent to obtain a mixed resin solution; Si powder, Zr powder, graphite powder and ammonia in the mixed resin solution The mass ratio of phenolic resin is 3:6:5:100.

[0067] ③Using the mixed resin prepared in step ② with a mass ratio of silicon powder, zirconium powder, graphite powder and aminophenol-formaldehyde resin of 3:6:5:100 as an impregnating agent to vacuum impregnate the low-density C / C green body obtained in step ①, Then the impregnated low-density C / C green body is subjected to pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com