Tissue engineering double-layered tubular support and preparation method thereof

A tissue engineering and tubular technology, applied in the field of tissue engineering tubular stent and its preparation, can solve the problems that the mechanical properties are difficult to satisfy the tubular tissue, the stent has a single component, etc., and achieves the effects of low preparation cost, simple operation, and improved overall mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

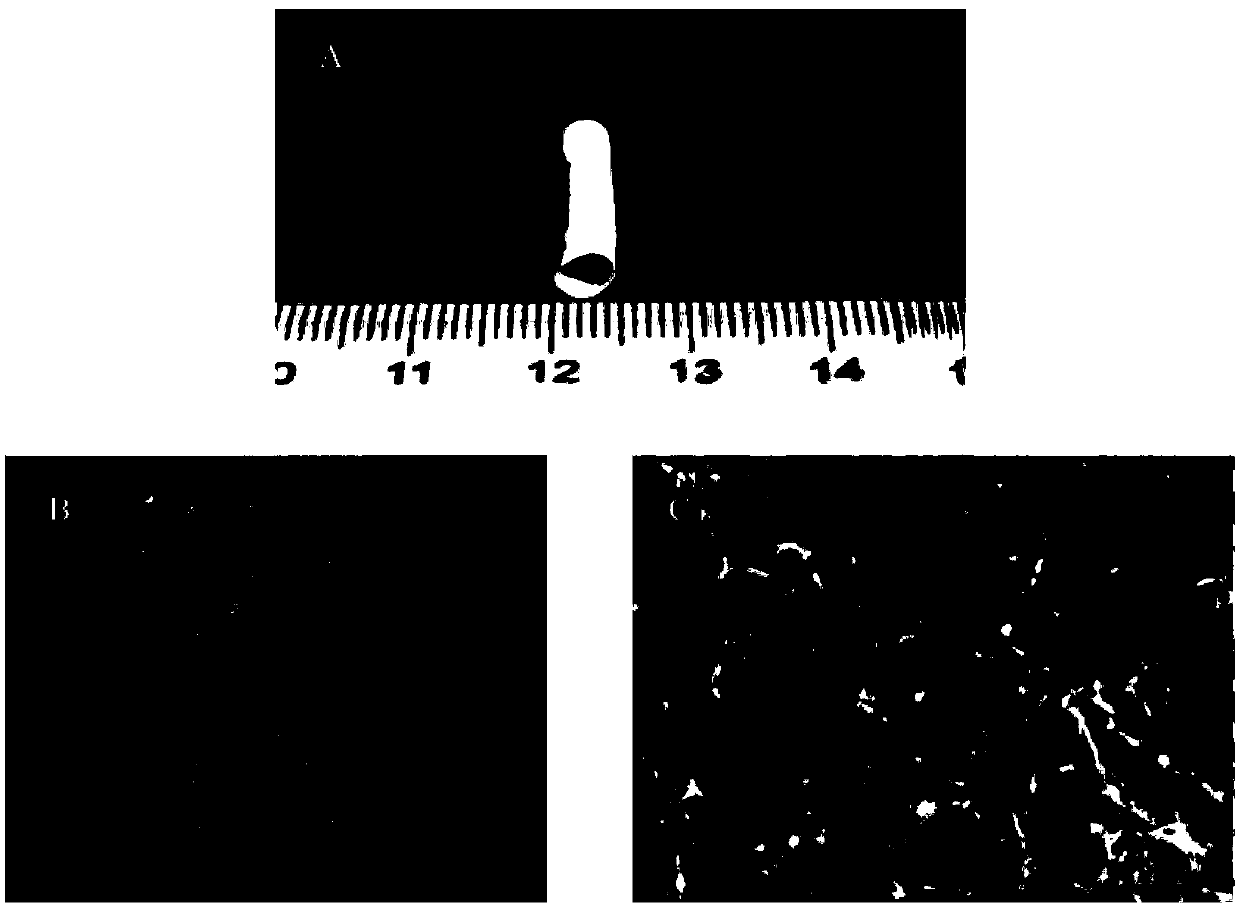

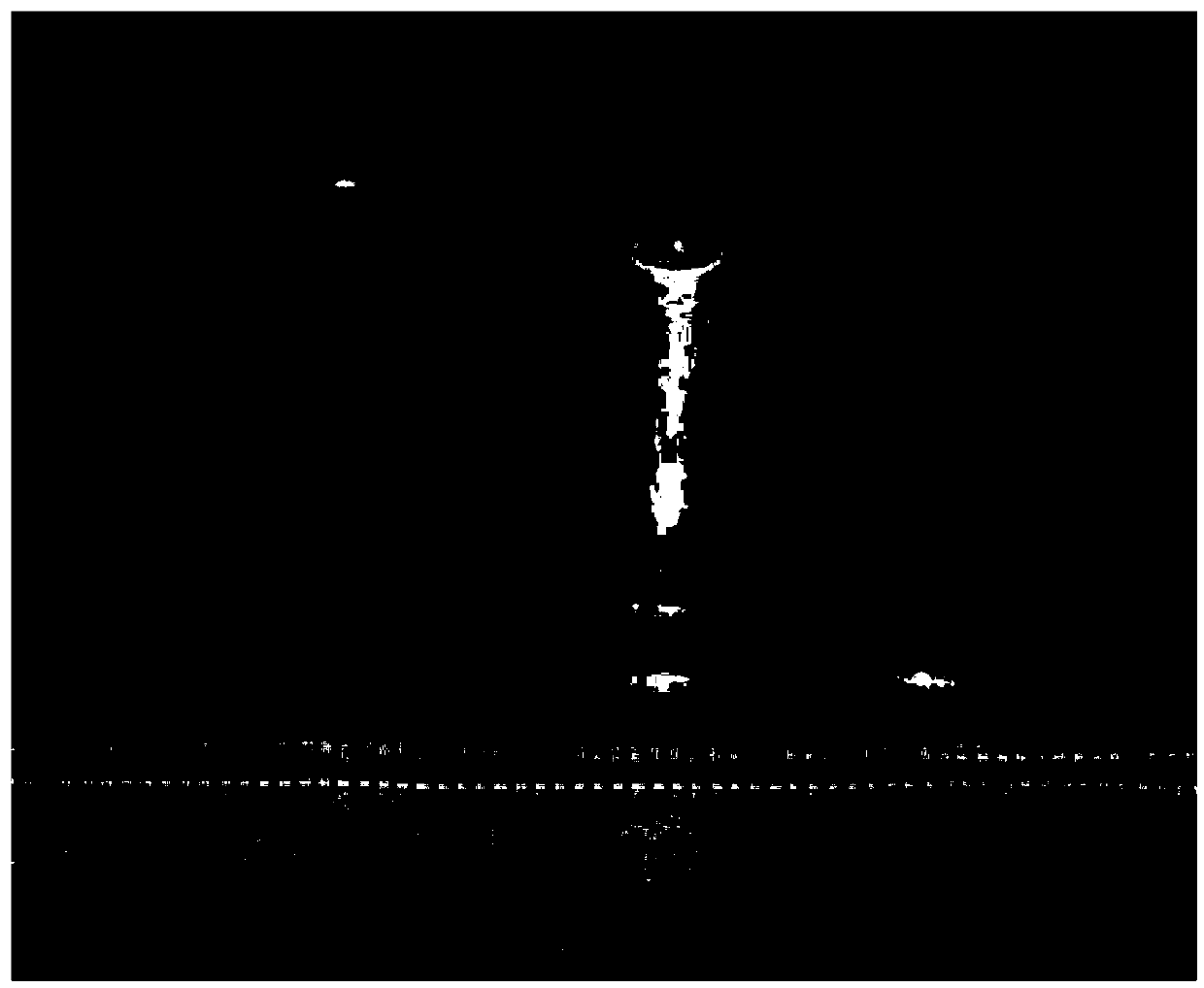

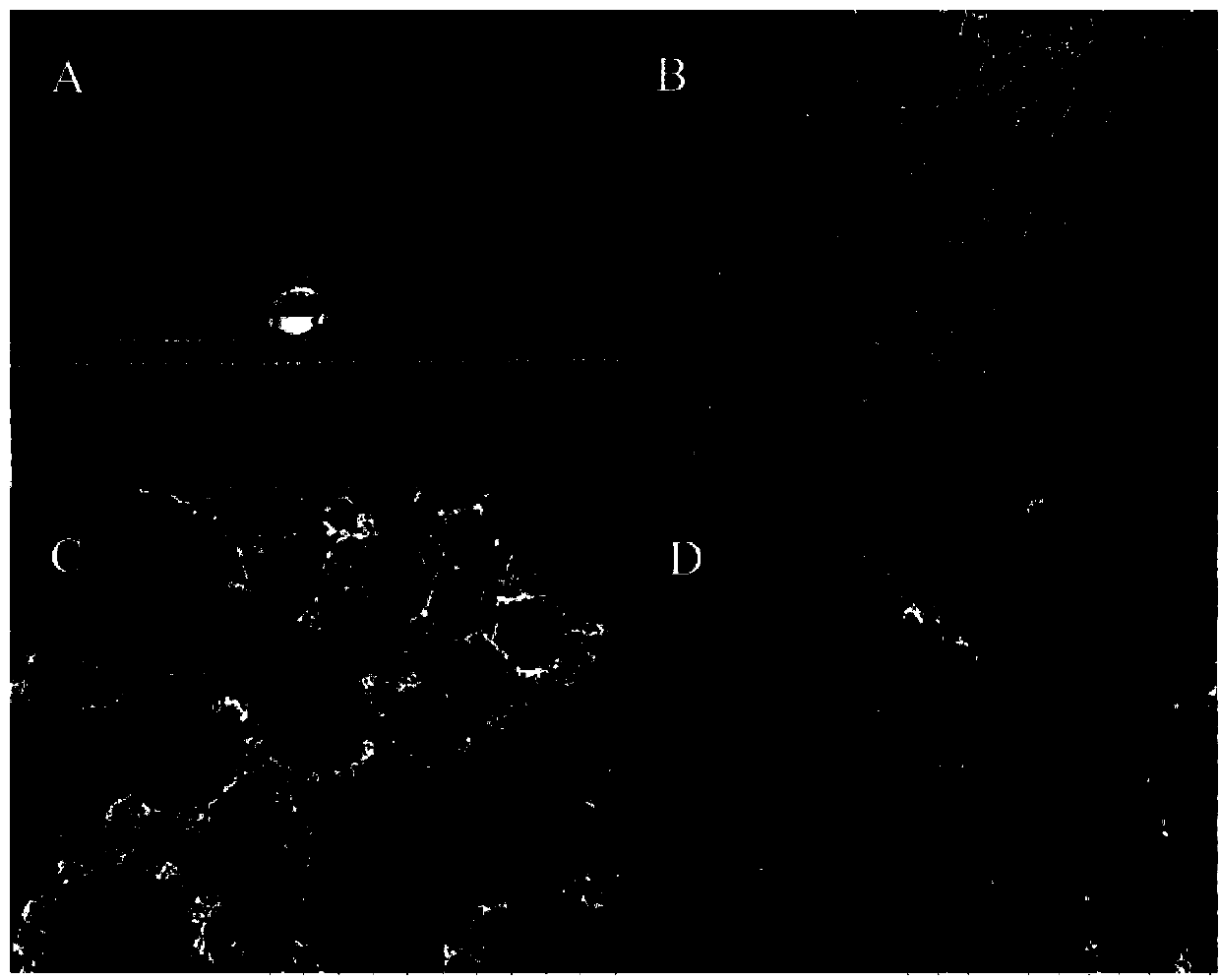

[0027] The inner layer structure is a PLLA / PLCL dense nanofiber structure, and the outer layer structure is a double-layer tubular scaffold of the PLLA / PCL self-forming pore system.

[0028] (1) Dissolve PLLA and PLCL in tetrahydrofuran at 55°C with a mass ratio of 40:60, and stir to prepare a 10% (w / v) homogeneous solution;

[0029] (2) Cast the PLLA / PLCL mixed solution into a polytetrafluoroethylene mold, and quickly place it at -80°C to separate the phases overnight;

[0030] (3) Take out the mold from the low temperature, and remove the mold, soak the gel polymer in the deionized ice-water mixture to exchange the solvent for 2 days, and change the deionized ice water 3 times a day;

[0031] (4) Take out the tubular scaffold from deionized water and freeze-dry to obtain the PLLA / PLCL nanofiber tubular scaffold with dense structure;

[0032] (5) Put the dense nanofiber tubular support prepared in (4) on the stem of the polytetrafluoroethylene mold to assemble a new casting mo...

Embodiment 2

[0038] The inner layer structure is a PLLA / PLCL dense nanofiber structure, and the outer layer structure is a double-layer tubular scaffold with a PLLA porous nanofiber structure caused by sugar spheres.

[0039] (1) Dissolve PLLA and PLCL in tetrahydrofuran at 55°C with a mass ratio of 70:30, and stir to prepare a 10% (w / v) homogeneous solution;

[0040] (2) Cast the PLLA / PLCL mixed solution into a polytetrafluoroethylene mold, and quickly place it at -20°C to separate the phases overnight;

[0041] (3) Take out the mold from the low temperature, and remove the mold, soak the gel polymer in deionized ice water to exchange solvent for 2 days, and change the deionized ice water 3 times a day;

[0042] (4) Take out the tubular scaffold from deionized water and freeze-dry to obtain the PLLA / PLCL nanofiber tubular scaffold with dense structure;

[0043] (5) Put the dense nanofiber tubular support prepared in (4) on the stem of the polytetrafluoroethylene mold to assemble a new ca...

Embodiment 3

[0051] The inner layer structure is a PLLA / PLCL dense nanofiber structure, and the outer layer structure is a double-layer tubular scaffold with a PLLA porous nanofiber structure prepared by a gas foaming method.

[0052] (1) Dissolve PLLA and PLCL in tetrahydrofuran at 55°C with a mass ratio of 50:50, and stir to prepare a 10% (w / v) homogeneous solution;

[0053] (2) Cast the PLLA / PLCL mixed solution into a polytetrafluoroethylene mold, and quickly place it at -80°C to separate the phases overnight;

[0054] (3) Take out the mold from the low temperature, and remove the mold, soak the gel polymer in deionized ice water to exchange solvent for 2 days, and change the deionized ice water 3 times a day;

[0055] (4) Take out the tubular scaffold from deionized water and freeze-dry to obtain the PLLA / PLCL nanofiber tubular scaffold with dense structure;

[0056] (5) Put the dense nanofiber tubular support prepared in (4) on the stem of the polytetrafluoroethylene mold to assemble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com