Preparation method of standard spectrum sample

A spectral standard sample and standard sample technology, which is applied in the field of spectral standard sample preparation, can solve the problems of not being able to meet the requirements of fast production in front of the furnace, increasing the frequency of standard sample replacement, and unfavorable coordination, so as to achieve high practical value and reduce preparation costs. Cost, effect of increasing sample size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

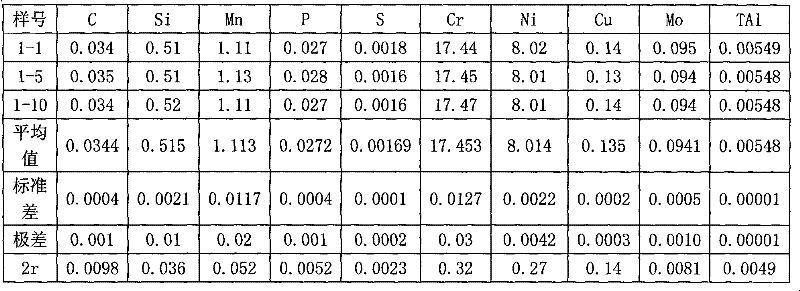

[0035] Present embodiment is the preparation method of stainless steel 304 standard sample, and its steps are as follows:

[0036] 1. Chemical composition selection:

[0037] The elemental composition range of the calibration sample should meet the requirements of the analysis and control of the AOD furnace refining period samples and product samples in front of the furnace. Referring to the 304 product standard, the molten steel in the furnace with the appropriate composition is selected during AOD furnace smelting, and the basis for selection is to select according to the composition range requirements shown in Table 1 below.

[0038] Table 1: Chemical composition range table (%)

[0039] the element

C

Si

mn

P

S

content

0.03-0.06

0.30-0.65

0.30-1.50

≤0.035

≤0.010

the element

Cr

Ni

Cu

Mo

TA

content

16.50-17.50

7.50-8.50

≤0.50

≤0.30

≤0.10 ...

Embodiment 2

[0091] This embodiment adopts the method of preparing the standard sample of heat-resistant stainless steel TP310 in continuous casting, and the steps and equipment used are the same as those in the first embodiment. The difference between the second embodiment and the first embodiment is the difference in the content of chromium and nickel, and the second embodiment increases the elements of Ti, N, Co and Nb.

[0092] The standard composition of the heat-resistant stainless steel TP310 is as follows in Table 10:

[0093] Table 10: Fixed value data table (%)

[0094] the element

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com