Patents

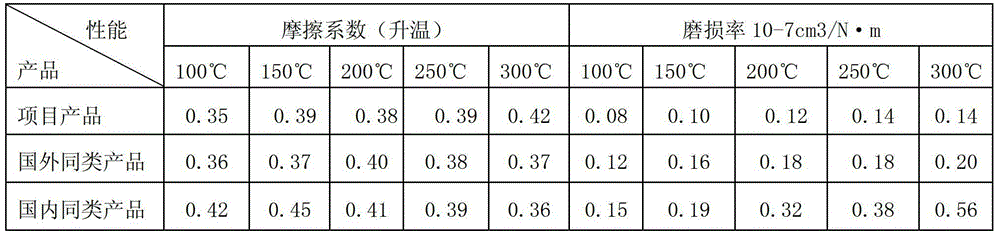

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

440 results about "Fiber carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

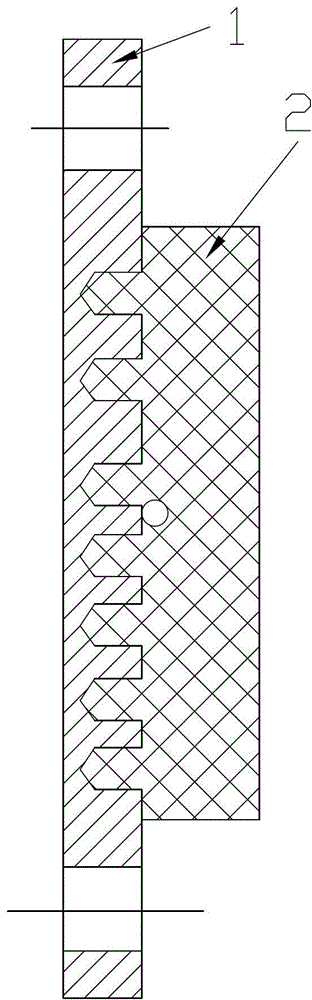

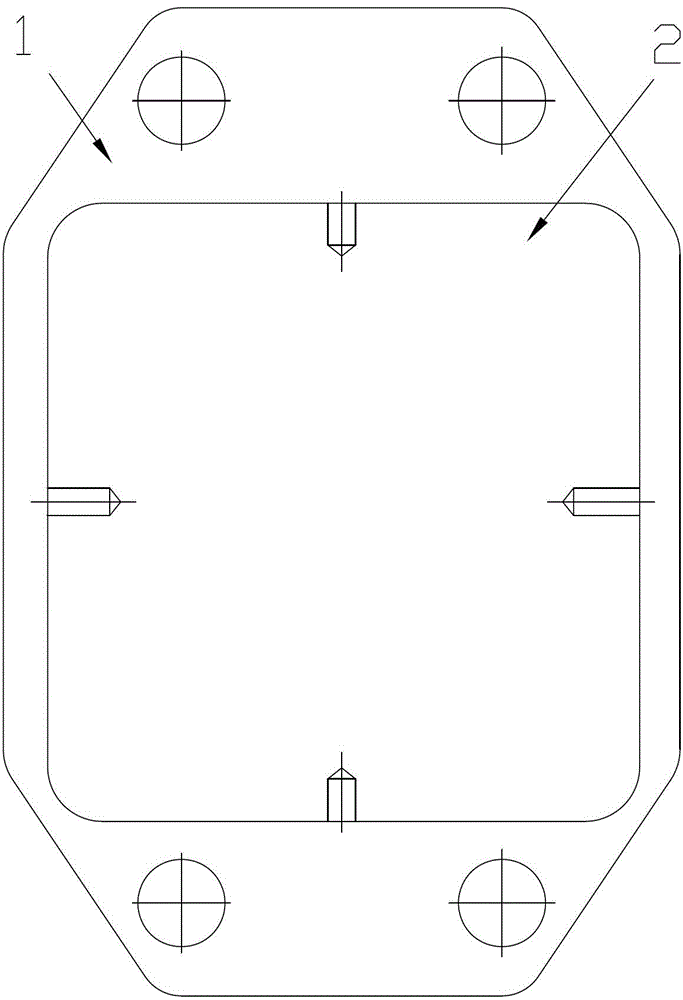

Ultra-high damping rubber composite material and preparation process of rubber composite material

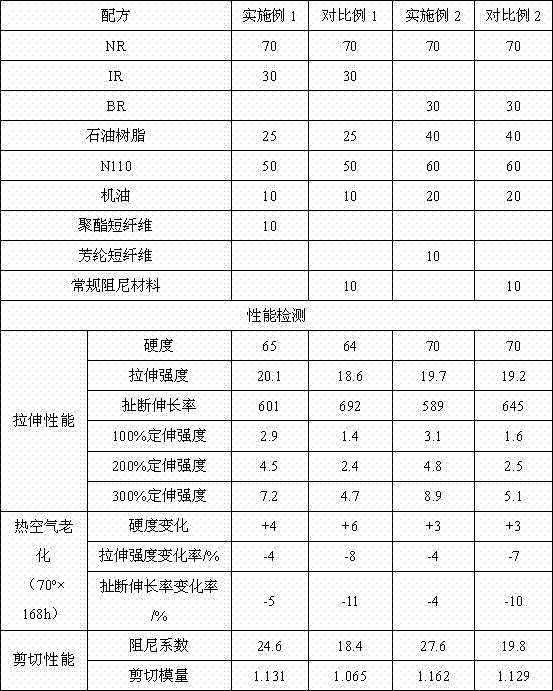

The invention belongs to the technical field of rubber and discloses an ultra-high damping rubber composite material and a preparation process of the rubber composite material. The preparation process disclosed by the invention is mainly technically characterized by comprising the following steps of: adding short fibers, carbon black, petroleum resin, a plasticizer, a vulcanizing agent, an active agent, an accelerant and an anti-aging agent in rubber; and mixing the components in an internal mixer and then vulcanizing in a flat vulcanizing machine. According to the ultra-high damping rubber composite material disclosed by the invention, a predetermined amount of short fibers, carbon black and petroleum resin are uniformly dispersed in a rubber matrix; compared with the common high-damping material, the damping coefficient of the ultra-high damping rubber composite material disclosed by the invention is increased by more than 20%; and the ultra-high damping rubber composite material disclosed by the invention has the advantages of being strong in energy consumption property and ductility and obvious in damping and shock insulating effects, effectively controlling the earthquake response of shock insulating structures, and being environment-friendly and stable in property. The stretching strength is greater under the condition with the same hardness, so that a rubber bearing prepared by the ultra-high damping rubber composite material disclosed by the invention is greater in bearing force; the whole size of the bearing is smaller than the size of the traditional high-damping rubber bearing; and the rubber bearing has the advantages of saving the use space, being convenient to construct and more excellent in resistance to fatigue performance.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER +1

Composite core for power grid transmission line wire and preparation method thereof

The invention provides a composite core for a power grid transmission line wire and a preparation method thereof. The composite core has high strength, high toughness, high glass-transition temperature and surface cleanness. Materials of the composite core comprise a resin material and a strengthening material. The resin material comprises a thermosetting resin, a curing agent, an accelerating agent, a releasing agent, a flexibilizer and nanometer particles. The strengthening material is one kind or a plurality of kinds of carbon fiber, glass fiber, basalt fiber, boron fiber, aramid fiber, silicon carbonate fiber and protein bound iodine (PBI) fiber. The content of composite core fiber Vf=50-80%, tensile strength of the composite core is not lower than 2100MPa, and glass transition temperature of the composite core is not lower than 180 DEG C. The toughness of the composite core is remarkably improved, and breakage and cracking probability caused by brittleness factors in production, transportation and wire hanging construction processes are reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

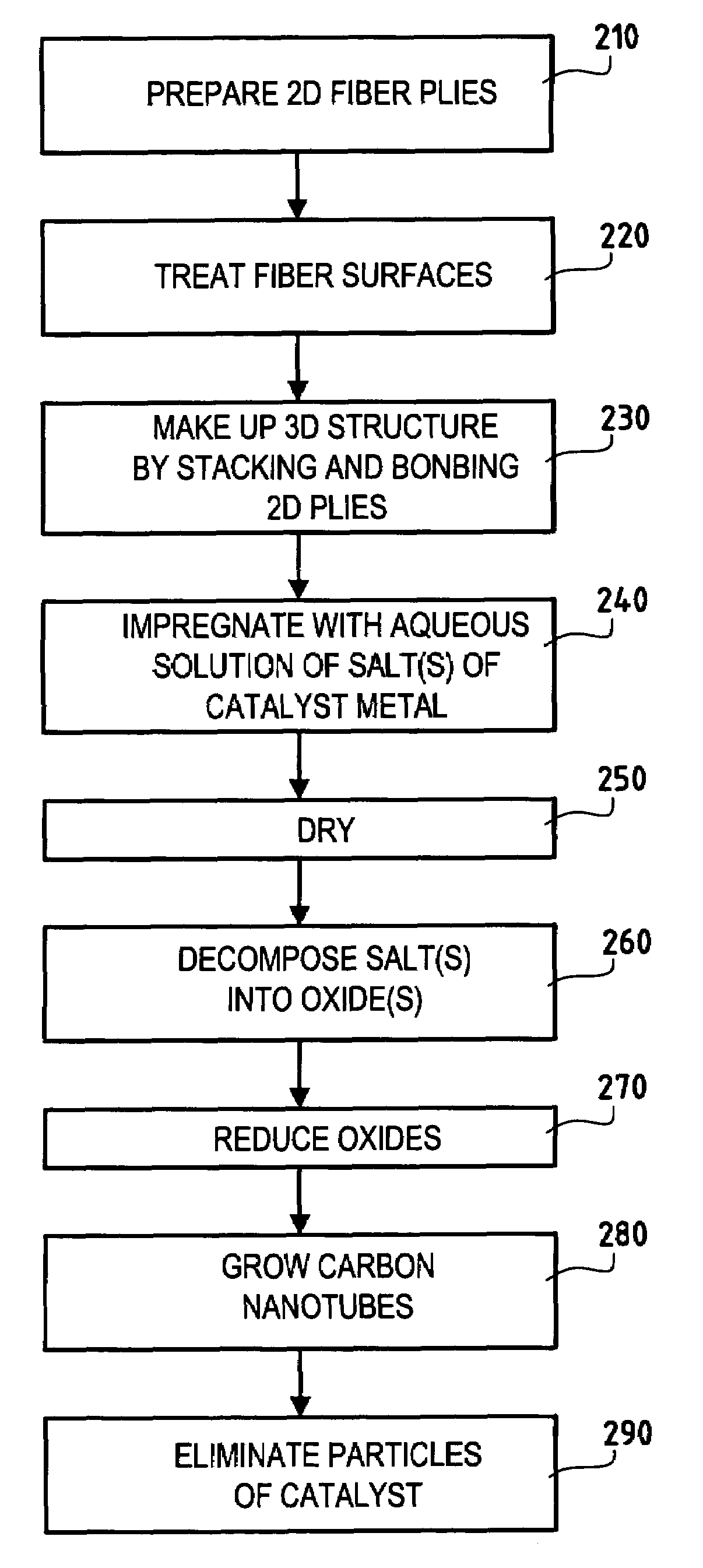

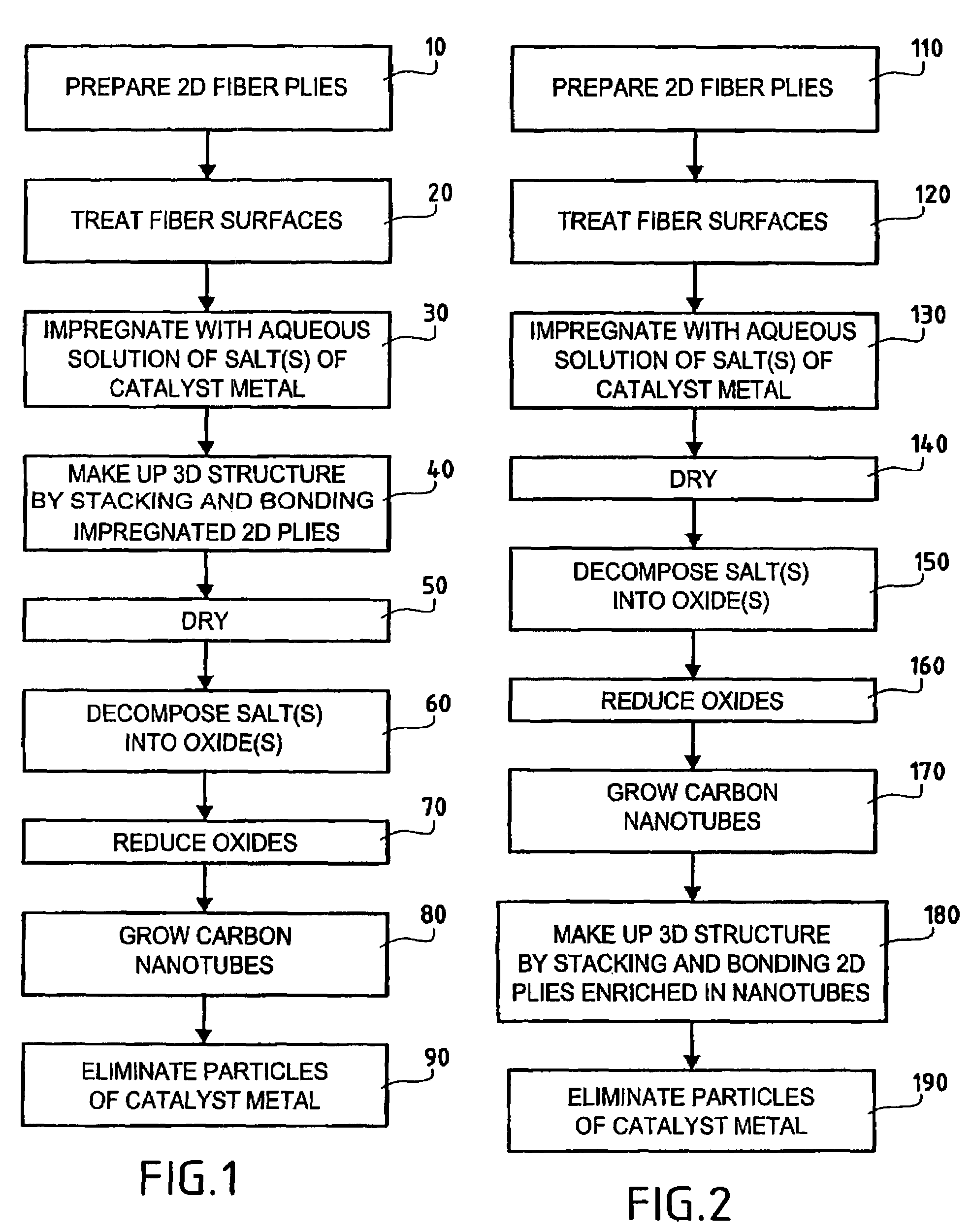

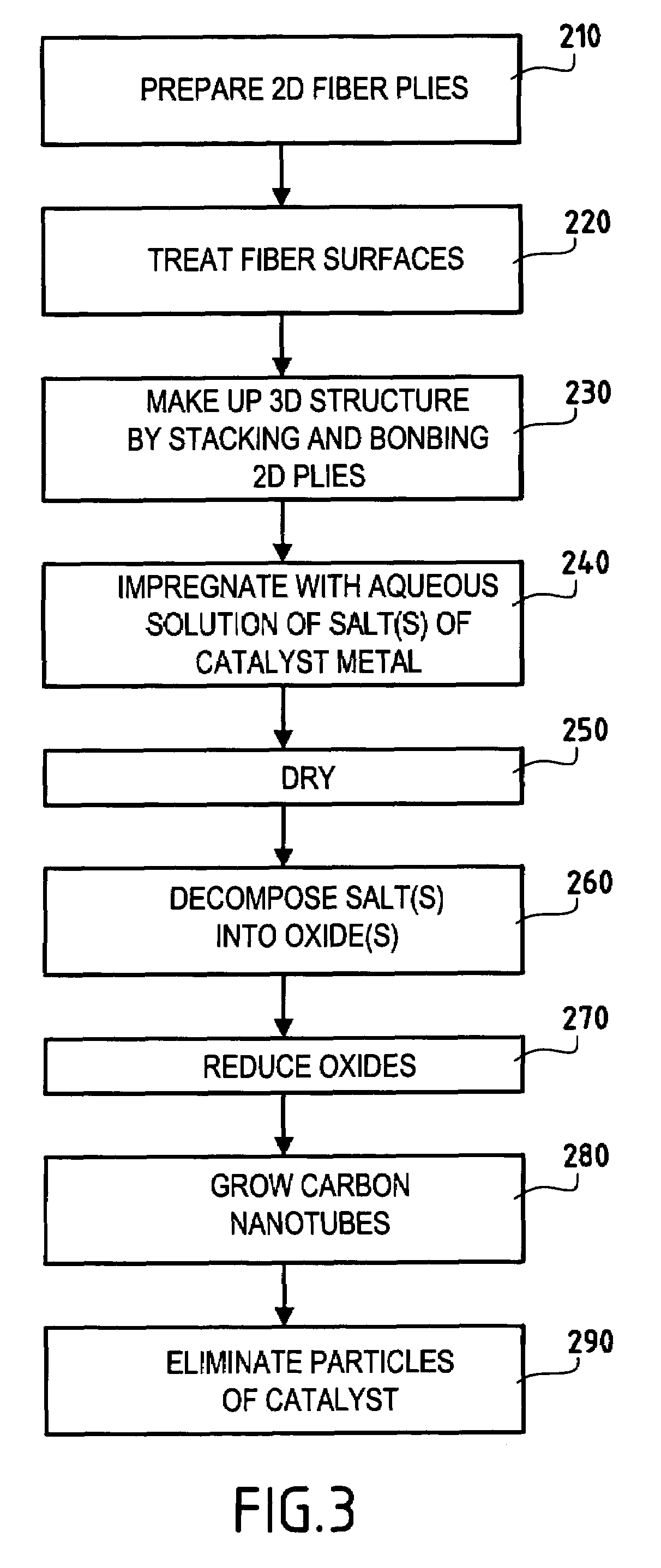

Method of making a three-dimensional fiber structure of refractory fibers

ActiveUS7384663B2Improve propertiesEasy to prepareMaterial nanotechnologyCarbon fibresNanotubeFiber carbon

Owner:CENT NAT DE LA RECHERCHE SCI

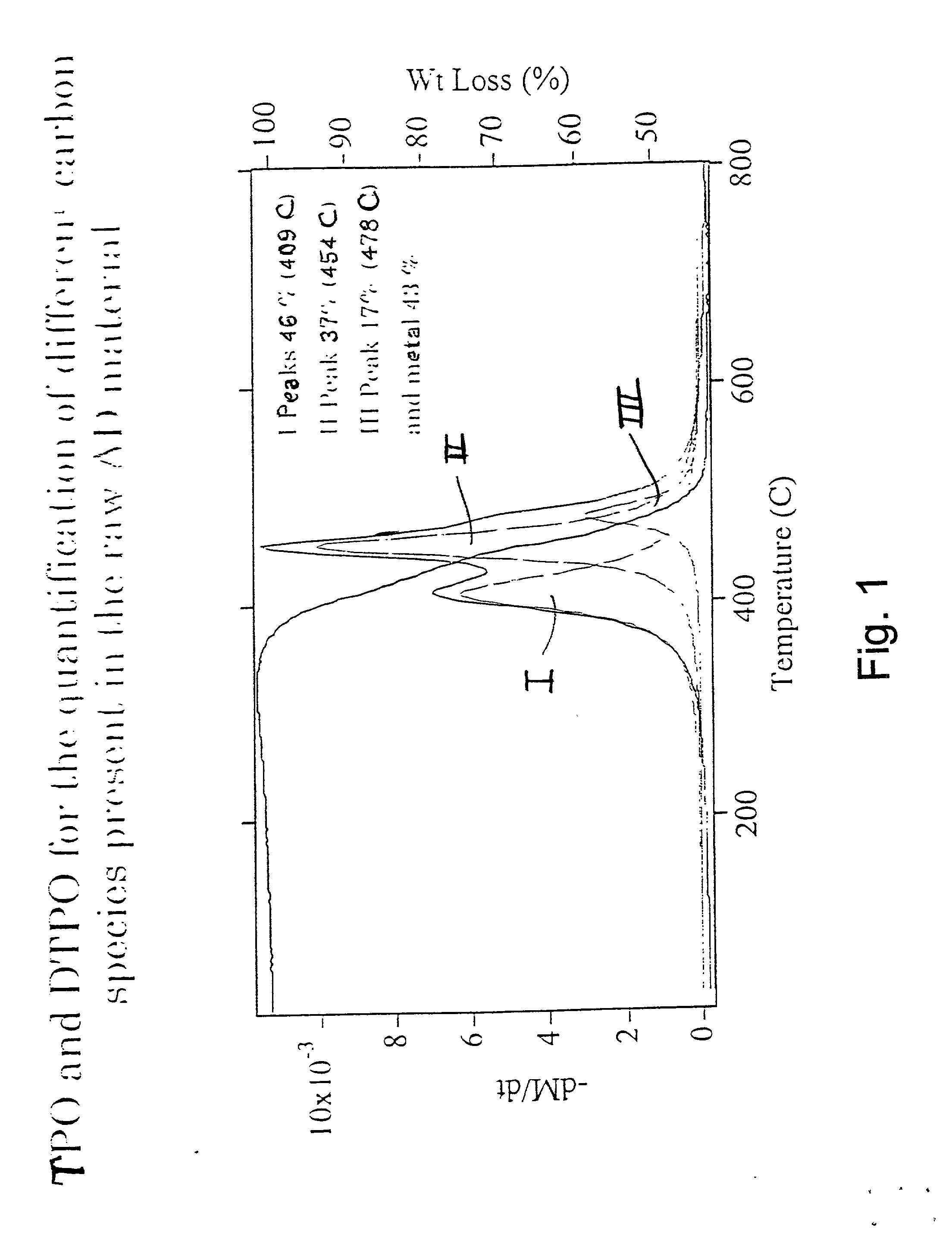

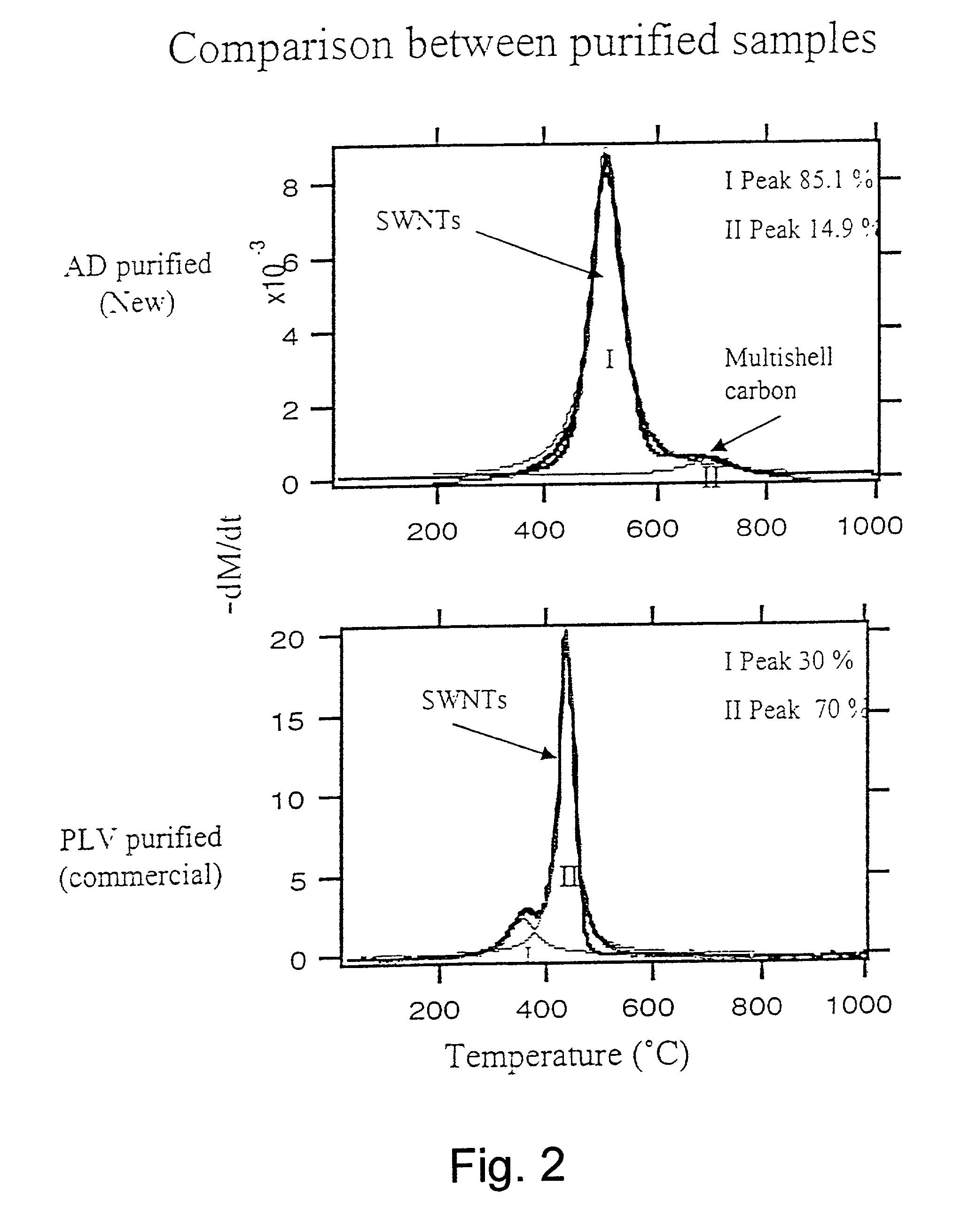

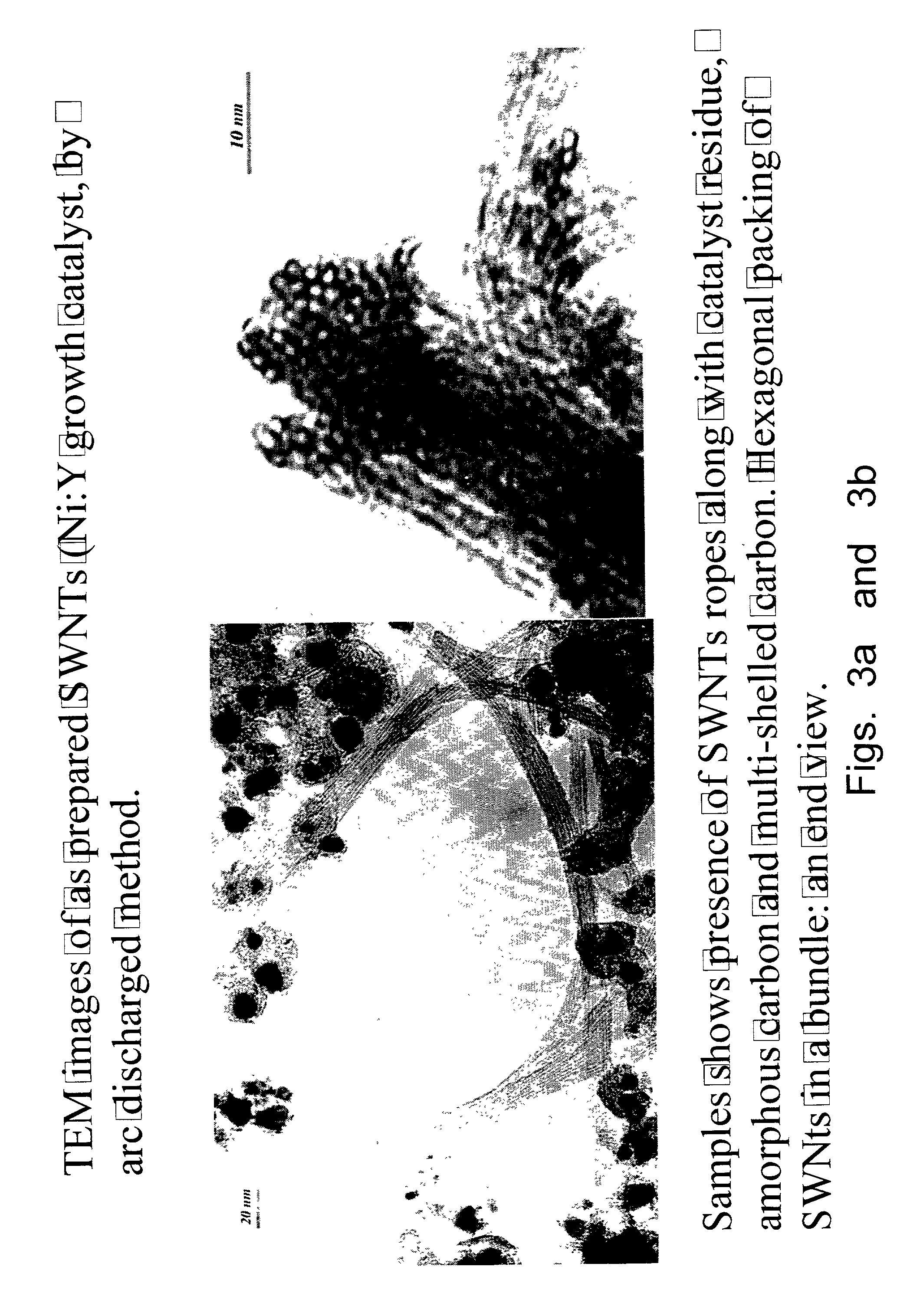

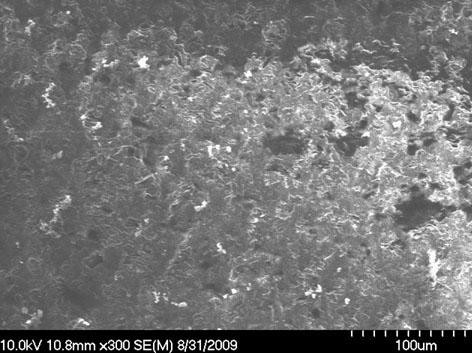

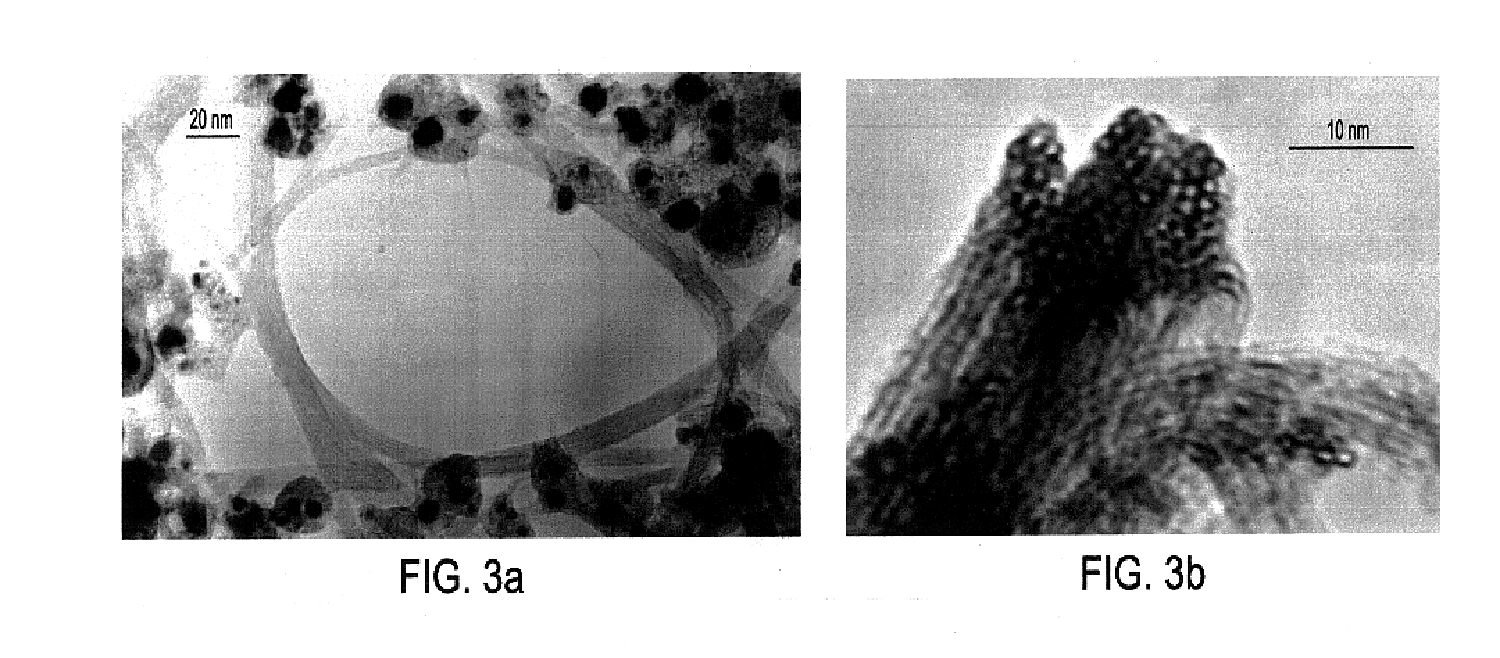

Purification of carbon filaments and their use in storing hydrogen

InactiveUS20030031620A1High yieldReduce the amount requiredMaterial nanotechnologyReversible hydrogen uptakeMetal impuritiesPhysical chemistry

Carbon structures, e.g. carbon nano-fibers, suitable for absorbing hydrogen at low pressures and low temperatures are produced by a selective oxidation and / or acid reflux process. The process includes heating an impure mixture containing a crystalline form of carbon in the presence of an oxidizing gas at a temperature and time sufficient to selectively oxidize and remove a substantial amount of any amorphous carbon impurities from the mixture. Metal containing impurities can be removed from the mixture by exposing the desired carbon and accompanying impurities to an acid to produce a carbon fiber that is substantially free of both non-fiber carbon impurities and metal impurities. Another aspect of the present invention includes purified carbon structures that can store hydrogen at low pressures and temperatures.

Owner:PENN STATE RES FOUND

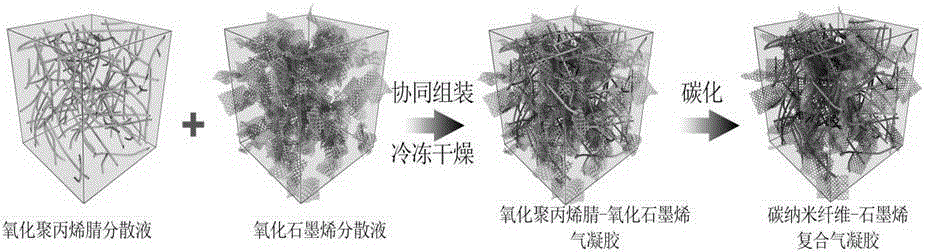

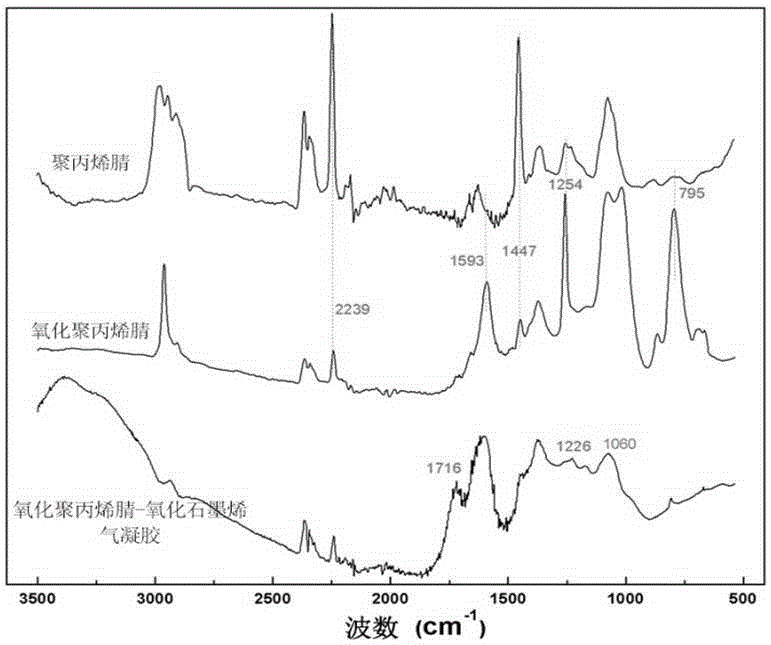

Carbon nano fiber-graphene composite aerogel and cooperative assembly preparation method thereof

InactiveCN105161312AEnvironmentally friendlyEasy to makeHybrid capacitor electrodesSpinningFreeze-drying

The invention belongs to the field of nano fiber carbon aerogel, and specifically discloses a carbon nano fiber-graphene composite aerogel and a cooperative assembly preparation method thereof. The method comprises: preparing polyacrylonitrile nano fibers by adopting an electrostatic spinning method; preparing surface-functionalized oxidized polyacrylonitrile nano fibers by temperature programmed pre-oxidation; and homogenizing the oxidized polyacrylonitrile nano fibers, then performing cooperative assembly on the oxidized polyacrylonitrile nano fibers and graphene oxide, and performing freeze drying and high-temperature carbonization to obtain the carbon nano fiber-graphene composite aerogel. The preparation method is simple, efficient and environment-friendly, and does not adopt any toxic reagent; the prepared carbon nano fiber-graphene composite aerogel has the advantages of light weight, multiple pores, good elasticity and the like; and the method solves the problem that the traditional film-like electrostatic spinning fiber material is difficult in three-dimensional forming. The prepared carbon nano fiber-graphene composite aerogel serving as a super-capacitor electrode material has excellent capacitance performance.

Owner:FUDAN UNIV

Carbon nano-tube fiber cement-based material and preparation thereof

The invention relates to a cement-based material of carbon nano tube fiber and a preparation method thereof, in particular to a toughened cement-based material and a preparation method thereof. The invention solves the problems of relatively low anti-bending and anti-breaking intensity and toughness of the existing fiber toughened cement-based material. The material is produced by a fiber dispersant, an organic solvent, carbon fibers, carbon nano tubes, deionized water, a superplasticizer, a polymer emulsion, mineral admixture and cement. The preparation method of the invention is as follows: the fiber dispersant is added into mixed slurry of the cement and stirred; the primarily mixed slurry is fed into a high shearing colloid mill for shearing at high speed for 5 to 30min; the evenly stirred slurry is poured into a test mould which is moved to a vacuum drying case for pressure reducing and bubble-removing and heated for evaporation of the solvent for 0.5 to 3 hours; after 24 hours, and the material is obtained after tearing the mould and maintained in water at room temperature. The fracture energy GF and the fracture toughness of the material obtained by using the method of the invention respectively are 106.3N question mark m and 0.998Mpa / m<-1 / 2>, which are respectively 112.6 percent and 33.1 percent higher than the fracture energy and the fracture toughness of the existing fiber toughened cement-based material.

Owner:HARBIN INST OF TECH

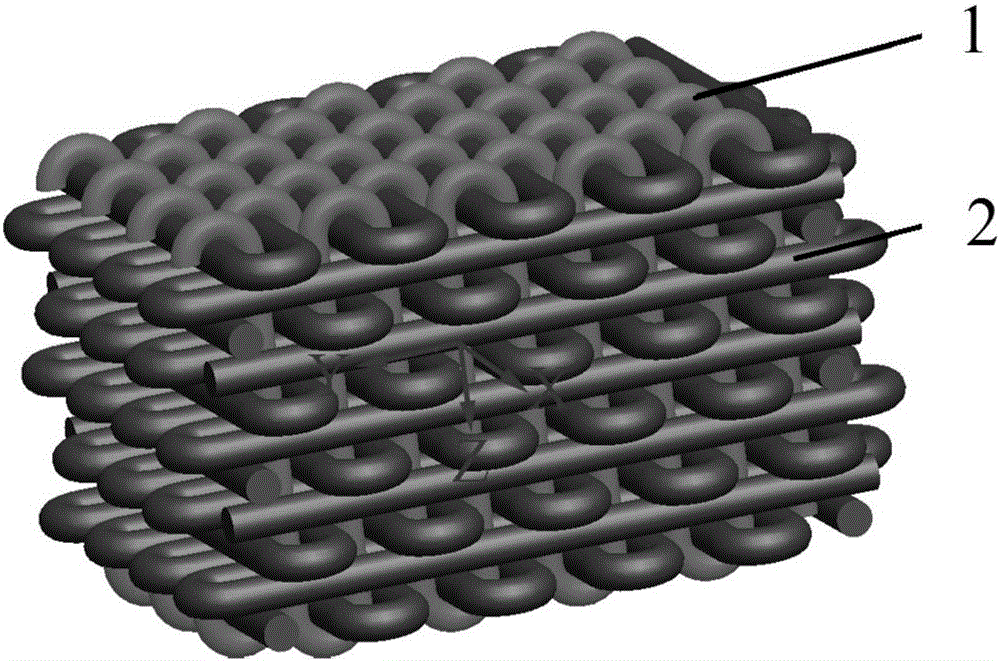

Metal fiber-nanometer carbon fiber-carbon aerogel composite material and preparation method and use thereof

InactiveCN101661839ASelf-supportingGood for electrolyte storageElectrode manufacturing processesHybrid capacitor electrodesMetal fiberInternal resistance

The invention discloses a metal fiber-nanometer carbon fiber-carbon aerogel composite material and a preparation method and a use thereof, wherein, the material contains metal fiber, nanometer carbonfiber and carbon aerogel; a binding point of the metal fiber is sintered on a tri-dimensional net structure, the nanometer carbon fiber grows on the metal fiber, and the carbon aerogel is coated on the nanometer carbon fiber. The preparation method comprises the following steps: sintering the metal fiber net structure in a large area on a selected thin layer; allowing the nanometer carbon fiber togrow by catalyzing a selected chemical vapor phase deposition method of a carbon-containing compound under a specified condition; then coating a selected organic polymer on the nanometer carbon fiber, and carbonizing the polymer at a certain temperature to obtain the metal fiber-nanometer carbon fiber-carbon aerogel composite material. The material can be taken as an electrode material of a novelchemical power supply; and the material has a self-supporting integral structure without an organic polymer macromolecular binding agent, has a tri-dimensional layered hole structure which is beneficial to ion transmission and storage, and has high electrical conductivity, small internal resistance and good chemical energy storage performance.

Owner:EAST CHINA NORMAL UNIV

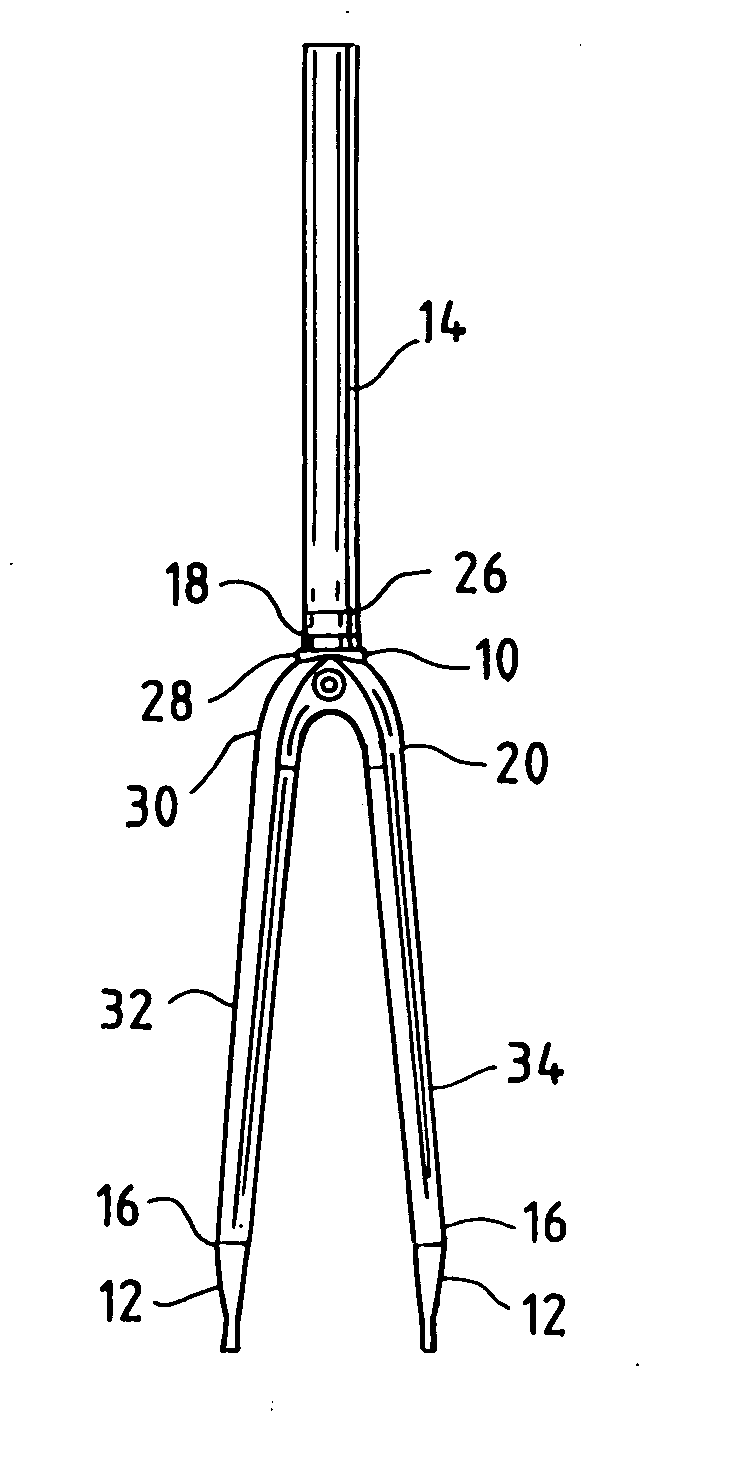

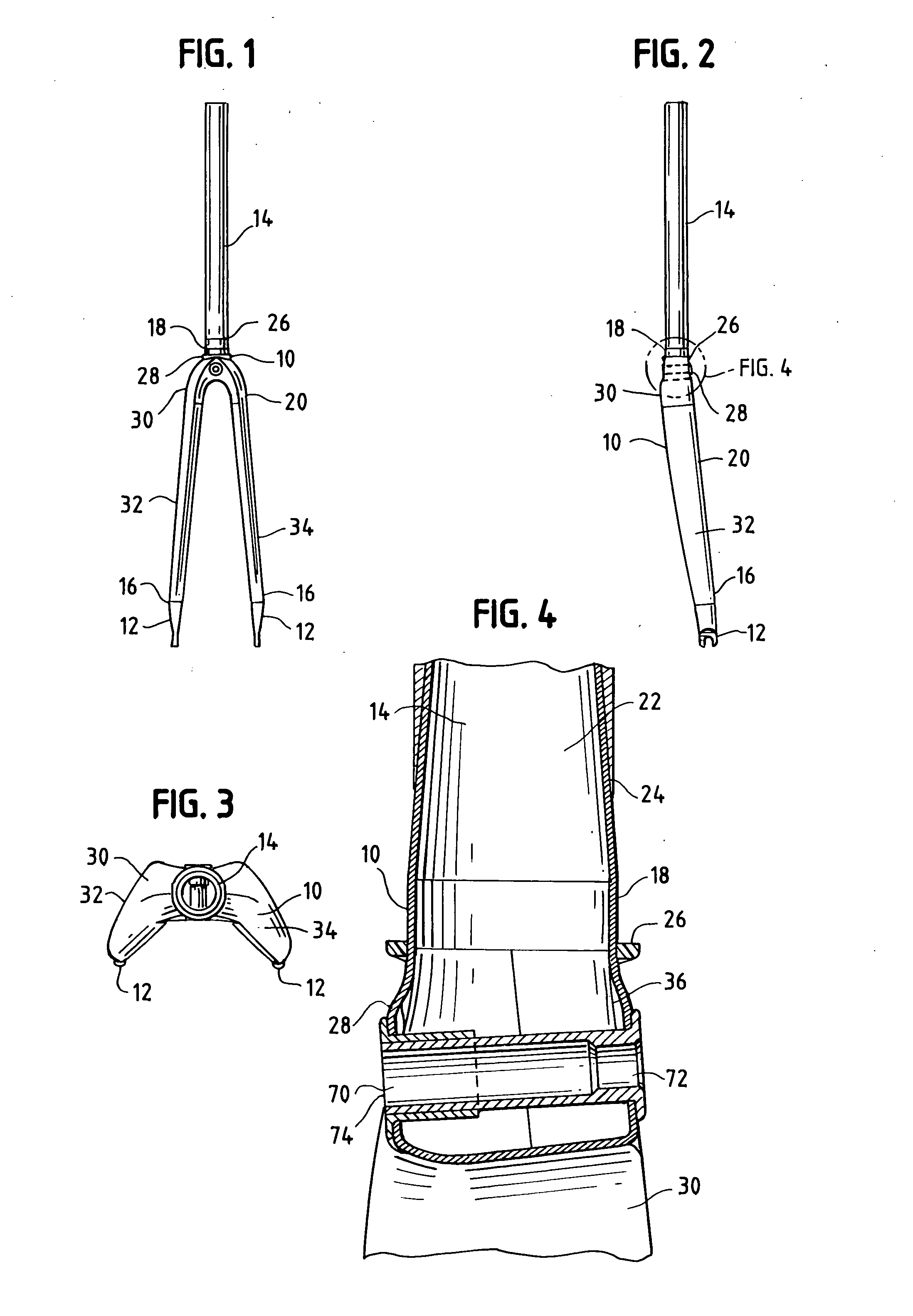

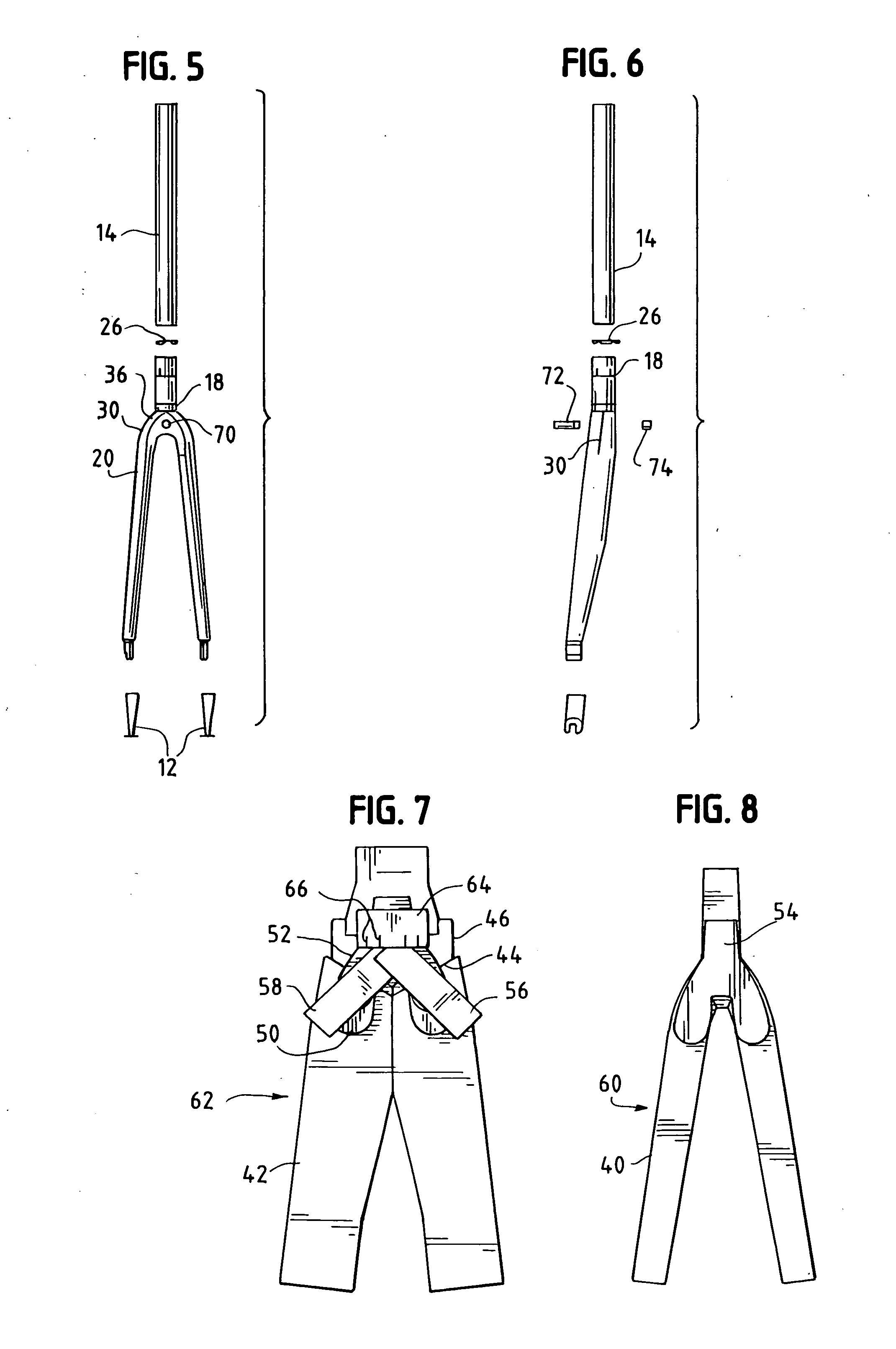

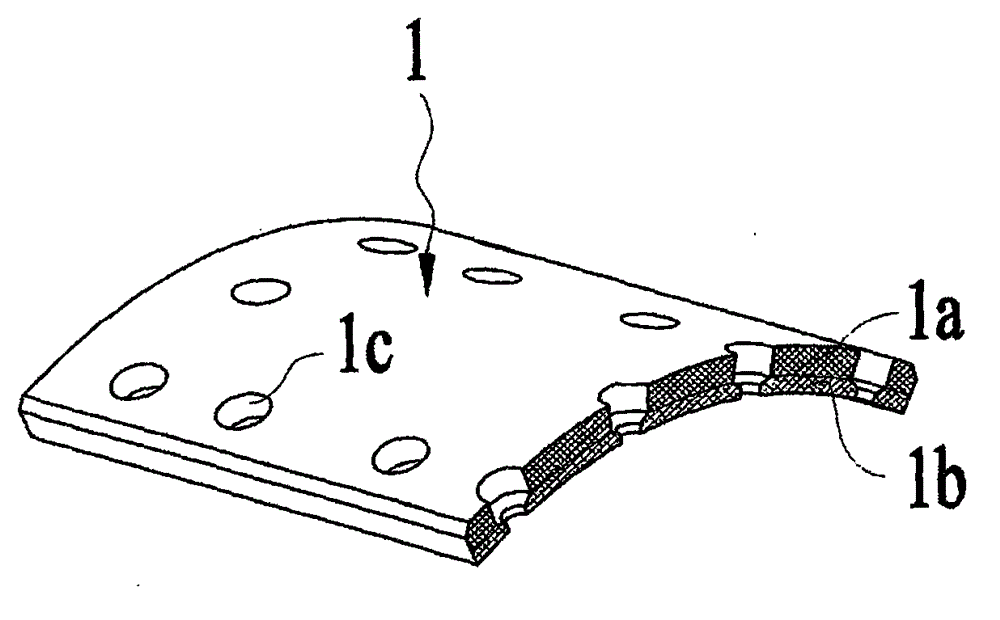

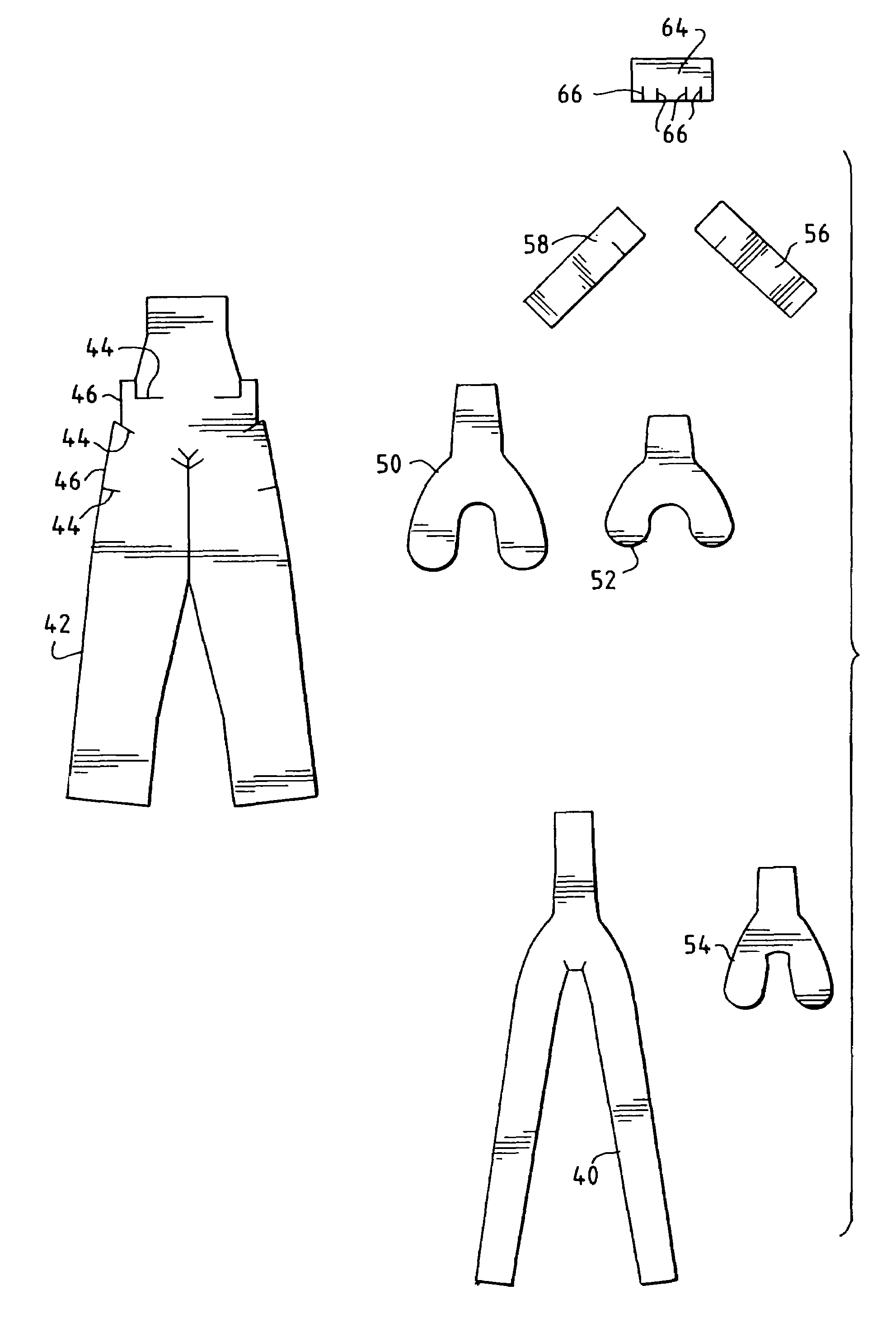

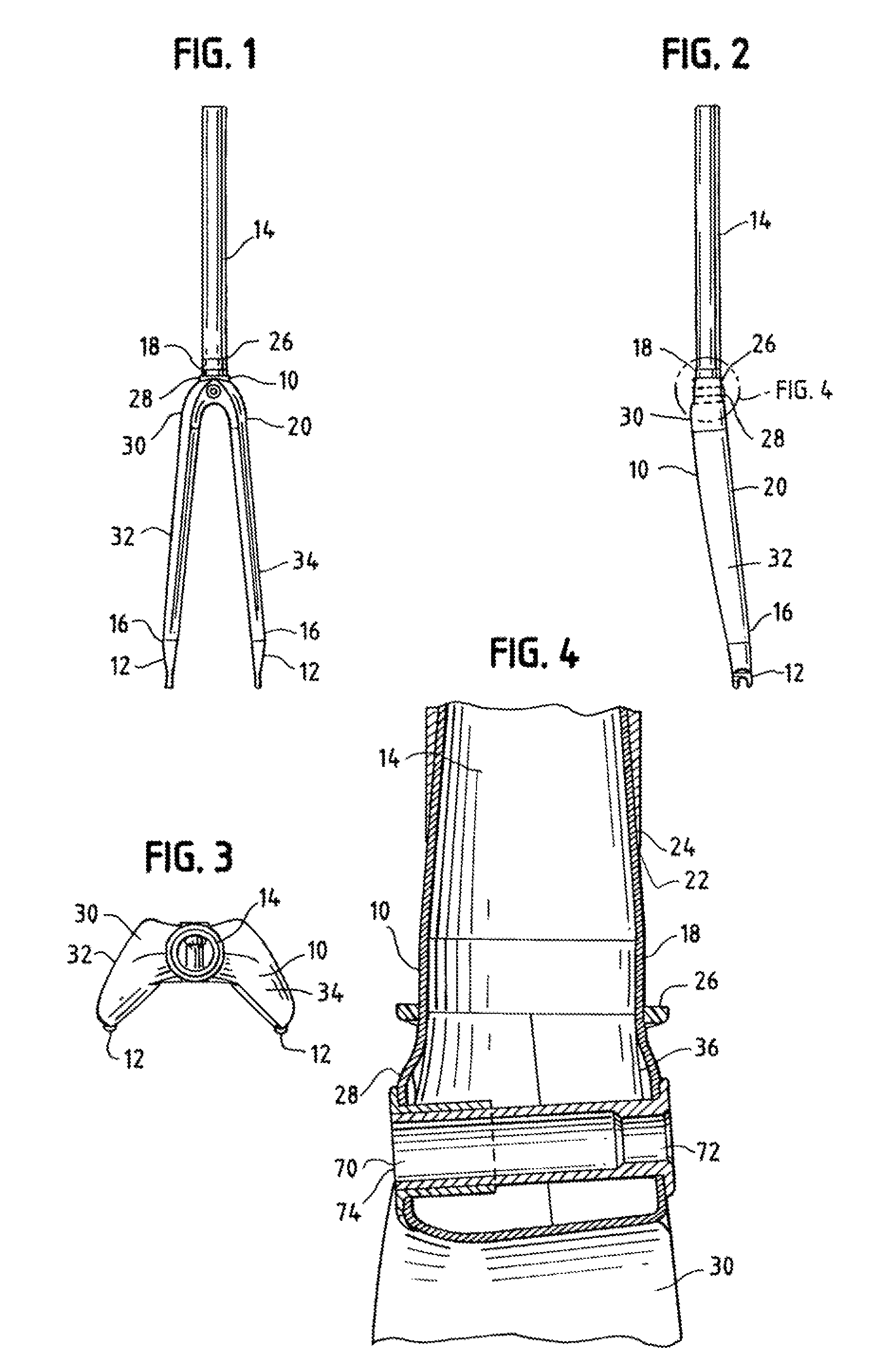

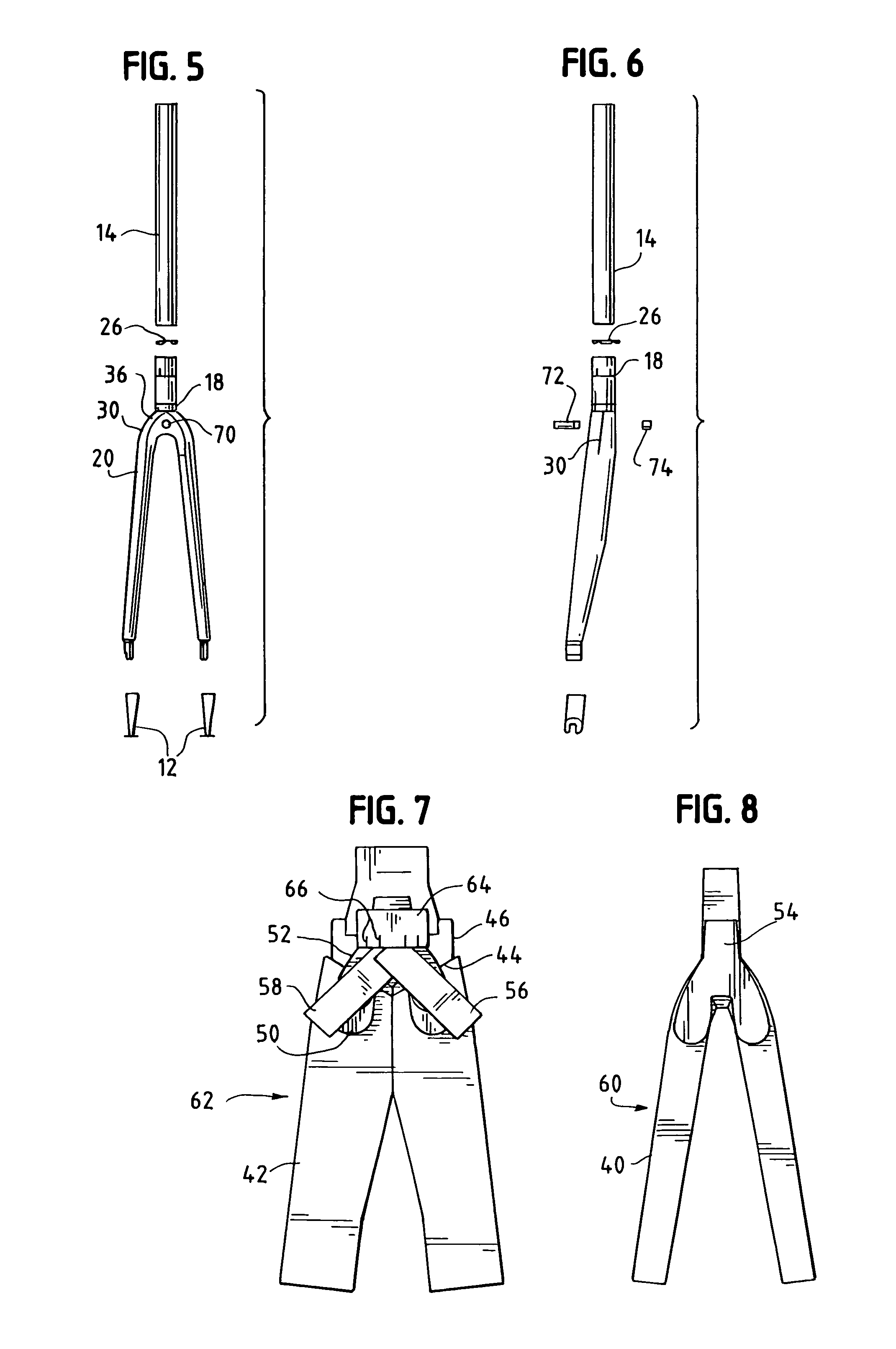

Continuous fiber carbon fork

ActiveUS20050012299A1Adds to overall fork strengthReduce intensityPassenger cyclesWheel based transmissionEngineeringFiber carbon

A continuous fiber reinforced plastic bicycle fork has continuous fibers extending from the tip of the fork blades to the steer tube, formed through optimum compaction, low void molding resulting in precise forming of the fork shell such that a metal steer tube, metal bearing races, metal dropouts and metal brake mount are used to attach metal components such as a headset and star-fangled nut, handlebar stem, wheel and brake thereby eliminating metal component to carbon fiber contact to preserve the integrity of the fiber reinforcements and plastic matrix.

Owner:TREK BICYCLE CORPORATION

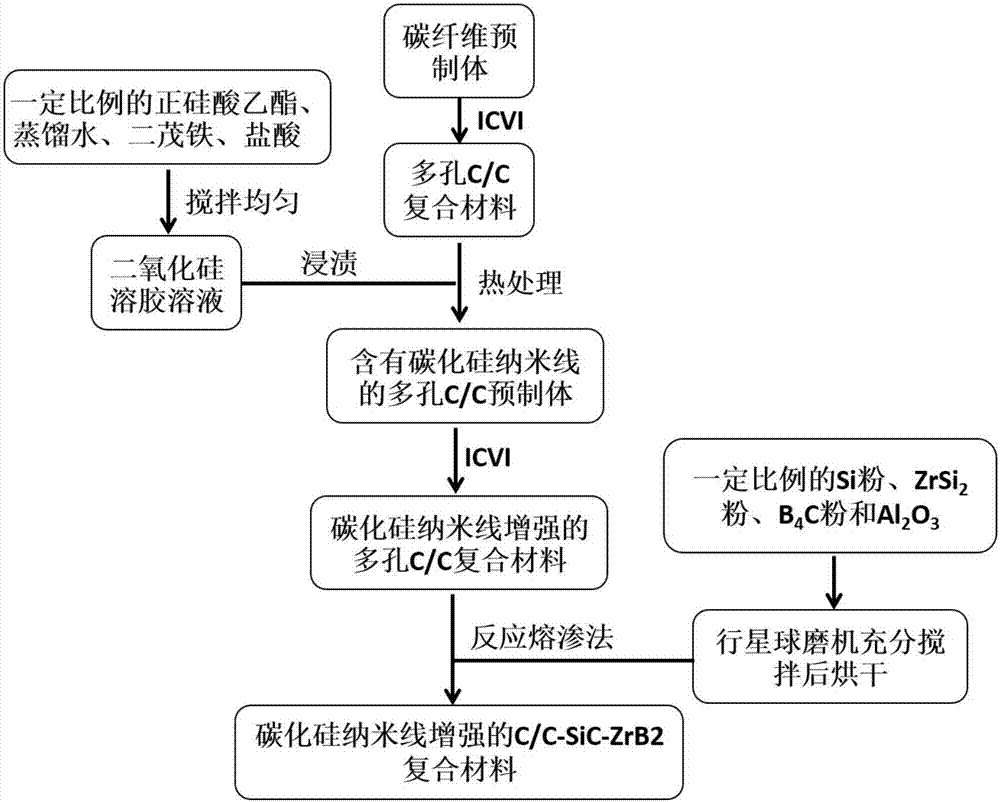

Preparation method of silicon carbide nanowire enhanced C/C-SiC-ZrB2 ceramic-based composite material

The invention relates to a preparation method of a silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material. A pretreated carbon fiber prefabricating body is thermally treated to obtain a silicon carbide nanowire. The silicon carbide nanowire prepared by a sol-gel carbon-thermal reaction method is evenly distributed at the inner part of a porous carbon / carbon composite material. Subsequently, pyrolytic carbon deposited in an isothermal chemical vapor deposition furnace is coated at the surface of the silicon carbide nanowire, thus the dropping, growing and rupture of the silicon carbide nanowire in the following reaction and infiltration processes are effectively avoided. A ceramic-based composite material carbon fiber, a silicon carbide nanowire and a pyrolytic carbon middle layer after reaction and infiltration are not eroded by a high-temperature metal bath and are well preserved; thus the physical performance of the composite material can be improved. Compared with the C / C-SiC-ZrB2 ceramic-based composite material without adding the silicon carbide nanowire, the bending strength and the fracture toughness property of the silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material are improved by 26.9-41.3% and 45.2-59.1% respectively.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

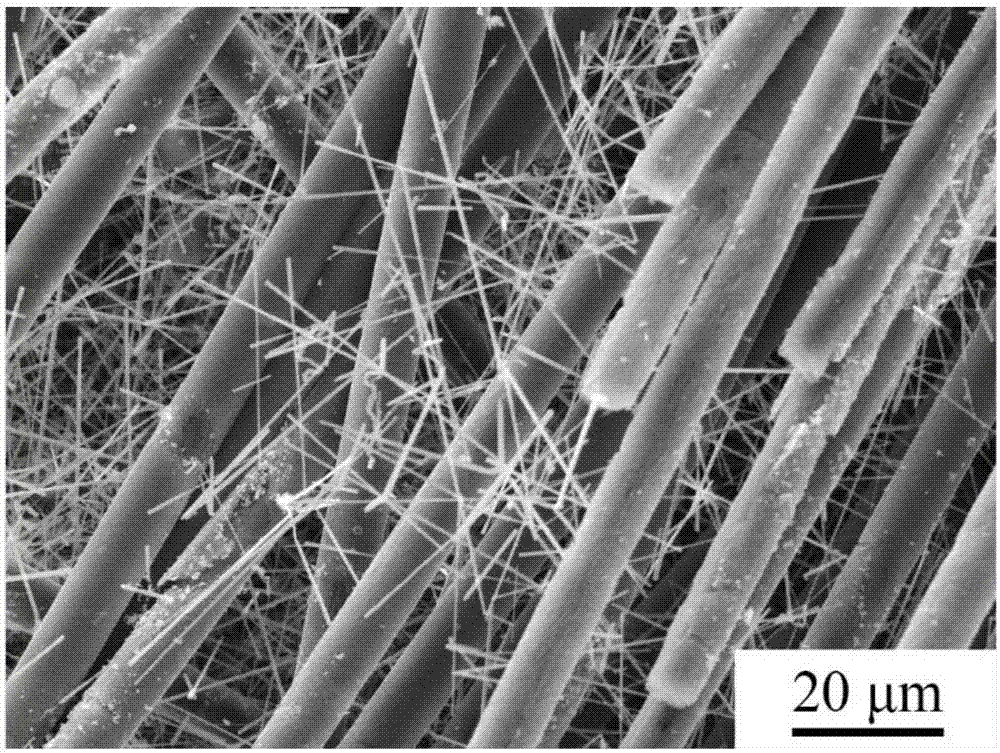

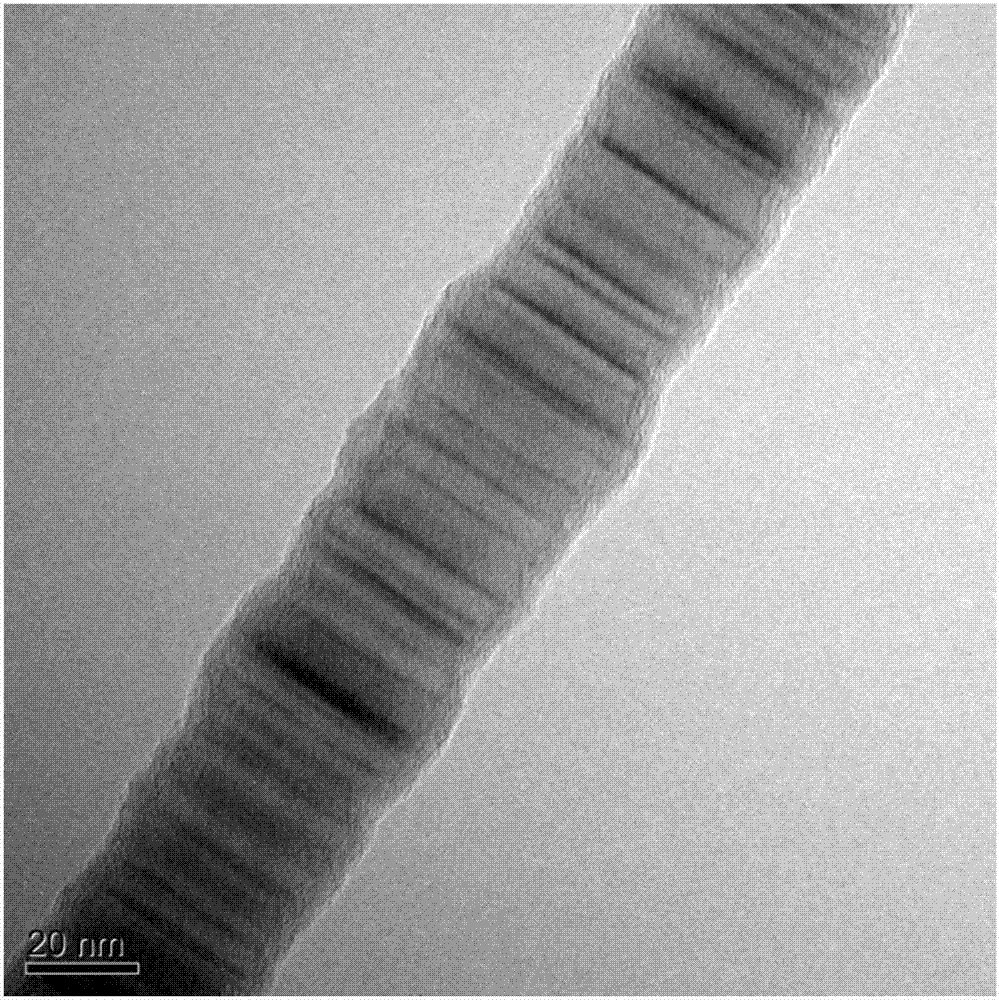

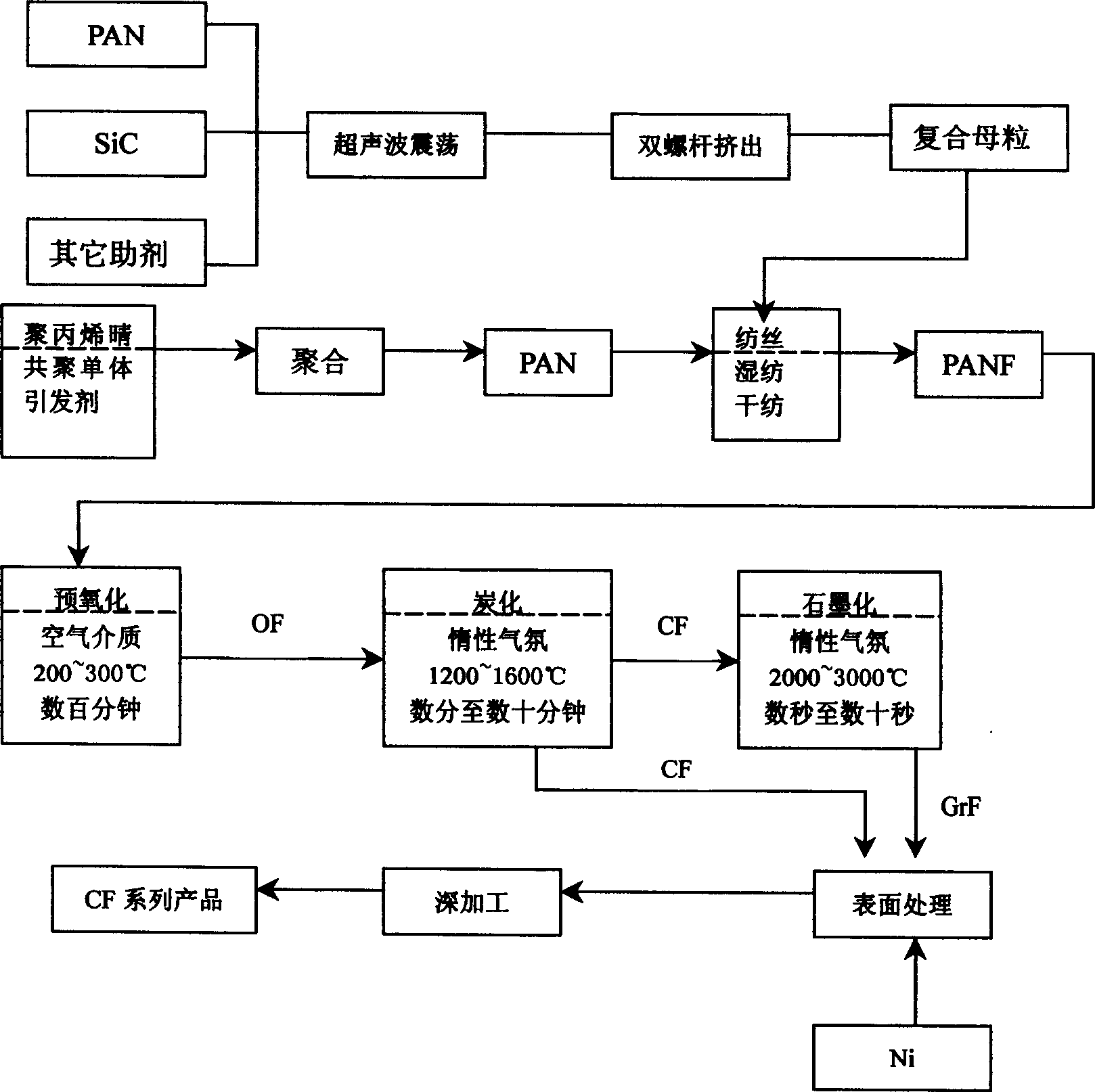

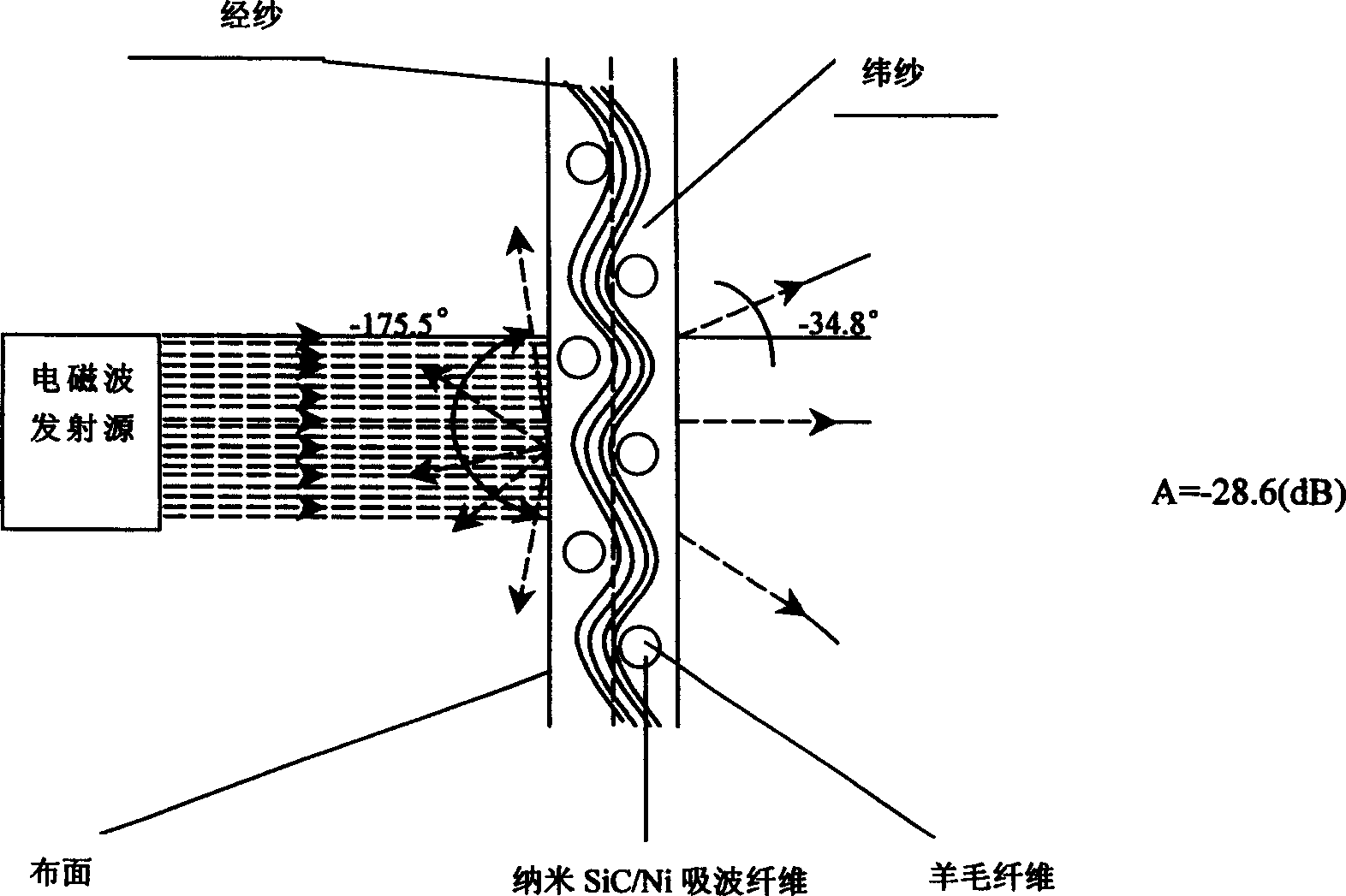

Wave absorbing composite nano-fiber material textile composition and its preparation process

InactiveCN1544723AHigh strengthHigh modulusElectroconductive/antistatic filament manufactureNano siliconComposite nanofibers

The invention relates to a composite fiber material, and the combination contains polyacrylonitrile carbon 80-96, nano silicon carbide 4-20%; nickel powder is 6-20% of the fiber in weight, assistant 5-8%. The steps: making ultrasonic wave vibration, mixing and extrusion on silicon carbide, polyacrylonitrile carbon and assistant to produce compound particles; making copolymerization and commixture on copolymerizable monomer to make polyacrylonitrile carbon wave absorbing fiber; spinning silicon carbide / nickel fiber; making preoxidation, carbonization, graphitization, surface nickel processing and weaving on the spinning to obtain the finished product. It has wide screened wave bands, and high electromagnetic wave absorbing rate, has no secondary pollution. It shortens working procedure, reduces cost, and has the characters of high strength, high modulus, low expansion coefficient, etc.

Owner:西安华捷科技发展有限责任公司

Method of making carbon fiber-carbon matrix reinforced ceramic composites

InactiveUS7297368B2Excessive crackingAggressive in diffusingCeramic shaping apparatusChemical vapor deposition coatingCeramic compositeCarbide

A method of making a carbon fiber-carbon matrix reinforced ceramic composite wherein the result is a carbon fiber-carbon matrix reinforcement is embedded within a ceramic matrix. The ceramic matrix does not penetrate into the carbon fiber-carbon matrix reinforcement to any significant degree. The carbide matrix is a formed in situ solid carbide of at least one metal having a melting point above about 1850 degrees centigrade. At least when the composite is intended to operate between approximately 1500 and 2000 degrees centigrade for extended periods of time the solid carbide with the embedded reinforcement is formed first by reaction infiltration. Molten silicon is then diffused into the carbide. The molten silicon diffuses preferentially into the carbide matrix but not to any significant degree into the carbon-carbon reinforcement. Where the composite is intended to operate between approximately 2000 and 2700 degrees centigrade for extended periods of time such diffusion of molten silicon into the carbide is optional and generally preferred, but not essential.

Owner:ULSTREETCARET

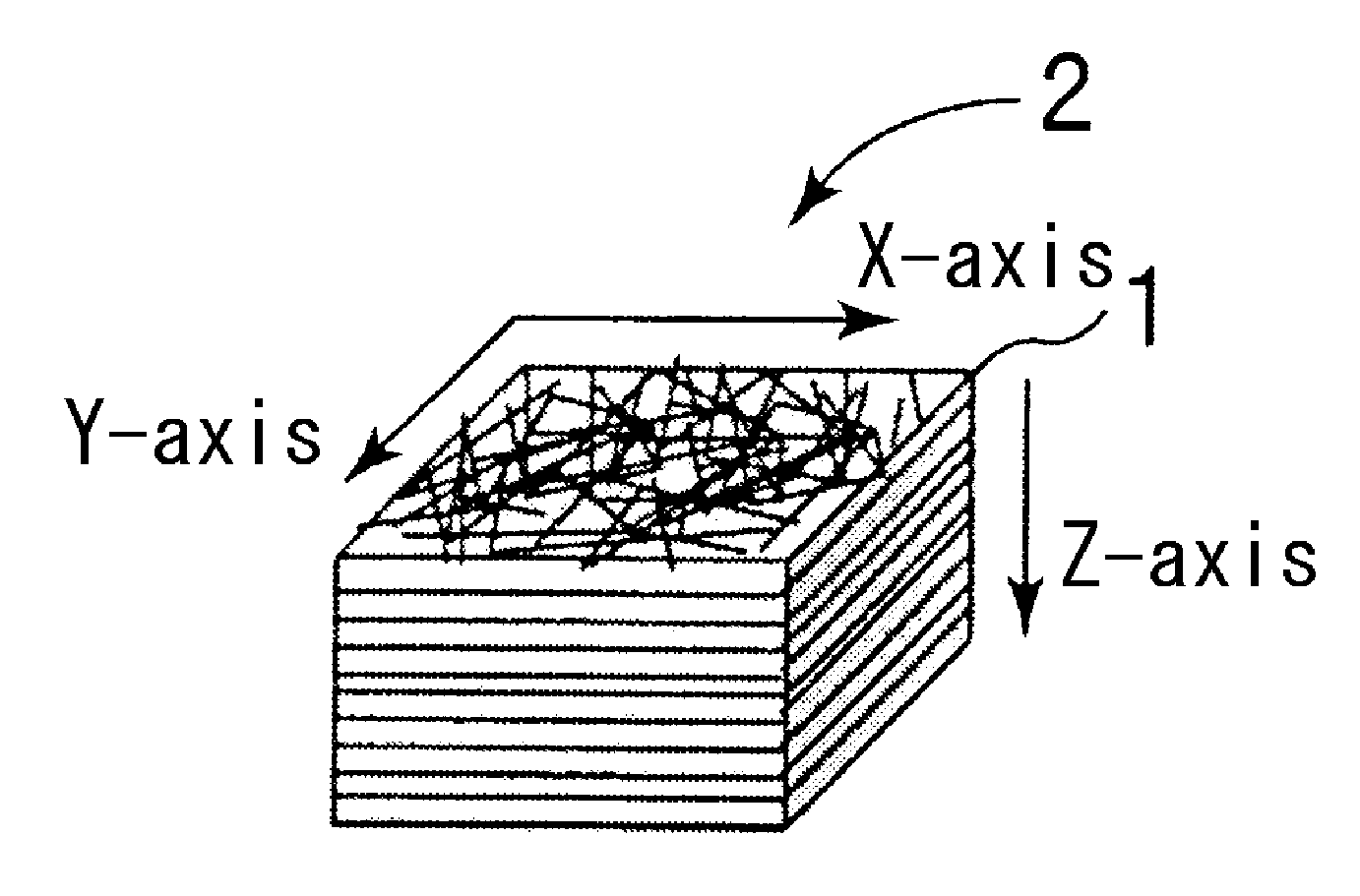

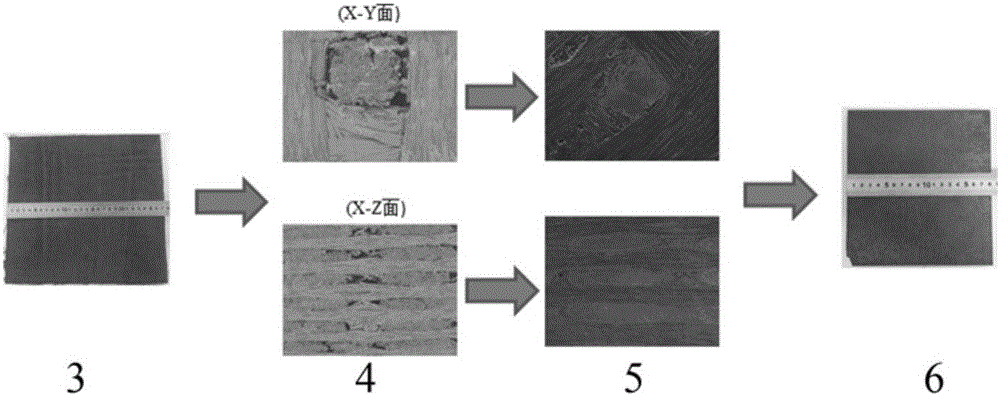

Carbon fiber carbon composite molded body, carbon fiber-reinforced carbon composite material and manufacturing method thereof

InactiveUS20110030940A1Improve thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesCarbon compositesPyrolytic carbon

To obtain a carbon fiber-reinforced carbon composite material exhibiting excellent thermal conductivity in every direction in the plane containing the X and Y axes. A carbon fiber-carbon composite formed body in which a number of sheet-like dispersions containing pitch-based carbon fibers dispersed therein randomly in the plane containing the X and Y axes are laminated into a carbon fiber laminate, and pyrolytic carbon is deposited on the surfaces of the carbon fibers of the carbon fiber laminate to coat around the carbon fibers, whereby the carbon fiber laminate is filled with the pyrolytic carbon, and a carbon fiber-reinforced carbon composite material obtained using the carbon fiber-carbon composite formed body.

Owner:TOYO TANSO KK

Preparation method of carbon/carbon composite material with high heat conduction

ActiveCN105967715AImprove thermal conductivityOvercoming Poor Weavable PerformanceCarbon compositesCarbonization

The invention discloses a preparation method of a carbon / carbon composite material with high heat conduction. The method comprises the following steps: a mesophase asphalt based carbon fiber which is treated by low temperature carbonization at 350-500 DEG C is prepared into an X-Y directional orthogonal paving layer whose thickness is 5-50mm by a winding method; a piece of PAN based carbon fiber carbon cloth is used for clamping the upper and lower surfaces of the asphalt based carbon fiber paving layer, bundles of the PAN based carbon fiber are used for carrying out puncture at a Z direction of the layer, and a three dimensional orthogonal fiber prefabricated body is obtained. High temperature carbonization and graphitization heat treatment are carried out, and a prefabricated body of the carbon / carbon composite material with high heat conduction is prepared. The carbon fiber prefabricated body is primarily densified to 1.30-1.60g / cm<3>, and the PAN based carbon fiber carbon cloth layers on the surface are removed; liquid phase infiltration pyrolysis is carried out, the material is densified to 1.70-2.10g / cm<3>, and finally the heat conductivity coefficient of the carbon / carbon composite material at X or Y direction is 200-350W / (m.K), and bending strength is 100-250MPa.

Owner:湖南东映碳材料科技股份有限公司

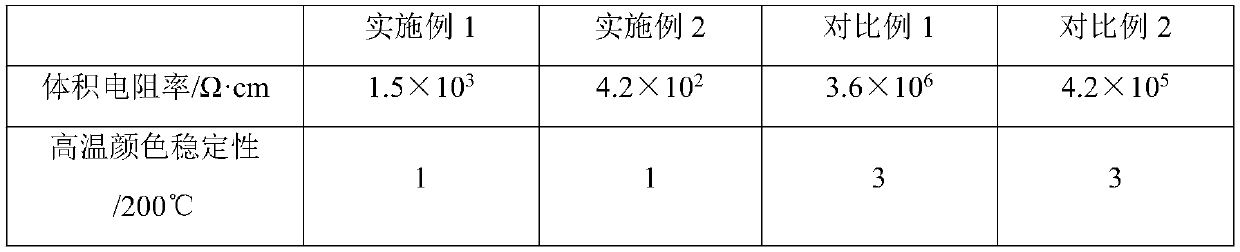

High-conductivity polyetheretherketone composite material and preparation method thereof

The invention provides a high-conductivity polyetheretherketone composite material and a preparation method thereof, and belongs to the field of conductive polymer materials. The high-conductivity polyetheretherketone composite material comprises, by weight, the following raw materials: 80-100 parts of PEEK, 10-20 parts of a reinforced fiber, 10-15 parts of grafted modified carbon nanotube, 3-8 parts of a wear-resistant agent, 2-5 parts of a coupling agent, 0.5-1 part of an antioxidant and 1-2 parts of a lubricant. According to the material, PEEK is used as a base material, and the reinforcingfiber, the carbon nanotube, the wear-resistant agent and the like are added, so that the prepared composite material not only has excellent mechanical properties, high temperature resistance and wearresistance, but also is chemically grafted and modified from the carbon nanotube, so that the composite material has high electrical conductivity and high-temperature appearance color stability.

Owner:苏州聚泰新材料有限公司

Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

InactiveCN102276795AIncreased interlaminar shear strengthImprove interface strengthResin matrixCarbon nanotube

The invention relates to a preparation method of a glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material. The preparation method provided by the invention comprises the following steps of: treating glass fiber with a silane coupling agent; carrying out surface carboxylation and chlorination on carbon nanotubes, then introducing diamine or polyamine to the carbon nanotubes, and modifying the carbon nanotubes connected with an amino group by a polybasic anhydride compound to prepare the carbon nanotubes carrying an anhydride group; dispersing the treated carbon nanotubes in an epoxy resin matrix by ultrasonic oscillation and high-speed stirring, and curing with an organic anhydride curing agent; and compounding the obtained carbon-nanotube-containing epoxy resin polymer used as a matrix with the coupling-agent-treated glass fiber to form a multi-dimensional hybrid composite material structure linked through covalent bonds. The preparation method provided by the invention has the advantages that: the composite material is convenient to prepare, the dispersion of the carbon nanotubes in epoxy resin is improved, and the strength and toughness of the carbon nanotubes are utilized to toughen epoxy resin and to improve the bonding strength with the base surface of the glass fiber, thereby enhancing the overall performance of the glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material and broadening the applications of the glass fiber, carbon nanotubes and epoxy resin.

Owner:TONGJI UNIV

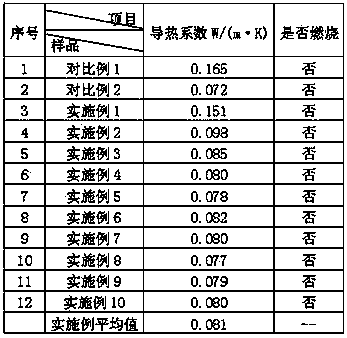

Carbon aerogel thermal insulation material and preparation method thereof

ActiveCN103466998ALow thermal conductivityImprove insulation effectThermal insulationIndustrial equipment

Aiming at the problems in the prior art that the silica aerogel is high in price and the heat conductivity coefficient of an ordinary thermal insulation material is large, the invention particularly relates to a carbon aerogel thermal insulation material and a preparation method thereof. The carbon aerogel thermal insulation material consists of the following components in parts by weight: 100 parts of a man-made inorganic fiber, 0-200 parts of a carbon material, 0.5-2.0 parts of a dispersing agent and 0.5-2.0 parts of an adhering agent. The carbon aerogel thermal insulation material provided by the invention can be a powder material, a slurry material, a felt material or a plate material in state. The carbon aerogel thermal insulation material has the advantages of small heat conductivity coefficient and moderate price, is easy to construct and popularize, and can be widely applied to insulation of buildings, industrial equipment and pipelines; and the preparation method is low in cost and simple and easy to operate.

Owner:CHENGDU SOLVER TECH

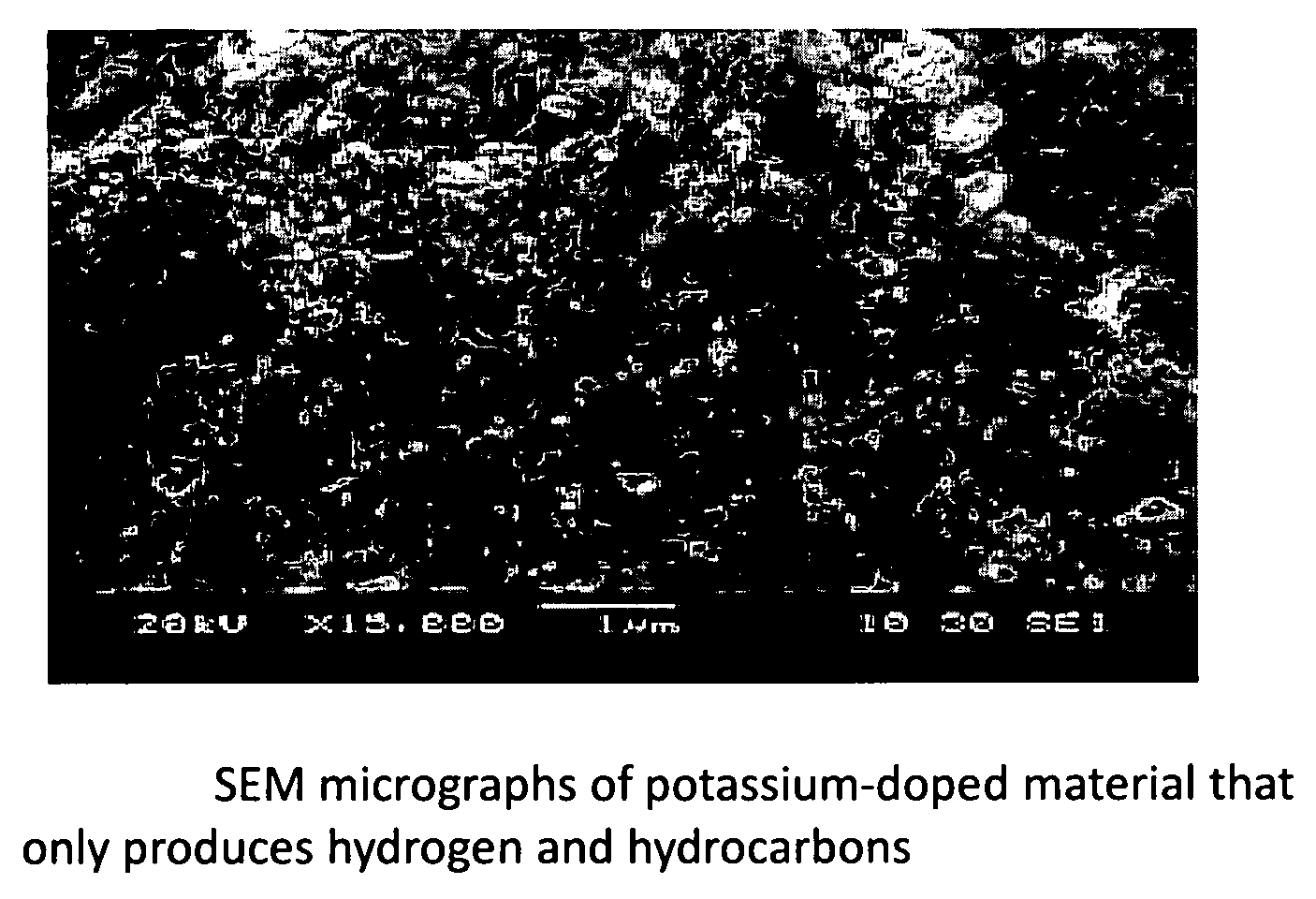

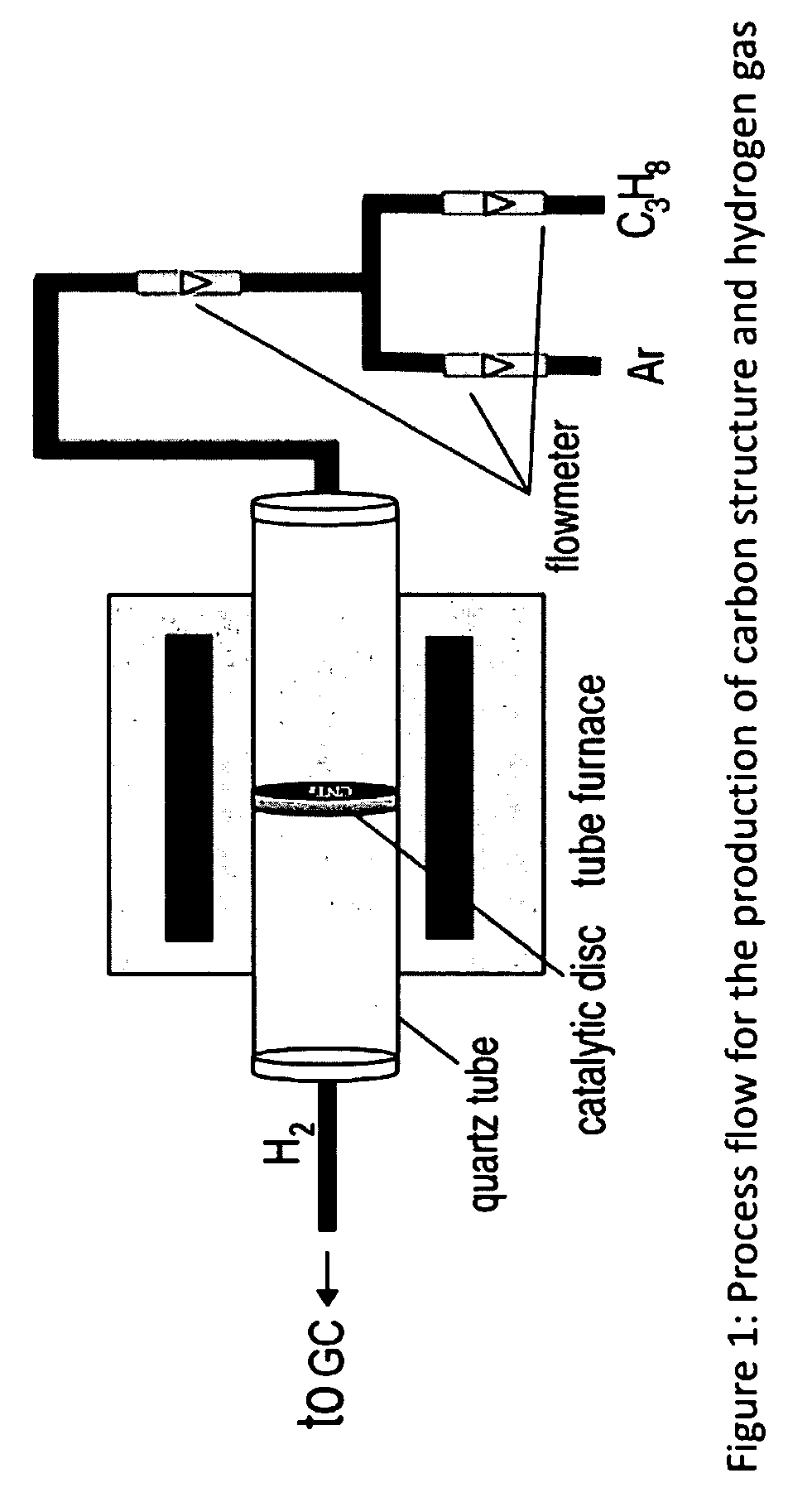

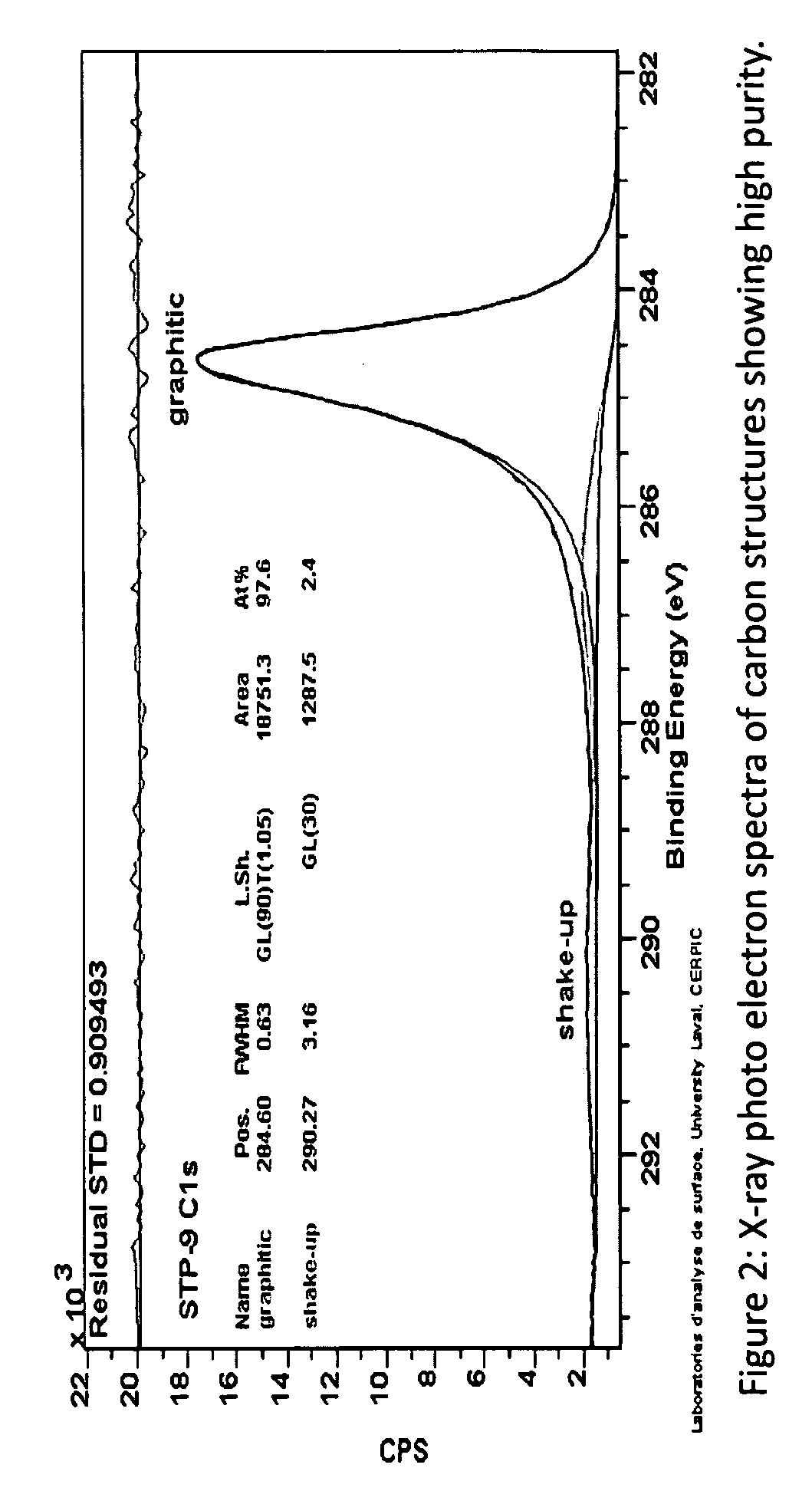

Novel catalyst to manufacture carbon nanotubes and hydrogen gas

This invention relates primarily to a novel method to manufacture single / multi / fibers carbon filaments (nano tubes) in pure form optionally with antiferromagnetic and electrical property wherein the byproduct is hydrogen gas resulting in reduction of environmental carbon emissions by at least 20%; both carbon filaments and resultant exhaust are useful products.

Owner:QUAID E AZAM UNIV

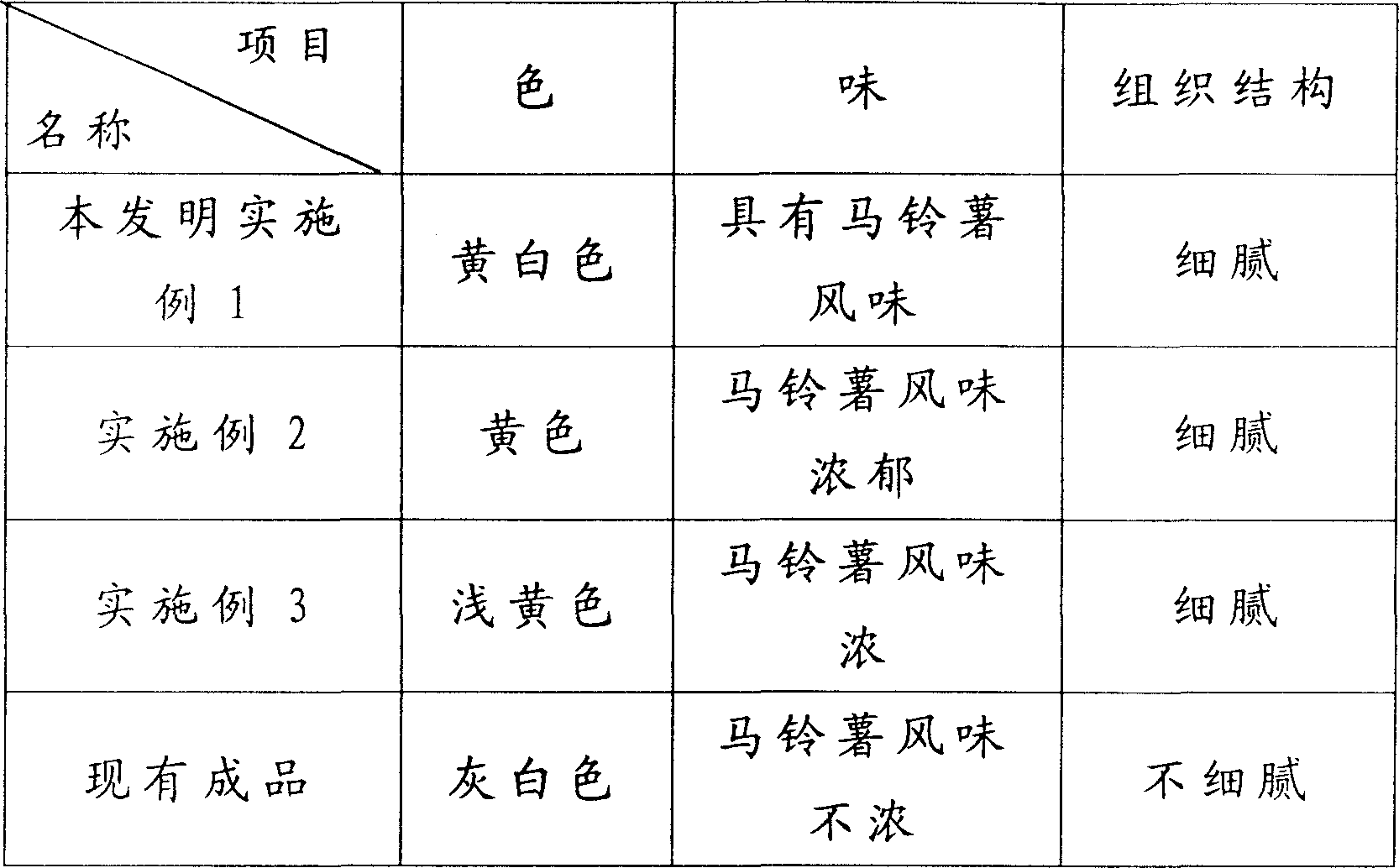

Extruded-puffed potato full-powder food and its processing method

InactiveCN1891071APrevent polyphenol oxidative browningPrevent discolorationFood preparationCorn mealSugar

The present invention discloses a kind of extrusion-puffed potato powder food and its production method. It is made up by using (by wt%) 30-70% of potato powder, 0-30% of rice flour, 0-15% of corn meal, 0-15% of starch, 1-8% of white granulated sugar, 0-2% of full-fat milk powder, 1-4% of dietary fibre. 0.2-0.4% of calcium carbonate, 0.1-0.3% of soya lecithin and proper quantity of water through the processes of mixing them, extrusion-puffing, cutting, roasting to obtain blank material, spraying cream and flavouring powder so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

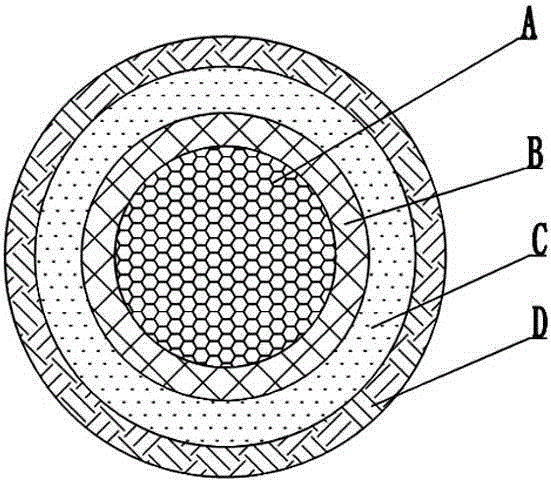

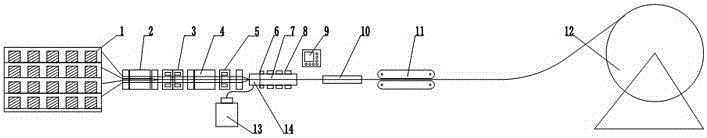

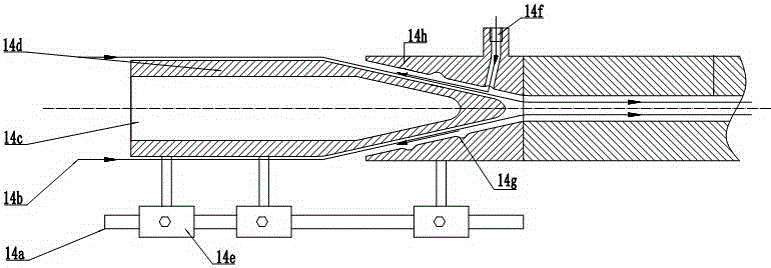

High-temperature-resisting carbon fiber reinforced composite continuous sucker rod and preparing device and method

ActiveCN105172169AAccelerated corrosionExcellent wear resistanceDrilling rodsDrilling casingsEpoxyAxial pressure

The invention relates to a high-temperature-resisting carbon fiber reinforced composite continuous sucker rod and a preparing device and method. According to the technical scheme, reinforced fiber carbon fiber (A) and fiber winding reinforced layer aramid fiber 1414 fiber (B) in the axial direction of a rod body are sequentially arranged from interior to exterior; and reinforced fiber high-strength glass fiber (C) and fiber weaving reinforced layer aramid fiber 1414 fiber (D) are arranged in the axial direction of the rod body, polyfunctional group epoxy resin is injected into the exterior of the outermost fiber weaving reinforced layer aramid fiber 1414 fiber (D), and four layers of structures are solidified and formed at the same time, wherein the Tg value reaches more than 210 DEG C, and the continuous length of the manufactured rod body ranges from 300 m to 5,000m. The sucker rod has the beneficial effects that the sucker rod is endowed with superior temperature resistance, eccentric wear resistance and radial and axial pressure resistance and small winding diameter, the production efficiency of products formed at a time is high, operation is easy and convenient, and performance is stable.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Purification of carbon filaments and their use in storing hydrogen

InactiveUS6869583B2High yieldReduce the amount requiredMaterial nanotechnologyReversible hydrogen uptakeRefluxHydrogen

Carbon structures, e.g. carbon nano-fibers, suitable for absorbing hydrogen at low pressures and low temperatures are produced by a selective oxidation and / or acid reflux process. The process includes heating an impure mixture containing a crystalline form of carbon in the presence of an oxidizing gas at a temperature and time sufficient to selectively oxidize and remove a substantial amount of any amorphous carbon impurities from the mixture. Metal containing impurities can be removed from the mixture by exposing the desired carbon and accompanying impurities to an acid to produce a carbon fiber that is substantially free of both non-fiber carbon impurities and metal impurities. Another aspect of the present invention includes purified carbon structures that can store hydrogen at low pressures and temperatures.

Owner:PENN STATE RES FOUND

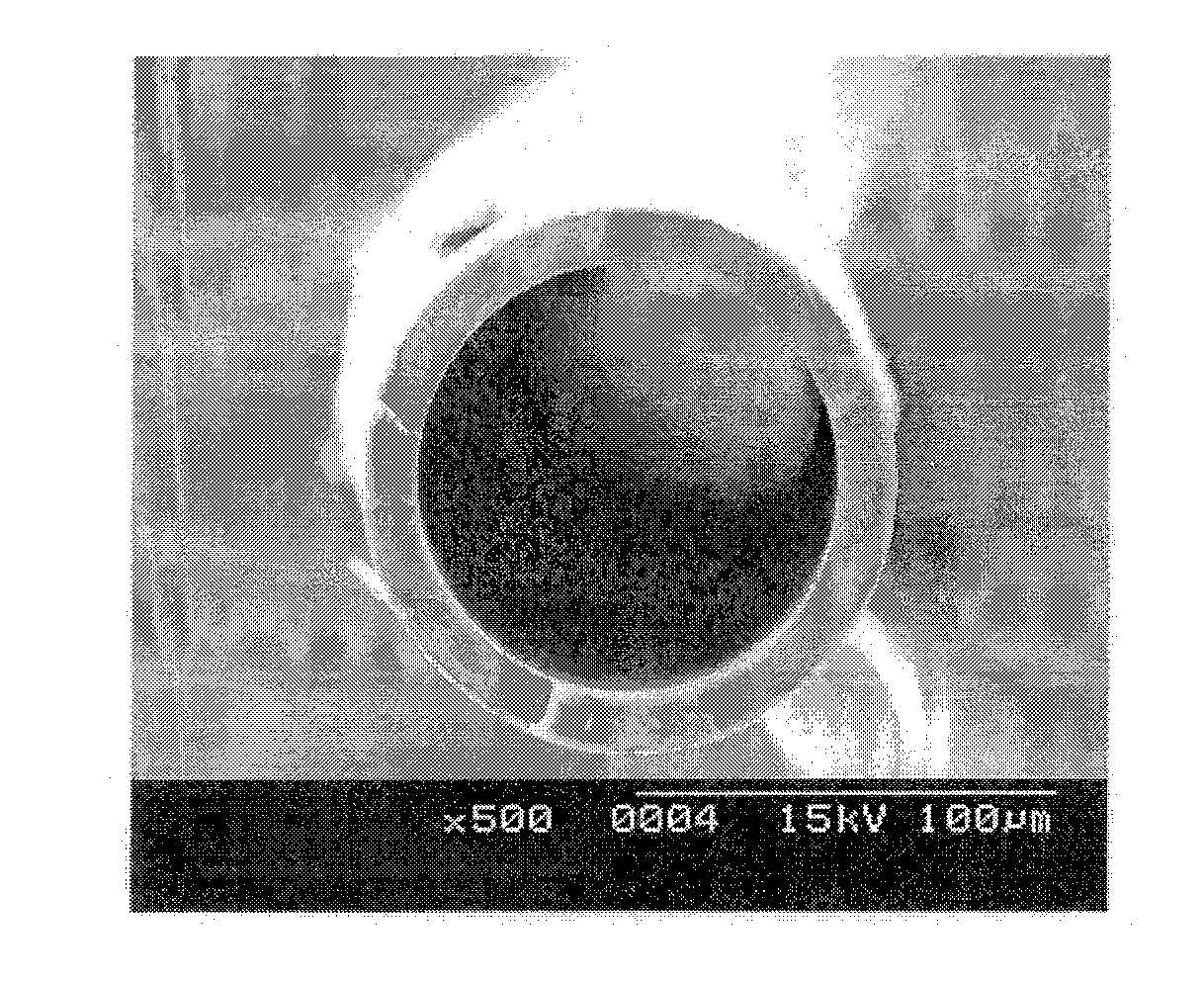

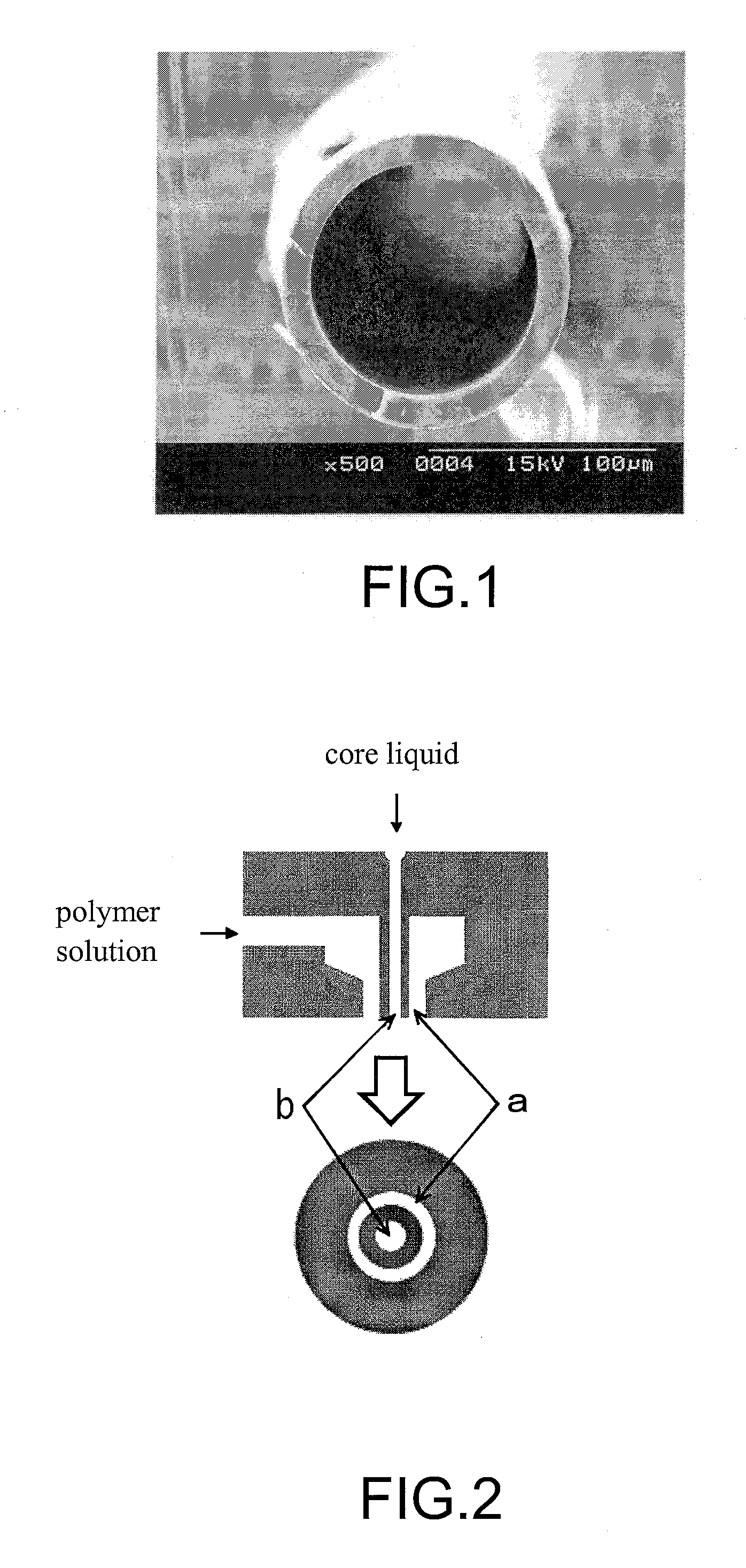

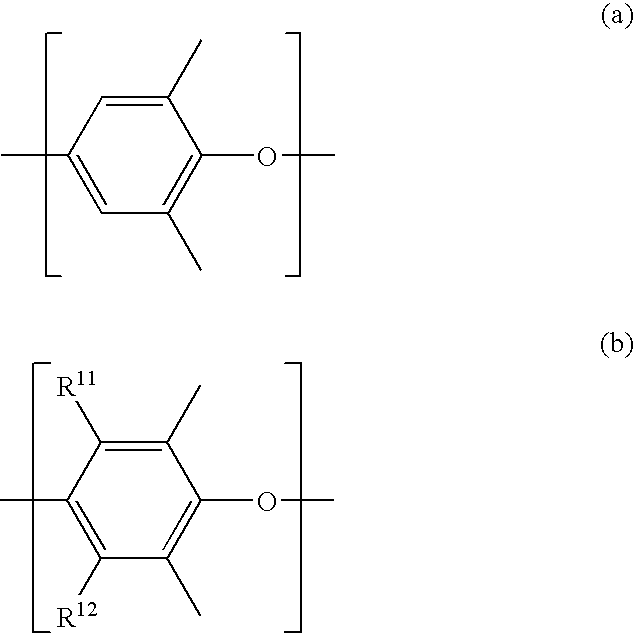

Hollow fiber carbon membrane and method for production thereof

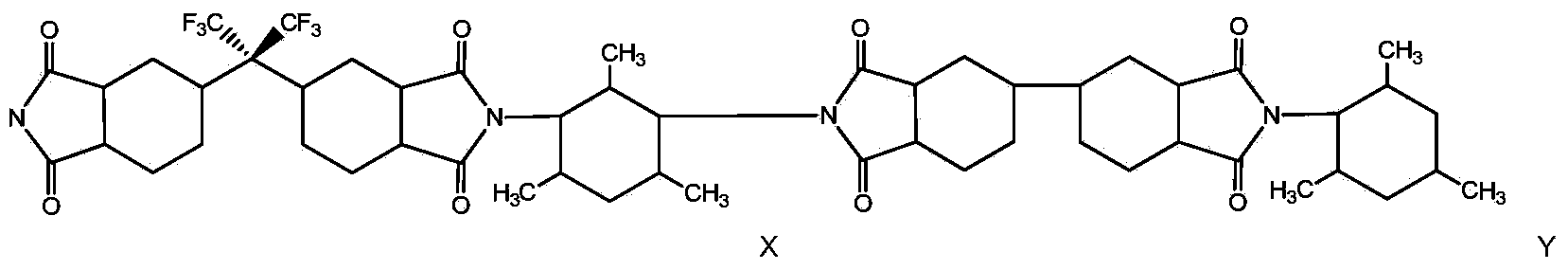

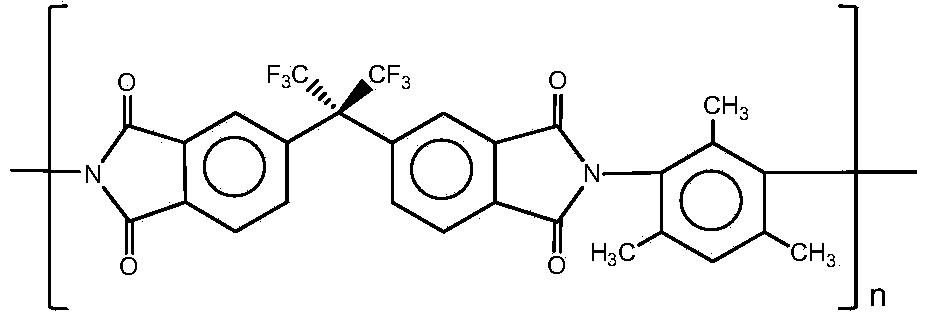

ActiveUS20100212503A1Improve gas permeabilityImprove gas separation performanceSemi-permeable membranesMembranesCarbon filmStructural formula

A hollow fiber carbon membrane is provided, which has excellent gas separation performance, unbreakable flexibility and high utility. The hollow fiber carbon membrane comprises carbonized substance obtained by calcination of a hollow fiber-like material formed from a polyphenylene oxide derivative, and has an external diameter in the range of 0.08 mm to 0.25 mm. The polyphenylene oxide derivative substantially comprises repeating units represented by the following (a) and (b) (in the structural formula, R11 and R12 independently represent hydrogen atom or sulfone group, except that R11 and R12 are both hydrogen atoms), wherein the ratio A (%) of the repeating unit (b) to the repeating units (a)+(b) satisfies 15%<A<60%.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Automobile brake lining and fabrication method thereof

InactiveCN103148139AHigh friction coefficientImprove impact strengthDomestic articlesFriction liningBrake liningAdhesive

The invention provides an automobile brake lining which comprises a friction part and a connecting part, wherein the friction part comprises the following components by mass percentage: 10-20% of adhesive, 25-35% of composite fiber, 2-10% of carbon fiber, 5-10% of glass fiber, 2-10% of aramid fiber, 5-15% of friction increasing agent, 2-15% of friction reducing agent, 20-25% of filler, 1-2% of releasing agent, and 0-5% of colorant. The connecting part comprises the following components by mass percentage: 10-20% of adhesive, 30-40% of composite fiber, 0-15% of mineral fiber, 0-15% of friction increasing agent, 0-15% of friction reducing agent, 30-45% of filler, 1-2% of releasing agent, and 0-5% of colorant. With the adoption of the automobile brake lining, the connection between the brake lining and a brake assembly is firmer and more reliable, the material cost of the connecting part is lowered greatly, and great resource waste caused by replacement of the brake lining is reduced effectively.

Owner:SHANDONG LIANGSHAN SHENLI AUTO PARTS

Carbon fiber and catalyst for manufacture of carbon fiber

InactiveUS20080176070A1Low amountResidue reductionMaterial nanotechnologyEnvelopes/bags making machineryMetallurgyLanthanide

Carbon fibers containing at least one element (I) selected from the group consisting of Fe, Co and Ni, at least one element (II) selected from the group consisting of Sc, Ti, V, Cr, Mn, Cu, Y, Zr, Nb, Tc, Ru, Rh, Pd, Ag, a lanthanide, Hf, Ta, Re, Os, Ir, Pt and Au, and at least one element (III) selected from the group of W and Mo, wherein the element (II) and the element (III) each is 1 to 100 mol % relative to the mols of element (I).

Owner:SHOWA DENKO KK

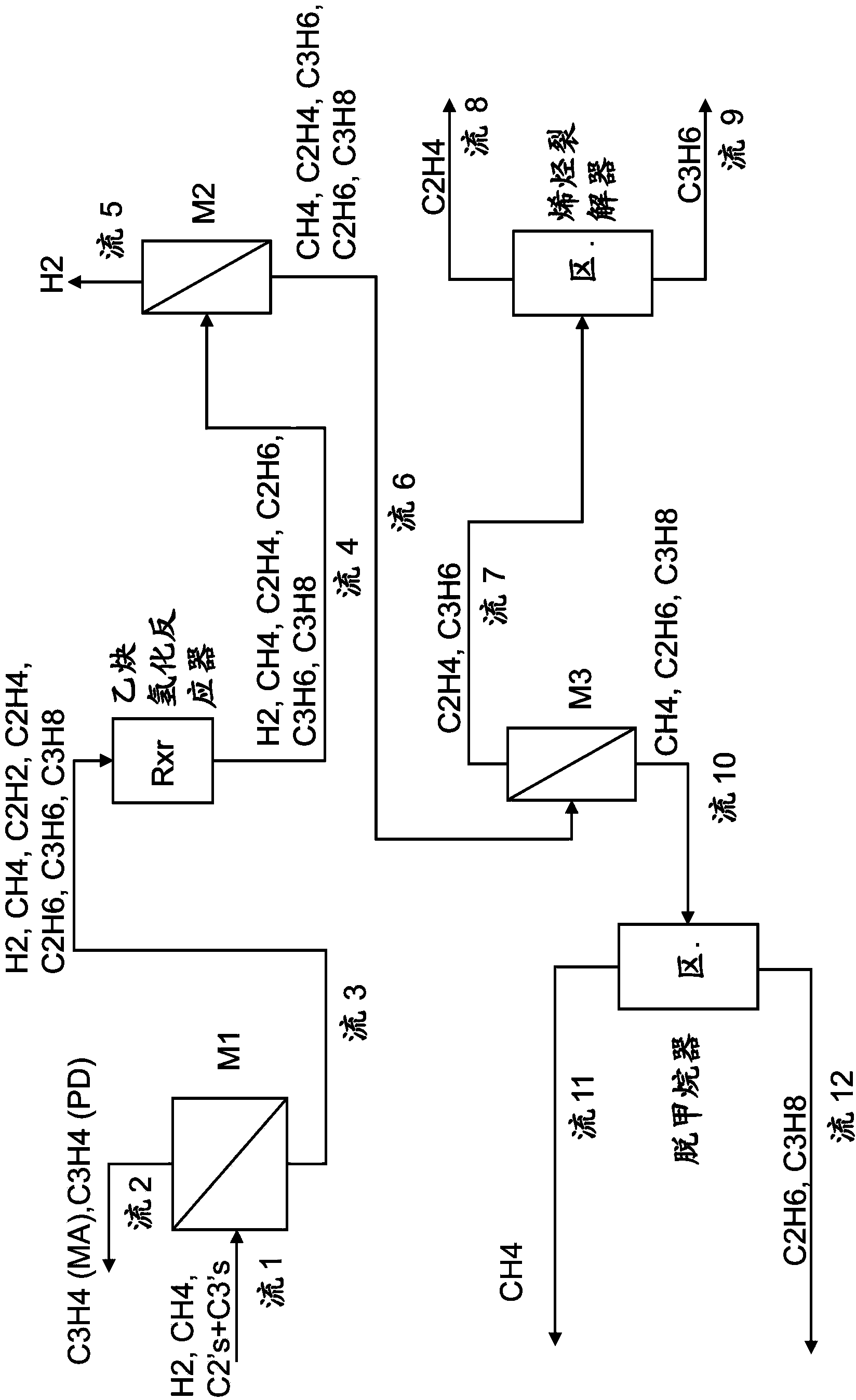

A hollow fiber carbon molecular sieve membrane and preparation and use thereof

A hollow fiber carbon molecular sieve membrane, a process for preparing the hollow fiber carbon molecular sieve membrane, and a process for effecting separation of an olefin from a gaseous mixture that comprises the olefin in admixture with its corresponding paraffin and optionally one or more gaseous components selected from hydrogen, an olefin other than the olefin and a paraffin other than the corresponding paraffin. The process and membrane may also be used to effect separation of the olefin(s) from remaining feedstream components subsequent to an olefin-paraffin separation.

Owner:DOW GLOBAL TECH LLC +1

Process for the preparation of carbon fiber-carbon nanotubes reinforced hybrid polymer composites for high strength structural applications

ActiveUS20180112046A1Light weightIncrease loadMaterial nanotechnologyCarbon fibresPolymer scienceMultiwalled carbon

The present invention relates to the development of carbon fiber carbon nanotubes reinforced polymer composites for high strength structural applications. It is very difficult to incorporate higher amount of carbon fiber >60 vol % in any of the polymer matrix. Beyond this loading the mechanical properties of these composite starts deteriorate. Therefore, further improvement in the mechanical properties is not possible. Herein, a novel method is developed to fabricate the hybrid carbon fiber epoxy composites reinforced with multiwalled carbon nanotubes. The flexural strength of the hybrid composites (˜45 vol % CF+CNT) was achieved more than 600 MPa which is more than 35% over pure carbon fiber / epoxy composites (˜50 vol % CF). These high strength hybrid composites can be used in wind mill blades, turbine blades, sport industries, automobile and airframe.

Owner:COUNCIL OF SCI & IND RES

Offshore oil drilling platform rig disc brake pad and preparation method thereof

The invention relates to an offshore oil drilling platform rig disc brake pad and a preparation method thereof, and aims to provide a brake pad which has the characteristics of large braking torque and high shearing strength, as well as the preparation method which has the characteristics of simple process, convenience in manufacturing and lower cost. The adopted technical scheme is that the offshore oil drilling platform rig disc brake pad comprises a metal skeleton and a friction material layer, and is characterized in that the friction material layer is prepared from the following raw materials: boric acid-tung oil dual-modified phenolic resin, aramid pulp fiber, carbon fiber, sisal fiber, precipitated barium sulfate, sodium fluoride, antimony sulfide, aluminum hydroxide, diatomaceous earth, polytetrafluoroethylene suspension resin, zinc stearate, cashew nut shell oil friction powder, artificial graphite, foam powdered iron, yellow pyrites powder, hydrogenated nitrile-butadiene rubber and butyronitrile emulsion. The preparation method of the offshore oil drilling platform rig disc brake pad comprises the following steps: 1), weighing the raw materials; 2), mixing and taking out a mixture; 3), mould pressing for molding; 4), thermal curing; 5), processing to obtain the disc brake pad.

Owner:杭州克尔菲利科技有限公司

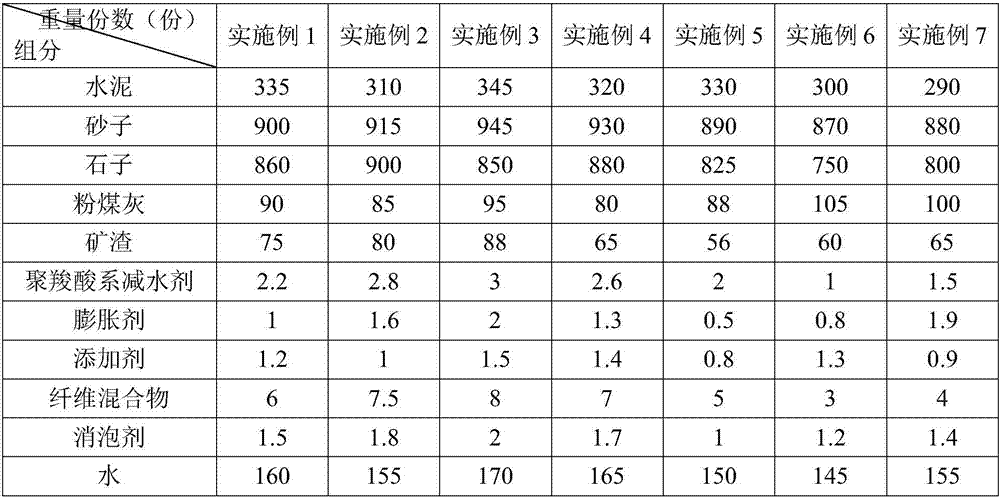

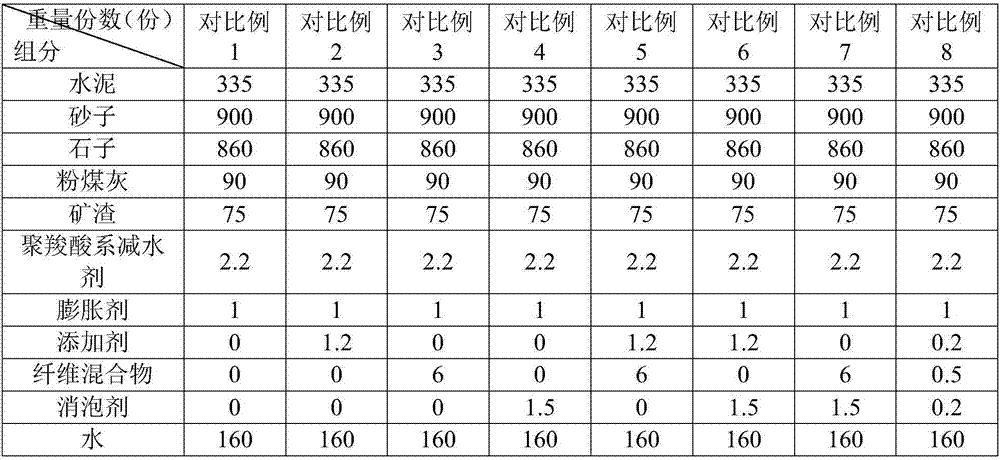

Concrete and preparation technology thereof

The invention discloses concrete and a preparation technology thereof. The concrete comprises, by weight, 290-345 parts of cement, 870-945 parts of sand, 750-900 parts of stones, 80-105 parts of fly ash, 56-88 parts of slag, 1-3 parts of polycarboxylate-type water reducing agent, 0.5-2 parts of expanding agent, 0.8-1.5 parts of addictive, 3-8 parts of fiber mixtures, 1-2 parts of defoaming agent and 145-170 parts of water. The cement is P.O 42.5 cement, the additive comprises MCC, xanthan gum and polyvinylpyrrolidone, the fiber mixtures comprise at least two kinds of glass fiber, steel fiber and carbon fiber, and the defoaming agent comprises at least one kind of polysiloxane and polyether modified polysiloxane. The concrete and the preparation technology have the advantages that the air content is lowered, and the impervious performance and the crack resistance of the solidified concrete are improved.

Owner:深圳市圣威宝混凝土有限公司

Continuous fiber carbon fork

A continuous fiber reinforced plastic bicycle fork has continuous fibers extending from the tip of the fork blades to the steer tube, formed through optimum compaction, low void molding resulting in precise forming of the fork shell such that a metal steer tube, metal bearing races, metal dropouts and metal brake mount are used to attach metal components such as a headset and star-fangled nut, handlebar stem, wheel and brake thereby eliminating metal component to carbon fiber contact to preserve the integrity of the fiber reinforcements and plastic matrix.

Owner:TREK BICYCLE CORPORATION

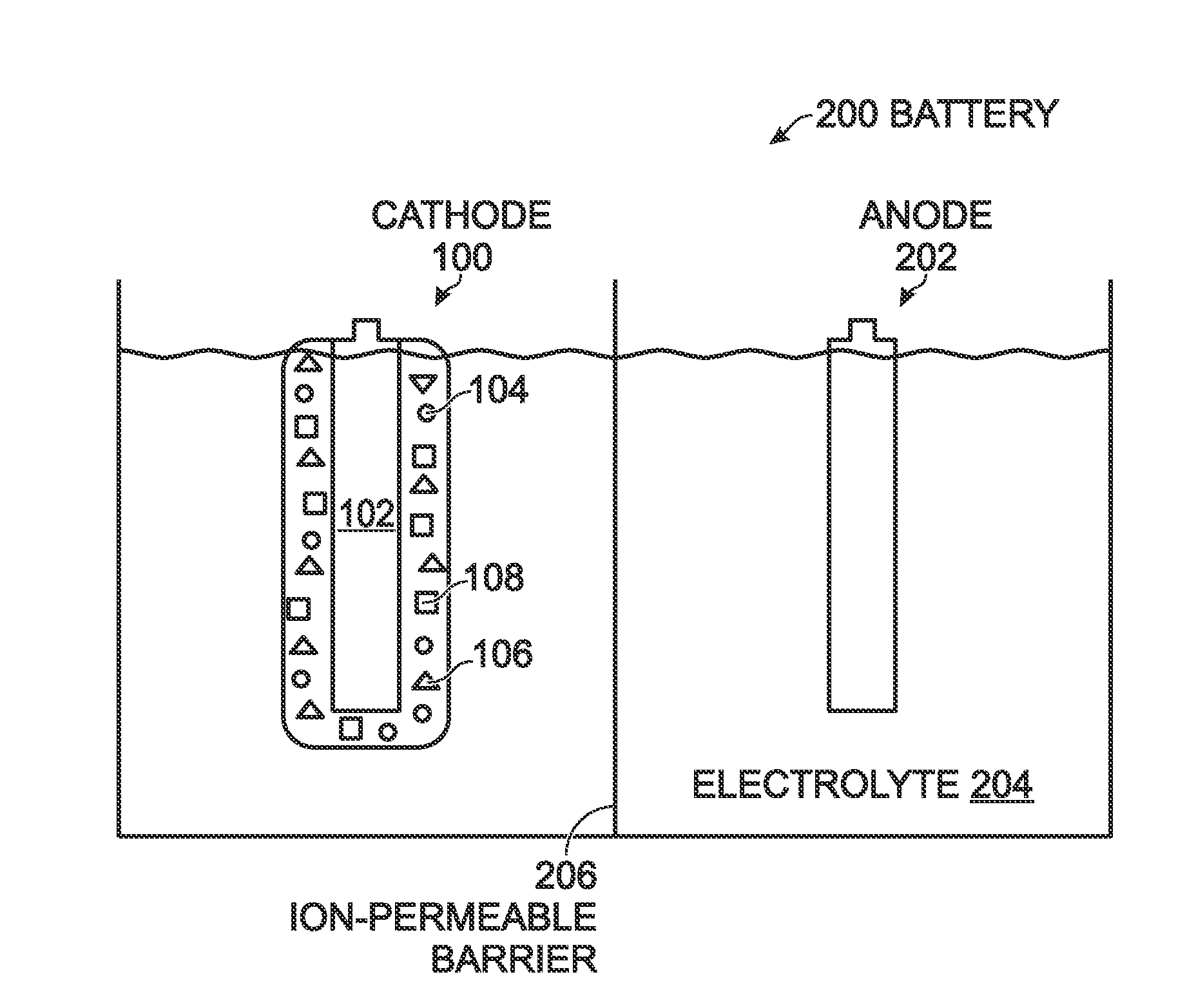

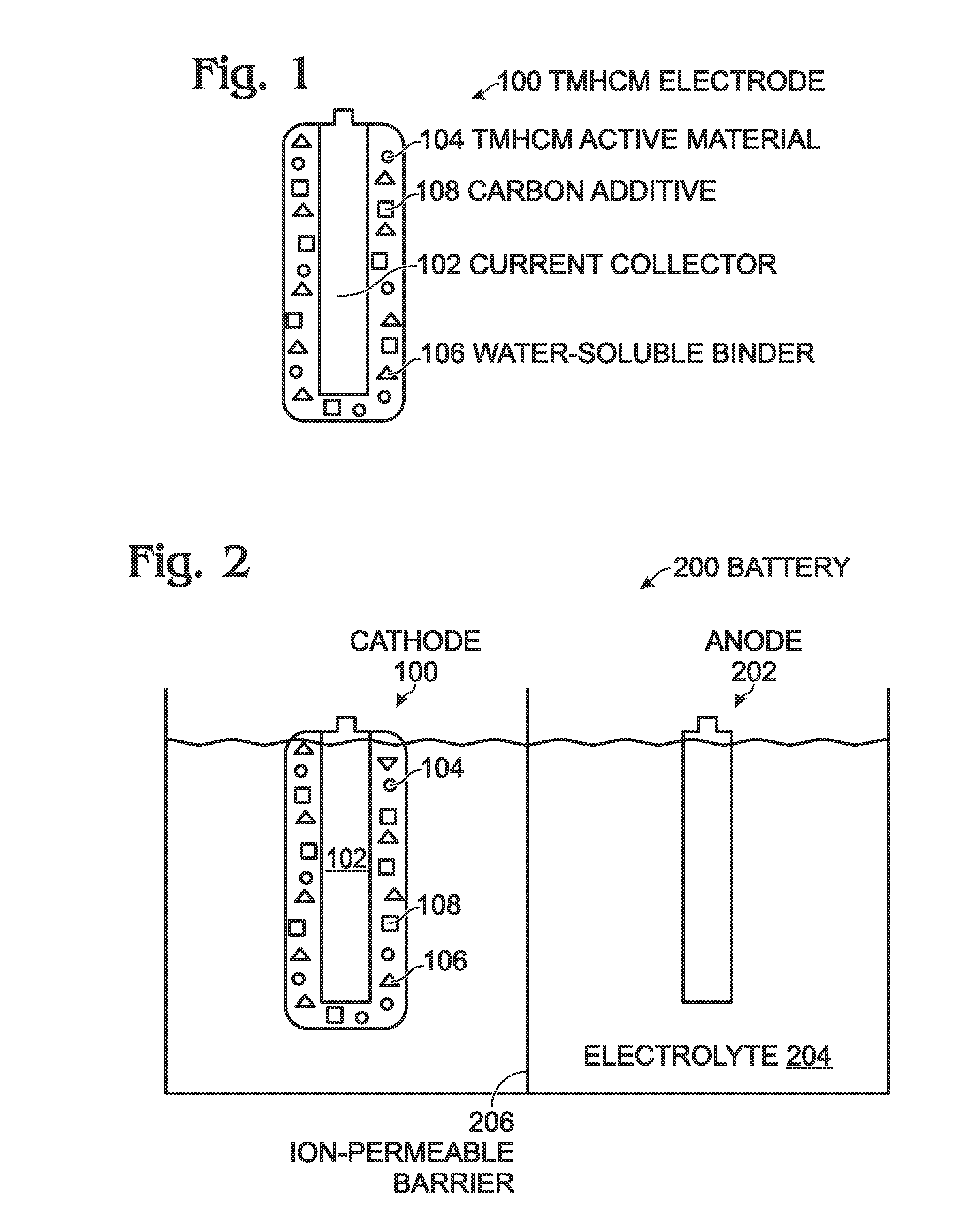

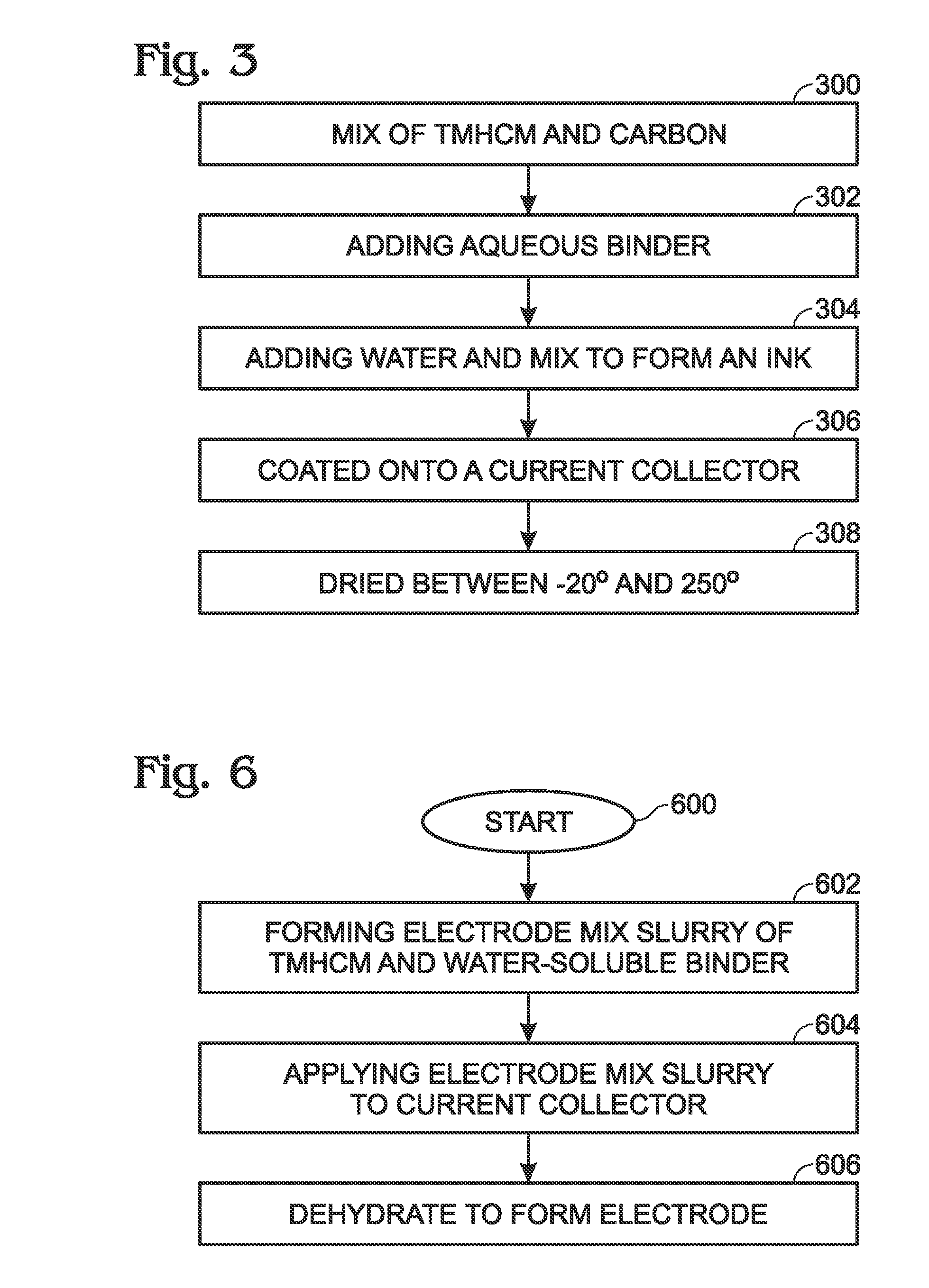

Transition Metal Hexacyanometallate Electrode with Water-soluble Binder

ActiveUS20140335409A1Final product manufactureElectrode collector coatingElectrical batteryCarbon nanotube

A method is provided for fabricating a transition metal hexacyanometallate (TMHCM) electrode with a water-soluble binder. The method initially forms an electrode mix slurry comprising TMHCF and a water-soluble binder. The electrode mix slurry is applied to a current collector, and then dehydrated to form an electrode. The electrode mix slurry may additionally comprise a carbon additive such as carbon black, carbon fiber, carbon nanotubes, graphite, or graphene. The electrode is typically formed with TMHCM greater than 50%, by weight, as compared to a combined weight of the TMHCM, carbon additive, and binder. Also provided are a TMHCM electrode made with a water-soluble binder and a battery having a TMHCM cathode that is made with a water-soluble binder.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com