Concrete and preparation technology thereof

A concrete and mixture technology, applied in the field of concrete and its preparation technology, can solve the problems of large shrinkage and deformation of concrete, cracking of concrete, high heat of hydration of concrete, etc., and achieve the effect of increasing connection effect, improving compressive strength, and improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: A kind of concrete, the component that comprises and corresponding weight parts thereof are as shown in Table 1, and obtain through following steps preparation:

[0084] S1, fully mix P.O42.5 cement, sand, gravel, secondary fly ash, slag, polycarboxylate water reducing agent, and expansion agent to form the first mixture;

[0085] S2, adding the additive into the water, and fully mixing to form a second mixture;

[0086] S3, adding a fiber mixture and an antifoaming agent to the second mixture obtained in step S2, and fully mixing to form a third mixture;

[0087] S4, adding the third mixture obtained in step S3 to the first mixture obtained in step S1, and mixing thoroughly to obtain.

[0088] Wherein, the stones include fine stones and coarse stones, the ratio of the parts by weight of fine stones and coarse stones is 0.4-0.5:1, the single particle size of fine stones is 5-10mm, and the single particle size of coarse stones is 16-31.5mm ;

[0089] The...

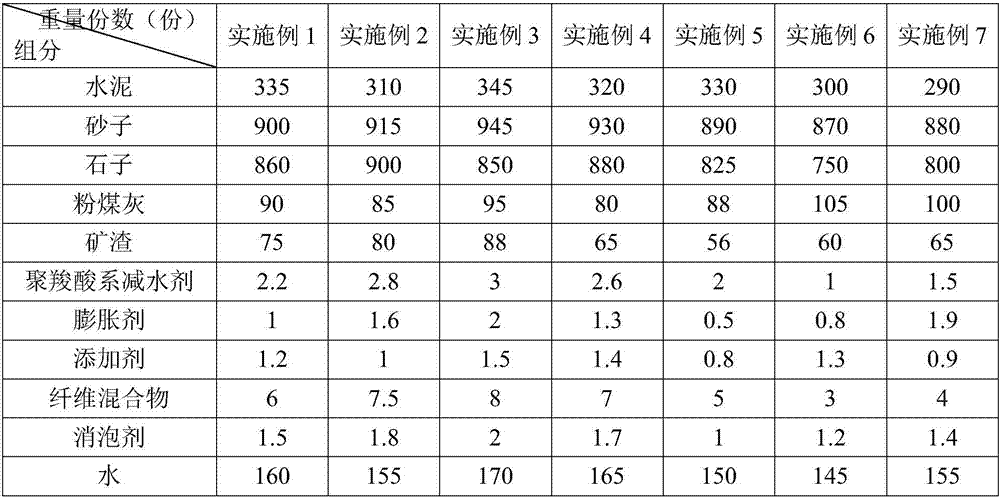

Embodiment 2-7

[0094] Embodiment 2-7: a kind of concrete, the difference from embodiment 1 is that the components and their corresponding parts by weight are shown in Table 1.

[0095] Components and corresponding parts by weight thereof included in Table 1 embodiment 1-7

[0096]

Embodiment 8

[0097] Embodiment 8: A kind of concrete. The difference from Embodiment 1 is that in the additive, the ratio of parts by weight of MCC, xanthan gum and polyvinylpyrrolidone is 1:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com