Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

485 results about "Boron fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron Fiber (also commonly called "boron filament") is an amorphous elemental boron product which represents the major industrial use of elemental (free) boron. Boron fiber manifests a combination of high strength and high elastic modulus.

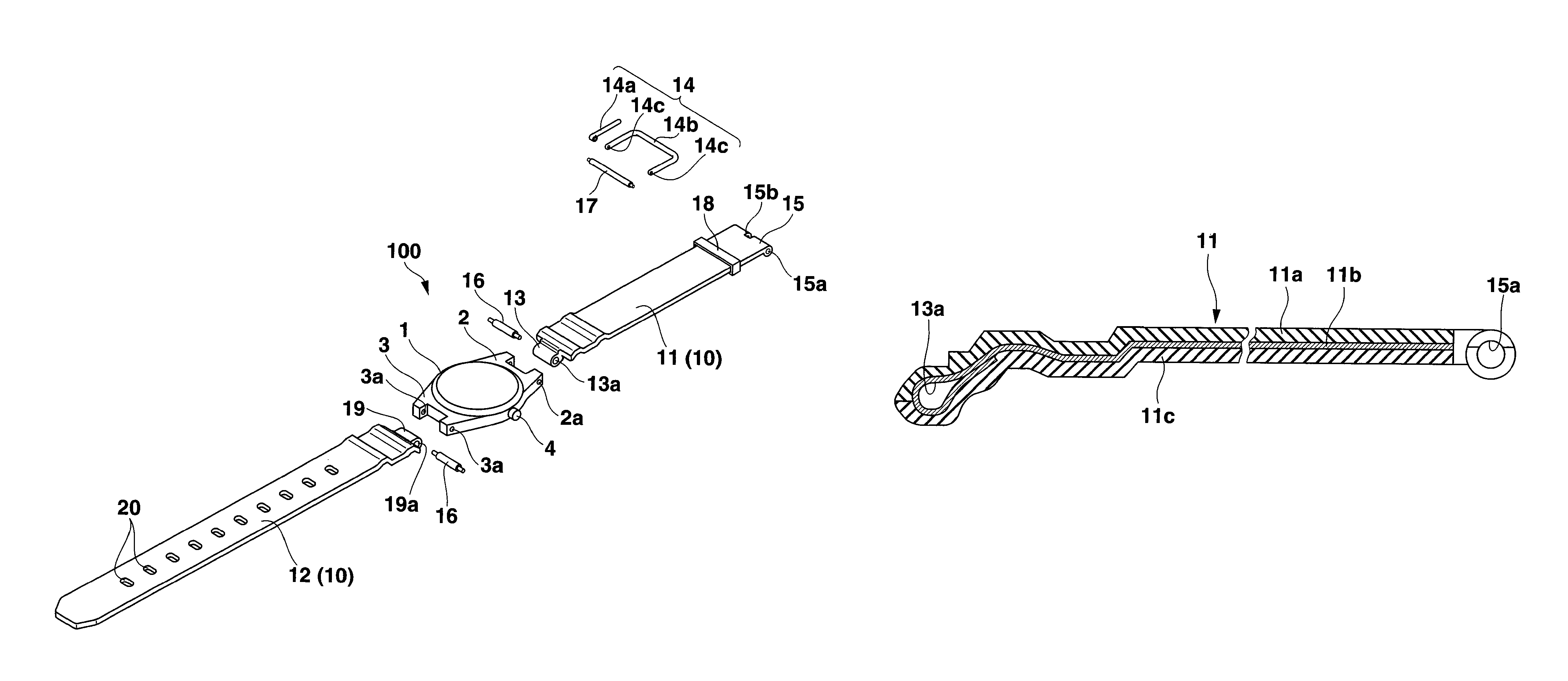

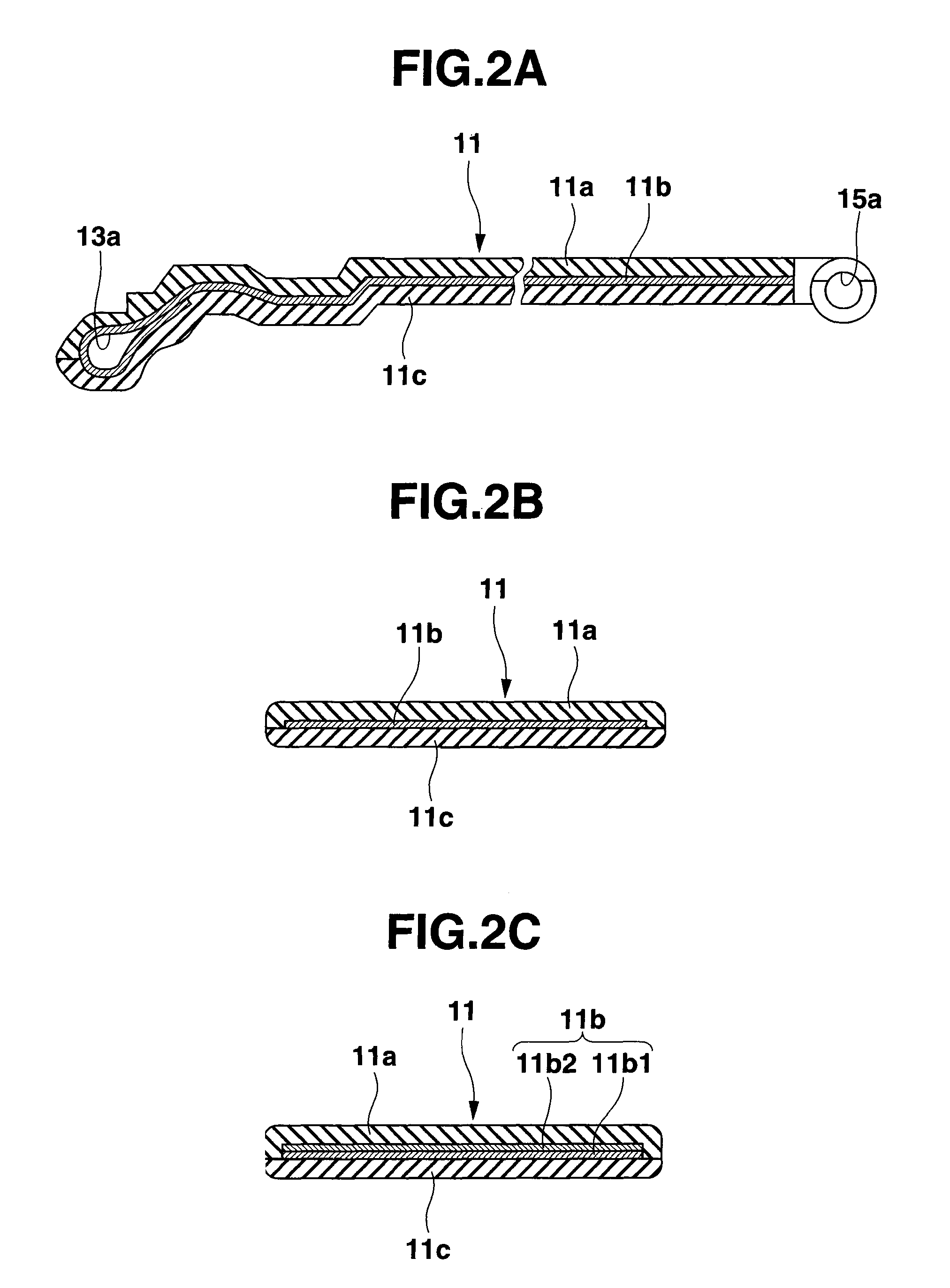

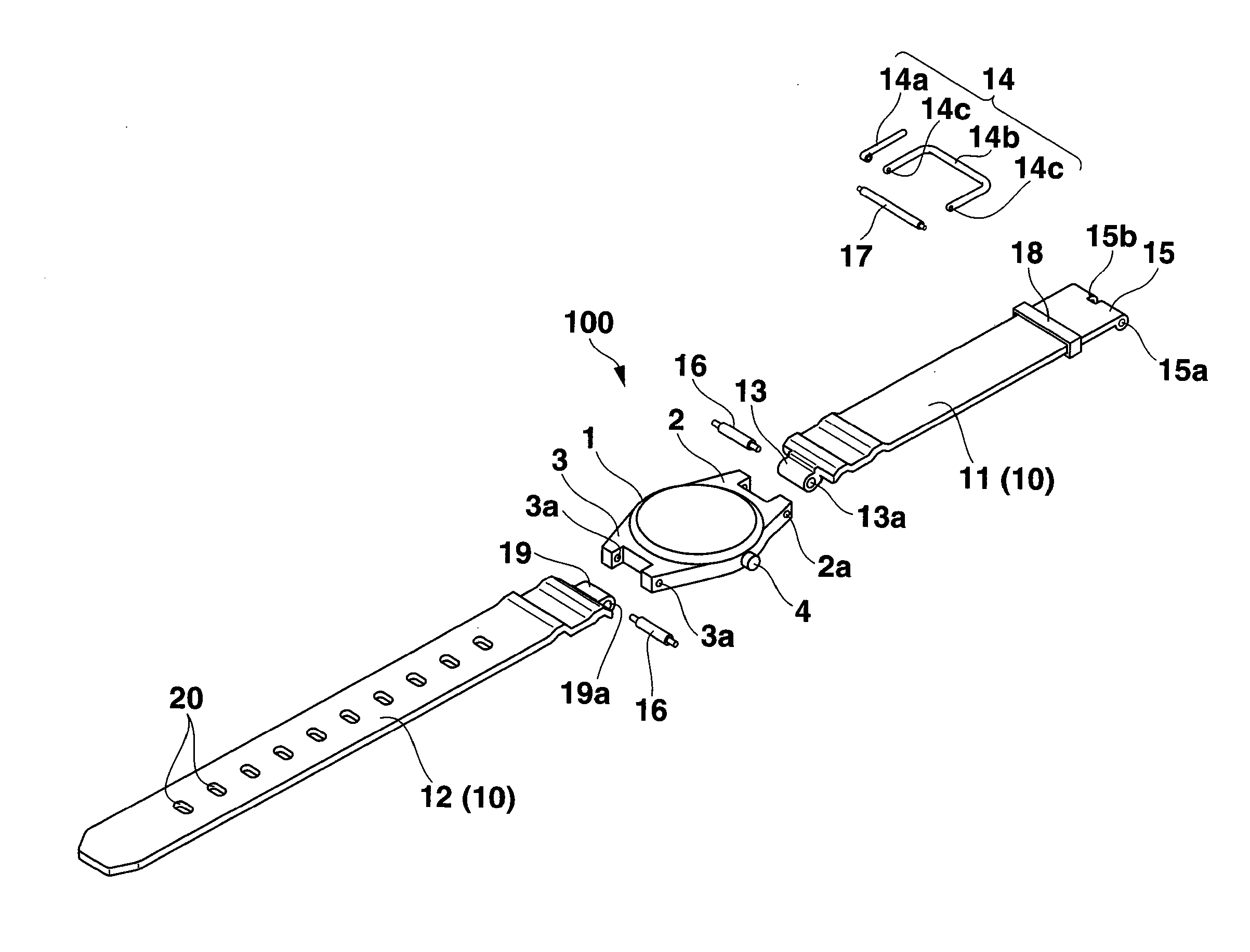

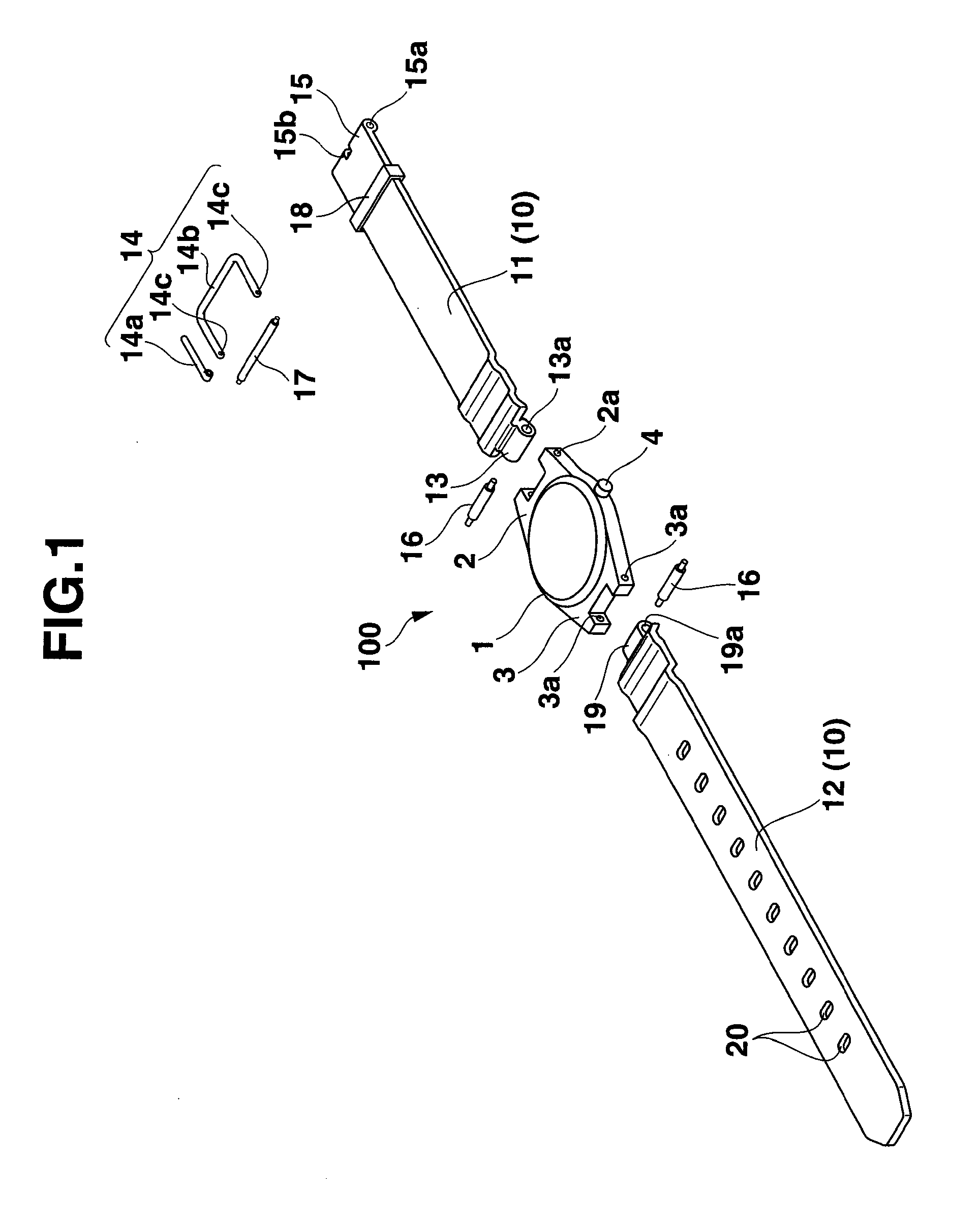

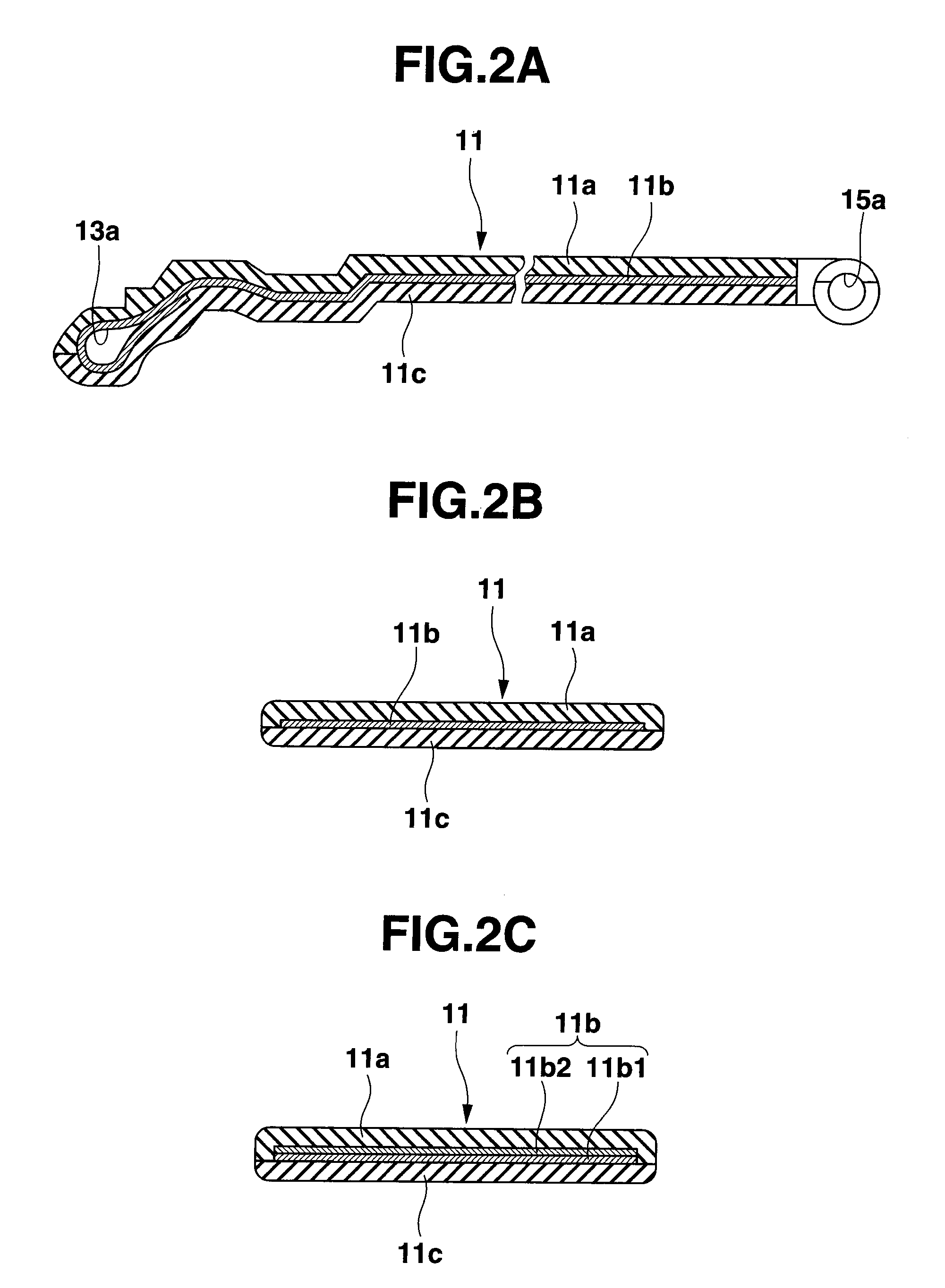

Band, wristwatch with the band and method of making the band

ActiveUS8613544B2High strengthEasy to liftSynthetic resin layered productsBraceletsPolymer scienceFiber bundle

A band, a wristwatch with the band and a method of making the band are described. The band includes a strip-like body with a series of holes provided therein along a length thereof for adjusting an effective length thereof. The body includes a band-shaped support layer of woven or knit fabric of bundles of one or more kinds of fibers, the fibers being selected from a group including carbon fibers, glass fibers, aramid fibers and boron fibers. The body also includes a first resin layer adhering closely to one surface of the support layer, and a second resin layer adhering closely to the other surface of the support layer. The fibers of the support layer extend at a predetermined angle to longitudinal and transverse directions of the body.

Owner:CASIO COMPUTER CO LTD

Composite core for power grid transmission line wire and preparation method thereof

The invention provides a composite core for a power grid transmission line wire and a preparation method thereof. The composite core has high strength, high toughness, high glass-transition temperature and surface cleanness. Materials of the composite core comprise a resin material and a strengthening material. The resin material comprises a thermosetting resin, a curing agent, an accelerating agent, a releasing agent, a flexibilizer and nanometer particles. The strengthening material is one kind or a plurality of kinds of carbon fiber, glass fiber, basalt fiber, boron fiber, aramid fiber, silicon carbonate fiber and protein bound iodine (PBI) fiber. The content of composite core fiber Vf=50-80%, tensile strength of the composite core is not lower than 2100MPa, and glass transition temperature of the composite core is not lower than 180 DEG C. The toughness of the composite core is remarkably improved, and breakage and cracking probability caused by brittleness factors in production, transportation and wire hanging construction processes are reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

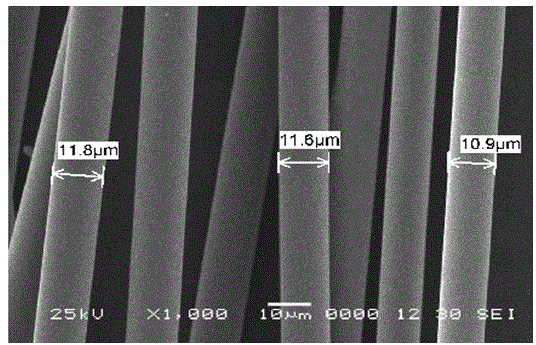

Preparation method of silicon-nitrogen-boron continuous ceramic fibers

ActiveCN103952796ALow equipment requirementsSimple process controlInorganic material artificial filamentsArtificial filament chemical after-treatmentBoron fiberSilicon nitride

The invention relates to a preparation method of silicon-nitrogen-boron continuous ceramic fibers. The method comprises the following steps: (1) nitriding and removing carbon; (2) carrying out boronizing; and (3) firing at high temperature to obtain the silicon-nitrogen-boron continuous ceramic fibers. According to the preparation method, boron is added in silicon nitride fibers to prepare silicon-nitrogen-boron fibers, compared with existing silicon-nitrogen-boron fibers, the preparation method provided by the invention adopts a simple process and is low in manufacturing cost. The preparation method can be implemented by production equipment of silicon nitride fibers and is easy to industrialize.

Owner:NAT UNIV OF DEFENSE TECH

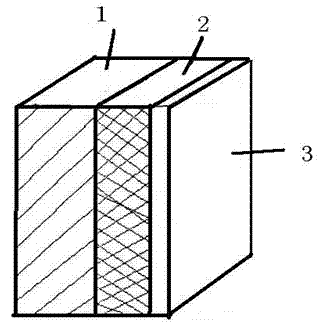

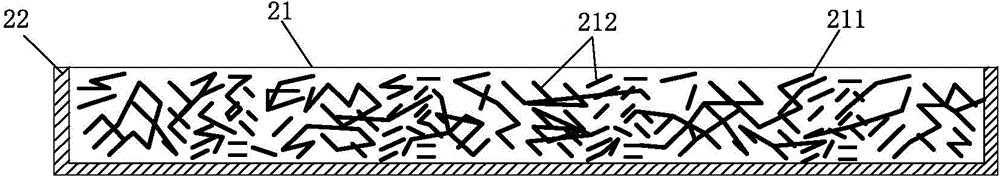

Laminated neutron radiation shielding composite material and preparation method thereof

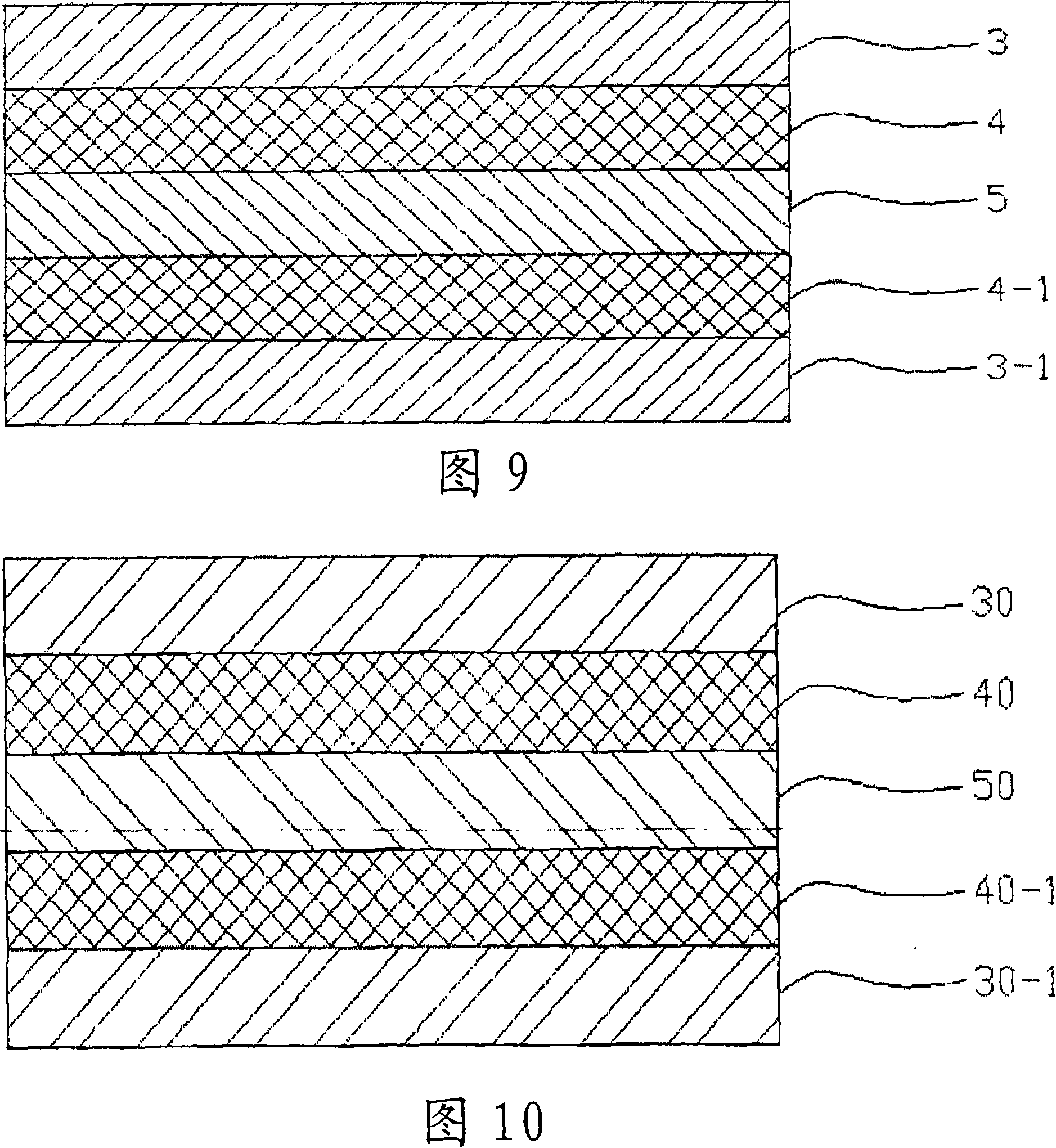

InactiveCN102529239AFull functionHigh shielding efficiencySynthetic resin layered productsLaminationResin matrixBoron fiber

The invention discloses a laminated neutron radiation shielding composite material and a preparation method thereof; the laminated neutron radiation shielding composite material is in a three-layer composite structure, wherein a bottom layer is a polyethylene fiber reinforced epoxy resin matrix, a middle layer is a boron fiber reinforced epoxy resin matrix, and an upper layer is a polyethylene fiber reinforced epoxy resin matrix which is grafted with acrylic lead. The epoxy resin matrixes comprise materials basically in the following weight portions: 100 portions of bisphenol A epoxy resin, 8 portions to 15 portions of imidazole curing agent and 3 portions to 7 portions of silane coupling agent. In addition, boron carbide (B4C) which occupies 5 weight percent to 20 weight percent of the total weight of the epoxy resin is added into the epoxy resin matrix on the bottom layer; and lead oxide which occupies 10 weight percent to 30 weight percent of the total weight of the epoxy resin is added into the epoxy resin matrix on the upper layer. The laminated neutron radiation shielding composite material is specially manufactured to overcome the defects of a traditional neutron radiation shielding composite material that slowing and absorption functions are not separated so that the functions of an absorbing body cannot be displayed well.

Owner:南京核安核能科技有限公司

The member for headliner on motor vehicles of multilayer structure

ActiveCN101132953AHeat resistantImprove heat resistancePedestrian/occupant safety arrangementMotor vehicle partThermal insulation

The present invention relates to an automotive headliner, and more particularly to a multilayer automotive headliner, which is manufactured by blending at least one thermoplastic fiber, a sheath-core bicomponent fiber composed of a core component and a sheath component having a melting point and properties different from those of the core component, and at least one functional thermoplastic organic fiber and natural fiber with each other at various blending ratios, and forming the fiber blends into a multilayer structure. The inventive automotive headliner is a thermoplastic organic fiber-reinforced composite material reinforced with functional thermoplastic organic fiber or natural fiber at a suitable ratio and having a two-layer, three-layer or five-layer molded structure, and thus has effects of excellent sound absorption, thermal insulation, impact resistance, moldability and durability. Also, it is a multilayer lightweight automotive headliner which is eco-friendly and recyclable because it contains pure thermoplastic organic fiber and natural fiber without using thermosetting adhesives, polyurethane foams and inorganic reinforcing fibers, such as glass fiber, carbon fiber and boron fiber, as used in the prior automotive headliner.

Owner:普莱科斯普可利亚有限会社

Preparation method of boron nitride fiber three-dimensional structure material and product of boron nitride fiber three-dimensional structure material

ActiveCN107793174AHydrophobicHigh strengthPhysical/chemical process catalystsFatty/oily/floating substances removal devicesPollutantFunctional composite

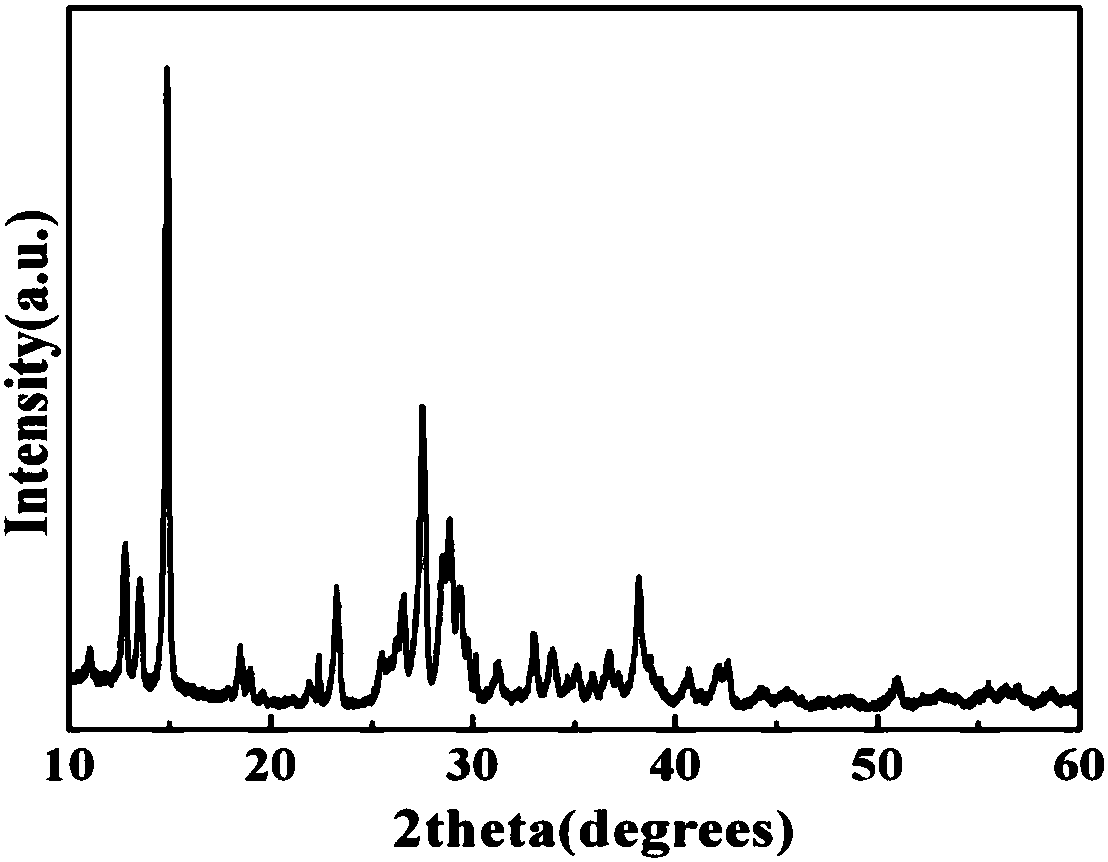

The invention provides a preparation method of a boron nitride fiber three-dimensional structure material and the product of the boron nitride fiber three-dimensional structure material. According tothe preparation method, melamine and boric acid are taken as raw materials, water is taken as a reaction medium, and M.2B (with an English name of Melamine diborate) fibrils can be prepared by means of simple and convenient water bath synthesis; furthermore, the prepared fibrils are taken as a raw material, and a fibril-based three-dimensional net structure is obtained by adopting a freeze-moldingtechnology; the fibril-based three-dimensional net structure is converted into a boron nitride fiber three-dimensional structure by means of the conventional heat treatment process. The technical method provided by the invention is simple and convenient in technology, low in raw material cost and environmentally-friendly; the material provided by the invention has the three-dimensional net structure taking boron nitride fibers as structural units and has the characteristics of being light in weight, high in strength and hydrophobic, thus having wide application prospect in the fields of pollutant treatment, catalyst carriers and enhanced functional composite materials.

Owner:NAT UNIV OF DEFENSE TECH

High-flowability plastic composite powder material and preparation method thereof

The invention discloses a high-flowability plastic composite powder material and a preparation method thereof. The composite powder material comprises a plastic matrix material and a fiber-reinforced component, wherein the plastic matrix material is one or more selected from polypropylene (PP), ABS (Acrylonitrile Butadiene Styrene), polyamide, polyimide, poly(aryl ether ketone), polyether sulfone, polyphenylene sulfide and polytetrafluoroethylene; the fiber-reinforced component is one or more selected from glass fiber, carbon fiber, carbon fiber powder, mineral fiber powder, aramid fiber, ceramic fiber and boron fiber; the additive amount of the fiber-reinforced component is 0.01-30%, and the volume fraction of the fiber-reinforced component is 0-40%. According to the preparation method, firstly, the fiber-reinforced component is subjected to coupling modification, and then, the modified fiber-reinforced component is mixed with a plastic powder matrix to obtain the composite powder material, so that the flowability of the plastic powder is enhanced, the laser energy absorption efficiency of the plastic powder is improved, the powder packing density is also increased, and the mechanical performance and heat stability of a sintered material are enhanced. The high-flowability plastic composite powder material is wide in material source, simple in preparation process and very remarkable in effect.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Polymer epoxy resin composite material and process for fabricating super-light and high-grade fishing rod therefrom

The invention relates to a polymer epoxy resin composite material, comprising the following raw materials by concrete weight ratio: 70-80% of polymeric thermosetting high-strength resin, 15-25% of fibrous reinforcing material and 5-15% of solidifying cross-linking agent, wherein the fibrous reinforcing material comprises glass fiber, boron fiber and carbon fiber; the solidifying cross-linking agent is one or two of fat polyamine, aromatic amine and polyamide. The fishing rod fabricated by adopting the epoxy resin composite material is light in weight, good in mechanical property and smooth and dense in surface.

Owner:ANHUI FOSTER FISHING GEAR

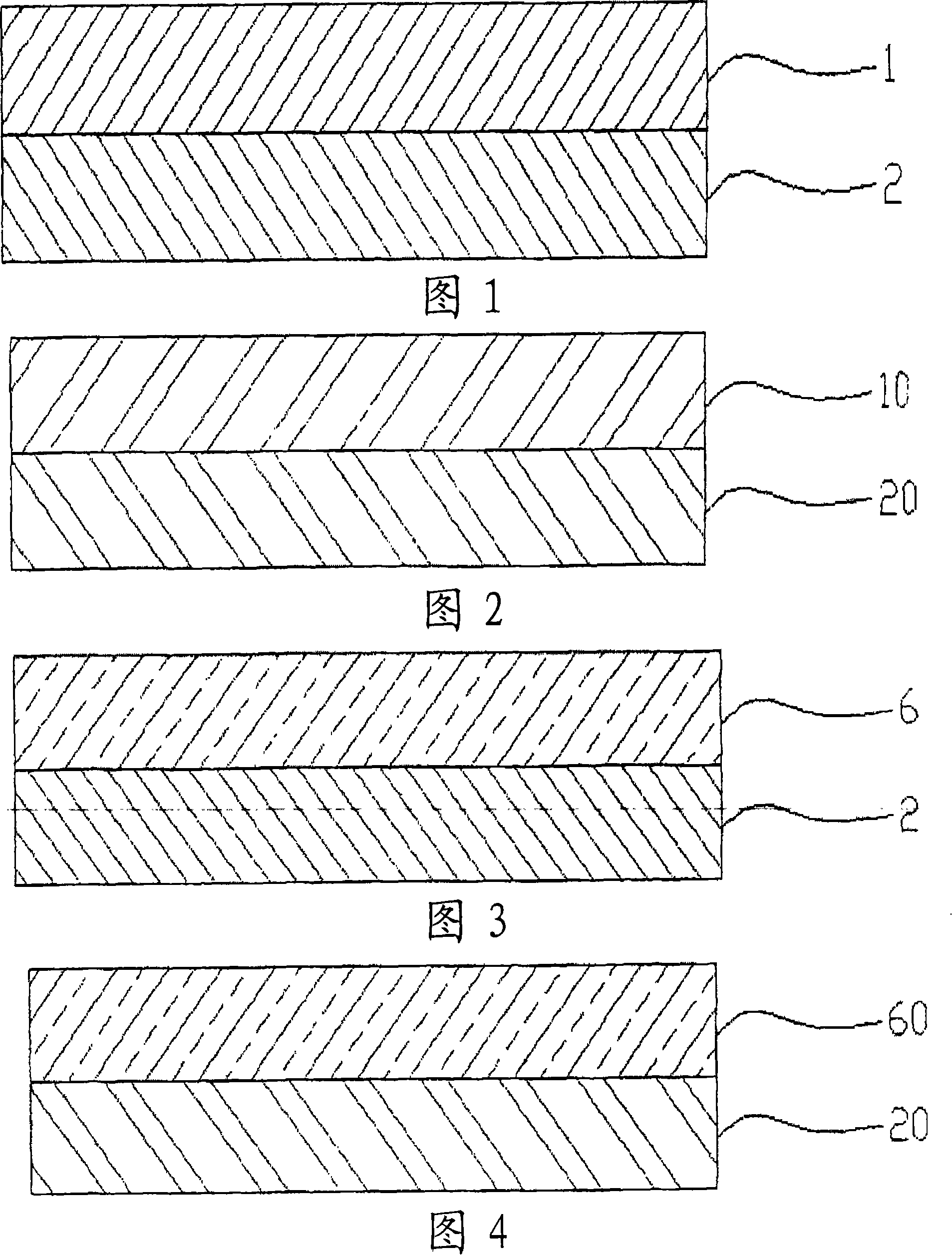

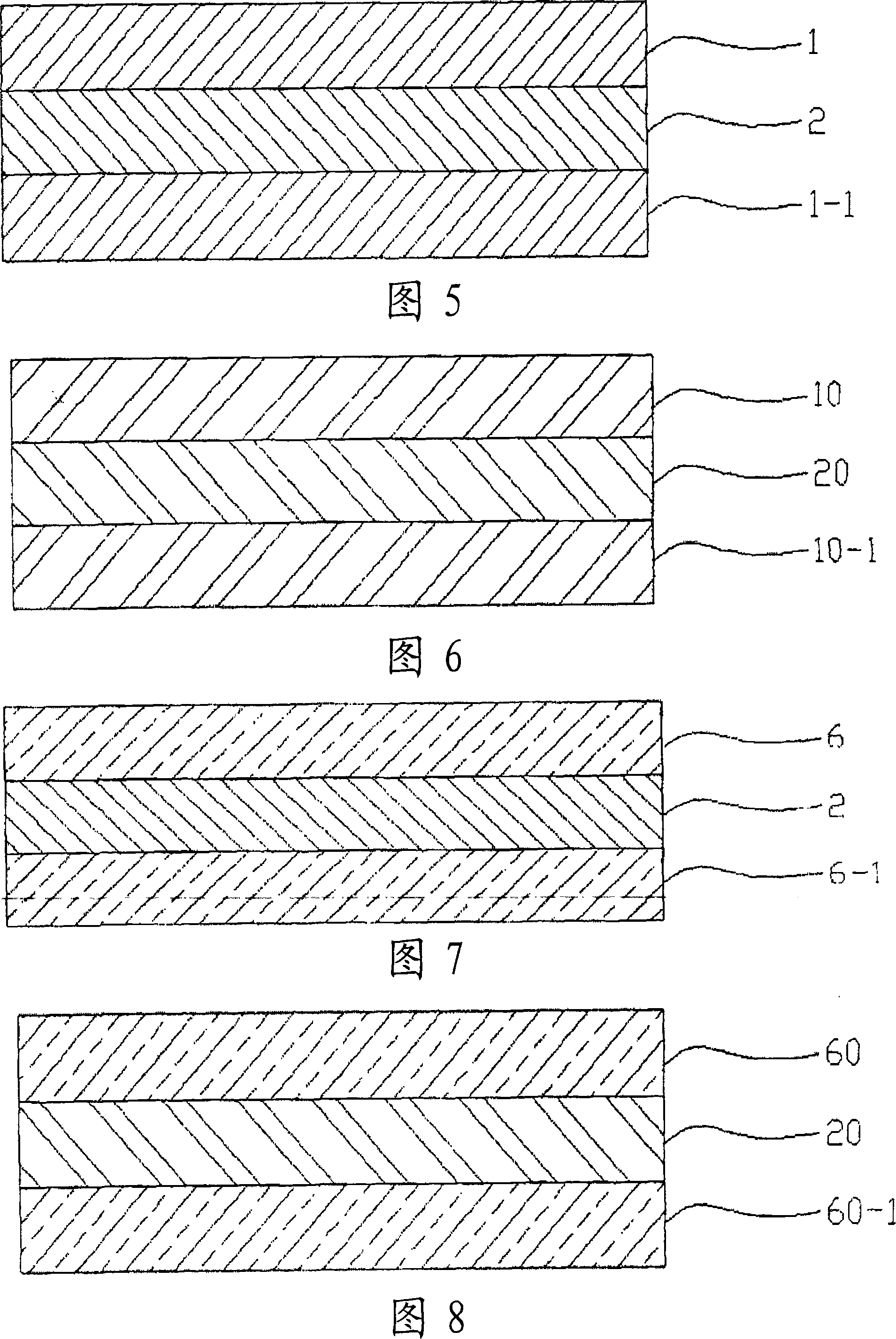

Band, wristwatch with the band and method of making the band

ActiveUS20110051569A1High strengthEasy to liftSynthetic resin layered productsLaminationBand shapeEffective length

A band, a wristwatch with the band and a method of making the band are described. The band includes a strip-like body with a series of holes provided therein along a length thereof for adjusting an effective length thereof. The body includes a band-shaped support layer of woven or knit fabric of bundles of one or more kinds of fibers, the fibers being selected from a group including carbon fibers, glass fibers, aramid fibers and boron fibers. The body also includes a first resin layer adhering closely to one surface of the support layer, and a second resin layer adhering closely to the other surface of the support layer. The fibers of the support layer extend at a predetermined angle to longitudinal and transverse directions of the body.

Owner:CASIO COMPUTER CO LTD

Corrosion resistant ceramic and preparation method thereof

The invention discloses corrosion resistant ceramic and a preparation method thereof. The corrosion resistant ceramic is prepared from the following raw materials in parts by weight: 12-14 parts of quartz, 11-13 parts of forsterite, 3.5-3.8 parts of sodium oxide, 4-6 parts of titanium dioxide, 1-3 parts of red stoneware ore, 40-45 parts of clay, 18-20 parts of deionized water, 8-10 parts of kaolinite, 16-18 parts of feldspar, 5-7 parts of magnesium oxide, 3-5 parts of tetraethyl orthosilicate, 1-3 parts of zinc tetroxy chromate, 15-20 parts of nickel powder, 8-15 parts of copper powder and 13-15 parts of an assistant. The assistant is prepared from the following components in parts by weight: 5-7 parts of zirconite, 12-18 parts of kaolinite, 4-6 parts of clay, 10-15 parts of deionized water, 2-4 parts of graphite powder, 1-3 parts of feldspar, 7-9 parts of polyethylene glycol and 0.3-0.8 part of nano boron fiber.

Owner:SUZHOU TONGMING MACHINERY

Composite material of carbon fibers or carbon fiber powder, and processing process thereof

InactiveCN103333473AHigh specific strengthHigh specific modulusGlass ballElectrical resistance and conductance

The invention provides a composite material of carbon fibers or carbon fiber powder, and a processing process thereof. The composite material comprises, by mass, (1) 35-55% of a matrix, wherein an unsaturated polyester resin or an epoxy resin is adopted as the matrix, (2) 2-20% of carbon fibers or boron fibers, (3) 5-15% of micro glass balls or silicon carbide balls, (4) 35-55% of carbon fiber powder, and (5) 2-20% of copper powder or copper alloy powder. The composite material of carbon fibers or carbon fiber powder has high specific strength and high specific modulus, wherein the structure member formed from the composite material has characteristics of low density, fine surface burnishing effect, impact resistance, low resistivity, and good electrical conductivity.

Owner:邱献腾

High-temperature-resistant capacitor plastic shell and preparation method thereof

InactiveCN104311991AImprove performanceImprove securityBulk chemical productionCyclohexanoneSimple component

A high-temperature-resistant capacitor plastic shell consists of the following components in parts by weight: 35 parts of polypropylene, 15 parts of linear polyethylene, 10 parts of methyl silicone rubber, 5 parts of diphenyl silanediol, 5 parts of dimethyl siloxane, 5 parts of nano silica, 5 parts of a modified wood plastic powder, 2 parts of azadirachtin, 2 parts of an emulsifier, 2 parts of soybean oil, 5 parts of carbon fibers, 5 parts of metallocene polyethylene, 0.5 part of a catalyst, 2 parts of a plasticizer, 2 parts of oxidized polyethylene, 2 parts of cyclohexanone, 2 parts of paraffin, 2 parts of boron fibers, 2 parts of sepiolite velvet, 2 parts of glass fibers, 2 parts of butyl acetate, and 2 parts of a talc powder. The high-temperature-resistant capacitor plastic shell has the advantages of simple components, and low cost; the prepared finished product has the advantages of high temperature resistance, stable performance, and no toxicity under a high-temperature environment; and at the same time, due to change of a conventional preparation process, a freezing process is increased, the safety of the product is improved, and the product still has relatively good stable performance at higher temperatures.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Ceramic pancake turner with good heat dissipation performance and preparation process of ceramic pancake turner

The invention discloses a ceramic pancake turner with good heat dissipation performance, relating to the technical field of tableware. The ceramic pancake turner is composed of the following components in parts by weight: 40-70 parts of silica, 10-20 parts of kaolin, 10-20 parts of aluminum trioxide, 3-8 parts of titanium dioxide, 5-9 parts of purple sand, 0.5-1 part of vermiculite powder, 2-4 parts of zinc oxide, 0.2-2 parts of sodium silicate, 2-4 parts of carbon fiber, 0.5-1 part of carbon nanotubes, 2-5 parts of graphene nanosheets and 1-3 parts of boron fiber. The pancake turner prepared from specially proportioned raw materials is smooth in surface, high in strength and incapable of breaking and scalding hands. Compared with the traditional process, the preparation process of the ceramic pancake turner consumes less time and energy and is capable of ensuring that the ceramic pancake turner is good in texture and free of residual toxic and harmful substances.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

Glass ceramic bowl with good strength and preparation process thereof

The invention relates to a glass ceramic bowl with good strength, and relates to the technical field of tableware. The glass ceramic bowl comprises the following components in parts by weight: 50-55 parts of silicon dioxide, 15-20 parts of nanometer silicon carbide, 10-15 parts of aluminium trioxide, 3-8 parts of glass fibers, 0.5-1 part of platinum compounds, 0.5-1 part of tourmaline micropowder, 2-4 parts of boron nitride, 0.2-2 parts of sodium silicate, 2-4 parts of carbon fibers, 0.1-0.5 part of selenium powder, 0.1-1 part of graphene mini-sheets and 0.5-1 part of boron fibers. The glass ceramic bowl disclosed by the invention is smooth in surface, good in strength and low in possibility of breaking due to dropping through special preparation on raw materials. Compared with the traditional process, the glass ceramic bowl disclosed by the invention has the advantages of short required time, low energy consumption, good product texture and no toxic substance residue.

Owner:米兰度骨瓷(上海)有限公司

Corrosion-resistant inflaming retarding heat-proof cable sheath material

InactiveCN104098899AImprove high temperature resistanceImprove corrosion resistancePlastic/resin/waxes insulatorsBoron fiberFluorinated ethylene propylene

The invention discloses a corrosion-resistant inflaming retarding heat-proof cable sheath material which comprises the following raw materials in parts by weight: 19-21 parts of fluorinated ethylene propylene copolymer (FEP), 4-6 parts of polytetrafluoroethylene, 20-23 parts of polyphenylene sulfide (PPS), 7-9 parts of boron fiber, 4-6 parts of nylon fiber, 10-13 parts of short glass fiber, 0.5-1.2 parts of dimethyl phthalate (DMP), 9-11 parts of kaolin, 4-6 parts of mica, 3-5 parts of quartz, 10-12 parts of nano-montmorillonite, 3-4 parts of ammonium phosphate, 1-2 parts of hydrated zinc borate, 0.5-1.5 parts of bis stearamide, 4-6 parts of silicone oil, 1-2 parts of a titanate coupling agent NDZ-101 and 2-3 parts of castor acid barium. The corrosion-resistant inflaming retarding heat-proof cable sheath material has excellent corrosion-resistant performance and inflaming retarding heatproof performance, and is good in processability and excellent in impact strength.

Owner:安徽宁国市高新管业有限公司

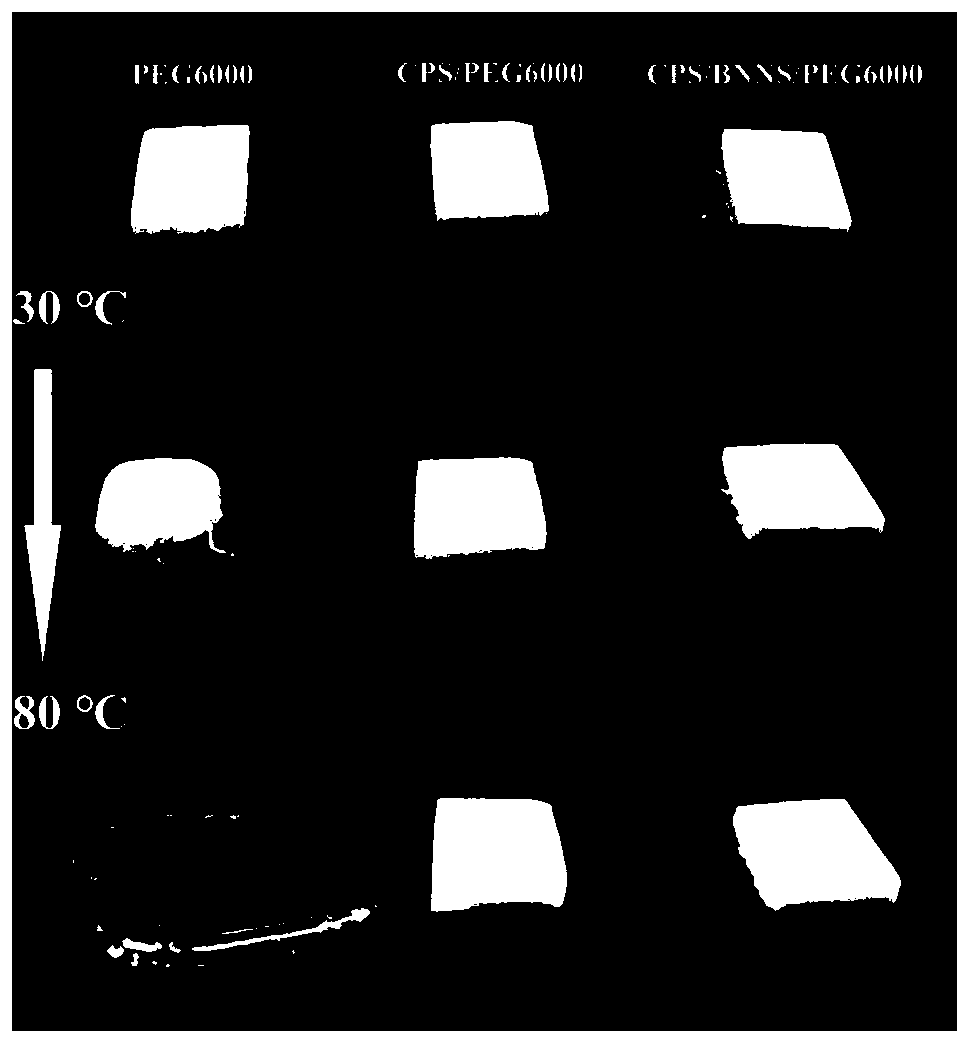

Boron nitride/cellulose encapsulated thermal-conductivity-enhanced formalized phase-change material

InactiveCN110746937AIncrease enthalpyHigh thermal conductivityHeat-exchange elementsCelluloseThermal insulation

The invention relates to a boron nitride / cellulose encapsulated thermal-conductivity-enhanced formalized phase-change material. The material is prepared by enabling a boron nitride nanosheet suspension to flow through a cellulose porous material, performing freeze-drying, and by impregnating a phase-change material into the obtained cellulose / boron nitride porous material in a vacuum impregnationmode. The material has the characteristics of high enthalpy value, high thermal conductivity, solid state maintenance above a melting point, no flow and no leakage, and has broad application prospectsin fields of temperature management, building thermal insulation, thermal energy storage and temperature-regulating textiles.

Owner:DONGHUA UNIV

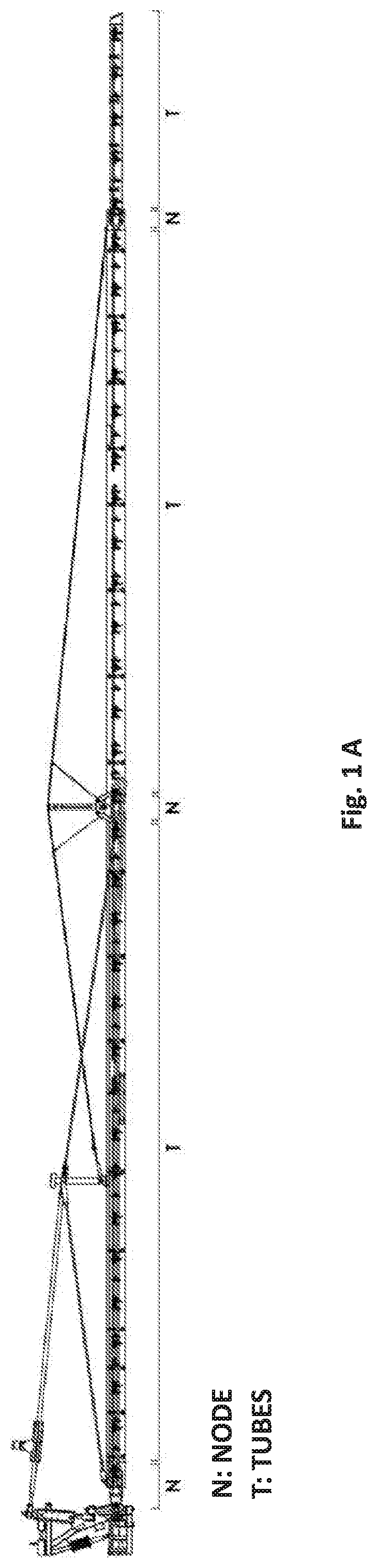

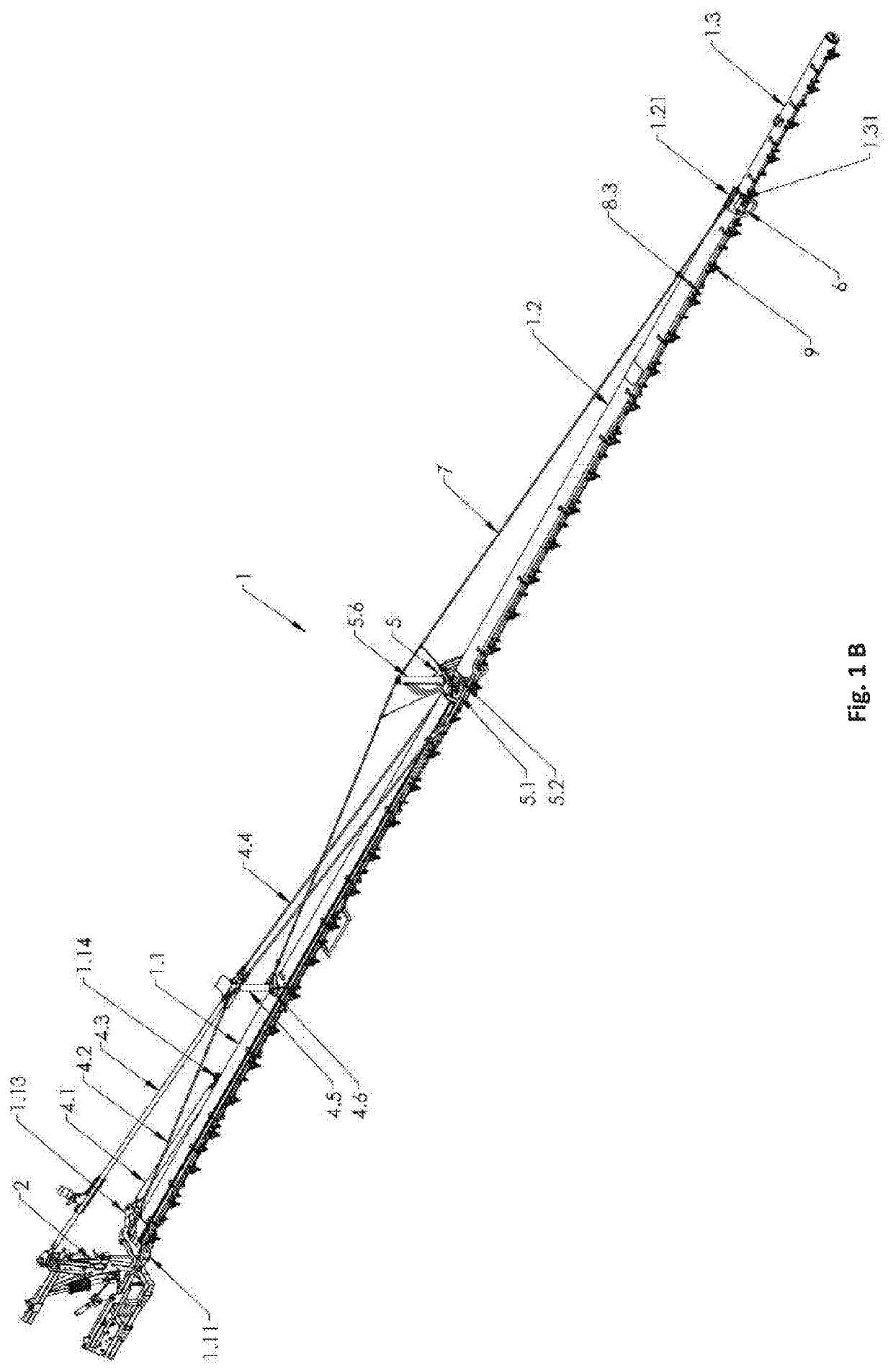

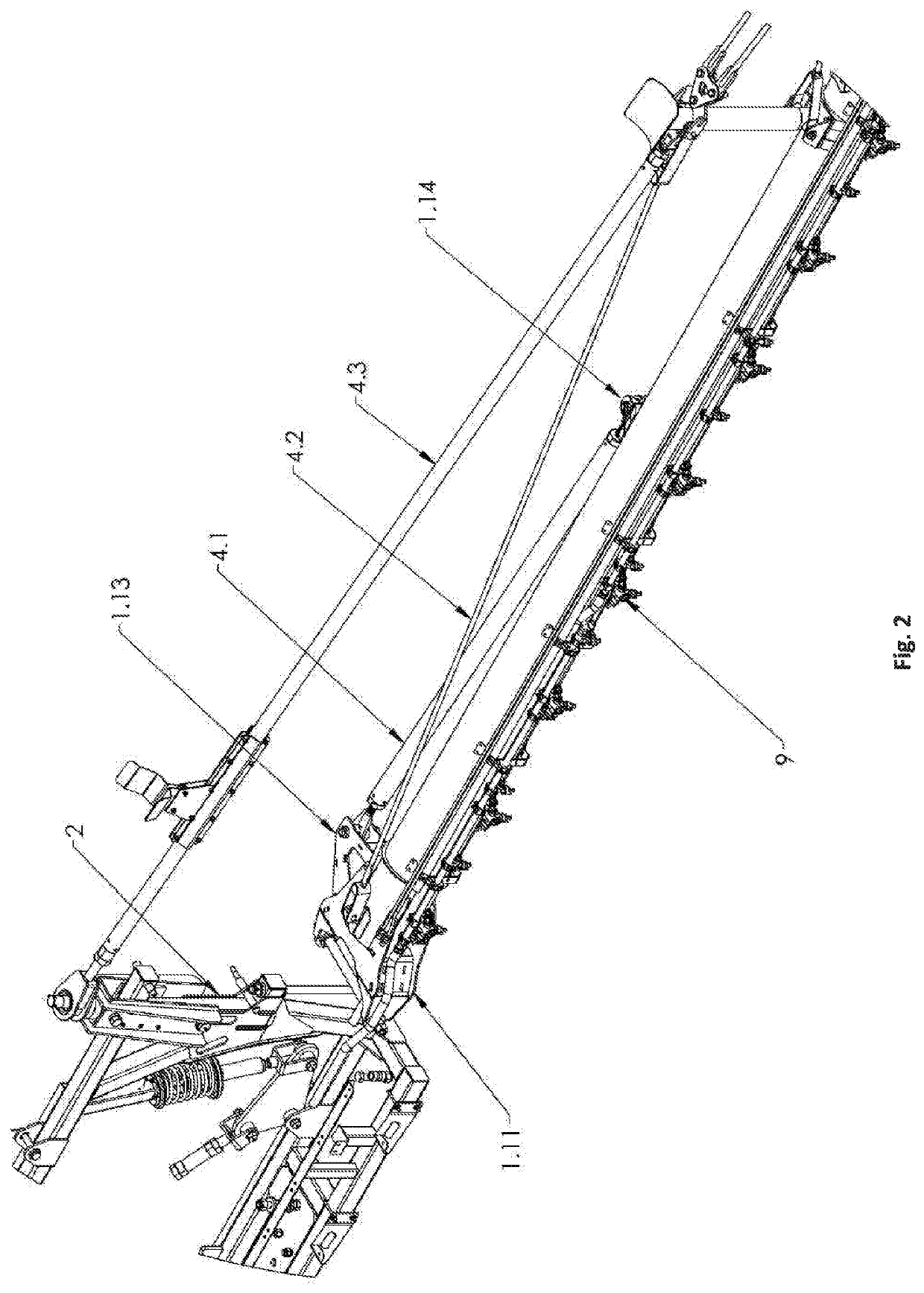

Support for spreading boom of an agricultural sprayer

ActiveUS20190357519A1Promote repairReduce maintenance costsAircraft componentsSpray nozzlesSprayerAramides

Spraying boom support for agricultural sprayers, whether trailed, self-propelled and / or airborne, which includes identical articulated arms arranged on either side of the sprayer. Said arms are extended transversely to the direction of advance of the sprayer, and are coupled in an articulated manner to a central support section of the chassis of said sprayer. Each articulated arm is comprised of bar sections formed by a composite material consisting of a reinforcing agent selected from carbon fiber, fiberglass, aramid fiber, boron fiber or a combination thereof, and a matrix of epoxy, vinyl ester, phenolic, polyester resins or thermoplastic material. At its ends, the bar sections have metal nodes that make up the joints and links, also fulfilling the role of taking the concentrated loads of them and distribute them in the bar sections of composite material. In this way areas of great thickness of composite material are avoided and the advantages of each material are exploited resulting in an economical, efficient, lightweight, low maintenance and easily repairable design.

Owner:BK COMPONENTS SA

Rubber shock pad for motor, and preparation method of rubber shock pad

The invention belongs to the technical field of rubber, and in particular relates to a rubber shock pad for a motor, and a preparation method of the rubber shock pad. The shock pad is prepared from the following raw materials in parts by weight: 60-70 parts of natural rubber, 20-30 parts of ethylene propylene diene monomer, 10-20 parts of a tetrafluoroethylene-hexafluoropropylene copolymer, 5-10 parts of boron fibers, 5-10 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of an anti-aging agent RD, 1-3 parts of an anti-aging agent 4010 NA, 10-15 parts of white carbon black, 10-15 parts of attapulgite, 30-50 parts of light calcium carbonate, 3-6 parts of chlorinated paraffin, 20-30 parts of liquid coumarone, 1-3 parts of 2, 5-dimethyl-2, 5-di(tert-butyl peroxy) hexane, 2-8 parts of a silane coupling agent, 0.1-1 part of an accelerant TBTD and 0.2-0.5 part of an accelerant M. All the raw materials of the rubber shock pad have a synergistic effect, so that the rubber shock pad is small in compression deformation, high in elasticity and strength, and good in wear resistance and high-temperature resistance.

Owner:国网河南省电力公司唐河县供电公司

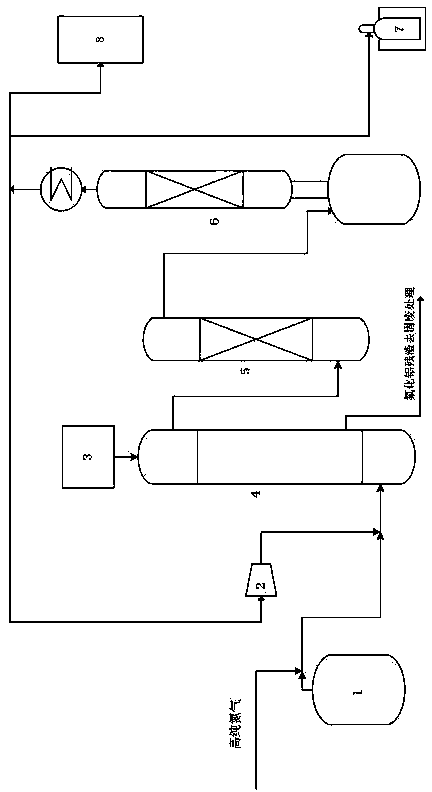

Preparation method of high-purity boron trichloride-11

ActiveCN103950947AHigh purityMeet the requirements of the processBoron halogen compoundsAluminium chlorideVery large scale integrated circuits

The invention discloses a preparation method of high-purity boron trichloride-11, and belongs to the field of preparation methods of boron compounds. The preparation method comprises the steps such as pretreating raw materials, synthesizing boron trichloride-11 through reaction of aluminum chloride and boron trifluoride-11, filtering, preliminarily separating, rectifying and purifying, collecting the high-purity boron trichloride-11 product, treating tail gas, and the like. The high-purity boron trichloride-11 prepared by the preparation method disclosed by the invention is high in purity which can reach over 99.9999%, can satisfy requirements of manufacturing integrated circuit semiconductor apparatuses on a large scale, effectively improves interference resistance and radiation resistance of an integrated circuit, and can be used as the raw material for manufacturing raw materials such as a high-purity boron-11 isotope material, a special boron fiber material and light-guide fiber.

Owner:方治文

Nitrile-butadiene rubber modified polyvinyl chloride sheath material for communication cables and preparation method thereof

InactiveCN104893151AHigh tensile strengthImprove air tightnessPlastic/resin/waxes insulatorsInsulated cablesMicrocrystalline waxVulcanization

The invention relates to a nitrile-butadiene rubber modified polyvinyl chloride sheath material for communication cables, which is prepared from the following raw materials in parts by weight: 65-70 parts of polyvinyl chloride, 20-25 parts of nitrile-butadiene rubber, 0.3-0.5 part of soft microcrystalline wax, 4-4.5 parts of high-molecular-weight polyisobutylene, 2.5-3 parts of triallyl isocyanurate, 0.3-0.6 part of dicumyl peroxide, 0.3-0.5 part of polyisovinyl succimide and 3-4 parts of nano boron fiber. The polyvinyl chloride and nitrile-butadiene rubber are subjected to secondary crosslinking compounding without vulcanization, thereby greatly simplifying the tool set equipment and technique, enhancing the efficiency and lowering the cost; and thus, the sheath material has high strength and favorable oil resistance, has better softness and elasticity than the single use of polyvinyl chloride, and is convenient to install and use. The high-molecular-weight polyisobutylene and nano boron fiber are utilized to enhance the tensile strength, air tightness and moisture resistance of the sheath material.

Owner:合肥得润电子器件有限公司

Air-purifying environmental protection insulation material and preparation method thereof

The invention provides an air-purifying environmental protection insulation material and a preparation method thereof, which relates to the field of a building material. The insulation material comprises the following raw materials in parts by weight: 35 parts of expanded perlite, 12 parts of magnesium oxide, 25 parts of cement, 18 parts of urea-formaldehyde resin, 0.6 parts of sodium dodecyl benzene sulfonate, 5 parts of a negative ion additive, 14 parts of quartz sand, 26 parts of vermiculite, 21 parts of nano zinc oxide, 18 parts of waste rock wool plate, 14 parts of waste urethane foam plastic, 10 parts of bentonite, 8 parts of diatomite, 16 parts of active carbon, 9 parts of boron fiber, 18 parts of glass fiber, 14 parts of floating beads, 0.6 parts of a binder, 0.8 parts of a heat stabilizer, 0.5 parts of an anti-oxidant, 0.5 parts of a delayed coagulant, 0.7 parts of a water reducer, and 8 parts of water. The preparation method comprises the following steps: 1) material weighing; 2) vermiculite roasting; 3) stirring; and 4) casting molding, demoulding, piling and maintenance. The material has the advantages of high compressive strength, high tensile strength, good heat insulation, energy saving and environmental protection.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Lepidolite tailing one-time sintered ceramic foaming belt microcrystal decoration integrated plate

PendingCN111348895AMeet specific color requirementsConsistent colorCeramic materials productionCeramicwareCrack resistanceKaolin clay

The invention discloses a lepidolite tailing one-time sintered ceramic foaming belt microcrystal decoration integrated plate. A ceramic foaming matrix is prepared from ceramic foaming material fine powder at high temperature, and the ceramic foaming matrix is sintered to form a decorative microcrystalline surface layer; the ceramic foaming material fine powder comprises the following components: 102-118 parts of lepidolite tailings, 92-98 parts of modified clay, 2-10 parts of bone glue powder, 2-4 parts of nano boron fibers, 12-16 parts of zirconium silicate, 26-38 parts of industrial solid waste, 3-6 parts of dolomite, 22-28 parts of quartz powder, 3-6 parts of volcanic rock, 1-6 parts of graphene, 3-7 parts of nano titanium dioxide, 11-14 parts of calcite, 9-10 parts of calcined talc, 6-8 parts of calcined kaolin, 6-8 parts of chromium oxide, 3-5 parts of a foaming agent and 1-2 parts of a toner. The building block can meet the specific color requirement of a building material decorative surface, the plate color is consistent, the crack resistance is high, the service life is long, the firing temperature is reduced to some extent, the firing period is shortened to some extent, and the energy consumption is correspondingly reduced.

Owner:江西鼎盛新材料科技有限公司 +1

Super thermal insulation coating and preparation method therefor

InactiveCN105001756AImprove the serious phenomenon of reunionImprove insulation effectSilicaEpoxy resin coatingsThermal insulationDiethylenetriamine

A super thermal insulation coating is prepared from the following raw materials in parts by weight: 32-35 parts of ethyl orthosilicate, a proper amount of hydrochloric acid, ammonia water, ethanol and deionized water, 4-5 parts of trimethylchlorosilane, 1-1.5 parts of 3-aminopropylsilanetriol, 0.02-0.05 part of a silane coupling agent KH550, 0.01-0.02 part of sodium lauroyl sarcosine, 0.6-0.8 part of nano boron fiber, 70-75 parts of E-12 epoxy resin, 9-12 parts of ethylene diglycidyl ether, 1.3-1.7 parts of nano calcium carbonate and 7-7.5 parts of diethylenetriamine. According to the super insulation coating provided by the invention, the defect that a silicon dioxide aerogel is hard to break and low in strength is improved by adding modified nano boron fiber. The coating which is modified by using trimethylchlorosilane and 3-aminopropylsilanetriol, the aerogel can be prevented from absorbing water and cracking and the bonding fastness of the aerogel and a film forming substance can be further increased. The coating provided by the invention has a super insulation property and a lot of energy sources can be saved.

Owner:DANGTU COUNTY KEHUI TRADING

Method for preparing self-lubricating silicon carbide composite ceramic-based sealing material

InactiveCN104671791AGood self-lubricating performanceReduce the ratioComposite ceramicPyrrolidinones

The invention discloses a method for preparing a self-lubricating silicon carbide composite ceramic-based sealing material. The self-lubricating silicon carbide composite ceramic-based sealing material is characterized by comprising the following raw materials in parts by weight: 70-90 parts of silicon carbide, 8-12 parts of stainless steel powder, 5-7 parts of molybdenum disulfide, 2-5 parts of carbon powder, 2-3 parts of magnesium oxide, 1-2 parts of silane coupling agent KH-550, 4-5 parts of boron fibre, 2-3 parts of polyvinylidene fluoride, 1-2 parts of polyvinylpyrrolidone, 3-5 parts of sintering aids and 80-100 parts of deionized water. The self-lubrication of the ceramic is increased, the abrasion is reduced and the service life is prolonged by adding molybdenum disulfide and the carbon powder into the silicon carbide composite ceramic; the added stainless steel powder has the characteristics of low sintering temperature, low sintering aid proportion and high silicon carbide ceramic performance. The method is simple in process, moderate in cost and suitable for mass production.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

Automobile shaft component powder metallurgy material

InactiveCN106623891AImprove performanceHigh strengthTransportation and packagingMetal-working apparatusTitanium carbideBoron fiber

The invention discloses an automobile shaft component powder metallurgy material. The automobile shaft component powder metallurgy material comprises the following raw materials of iron powder, chromium powder, molybdenum powder, copper powder, nickel powder, lead oxide powder, yttrium powder, titanium carbide powder, tantalum carbide powder, tin powder, zinc oxide powder, aluminum oxide powder, graphene powder, pentaerythritol, stearic acid, boron fibers, basalt fibers, polypropylene resin, hydroxypropyl methylcellulose, ethylene-bis-stearamide, polyethylene wax, epoxy propoxy propyl trimethoxy silane, silicon carbide, manganous sulphide, tributoxyethyl phosphate, an inhibitor, a binder, an enhancer, a cutting agent, a lubricating agent, a cross-linking agent, a dispersing agent and an adjusting agent. According to the automobile shaft component powder metallurgy material, by means of the specific composition proportion, the automobile shaft component powder metallurgy material is uniform in overall density, high in density, large in ductility and percentage reduction of area, good in wear resistance, strength and hardness and high in material utilization rate, and high-performance automobile shaft component powder metallurgy materials can be produced fast on a large scale.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

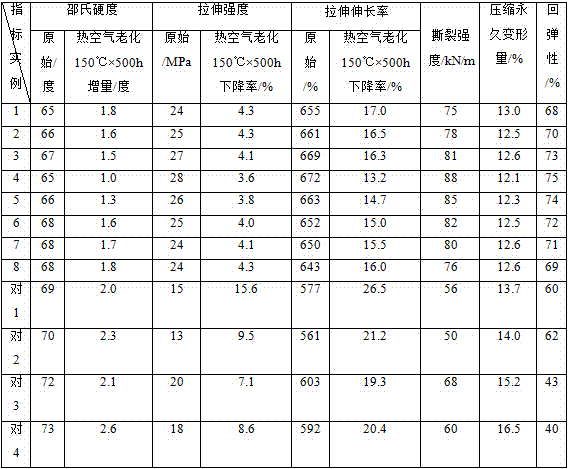

Modified silicone rubber and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to modified silicone rubber and a preparation method thereof. The modified silicone rubber is prepared from, by weight, 27-38% of methyl vinyl silicone rubber, 5-10% of boron fiber, 10-15% of fine ceramic powder, 8-13% of white carbon black, 1-3% of modified tree ashes, 0.5-1.0% of hydroxyl silicone oil, 0.4-0.8% of a vulcanizing agent and 30-40% of flame retardant. Accordingly, all raw materials act in synergy, the preparation method is simple, and the obtained modified silicone rubber is low in density, low in mass, proper in hardness, high in tensile strength, excellent in ageing property, high in tensile elongation, high in tear strength, good in toughness, elasticity and flame retardancy and capable of being widely applied to cable blocking materials.

Owner:STATE GRID CORP OF CHINA +2

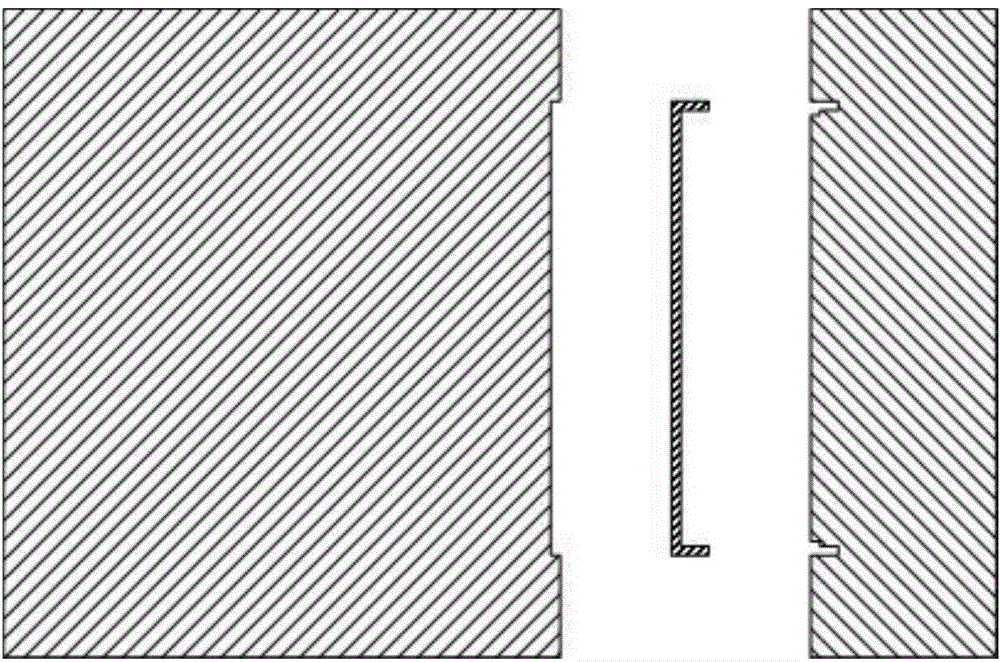

Injection molding composition for rubber and iron integrated frame, rubber and iron integrated frame and manufacture method of rubber and iron integrated frame

The invention discloses an injection molding composition for a rubber and iron integrated frame, the rubber and iron integrated frame and a manufacture method of the rubber and iron integrated frame. The injection molding composition for the rubber and iron integrated frame comprises a plastic granule and a solid additive, wherein the shrinking percentage of the solid additive is less than that of the plastic granule; the solid additive comprises at least one of a glass fiber, a carbon fiber or a boron fiber; when injection molding is carried out, the plastic granule and the solid additive are mixed and injection molded, so that the using volume of the plastic granule is reduced, the injection amount of the plastic granule is reduced and the shrinking percentage of the injection molding plastic of the rubber and iron integrated frame is reduced; the melting point of the solid additive is higher than that of the plastic granule, the injection molding temperature is controlled between the melting points of the solid additive and the plastic granule. The solid additive is kept in a solid state in the injection molding process so that the deformation degree after shaping the rubber and iron integrated frame is small or none.

Owner:SHENZHEN TECHASER TECH

Autoclaved aerated concrete block with high shock strength and manufacture method thereof

The invention discloses an autoclaved aerated concrete block with high shock strength. Dissociated hydroxyl in cellulose is enclosed by performing acetylation reaction on tea leaf straw fiber, and thus the hydrophobic performance and the heat stability of the material are improved; and then by cooperating with a physical modification method and adding other effective compositions, the durability and the dispersibility of fiber in autoclaved aerated concrete are improved. Added nanometer boron fiber increases the strength, the apparent density and the heat-conduction efficiency of the block, and added building garbage solves the environment pollution problem, replaces a part of cement, reduces production cost, and realizes the theme of saving energy and protecting environment, and changing waste into valuables. The aerated building block is good in shock resistance, possesses the shock resistance up to 9 grade or more, also possesses the advantages of heat resistance, good warm-keeping heat-insulation property, resistance to ageing, seepage prevention, resistance to water, and the like, and is wide in application prospect.

Owner:DANGTU COUNTY KEHUI TRADING

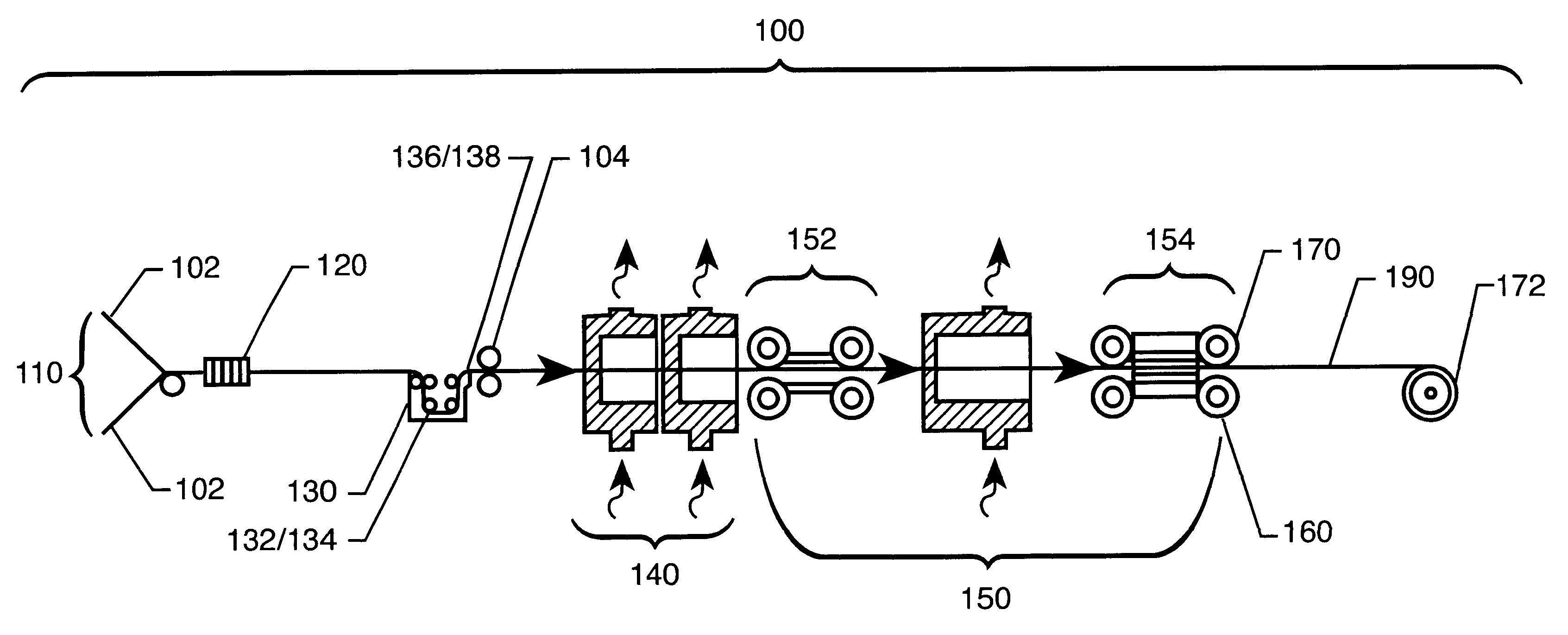

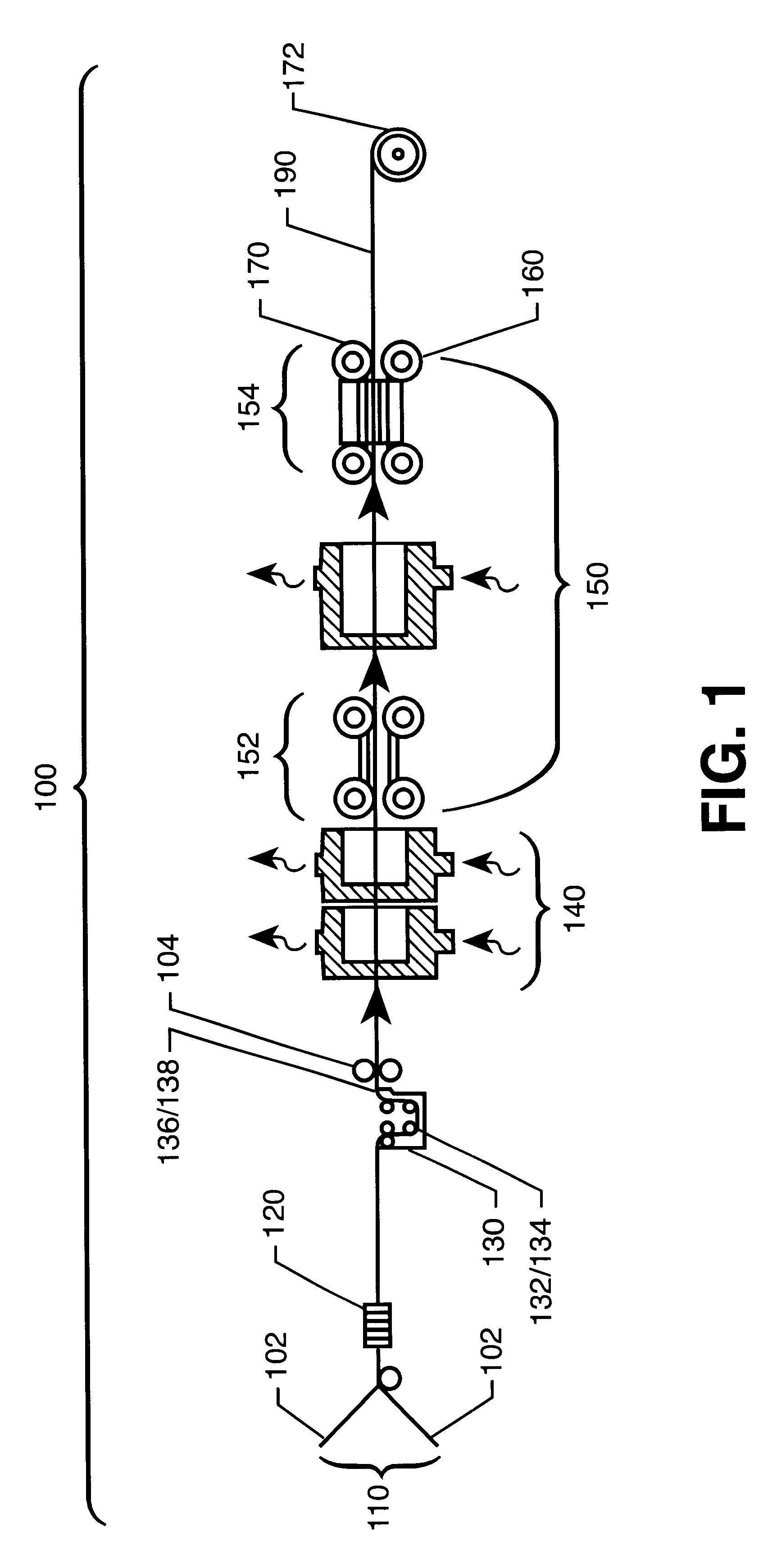

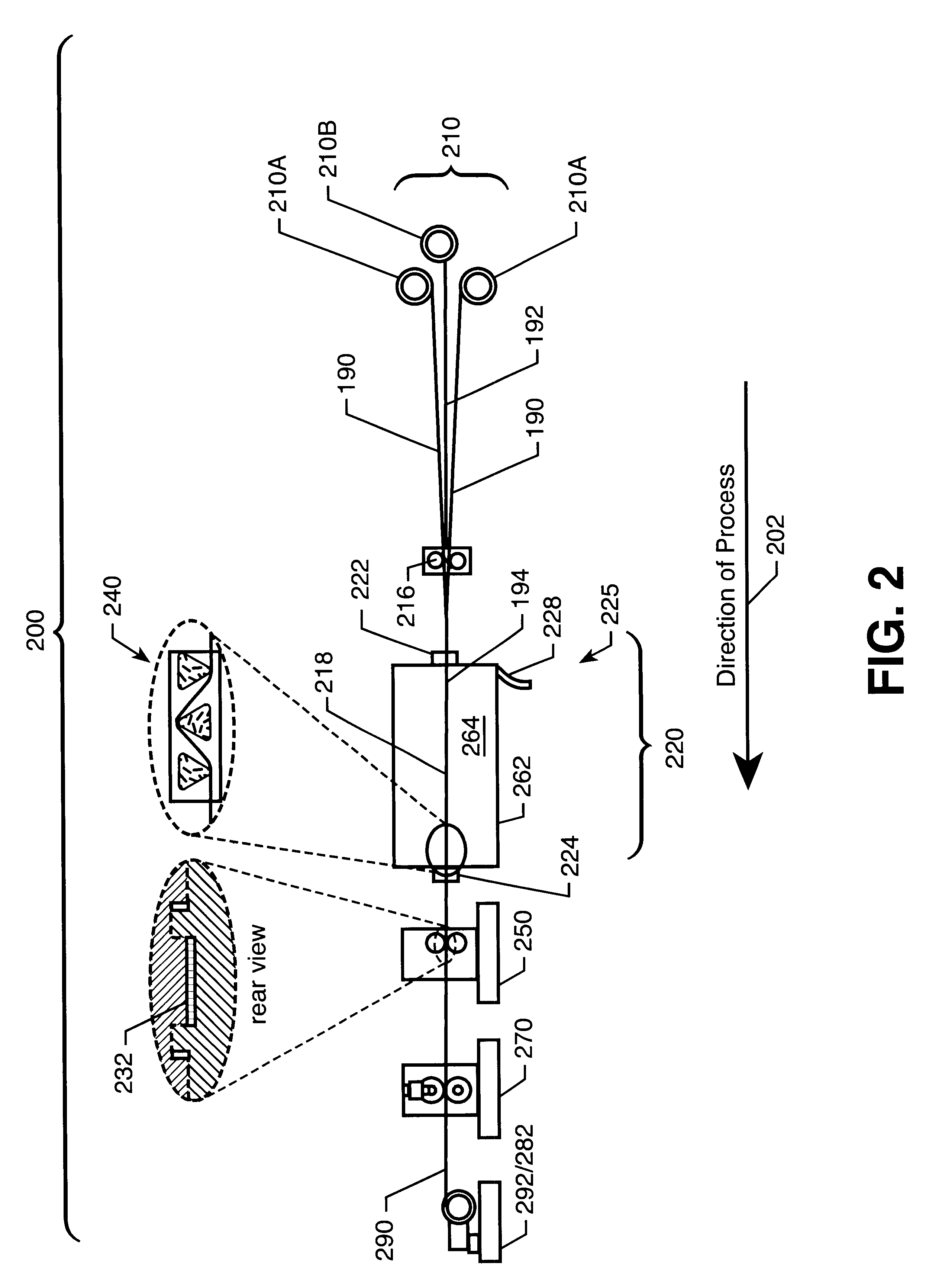

Dry process for manufacturing hybridized boron fiber/carbon fiber thermoplastic composite materials from a solution coated precursor

InactiveUS6514370B1Promote resultsReduce gradientAdhesive processes with surface pretreatmentLaminationBoron fiberThermoplastic composites

An apparatus for producing a hybrid boron reinforced polymer matrix composite from precursor tape and a linear array of boron fibers. The boron fibers are applied onto the precursor tapes and the precursor tape processed within a processing component having an impregnation bar assembly. After passing through variable-dimension forming nip-rollers, the precursor tape with the boron fibers becomes a hybrid boron reinforced polymer matrix composite. A driving mechanism is used to pulled the precursor tape through the method and a take-up spool is used to collect the formed hybrid boron reinforced polymer matrix composite.

Owner:NASA

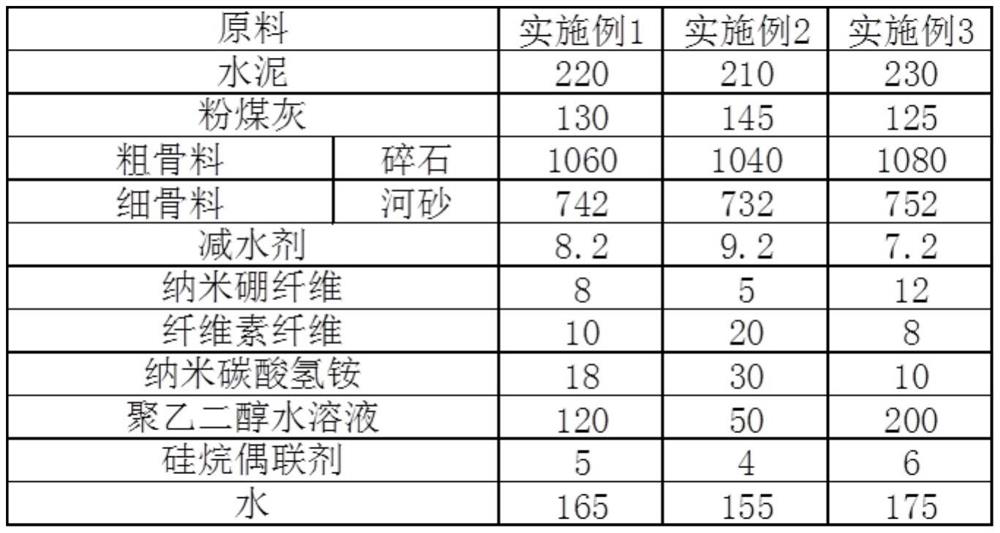

Anti-crack concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses anti-crack concrete and a preparation method thereof. The anti-crack concrete is prepared from cement, fly ash, coarse aggregate, fine aggregate, a water reducing agent, nano boron fibers, cellulose fibers, nano ammonium bicarbonate, a polyethylene glycol aqueous solution, a silane coupling agent and water. The preparationmethod comprises the following steps: preparing pre-modified cellulose fibers; uniformly mixing the pre-modified cellulose fibers, nano boron fibers and nano ammonium bicarbonate, and performing ball-milling modification to obtain modified fibers; mixing cement and fly ash to prepare a cementing material; mixing the coarse aggregate, the fine aggregate and the modified fibers to obtain aggregate;mixing a water reducing agent with water to obtain a water reducing agent solution; and uniformly mixing the cementing material, the aggregate and the water reducing agent solution to obtain the anti-crack concrete. The anti-crack concrete disclosed by the invention can be used as a building material and has the advantage of good anti-crack performance.

Owner:仁寿县陵州预拌商品混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com