Boron nitride/cellulose encapsulated thermal-conductivity-enhanced formalized phase-change material

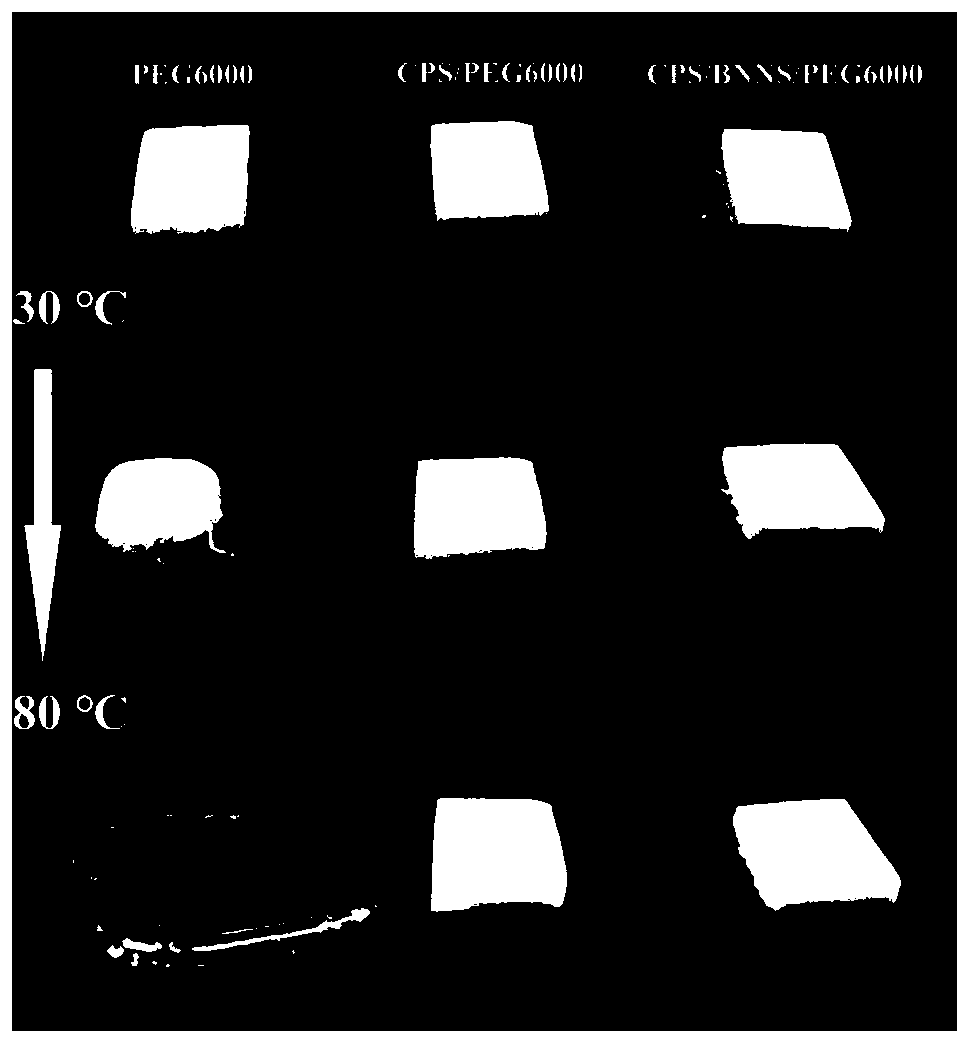

A technology of shape-setting phase change materials and phase change materials, which is applied in the field of heat conduction-enhanced shape-setting phase change materials, can solve the problems of low thermal conductivity and low enthalpy of phase change materials, and achieve high thermal conductivity, efficient heat conduction structure, The effect of good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Get 10.0g solid content and be the suspension of the cellulose nanowire / water of 1.8wt%, add 3-(2,3-epoxypropoxy)propyltrimethoxysilane (0.18g), polyethylene Amine (0.18 g) was stirred at room temperature for 2 h to obtain polyethyleneimine-modified cellulose nanowire suspension. The suspension was quickly frozen in a -80°C ultra-low temperature refrigerator for 1 hour, then freeze-dried in a freeze dryer for 36 hours at a temperature of -54°C and a pressure of 30 Pa, and then baked in an oven at 110°C for 30 minutes , the silane is hydrolyzed and cross-linked and solidified to obtain polyethyleneimine cross-linked reinforced cellulose porous material.

[0039] (2) Flowing 500mL of boron nitride nanosheet water / isopropanol (1:1) mixed solvent suspension with a concentration of 0.05wt% through the cellulose porous material in step (1), washing with water and freeze-drying to obtain cellulose / boron nitride composite porous material.

[0040] (3) After heating and ...

Embodiment 2

[0045] According to Example 1, the amount of polyethyleneimine in Step (1) of Example 1 is changed to 0.09g, polyethylene glycol (PEG6000) in step (3) is changed to Polyethylene Glycol (PEG10000), and all the other are the same as those in the implementation The same as in Example 1, a cellulose / boron nitride-stabilized heat conduction-enhanced shaped polyethylene glycol phase change material was obtained. Wherein the loading rate of polyethylene glycol is 96.0wt%, the melting enthalpy is 175.4J / g, and the melting temperature is 59.5°C.

Embodiment 3

[0047] According to Example 1, except that the suspension in step (1) is placed in liquid nitrogen (-196° C.) for quick freezing, and the freezing time is 20 minutes, the rest are the same as Example 1 to obtain cellulose / boron nitride stable heat Conductivity enhanced polyethylene glycol shape-changing materials. Wherein the loading ratio of polyethylene glycol is 94.4wt%, the melting enthalpy is 168.1J / g, and the melting temperature is 56.6°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com